LTC3425

1

3425p

s

Handheld Computers

s

Point-of-Load Regulators

s

3.3V to 5V Conversion

, LTC and LT are registered trademarks of Linear Technology Corporation.

s

High Efficiency: Up to 95%

s

Up to 3A Continuous Output Current

s

4-Phase Operation for Low Output Ripple

and Tiny Solution Size

s

Output Disconnect and Inrush Current Limiting

s

Very Low Quiescent Current: 12

µ

A

s

0.5V to 4.5V Input Range

s

2.4V to 5.25V Adjustable Output Voltage

s

Adjustable Current Limit

s

Adjustable, Fixed Frequency Operation from

100kHz to 2MHz per Phase

s

Synchronizable Oscillator with Sync Output

s

Internal Synchronous Rectifiers

s

Manual or Automatic Burst Mode

®

Operation

s

Power Good Comparator

s

<1

µ

A Shutdown Current

s

Antiringing Control

s

5mm

×

5mm Thermally Enhanced QFN Package

5A, 8MHz, 4-Phase

Synchronous Step-Up DC/DC Converter

June 2003

FEATURES

DESCRIPTIO

U

APPLICATIO S

U

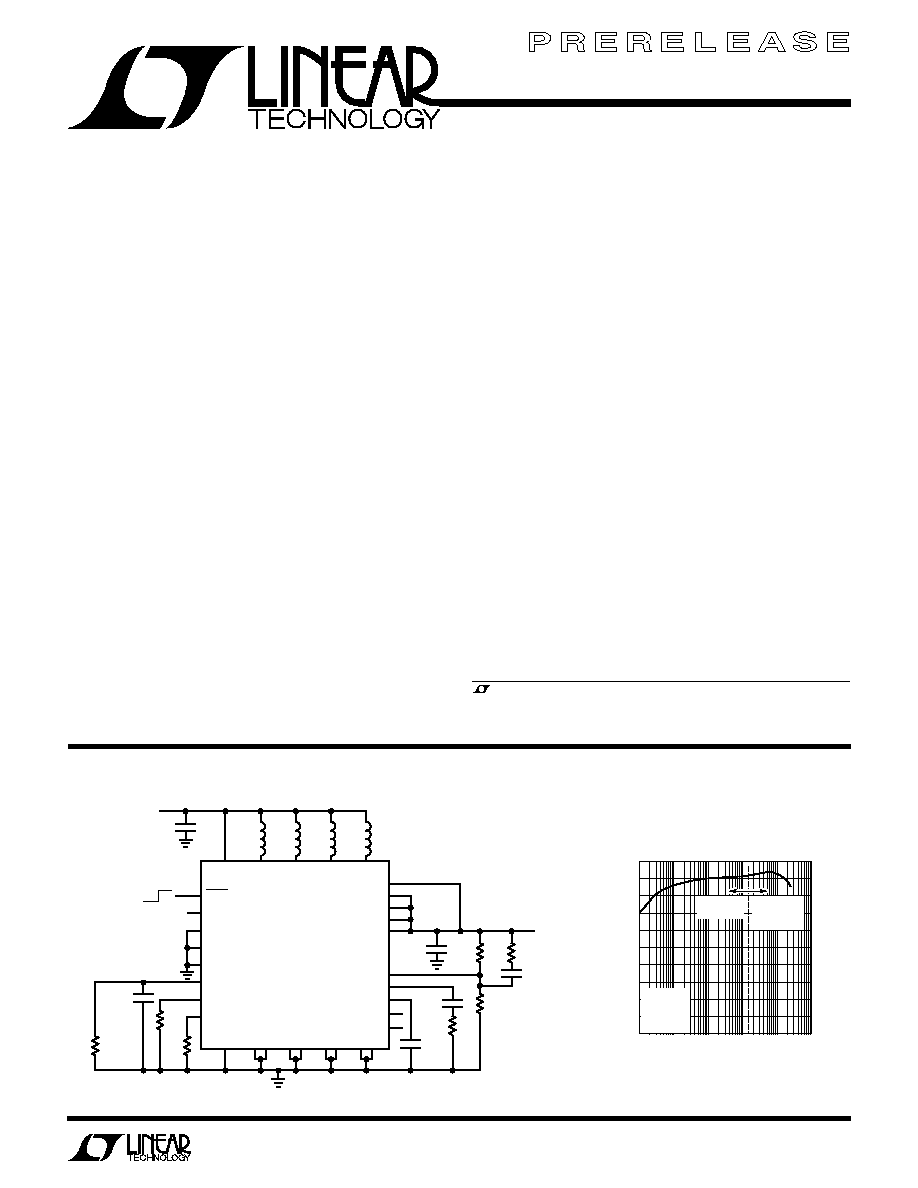

TYPICAL APPLICATIO

U

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

Burst Mode is a registered trademark of Linear Technology Corporation.

The LTC

®

3425 is a synchronous, 4-phase boost converter

with output disconnect capable of operation below 1V

input. It includes four N-channel MOSFET switches and

four P-channel synchronous rectifiers for an effective

R

DS(ON)

of 0.045

and 0.05

, respectively. 4-phase

operation greatly reduces peak inductor currents, capaci-

tor ripple current and increases effective switching fre-

quency, minimizing inductor and capacitor sizes. True

output disconnect eliminates inrush current and allows

zero load current in shutdown. External Schottky diodes

are not required in most applications (V

OUT

< 4.3V). Power

saving Burst Mode operation can be user controlled or left

in automatic mode.

Other features include 1

µ

A shutdown current, program-

mable frequency with sync in and out, programmable

soft-start, antiringing control, thermal shutdown, adjust-

able current limit, reference output and power good

comparator.

The LTC3425 is available in a small, thermally enhanced

32-pin QFN package.

2.7

µ

H

2.2

µ

F

0.01

µ

F

75k

15k

20k

2.7

µ

H

2.7

µ

H

2.7

µ

H

C

IN

: TAIYO YUDEN JMK107BJ225MA

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

4)

L1-L4: TDK RLF5018T-2R7M1R8

V

IN

SWA

V

IN

2V TO 3V

SWB

LTC3425

SWC

SWD

SGND

SHDN

OFF ON

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

330pF

22pF

3425 TA01

4.7

µ

F

×

4

0.01

µ

F

33k

590k

1M

10k

V

OUT

3.3V

2A

LOAD CURRENT (mA)

0.1

70

EFFICIENCY (%)

80

90

1

10

100

1000

10000

3425 TA02

60

50

40

30

20

10

0

100

V

IN

= 2.4V

V

OUT

= 3.3V

f = 1MHz

L = 2.7

µ

H

Burst Mode

OPERATION

FIXED

FREQUENCY

MODE

Electrical Specifications Subject to Change

LTC3425

2

3425p

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

Minimum Start-Up Voltage

V

OUT

= 0V, I

LOAD

< 1mA

0.88

1

V

Minimum Operating Voltage

SHDN > 0.65V (Note 3)

q

0.5

V

Output Voltage Adjust Range

q

2.4

5.25

V

Feedback Regulation Voltage

q

1.196

1.220

1.244

V

Feedback Input Current

V

FB

= 1.25V

1

50

nA

V

OUT

Quiescent Current--Burst Mode Operation

BURST = 0V, REFEN = 0V, FB = 1.3V (Note 2)

12

25

µ

A

BURST = 0V, REFEN = 2V, FB = 1.3V (Note 2)

18

35

µ

A

V

IN

Quiescent Current--Shutdown

SHDN = 0V, V

OUT

= 0V, Not Including Switch Leakage

0.1

1

µ

A

V

OUT

Quiescent Current--Active

V

C

= 0V, Nonswitching (Note 2)

1.8

mA

NMOS Switch Leakage

V

SW

= 5V

0.1

5

µ

A

PMOS Switch Leakage

V

SW

= 5V, V

OUT

= 0V

0.1

10

µ

A

NMOS Switch On Resistance

(Note 4)

0.045

PMOS Switch On Resistance

(Note 4)

0.05

NMOS Current Limit

I

LIM

Resistor = 75k (Note 4)

q

5.0

7.0

A

I

LIM

Resistor = 200k (Note 4)

q

1.8

2.7

A

V

IN

Voltage ................................................. 0.3V to 6V

SWA-D Voltages

DC .......................................................... 0.3V to 6V

Pulsed < 100ns ...................................... 0.3V to 7V

V

OUTA-D

, V

OUTS

Voltages............................ 0.3V to 6V

BURST, SHDN, SS, REFEN, SYNCOUT, PGOOD,

CCM, SYNCIN Voltages .............................. 0.3V to 6V

Operating Temperature Range (Note 5) ... 40

°

C to 85

°

C

Storage Temperature Range ................. 65

°

C to 125

°

C

Lead Temperature (Soldering, 10 sec).................. 300

°

C

ORDER PART

NUMBER

Consult LTC Marketing for parts specified with wider operating temperature ranges.

LTC3425EUH

ABSOLUTE AXI U

RATI GS

W

W

W

U

PACKAGE/ORDER I FOR ATIO

U

U

W

(Note 1)

T

JMAX

= 125

°

C,

JA

= 40

°

C/W 1 LAYER BOARD,

JA

= 35

°

C/W 4 LAYER BOARD

EXPOSED PAD IS ???? (PIN 33) MUST BE SOLDERED TO PCB

32 31 30 29 28 27 26 25

9

10 11 12

TOP VIEW

33

UH PACKAGE

32-LEAD (5mm

×

5mm) PLASTIC QFN

13 14 15 16

17

18

19

20

21

22

23

24

8

7

6

5

4

3

2

1

GNDA

GNDA

SWA

V

OUTA

V

OUTB

SWB

GNDB

GNDB

GNDD

GNDD

SWD

V

OUTD

V

OUTC

SWC

GNDC

GNDC

SS

SHDN

SYNCIN

V

IN

R

T

I

LIM

CCM

SYNCOUT

REFEN

V

OUTS

SGND

FB

COMP

BURST

REFOUT

PGOOD

ELECTRICAL CHARACTERISTICS

The

q

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

°

C. V

IN

= 1.2V, V

OUT

= 3.3V, R

T

= 15k, unless otherwise noted.

UH PART

MARKING

3425

LTC3425

3

3425p

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

PMOS Turn-Off Current

CCM < 0.4V

80

mA

PMOS Current Limit

CCM > 1.4V

0.6

A

Max Duty Cycle

q

83

90

97

%

Min Duty Cycle

q

0

%

Frequency Accuracy

R

T

= 15k

q

0.8

1

1.2

MHz

SHDN Input High

V

OUT

= 0V (Initial Start-Up)

q

1

V

V

OUT

> 2.4V

q

0.65

V

SHDN Input Low

q

0.25

V

SHDN Input Current

V

SHDN

= 0V, 3.3V

0.01

1

µ

A

V

SHDN

= 2V

0.50

µ

A

REFEN, CCM Input High

q

1.4

V

REFEN, CCM Input Low

q

0.4

V

REFEN, Input Current

V

REFEN

= 5V

0.01

1

µ

A

SYNCIN Input High

q

2.5

V

SYNCIN Input Low

q

0.5

V

SYNCIN Input Current

V

SYNCIN

= 5V

0.3

1

µ

A

CCM Input Current

V

CCM

= 5V

1.7

4

µ

A

SYNC Input Pulse Width

q

0.1

µ

s

SYNC Out High

3

V

SYNC Out Low

0.4

V

REFOUT

REFEN > 1.4V, No Load

q

1.190

1.220

1.251

V

REFOUT

I

SOURCE

< 100

µ

A, I

SINK

< 10

µ

A, REFEN > 1.4V

q

1.184

1.22

1.252

V

Error Amp Transconductance

50

µ

S

Error Amp Output High

I

LIM

Resistor = 75k

2.2

V

Error Amp Output Low

0.15

V

PGOOD Threshold (Falling Edge)

Referenced to Feedback Voltage

q

9.5

11.4

13.5

%

PGOOD Hysteresis

Referenced to Feedback Voltage

q

1.5

2.5

3.5

%

PGOOD Low Voltage

I

SINK

= 1mA (10mA Max)

q

0.12

0.25

V

PGOOD Leakage

V

PGOOD

= 5.5V

q

0.01

1

µ

A

SS Current Source

V

SS

= 1V

q

2.5

µ

A

Burst Threshold Voltage (Falling Edge)

q

0.84

0.94

1.04

V

Burst Threshold Hysteresis

115

mV

ELECTRICAL CHARACTERISTICS

The

q

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

°

C. V

IN

= 1.2V, V

OUT

= 3.3V, R

T

= 15k, unless otherwise noted.

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Current is measured into the V

OUTS

pin since the supply current is

bootstrapped to the output. The current will reflect to the input supply by

V

OUT

/(V

IN

· Efficiency). The outputs are not switching.

Note 3: Once the output is started, the IC is not dependent on the V

IN

supply as long as SHDN > 0.65V.

Note 4: Total with all four FETs in parallel.

Note 5: The LTC3425E is guaranteed to meet performance specifications

from 0

°

C to 70

°

C. Specifications over the 40

°

C to 85

°

C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 6: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125

°

C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may result in device degradation or failure.

LTC3425

4

3425p

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

SWA, SWB, SWC, SWD

at 1MHz/Phase

SW Pin and Oscillator SYNCOUT

SW Pin and Inductor Current in

Discontinous Mode. Antiring

Circuit Eliminates High Frequency

Ringing

Transient Response 0.5A to 1.5A

Fixed Frequency Mode Operation

Output Voltage Ripple at 2.5A

Load with Only Four 4.7

µ

F

Ceramic Capacitors

Soft-Start and Inrush Current

Limiting

Burst Mode Operation

SWA TO SWD

5V/DIV

250ns/DIV

3425 G01

SWA

2V/DIV

250ns/DIV

3425 G02

SYNCOUT

2V/DIV

V

IN

= 2.4V

250ns/DIV

3425 G03

V

OUT

= 3.3V

C

OUT

= 220

µ

F

I

L

0.2A/DIV

SW

2V/DIV

V

IN

= 2.4V

100

µ

s/DIV

3425 G04

V

OUT

= 3.3V

C

OUT

= 220

µ

F

V

OUT

AC

100mV/DIV

LOAD

CURRENT

0.5A/DIV

V

IN

= 2.4V

500ns/DIV

3425 G05

V

OUT

= 3.3V

FREQUENCY = 1MHz/PHASE

V

OUT

AC

50mV/DIV

Output Voltage Ripple at 2.5A

Load with a 47

µ

F Ceramic Bulk

Capacitor

V

IN

= 2.4V

500ns/DIV

3425 G06

V

OUT

= 3.3V

FREQUENCY = 1MHz/PHASE

V

OUT

AC

10mV/DIV

V

IN

= 2.4V

500

µ

s/DIV

3425 G07

V

OUT

= 3.3V

C

SOFTSTART

= 0.015

µ

F

I

IN

0.5A/DIV

SS Pin

1V/DIV

V

OUT

2V/DIV

V

IN

= 2.4V

25

µ

s/DIV

3425 G08

V

OUT

= 3.3V

C

OUT

= 220

µ

F

SWA

2V/DIV

V

OUT

AC

50mV/DIV

Transient Response 10mA to 1A

Automatic Burst Mode Operation

V

IN

= 2.4V

1ms/DIV

3425 G10

V

OUT

= 3.3V

C

OUT

= 220

µ

F

I

OUT

1A/DIV

BURST PIN

1V/DIV

V

OUT

AC

200mV/DIV

LTC3425

5

3425p

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

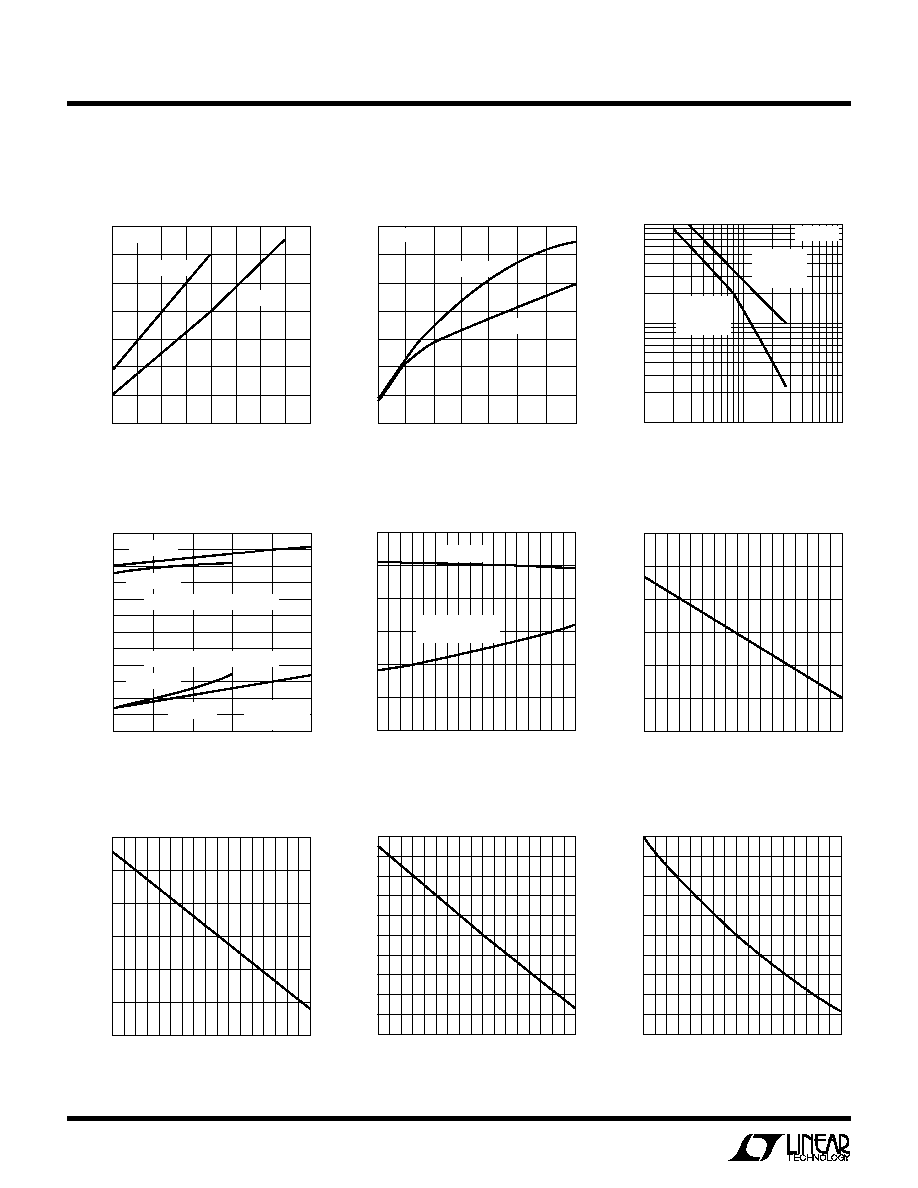

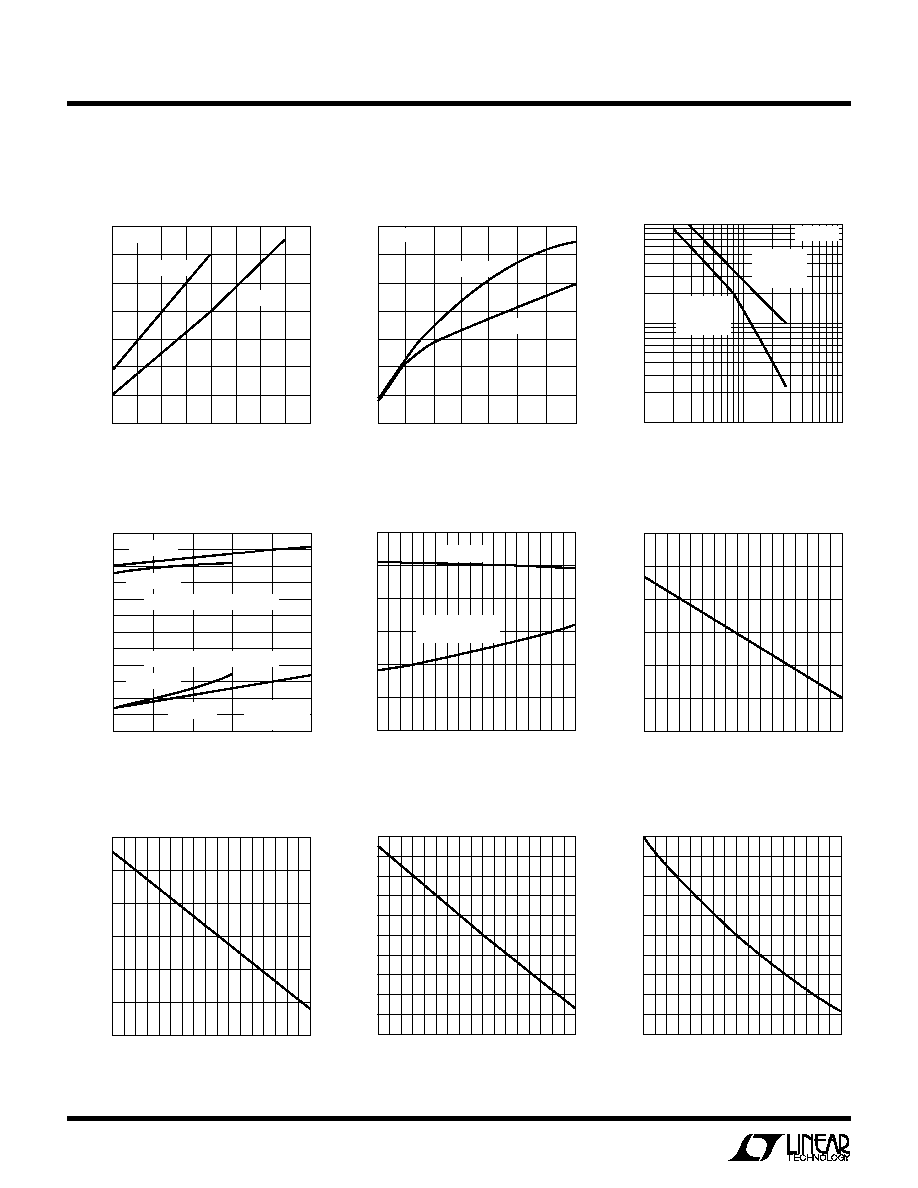

Converter Efficiency

for V

OUT

= 3.3V

Converter Efficiency for 2-, 3- and

4-Phase Operation

Efficiency Comparison of

Discontinuous Mode and Forced

Continuous Mode at Light Loads

for V

IN

= 2.4V, V

OUT

= 3.3V

Converter No Load Input Current

vs V

IN

(Burst Mode Operation)

Oscillator Frequency

Peak Current Limit

OUTPUT CURRENT (mA)

0.1

1

70

EFFICIENCY (%)

80

90

10

100

1000

10000

3425 G11

60

50

40

30

20

10

0

100

V

IN

= 2.4V

V

IN

= 1.2V

V

IN

= 1.2V

V

IN

= 2.4V

T

J

= 25

°

C

Burst Mode OPERATION

1MHz/PHASE

OUTPUT CURRENT (mA)

0.1

1

70

EFFICIENCY (%)

80

90

10

100

1000

10000

3425 G12

60

0

10

20

30

40

50

100

T

J

= 25

°

C

V

IN

= 3.3V

V

IN

= 3.3V

V

IN

= 2.4V

V

IN

= 2.4V

Burst Mode OPERATION

1MHz/PHASE

Converter Efficiency

for V

OUT

= 5V

LOAD (mA)

100

80

EFFICIENCY (%)

84

82

86

88

90

92

94

96

1000

10000

3425 G13

98

4 PHASE

T

J

= 25

°

C

V

IN

= 2.4V

V

OUT

= 3.3V

3 PHASE

2 PHASE

CONVERTER OUTPUT CURRENT (mA)

1

40

EFFICIENCY (%)

50

60

70

80

10

100

1000

3425 G14

30

20

10

0

90

100

T

J

= 25

°

C

DISCONTINUOUS

MODE

FORCED

CONTINUOUS

MODE

LOAD (mA)

1

40

EFFICIENCY (%)

50

60

70

80

10

100

1000

3425 G15

30

20

10

0

90

100

T

J

= 25

°

C

DISCONTINUOUS

MODE

FORCED

CONTINUOUS

MODE

Efficiency Comparison of

Discontinuous Mode and Forced

Continuous Mode at Light Loads

for V

IN

= 3.3V, V

OUT

= 5V

V

IN

(V)

1.5

140

120

100

80

60

40

20

0

3.0

4.0

3425 G16

2.0

2.5

3.5

4.5

CONVERTER INPUT CURRENT (

µ

A)

T

J

= 25

°

C

V

OUT

= 3.3V

V

OUT

= 5V

R

T

(k

)

1

1

FREQUENCY (MHz)

10

10

100

3425 G17

T

J

= 25

°

C

I

LIM

RESISTOR (k

)

60

PEAK CURRENT IN EACH PHASE (A)

1.4

1.6

1.8

120

160

3425 G18

1.2

1.0

80

100

140

180

200

0.8

0.6

T

J

= 25

°

C

Effective R

DS(ON)

V

OUT

(V)

2.5

R

DS(ON)

(ALL FOUR PHASES IN PARALLEL)

0.065

0.060

0.055

0.050

0.045

0.040

4.5

3425 G19

3

3.5

4

5

T

J

= 25

°

C

PMOS

NMOS

LTC3425

6

3425p

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Maximum Output Current

in Burst Mode Operation

V

IN

(V)

1

1.5

OUTPUT CURRENT (mA)

200

250

300

4

3425 G20

150

100

2

3

4.5

2.5

3.5

5

50

0

350

V

OUT

= 3.3V

V

OUT

= 5V

T

J

= 25

°

C

V

IN

(V)

0.9

0.4

0.5

0.7

1.2

1.4

3425 G21

0.3

0.2

1.0

1.1

1.3

1.5

1.6

0.1

0

0.6

LOAD CURRENT (A)

T

J

= 25

°

C

V

OUT

= 3.3V

V

OUT

= 5V

Maximum Start-Up Load vs V

IN

(Constant Current Load)

Soft-Start Charging Current

vs Temperature

Automatic Burst Mode Current

Thresholds vs R

BURST

BURST RESISTOR (k

)

10

1

AVERAGE LOAD CURRENT (mA)

10

100

100

1000

3425 G22

T

J

= 25

°

C

ENTER

Burst Mode

OPERATION

LEAVE

Burst Mode

OPERATION

V

IN

(V)

1.5

LOAD CURRENT (mA)

70

80

90

100

3.5

3425 G23

60

50

40

2

2.5

3

4

V

OUT

= 5V

T

J

= 25

°

C

R

BURST

= 33k

V

OUT

= 5V

V

OUT

= 3.3V

LEAVE Burst Mode OPERATION

ENTER Burst Mode OPERATION

V

OUT

= 3.3V

TEMPERATURE (

°

C)

45

0

SS CHARGE CURRENT (

µ

A)

0.5

1.0

1.5

2.0

3.0

25

5

15

35

75

55

3425 G24

95

115

2.5

V

IN

> 2.3V

V

IN

< 2.3V

(START-UP MODE)

Automatic Burst Mode Thresholds

vs V

IN

PGOOD Threshold vs Temperature

Shutdown Voltage vs Temperature

Minimum Start-Up Voltage

vs Temperature

TEMPERATURE (

°

C)

45

0.300

SHUTDOWN VOLTAGE (V)

0.325

0.350

0.375

0.400

0.450

25

5

15

35

75

55

3425 G25

95

115

0.425

TEMPERATURE (

°

C)

45

0.70

START VOLTAGE (V)

0.75

0.80

0.85

0.90

1.00

25

5

15

35

75

55

3425 G26

95

115

0.95

TEMPERATURE (

°

C)

45

10.8

PGOOD THRESHOLD (1% BELOW V

FB

)

11.0

10.9

11.1

11.5

11.4

11.3

11.2

11.6

11.8

25

5

15

35

75

55

3425 G27

95

115

11.7

PMOS Reverse Current in Forced

CCM vs Temperature

TEMPERATURE (

°

C)

45

300

PMOS REVERSE CURRENT (mA)

400

350

450

650

600

550

500

700

800

25

5

15

35

75

55

3425 G28

95

115

750

LTC3425

7

3425p

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Feedback Voltage vs Temperature

Peak Current Limit

vs Temperature

Error Amplifier g

m

vs Temperature

Oscillator Frequency

vs Temperature

Burst Mode V

OUT

Quiescent

Current vs Temperature

TEMPERATURE (

°

C)

45

1.200

V

FB

(V)

1.205

1.210

1.215

1.220

1.230

25

5

15

35

75

55

3425 G29

95

115

1.225

TEMPERATURE (

°

C)

45

3

PEAK I

LIM

(NORMALIZED) (%)

2

1

1

0

3

25

5

15

35

75

55

3425 G30

95

115

2

TEMPERATURE (

°

C)

45

2.0

OSCILLATOR (NORMALIZED) (%)

1.5

1.0

0.5

1.0

0.5

0

2.0

25

5

15

35

75

55

3425 G31

95

115

1.5

TEMPERATURE (

°

C)

45

5

QUIESCENT CURRENT (

µ

A)

10

15

20

25

5

15

35

75

55

3425 G32

95

115

TEMPERATURE (

°

C)

45

40

g

m

(

µ

S)

45

50

55

25

5

15

35

75

55

3425 G33

95

115

LTC3425

8

3425p

PI FU CTIO S

U

U

U

GNDAD (Pins 1, 2, 7, 8, 17, 18, 23, 24): Power Ground

for the IC and the Four Internal N-channel MOSFETs.

Connect directly to the power ground plane.

SWAD (Pins 3, 6, 19, 22): Switch Pins. Connect induc-

tors here. Minimize trace length to keep EMI to a mini-

mum. For discontinuous inductor current, a controlled

impedance is internally connected from the SW pins to V

IN

to minimize EMI. For applications where V

OUT

> 4.3V, it is

required to have Schottky diodes from SW to V

OUT

or a

snubber circuit to stay within absolute maximum rating on

the SW pins.

V

OUTAD

(Pins 4, 5, 20, 21): Output of the Four Synchro-

nous Rectifiers. Connect output filter capacitors to these

pins. Connect one low ESR ceramic capacitor directly

from each pin to the ground plane.

REFEN (Pin 9): Pull this pin above 1.4V to enable the REF

output. Grounding this pin turns the REF output off to

reduce quiescent current.

V

OUTS

(Pin 10): V

OUT

Sense Pin. Connect V

OUTS

directly to

an output filter capacitor. The top of the feedback divider

network should also be tied to this point.

SGND (Pin 11): Signal Ground Pin. Connect to ground

plane, near the feedback divider resistor.

FB (Pin 12): Feedback Pin. Connect FB to a resistor divider,

keeping the trace as short as possible. The output voltage

can be adjusted according to the following formula:

V

R

R

R

OUT

=

+

1 22

1

2

1

.

·

where R1 is connected from FB to SGND and R2 is

connected from FB to V

OUTS

.

COMP (Pin 13): Error Amp Output. A frequency compen-

sation network is connected from this pin to ground to

compensate the loop. See the section Closing the Feed-

back Loop for guidelines.

BURST (Pin 14): Burst Mode Threshold Adjust Pin. A

resistor/capacitor combination from this pin to ground

programs the average load current at which automatic

Burst Mode operation is entered.

For manual control of Burst Mode operation, ground the

BURST pin to force Burst Mode operation or connect it to

V

OUT

to force fixed frequency PWM mode. Note that the

BURST pin must not be pulled higher than V

OUT

.

REFOUT (Pin 15): Buffered 1.22V Reference Output. This

pin can source up to 100

µ

A and sink up to 10

µ

A (only

active when the REFEN pin is pulled high). This pin must

be decoupled with a 0.1

µ

F capacitor for stability.

PGOOD (Pin 16): Open-Drain Output of the Power Good

Comparator. This pin will go low when the output voltage

drops 11% below its regulated value. Maximum sink

current should be limited to 10mA.

SYNCOUT (Pin 25): Sync Output Pin. A clock is provided

at the oscillator frequency, but phase-shifted 180 degrees

to allow for synchronizing two devices for an 8-phase

converter.

CCM (Pin 26): This pin is used to select forced continuous

conduction mode. Normally this pin is grounded to allow

CCM or DCM operation. To force continuous conduction

mode, tie this pin to V

OUT

. In this mode, a reverse current

of up to about 0.5A will be allowed before turning off the

synchronous rectifier. This will prevent pulse skipping at

light load when Burst Mode operation is disabled, and will

also improve the large-signal transient response when

going from a heavy load to a light load. For Burst Mode

operation, the CCM pin should be low.

LTC3425

9

3425p

I

LIM

(Pin 27): Current Limit Adjust Pin. Connect a resistor

from I

LIM

to SGND to set the peak current limit threshold

for the N-channel MOSFETs, according to the formula

(note that this is the peak current in each inductor):

I

R

LIM

=

130

where I is in Amps and R is in k

. Do not use values less

than 75k.

R

T

(Pin 28): Connect a resistor from R

T

to SGND (or SGND

plane) to program the oscillator frequency, according to

the formula:

f

R

f

f

R

OSC

T

SWITCH

OSC

T

=

=

=

60

4

15

where f

OSC

is in MHz and R

T

is in k

.

V

IN

(Pin 29): Input Supply Pin. Connect this to the input

supply and decouple with 1

µ

F minimum low ESR

ceramic capacitor.

PI FU CTIO S

U

U

U

SYNCIN (Pin 30): Oscillator Synchronization Pin. A clock

pulse width of 100ns minimum is required to synchronize

the internal oscillator. If not used, SYNCIN should be

grounded. The typical logic threshold for this input is:

V

OUT

2

SHDN (Pin 31): Shutdown Pin. Grounding SHDN (or

pulling it below 0.25V) shuts down the IC. Pull pin up to

1V to enable. Once enabled, the pin only needs to be

0.65V.

SS (Pin 32): Soft-Start pin. Connect a capacitor from this

pin to ground to set the soft-start time, according to the

formula:

t(ms) = C

SS

(

µ

F) · 320

The nominal soft-start charging current is 2.5

µ

A. The

active range of SS is from 0.8V to 1.6V. Note that this is the

rise time of the SS pin. The actual rise time of V

OUT

will be

a function of load and output capacitance.

OPERATING MODE

BURST PIN

CCM PIN

Automatic Burst (Operating Mode is Load Dependent)

RC Network to Ground

Low

Forced Burst

Low

Low

Forced Fixed Frequency with Pulse Skipping at Light Load

High

Low

Forced Fixed Frequency, Low Noise (No Pulse Skipping)

High

High

LTC3425

10

3425p

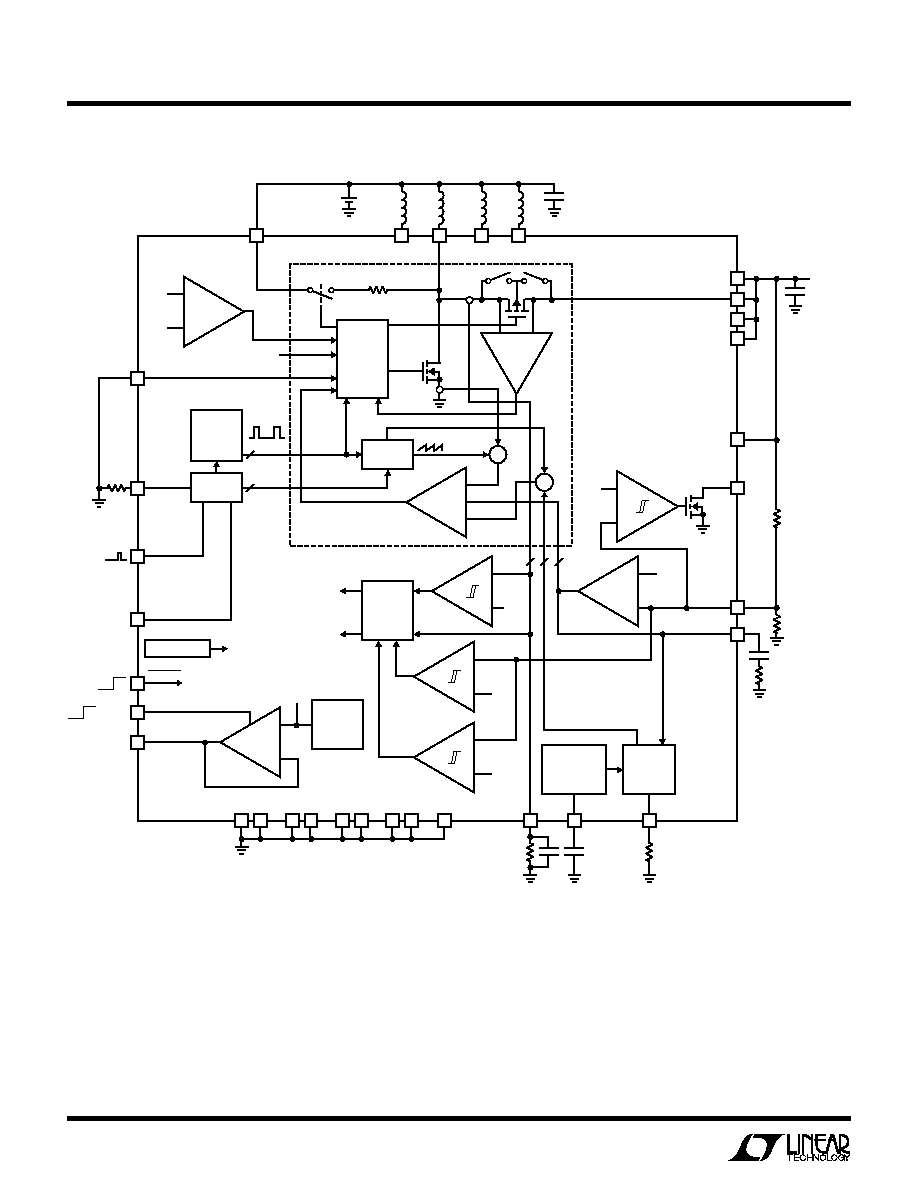

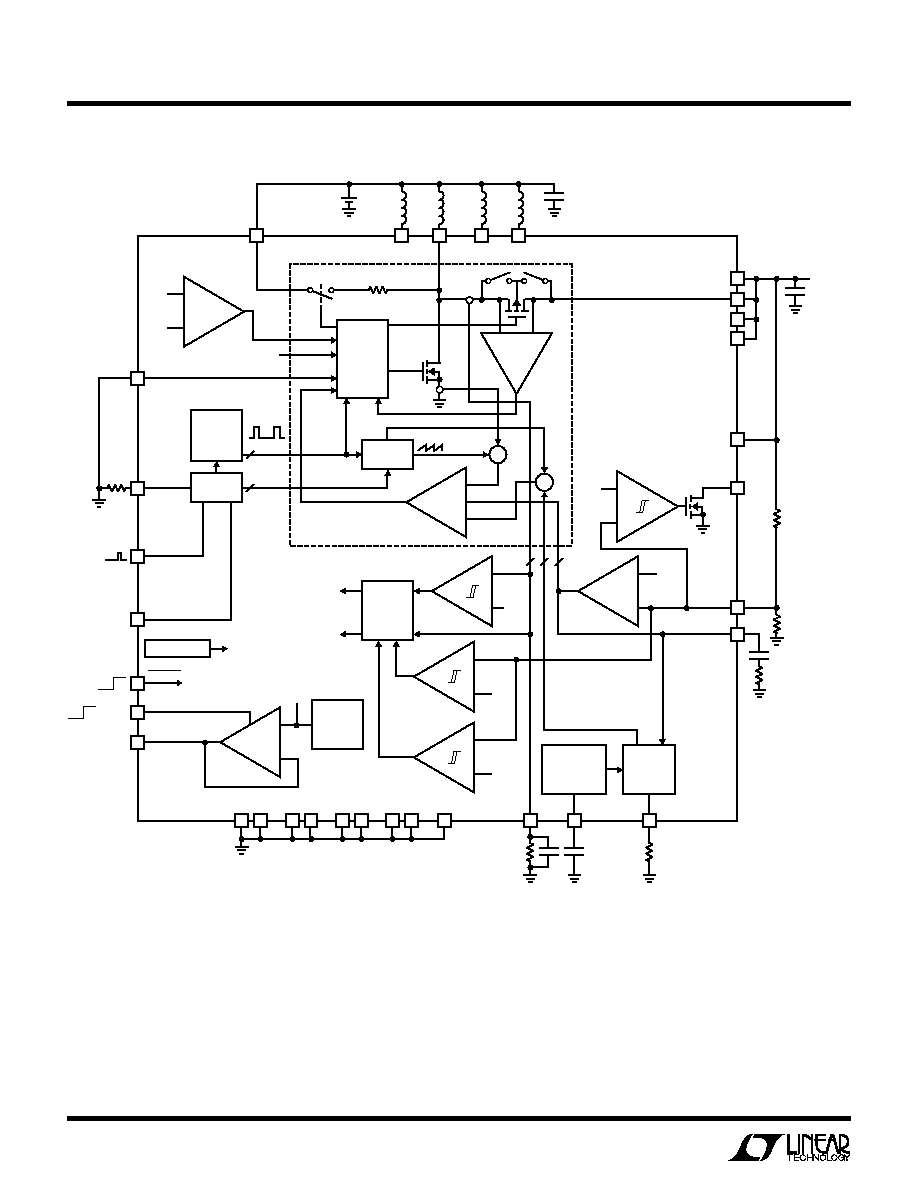

BLOCK DIAGRA

W

3%

0.94V

MODE

SLEEP

V

REF

3%

SGND

GNDD

GNDC

GNDB

GNDA

+

+

Burst Mode

CONTROL

+

+

BURST

COMP

UV

OV

ERROR

AMP

START-UP,

SOFT-START

AND

THERMAL REG

I

LIMIT

COMP

1.22V

1.086/

1.116

+

+

+

+

V

REF

1.22V

I

LIM

27

SS

32

BURST

14

24

23

18

17

8

7

2

1

REFOUT

15

REFEN

SHUTDOWN

9

SHDN

SYNCOUT

SYNCIN

SYNC

OFF ON 31

25

30

R

T

28

CCM

MODE CONTROL

PMOS

ENABLE

FB

0.8V

+

11

THERMAL SHDN

13

FB

12

PGOOD

16

V

OUTS

V

OUT

2.5V TO 5V

10

V

OUTB

5

V

OUTC

20

V

OUTA

4

V

OUTD

21

+

SLOPE

DIVIDER

4-PHASE

GEN

PWM LOGIC

AND

DRIVERS

ANTIRING

N

P

ZERO

I/2000

1V TO V

OUT

1 OF 4

+

OSC

IOSC

CLK

4

4

26

SWB

6

V

IN

+

SWA

29

3

SWC

19

SWD

22

+

4

4

4

+

OFF ON REFOUT

LTC3425

11

3425p

OPERATIO

U

DETAILED DESCRIPTION

The LTC3425 provides high efficiency, low noise power

for high current boost applications such as cellular phones

and PDAs. The true output disconnect feature eliminates

inrush current and allows V

OUT

to go to zero during

shutdown. The current mode architecture with adaptive

slope compensation provides ease of loop compensation

with excellent transient load response. The low R

DS(ON)

,

low gate charge synchronous switches eliminate the need

for an external Schottky rectifier, and provide efficient high

frequency pulse width modulation (PWM) control. High

efficiency is achieved at light loads when Burst Mode

operation is entered, where the IC's quiescent current is a

low 12

µ

A typical on V

OUT

.

MULTIPHASE OPERATION

The LTC3425 uses a 4-phase architecture, rather than the

conventional single phase of other boost converters. By

having multiple phases equally spaced (90

°

apart), not

only is the output ripple frequency increased by a factor of

four, but the output capacitor ripple current is greatly

reduced. Although this architecture requires four induc-

tors, rather than a single inductor, there are a number of

important advantages.

· Much lower peak inductor current allows the use of

smaller, lower cost inductors.

· Greatly reduced output ripple current minimizes output

capacitance requirement.

· Higher frequency output ripple is easier to filter for low

noise applications.

· Input ripple current is also reduced for lower noise on

V

IN

.

The peak boost inductor current is given by:

I

I

D N

di

LPEAK

O

=

+

( ) ·

1

2

Where I

O

is the average load current, D is the PWM duty

cycle, N is the number of phases and di is the inductor

ripple current. This relationship is shown graphically in

Figure 1 using a single phase and a 4-phase example.

Example:

The following example, operating at 50% duty cycle,

illustrates the advantages of multiphase operation over a

conventional single-phase design.

V

IN

= 1.9V, V

OUT

= 3.6V, Efficiency = 90% (approx),

I

OUT

= 2A, Frequency = 1MHz, L = 2.2

µ

H

Table 1

SINGLE

FOUR

CHANGE FROM

PARAMETER

PHASE

PHASE

1 TO 4 PHASE

Peak-Peak Output

4.227A

0.450A

Reduced by 89%

Ripple Current

RMS Output Ripple Current

2.00A

0.184A

Reduced by 91%

Peak Inductor Current

4.227A

1.227A

Reduced by 71%

Output Ripple Frequency

1MHz

4MHz

Increased by 4

×

With 4-phase operation, at least one of the phases will be

delivering current to the load whenever V

IN

is greater than

one quarter V

OUT

(duty cycles less than 75%). For lower

duty cycles, there can be as many as two or three phases

delivering load current simultaneously. This greatly re-

duces both the output ripple current and the peak current

in each inductor, compared with a single-phase converter.

This is illustrated in the waveforms of Figures 2 and 3.

Operation Using Only Two or Three Phases

The LTC3425 can operate as a 2- or 3-phase converter by

simply eliminating the inductor from the unused phase(s).

TIME (

µ

s)

0

OUTPUT RIPPLE CURRENT (A)

2

FOUR PHASE

SINGLE

PHASE

3

3425 F01

1

0

0.5

1

1.5

5

4

Figure 1. Comparison of Output Ripple Current with Single

Phase and 4-Phase Boost Converter in a 2A Load Application

Operating at 50% Duty Cycle

LTC3425

12

3425p

OPERATIO

U

SWITCH A

VOLTAGE

SWITCH B

VOLTAGE

SWITCH C

VOLTAGE

SWITCH D

VOLTAGE

INDUCTOR A

CURRENT

INDUCTOR B

CURRENT

INDUCTOR C

CURRENT

INDUCTOR D

CURRENT

RECTIFIER A

CURRENT

RECTIFIER B

CURRENT

RECTIFIER C

CURRENT

RECTIFIER D

CURRENT

OUTPUT RIPPLE

CURRENT

INPUT CURRENT

3425 F02

Figure 2. Simplified Voltage and Current Waveforms

for 4-Phase Operation at 50% Duty Cycle

This approach can be used to reduce solution cost and

board area in applications not requiring the full power

capability of the LTC3425, or where peak efficiency may

not be as important as cost and size. In this case, phase A

should always be used, since this is the only phase active

in Burst Mode operation and phase C is recommended as

the second phase for the lowest output ripple, since it is

180

°

out of phase with phase A. Figure 4 illustrates the

efficiency differences with two, three and four phases in a

typical 2-cell to 3.3V boost application. In this example,

you can see that for maximum loads less than 1A, the

efficiency penalty for using only two or three phases is

fairly small. Keep in mind, however, that this penalty will

grow larger as the input voltage drops. Output ripple will

also increase with each phase that is eliminated.

Low Voltage Start-Up

The LTC3425 includes an independent start-up oscillator

designed to start up at input voltages as low as 0.88V. The

frequency and peak current limit during start-up are

LTC3425

13

3425p

SWITCH A

VOLTAGE

SWITCH B

VOLTAGE

SWITCH C

VOLTAGE

SWITCH D

VOLTAGE

INDUCTOR A

CURRENT

INDUCTOR B

CURRENT

INDUCTOR C

CURRENT

INDUCTOR D

CURRENT

RECTIFIER A

CURRENT

RECTIFIER B

CURRENT

RECTIFIER C

CURRENT

RECTIFIER D

CURRENT

OUTPUT RIPPLE

CURRENT

INPUT CURRENT

3432 F03

OPERATIO

U

Figure 3. Simplified Voltage and Current Waveforms

for 4-Phase Operation at 75% Duty Cycle

internally controlled. The device can start up under some

load (see the graph Start-Up Current vs Input Voltage).

Soft-start and inrush current limiting is provided during

start-up as well as normal mode. The same soft-start

capacitor is used for each operating mode.

During start-up, all four phases switch in unison. When

either V

IN

or V

OUT

exceeds 2.3V, the IC enters normal

operating mode. Once the output voltage exceeds the

input by 0.3V, the IC powers itself from V

OUT

instead of

V

IN

. At this point the internal circuitry has no dependency

on the V

IN

input voltage, eliminating the requirement for a

large input capacitor. The input voltage can drop as low as

0.5V without affecting circuit operation. The limiting factor

for the application becomes the ability of the power source

to supply sufficient energy to the output at the low volt-

ages, and the maximum duty cycle which is clamped at

90%.

LTC3425

14

3425p

OPERATIO

U

Low Noise Fixed Frequency Operation

Shutdown: The part is shut down by pulling the SHDN pin

below 0.25V and made active by pulling the pin above 1V.

Note that the SHDN pin can be driven above V

IN

or V

OUT

,

as long as it is limited to less than 5.5V.

Soft-Start: The soft-start time is programmed with an

external capacitor to ground on the SS pin. An internal

current source charges it with a nominal 2.5

µ

A (1

µ

A while

in start-up mode when V

IN

and V

OUT

are both below 2.3V).

The voltage on the soft-start pin (in conjunction with the

external resistor on the I

LIM

pin) is used to control the peak

current limit until the voltage on the capacitor exceeds

1.6V, at which point the external resistor sets the peak

current. In the event of a commanded shutdown or a

thermal shutdown, the capacitor is discharged automati-

cally. Note that Burst Mode operation is inhibited during

the soft-start time.

t(ms) = C

SS

(

µ

F) · 320

Oscillator: The frequency of operation is set through a re-

sistor from the R

T

pin to ground. An internally trimmed

timing capacitor resides inside the IC. The internal

oscillator frequency is then divided by four to generate the

four phases, each phase shifted by 90

°

. The oscillator fre-

quency and resulting switching frequency of each of the four

phases are calculated using the following formula:

f

R

f

f

R

OSC

T

SWITCH

OSC

T

=

=

=

60

4

15

where f

OSC

is in MHz and R

T

is in k

.

The oscillator can be synchronized with an external clock

applied to the SYNCIN pin. When synchronizing the oscil-

lator, the free running frequency must be set to an approxi-

mately 30% lower frequency than the desired synchronized

frequency. A SYNCOUT pin is provided for synchronizing

two or more devices. The output sync pulse is 180

°

out of

phase from the internal oscillator, allowing two devices to

be synchronized to create an 8-phase converter. Note that

in Burst Mode operation, the oscillator is turned off and the

SYNCOUT pin is driven low.

In fixed frequency operation, the minimum on-time before

pulse skipping occurs (at light load) is typically 110ns.

Current Sensing: Lossless current sensing converts the

peak current signal to a voltage to sum in with the internal

slope compensation. This summed signal is compared to

the error amplifier output to provide a peak current control

command for the PWM. The slope compensation in the IC

is adaptive to the input and output voltage, therefore the

converter provides the proper amount of slope compensa-

tion to ensure stability, but not an excess to cause a loss

of phase margin in the converter.

Error Amp: The error amplifier is a transconductance

amplifier with its positive input internally connected to the

1.22V reference and its negative input connected to the FB

pin. A simple compensation network is placed from the

COMP pin to ground. Internal clamps limit the minimum

and maximum error amp output voltage for improved

large-signal transient response. During Burst Mode op-

eration, the compensation pin is high impedance, however

clamps limit the voltage on the external compensation

network, preventing the compensation capacitor from

discharging to zero.

Figure 4. LTC3425 Efficiency vs

Load for 2-, 3- and 4-Phase Operation

LOAD (mA)

100

80

EFFICIENCY (%)

84

82

86

88

90

92

94

96

1000

10000

3425 G13

98

4 PHASE

T

J

= 25

°

C

V

IN

= 2.4V

V

OUT

= 3.3V

3 PHASE

2 PHASE

LTC3425

15

3425p

Current Limit: The programmable current limit circuit sets

the maximum peak current in the NMOS switches. The

current limit level is programmed using a resistor to

ground on the I

LIM

pin. Do not use values below 75k. In

Burst Mode operation, the current limit is automatically

set to a nominal value of 0.6A peak for optimal efficiency.

I

R

LIM

=

130

per Phase

where I is in Amps and R is in k

.

Synchronous Rectifier and Zero Current Amp: To pre-

vent the inductor current from running away, the PMOS

synchronous rectifier is only enabled when V

OUT

> (V

IN

+

0.3V) and the FB pin is > 0.8V.The zero current amplifier

monitors the inductor current to the output and shuts off

the synchronous rectifier once the current is below 50mA

typical, preventing negative inductor current. If the CCM

pin is tied high, the amplifier will allow up to 0.6A of

negative current in the synchronous rectifier.

Antiringing Control: The antiringing control connects a

resistor across the inductor to damp the ringing on the SW

pin in discontinuous conduction mode. The LC

SW

ringing

(L = inductor, C

SW

= Capacitance on Switch pin) is low

energy, but can cause EMI radiation.

Power Good: An internal comparator monitors the FB pin

voltage. If the FB pin drops 11.4% below the regulation

value, the PGOOD pin will pull low (sink current should be

limited to 10mA max). The output will stay low until the FB

voltage is within 9.5% of the regulation voltage. A filter

prevents noise spikes from causing nuisance trips.

Reference Output: The internal 1.22V reference is buff-

ered and brought out to the REFOUT pin. It is active when

the REFEN pin is pulled high (above 1.4V). For stability, a

minimum of 0.1

µ

F capacitor must be placed on the REFOUT

pin. The output can source up to 100

µ

A and sink up to

10

µ

A. For the lowest possible quiescent current in Burst

Mode operation, the reference output should be disabled

by grounding the REFEN pin.

Thermal Shutdown: An internal temperature monitor will

start to reduce the programmed peak current limit if the

die temperature exceeds 135

°

C. If the die temperature

continues to rise and reaches 150

°

C, the part will go into

thermal shutdown and all switches will be turned off and

the soft-start capacitor will be reset. The part will be

enabled again when the die temperature has dropped

about 10

°

C. Note: Overtemperature protection is intended

to protect the device during momentary overload condi-

tions. Continuous operation above the specified maxi-

mum operating junction temperature may result in device

degradation or failure.

Burst Mode Operation

Burst Mode operation can be automatic or user controlled.

In automatic operation, the IC will automatically enter

Burst Mode operation at light load and return to fixed

frequency PWM mode for heavier loads. The user can

program the average load current at which the mode

transition occurs using a single resistor.

During Burst Mode operation, only Phase A is active and

the other three phases are turned off, reducing quiescent

current and switching losses by 75%. Note that the

oscillator is also shut down in this mode, since the on time

is determined by the time it takes the inductor current to

reach a fixed peak current, and the off time is determined

by the time it takes for the inductor current to return to

zero.

In Burst Mode operation, the IC delivers energy to the

output until it is regulated and then goes into a sleep mode

where the outputs are off and the IC is consuming only

12

µ

A of quiescent current. In this mode, the output ripple

has a variable frequency component with load current and

will be typically 2% peak-peak. This maximizes efficiency

at very light loads by minimizing switching and quiescent

losses. Burst Mode ripple can be reduced slightly by using

more output capacitance (47

µ

F or greater). This capacitor

does not need to be a low ESR type if low ESR ceramics are

also used. Another method of reducing Burst Mode ripple

is to place a small feedforward capacitor across the upper

resistor in the V

OUT

feedback divider network.

During Burst Mode operation, the COMP pin is discon-

nected from the error amplifier in an effort to hold the

voltage on the external compensation network where it

was before entering Burst Mode operation. To minimize

the effects of leakage current and stray resistance, voltage

clamps limit the min and max voltage on COMP during

OPERATIO

U

LTC3425

16

3425p

Burst Mode operation. This minimizes the transient expe-

rienced when a heavy load is suddenly applied to the

converter after being in Burst Mode operation for an

extended period of time.

For automatic operation, an RC network should be con-

nected from the BURST pin to ground. The value of the

resistor will control the average load current (I

BURST

) at

which Burst Mode operation will be entered and exited

(there is hysteresis to prevent oscillation between modes).

The equation given for the capacitor on the BURST pin is

for the minimum value, to prevent ripple on the BURST pin

from causing the part to oscillate in and out of Burst Mode

operation at the current where the mode transition occurs.

I

R

I

R

BURST

BURST

BURST

BURST

=

=

2 75

1 7

.

.

to leave Burst Mode operation

to enter Burst Mode operation

where R

BURST

is in k

and I

BURST

is in Amps. For load

currents under 20mA, refer to the curve Automatic Burst

Mode Thresholds vs R

BURST

.

C

C

V

BURST

OUT

OUT

=

·

,

10 000

where C

BURST(MIN)

and C

OUT

are in

µ

F.

When the voltage on the BURST pin drops below 0.94V,

the part will enter Burst Mode operation. When the BURST

pin voltage is above 1.06V, it will be in fixed frequency

mode.

In the event that a sudden load transient causes the

feedback pin to drop by more than 4% from the regulation

value, an internal pull-up is applied to the BURST pin,

forcing the part quickly out of Burst Mode operation. For

optimum transient response when going between Burst

Mode operation and PWM mode, the mode should be

controlled manually by the host. This way PWM mode can

be commanded before the load step occurs, minimizing

output voltage droop. For manual control of Burst Mode

operation, the RC network can be eliminated. To force

fixed frequency PWM mode, the BURST pin should be

connected to V

OUT

. To force Burst Mode operation, the

BURST pin should be grounded. The circuit connected to

OPERATIO

U

the BURST pin should be able to sink up to 2mA. Note that

Burst Mode operation is inhibited during start-up and

soft-start.

Note that if V

IN

is raised to within 200mV or less below

V

OUT

, the part will exit Burst Mode operation and the

synchronous rectifier will be disabled. It will remain in

fixed frequency mode until V

IN

is at least 300mV below

V

OUT

.

If the load applied during forced Burst Mode operation

(BURST = GND) exceeds the current that can be supplied,

the output voltage will start to droop and the part will

automatically come out of Burst Mode operation and enter

fixed frequency mode, raising V

OUT

. The part will then

enter Burst Mode operation once again, the cycle will

repeat, resulting in about 4% output ripple. The maximum

current that can be supplied in Burst Mode operation is

given by:

I

V

V

V

in Amps

O MAX

OUT

IN

IN

(

)

.

·

=

+

0 60

2

1

Output Disconnect and Inrush Limiting

The LTC3425 is designed to allow true output disconnect

by eliminating body diode conduction of the internal

PMOS rectifiers. This allows V

OUT

to go to zero volts

during shutdown, drawing no current from the input

source. It also allows for inrush current limiting at turn-on,

minimizing surge currents seen by the input supply. Note

that to obtain the advantages of output disconnect, there

cannot be any external Schottky diodes connected be-

tween the switch pins and V

OUT

.

Note: Board layout is extremely critical to minimize

voltage overshoot on the switch pins due to stray induc-

tance. Keep the output filter capacitors as close as

possible to the V

OUT

pins, and use very low ESR/ESL

ceramic capacitors tied to a good ground plane.

For applications with V

OUT

over 4.3V, Schottky diodes are

required to limit the peak switch voltage to less than 6V.

These must also be very close to minimize stray induc-

tance. See the section Applications Where V

OUT

> 4.3V.

LTC3425

17

3425p

COMPONENT SELECTION

Inductor Selection

The high frequency, multiphase operation of the LTC3425

allows the use of small surface mount inductors. The

minimum inductance value is proportional to the operat-

ing frequency and is limited by the following constraints:

L

f

and L

V

V

V

f Ripple V

IN MIN

OUT MAX

IN MIN

OUT MAX

>

>

(

)

2

(

)

(

)

(

)

(

)

·

·

·

where:

f = Operating frequency in MHz (of each phase)

Ripple = Allowable inductor current ripple (amps

peak-peak)

V

IN(MIN)

= Minimum input voltage

V

OUT(MAX)

= Maximum output voltage

The inductor current ripple is typically set to 20% to 40%

of the maximum inductor current.

For high efficiency, choose an inductor with high fre-

quency core material, such as ferrite to reduce core loses.

The inductor should have low ESR (equivalent series

resistance) to reduce the I

2

R losses, and must be able to

handle the peak inductor current without saturating. To

minimize radiated noise, use a shielded inductor. (Note

that the inductance of shielded types will drop more as

current increases, and will saturate more easily). See

Table 2 for a list of inductor manufacturers.

Table 2. Inductor Vendor Information

SUPPLIER

PHONE

FAX

WEB SITE

Coilcraft

(847) 639-6400

(847) 639-1469

www.coilcraft.com

Murata

USA:

USA:

www.murata.com

(814) 237-1431

(814) 238-0490

Sumida

USA:

USA:

www.japanlink.com/

(847) 956-0666

(847) 956-0702

sumida

Japan:

Japan:

81-3-3607-5111

81-3-3607-5144

TDK

(847) 803-6100

(847) 803-6296

www.component.

tdk.com

Some example inductor part types are:

Coilcraft DO-1608, DS-1608 and DT-1608 series

Murata LQH3C, LQH4C, LQH32C and LQN6C series

Sumida CDRH3D16, CDRH4D18, CDRH4D28, CR32,

CR43 series

TDK RLF5018T and NLFC453232T series

Output Capacitor Selection

The output voltage ripple has three components to it. The

bulk value of the capacitor is set to reduce the ripple due

to charge into the capacitor each cycle. The max ripple due

to charge is given by:

V

I

V

C

V

f

RBULK

P

IN

OUT

OUT

=

·

·

· · 4

where:

I

P

= peak inductor current

f = switching frequency of one phase

APPLICATIO S I FOR ATIO

W

U

U

U

LTC3425

L1

L2

L3

L4

3425 F05

C

IN

C

OUT

C

OUT

C

OUT

C

OUT

C

SS

R

T

Figure 5. Typical Board Layout

LTC3425

3425 F06

Figure 6. Example Board Layout for a 10W, 4-Phase Boost

Converter. Total Area = 0.50in

2

(with All Components Mounted

on the Topside of Board)

LTC3425

18

3425p

voltage from exceeding its maximum rating during the

break-before-make time. Surface mount diodes, such as

the MBR0520L or equivalent, must be used and must be

located very close to the pins to minimize stray inductance.

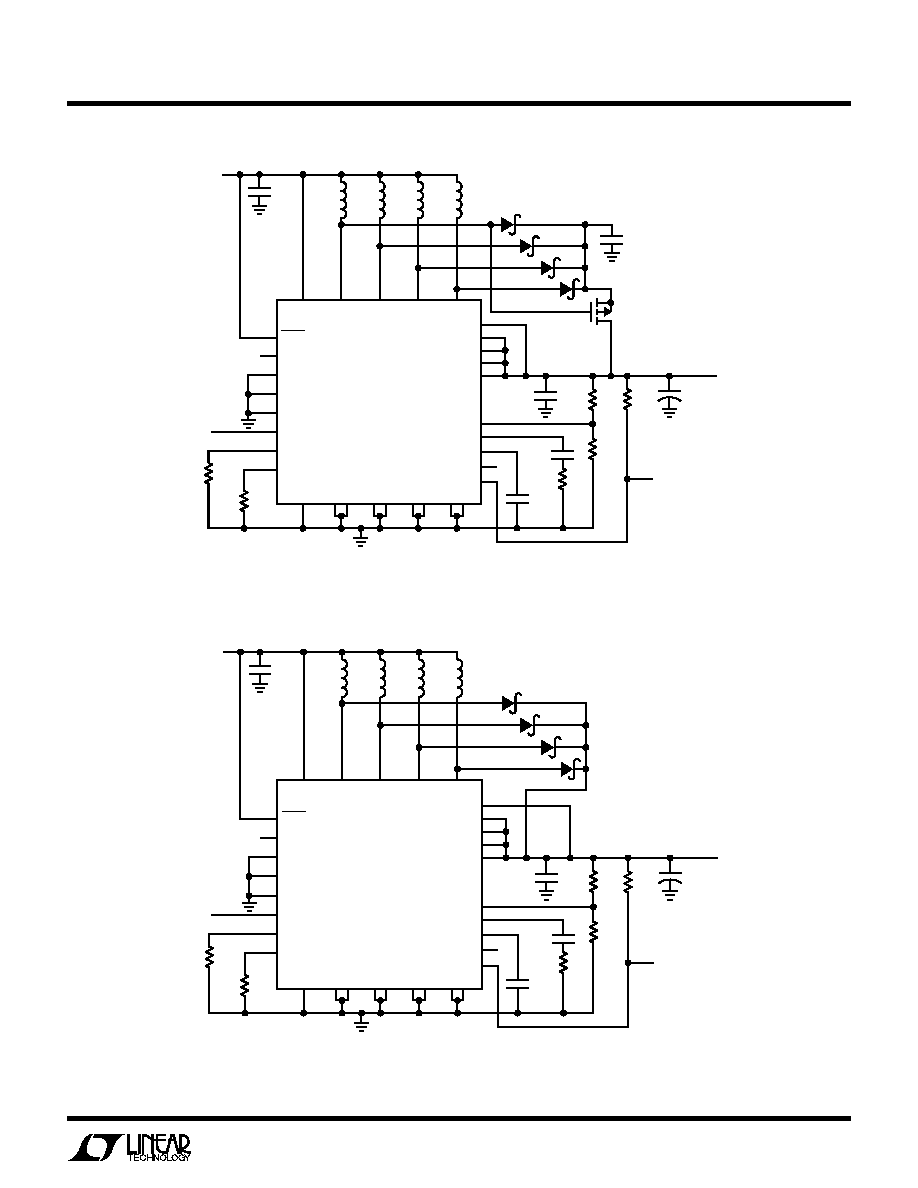

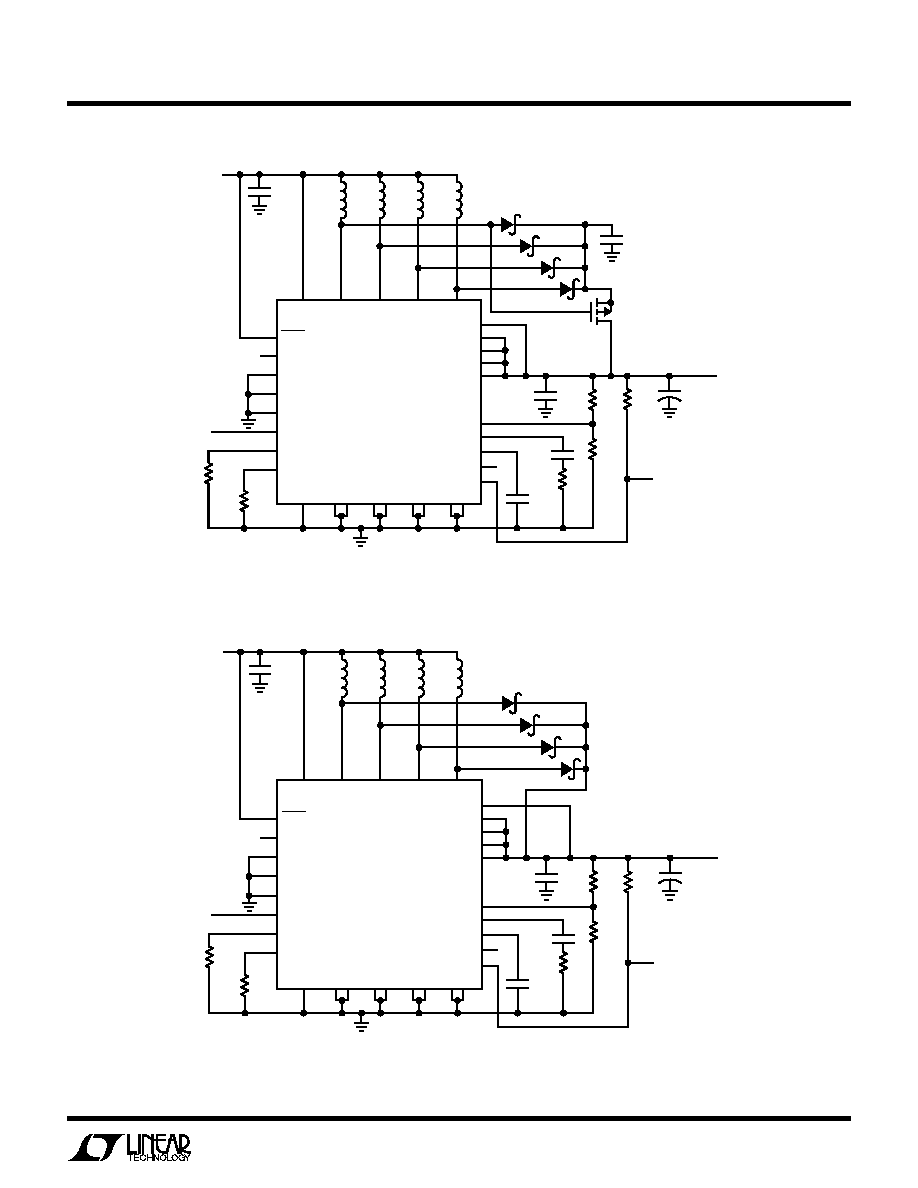

Two example application circuits are shown in Figures 7

and 8, one with output disconnect and one without.

Operating Frequency Selection

There are several considerations in selecting the operat-

ing frequency of the converter. The first is, which are the

sensitive frequency bands that cannot tolerate any spec-

tral noise? For example, in products incorporating RF

communications, the 455kHz IF frequency is sensitive to

any noise, therefore switching above 600kHz is desired.

Some communications have sensitivity to 1.1MHz, and

in that case, a 1.5MHz converter frequency may be

employed.

The second consideration is the physical size of the

converter. As the operating frequency goes up, the induc-

tor and filter capacitors go down in value and size. The

trade off is in efficiency, since the switching losses in-

crease proportionally with frequency.

Thermal Considerations

To deliver the power that the LTC3425 is capable of, it is

imperative that a good thermal path be provided to dissi-

pate the heat generated within the package. This can be

accomplished by taking advantage of the large thermal

pad on the underside of the IC. It is recommended that

multiple vias in the printed circuit board be used to

conduct heat away from the IC and into a copper plane with

as much area as possible. In the event that the junction

temperature gets too high, the peak current limit will

automatically be decreased. If the junction temperature

continues to rise, the part will go into thermal shutdown,

and all switching will stop until the temperature drops.

Closing the Feedback Loop

The LTC3425 uses current mode control with internal

adaptive slope compensation. Current mode control elimi-

nates the 2nd order filter, due to the inductor and output

capacitor exhibited in voltage mode controllers, and sim-

plifies it to a single pole filter response. The product of the

APPLICATIO S I FOR ATIO

W

U

U

U

The ESR (equivalent series resistance) is usually the most

dominant factor for ripple in most power converters. The

ripple due to capacitor ESR is given by:

V

RCESR

= I

P

· C

ESR

where C

ESR

= Capacitor Series Resistance

The ESL (equivalent series inductance) is also an impor-

tant factor for high frequency converters. Using small,

surface mount ceramic capacitors, placed as close as

possible to the V

OUT

pins, will minimize ESL.

Low ESR/ESL capacitors should be used to minimize

output voltage ripple. For surface mount applications, AVX

TPS Series tantalum capacitors, Sanyo POSCAP or X5R

type ceramic capacitors are recommended.

In all applications, a minimum of 1

µ

F, low ESR ceramic

capacitor should be placed as close to each of the four

V

OUT

pins as possible, and grounded to a local ground

plane.

Input Capacitor Selection

The input filter capacitor reduces peak currents drawn

from the input source and reduces input switching noise.

Since the IC can operate at voltages below 0.5V once the

output is regulated (as long as SHDN is above 0.65V), the

demand on the input capacitor to lower ripple is much less.

Taiyo Yuden offers very low ESR capacitors, for example

the 2.2

µ

F in a 0603 case (JMK107BJ22MA). See Table 3

for a list of capacitor manufacturers for input and output

capacitor selection.

Table 3. Capacitor Vendor Information

SUPPLIER

PHONE

FAX

WEB SITE

AVX

(803) 448-9411 (803) 448-1943 www.avxcorp.com

Sanyo

(619) 661-6322 (619) 661-1055 www.sanyovideo.com

TDK

(847) 803-6100 (847) 803-6296 www.component.tdk.com

Murata

USA:

USA:

www.murata.com

(814) 237-1431 (814) 238-0490

(800) 831-9172

Taiyo Yuden (408) 573-4150 (408) 573-4159 www.t-yuden.com

Applications Where V

OUT

> 4.3V

Due to the very high slew rates associated with the switch

nodes, Schottky diode clamps are required in any applica-

tion where V

OUT

can exceed 4.3V to prevent the switch

LTC3425

19

3425p

APPLICATIO S I FOR ATIO

W

U

U

U

L1

2.7

µ

H

C

IN

2.2

µ

F

R

LIM

75k

R

T

12.1k

L2

2.7

µ

H

L3

2.7

µ

H

L4

2.7

µ

H

D4

C

IN

: TAIYO YUDEN JMK107BJ225MA

C

S

: TAIYO YUDEN LMK107BJ474KA

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

4)

C

BULK

: AVX TPSD157M006R0050

V

IN

V

OUT

SWA

V

IN

3.3V

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

C2

220pF

3425 F07

C

OUT

4.7

µ

F

×

4

C

SS

0.01

µ

F

C

S

0.47

µ

F

×

2

Q1

C

BULK

150

µ

F

6.3V

R3

100k

R2

309k

R4

100k

PGOOD

R1

100k

V

OUT

5V

2.5A

+

D3

D2

D1

D1 TO D4: MOTOROLA MBR0520L

L1 TO L4: TDK RLF5018T-2R7M1R8

Q1: ZETEX ZXM61P02F

L1

2.7

µ

H

C

IN

2.2

µ

F

R

LIM

75k

R

T

12.1k

L2

2.7

µ

H

L3

2.7

µ

H

L4

2.7

µ

H

D4

C

IN

: TAIYO YUDEN JMK107BJ225MA

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

4)

C

BULK

: AVX TPSD157M006R0050

V

IN

V

OUT

SWA

V

IN

3.3V

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

C2

220pF

3425 F08

C

OUT

4.7

µ

F

×

4

C

SS

0.01

µ

F

C

BULK

150

µ

F

6.3V

R3

100k

R2

309k

R4

100k

PGOOD

R1

100k

V

OUT

5V

2.5A

+

D3

D2

D1

D1 TO D4: MOTOROLA MBR0520LT1

L1 TO L4: TDK RLF5018T-2R7M1R8

Figure 7. Application Circuit for V

OUT

> 4.3V with Inrush Limiting and Output Disconnect

Figure 8. Application Circuit for V

OUT

> 4.3V When Inrush Limiting and Output Disconnect are Not Required

LTC3425

20

3425p

modulator control to output DC gain, and the error amp

open-loop gain gives the DC gain of the system:

G

G

G

G

V

I

G

DC

CONTROLOUTPUT

EA

CONTROL

IN

OUT

EA

=

=

·

·

,

,

2

5 000

The output filter pole is given by:

F

I

V

C

FILTERPOLE

OUT

OUT

OUT

=

·

·

where C

OUT

is the output filter capacitor.

The output filter zero is given by:

F

R

C

FILTERZERO

ESR

OUT

=

1

2 ·

·

·

where R

ESR

is the output capacitor equivalent series

resistance.

A troublesome feature of the boost regulator topology is

the right half plane zero (RHP), and is given by:

F

V

I

L

RHPZ

IN

OUT

=

2

2 ·

·

·

At heavy loads this gain increase with phase lag can occur

at a relatively low frequency. The loop gain is typically

rolled off before the RHP zero frequency.

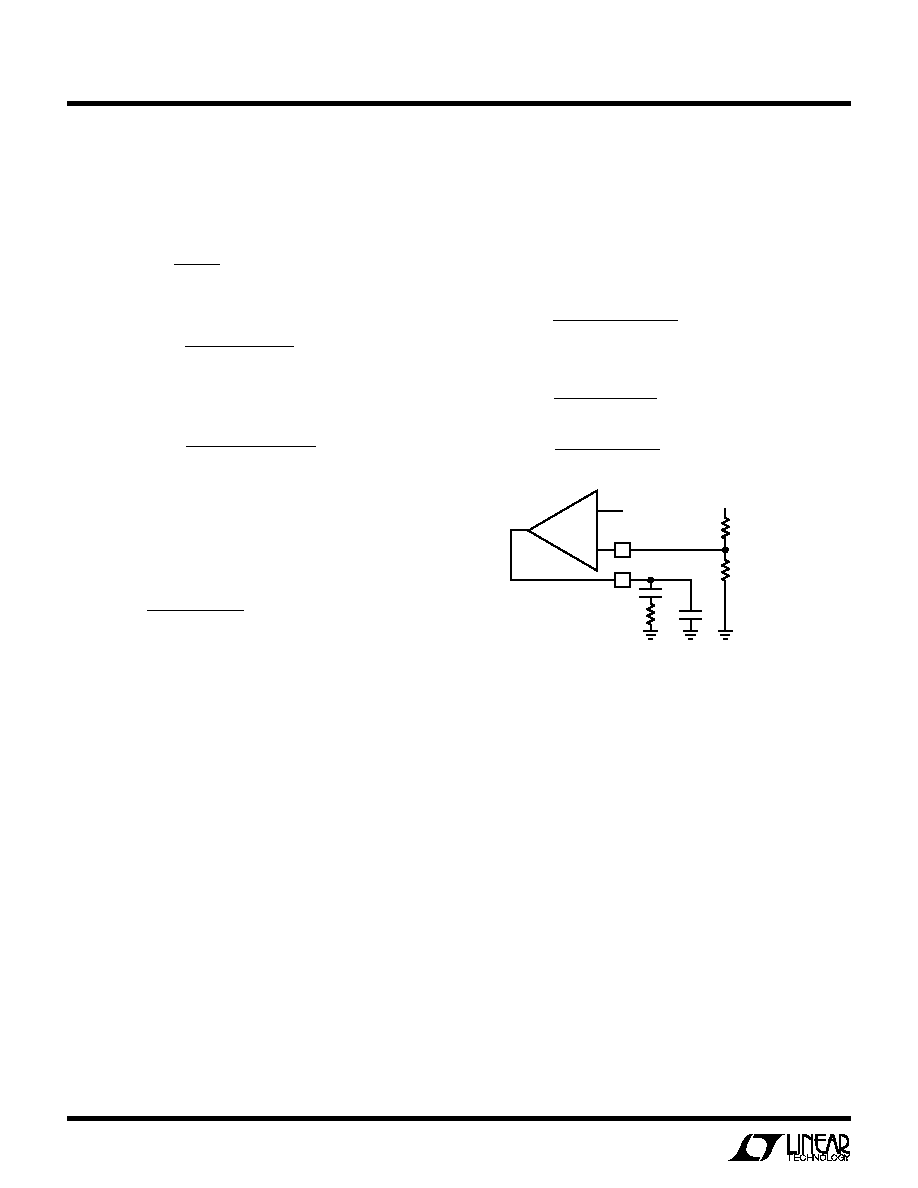

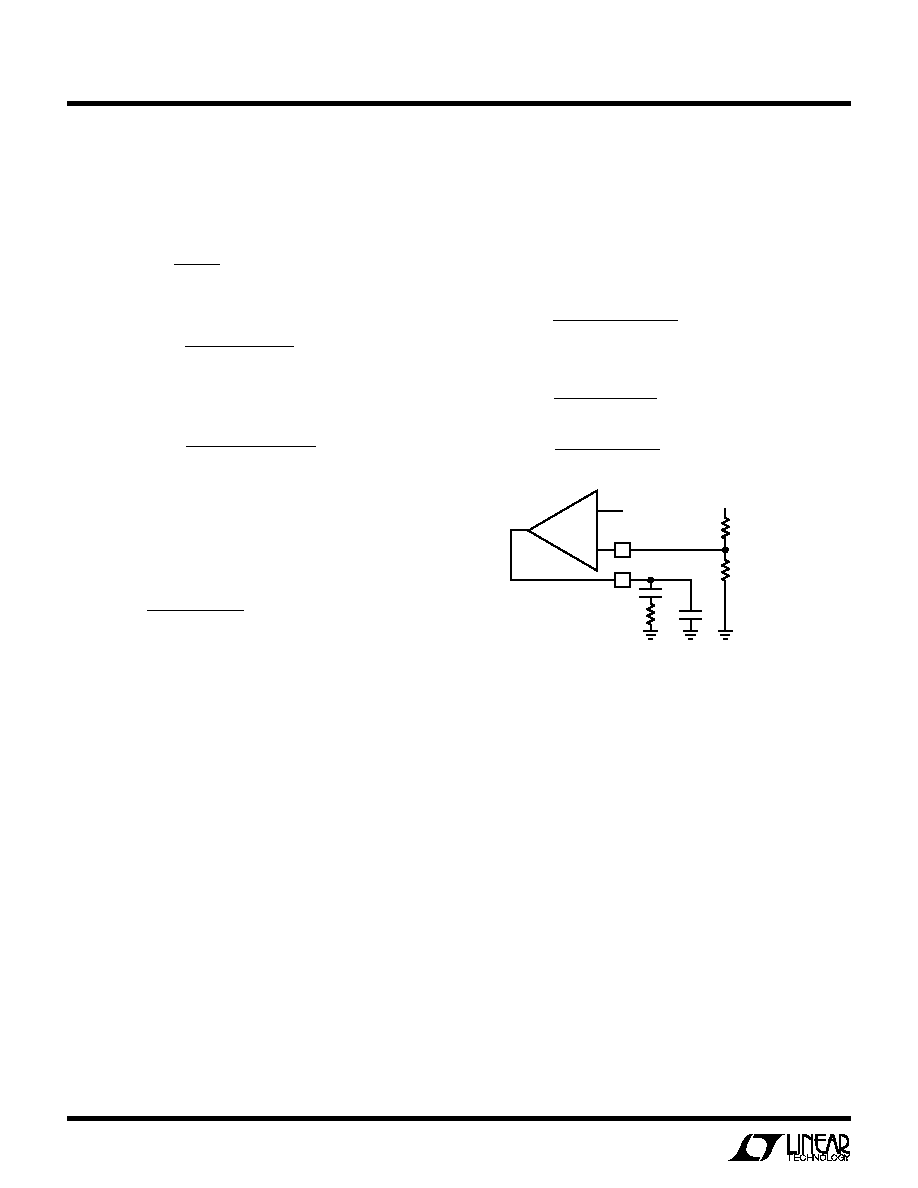

The typical error amp compensation is shown in Figure 9.

The equations for the loop dynamics are as follows:

F

e

C

which is extremely close to DC

F

R

C

F

R

C

POLE

C

ZERO

Z

C

POLE

Z

C

1

6

1

1

1

2

2

1

2

100

1

2

1

2

=

=

·

·

·

·

·

·

·

·

·

+

FB

1.25V

V

OUT

R1

R2

3425 F09

R

Z

V

C

C

C1

C

C2

ERROR

AMP

Figure 9

APPLICATIO S I FOR ATIO

W

U

U

U

LTC3425

21

3425p

TYPICAL APPLICATIO S

U

Single or Dual Cell to 3.3V Boost with Automatic Burst Mode Operation

L1

2.2

µ

H

C

IN

2.2

µ

F

C3

0.056

µ

F

R

LIM

75k

R

T

15k

R4

20k

L2

2.2

µ

H

L3

2.2

µ

H

L4

2.2

µ

H

C

BULK

: AVX TPSD157M004R0050

C

IN

: TAIYO YUDEN JMK107BJ225MA

V

IN

SWA

V

IN

= 1.1V TO 3V

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

+

C2

220pF

3425 TA03

C

OUT

4.7

µ

F

×

4

C

SS

0.01

µ

F

R3

100k

R2

511k

R5

10k

C1

22pF

R5

100k

C

BULK

150

µ

F

4V

PGOOD

R1

301k

V

OUT

3.3V

1A

+

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

4)

L1 TO L4: MURATA LQH4C2R2M04

LTC3425

22

3425p

Application with User Commanded Burst Mode Operation

and Buffered Reference Output Enabled

L1

3.3

µ

H

C

IN

2.2

µ

F

C1

0.1

µ

F

R

LIM

75k

R

T

30.1k

BURST PWM

L2

3.3

µ

H

L3

3.3

µ

H

L4

3.3

µ

H

C

IN

: TAIYO YUDEN JMK107BJ225MA

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

4)

L1 TO L4: SUMIDA CDRH4D28

V

IN

V

OUT

V

REF

SWA

V

IN

= 1.8V TO 3V

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

+

C2

330pF

3425 TA04

C

OUT

4.7

µ

F

×

4

C

SS

0.01

µ

F

R3

33k

R2

511k

R4

100k

PGOOD

R1

301k

V

OUT

3.3V

2A

R4

10k

C3

22pF

TYPICAL APPLICATIO S

U

LTC3425

23

3425p

PACKAGE DESCRIPTIO

U

UH Package

32-Lead Plastic QFN (5mm

×

5mm)

(Reference LTC DWG # 05-08-1693)

5.00

±

0.10

(4 SIDES)

NOTE:

1. DRAWING PROPOSED TO BE A JEDEC PACKAGE OUTLINE

M0-220 VARIATION WHHD-(X) (TO BE APPROVED)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.20mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

PIN 1

TOP MARK

0.40

±

0.10

31

1

2

32

BOTTOM VIEW--EXPOSED PAD

3.45

±

0.10

(4-SIDES)

0.75

±

0.05

R = 0.115

TYP

0.23

±

0.05

(UH) QFN 0102

0.50 BSC

0.200 REF

0.00 0.05

0.57

±

0.05

3.45

±

0.05

(4 SIDES)

4.20

±

0.05

5.35

±

0.05

0.23

±

0.05

PACKAGE OUTLINE

0.50 BSC

RECOMMENDED SOLDER PAD LAYOUT

LTC3425

24

3425p

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

q

FAX: (408) 434-0507

q

www.linear.com

©

LINEAR TECHNOLOGY CORPORATION 2003

LT/TP 0603 1K PRINTED IN USA

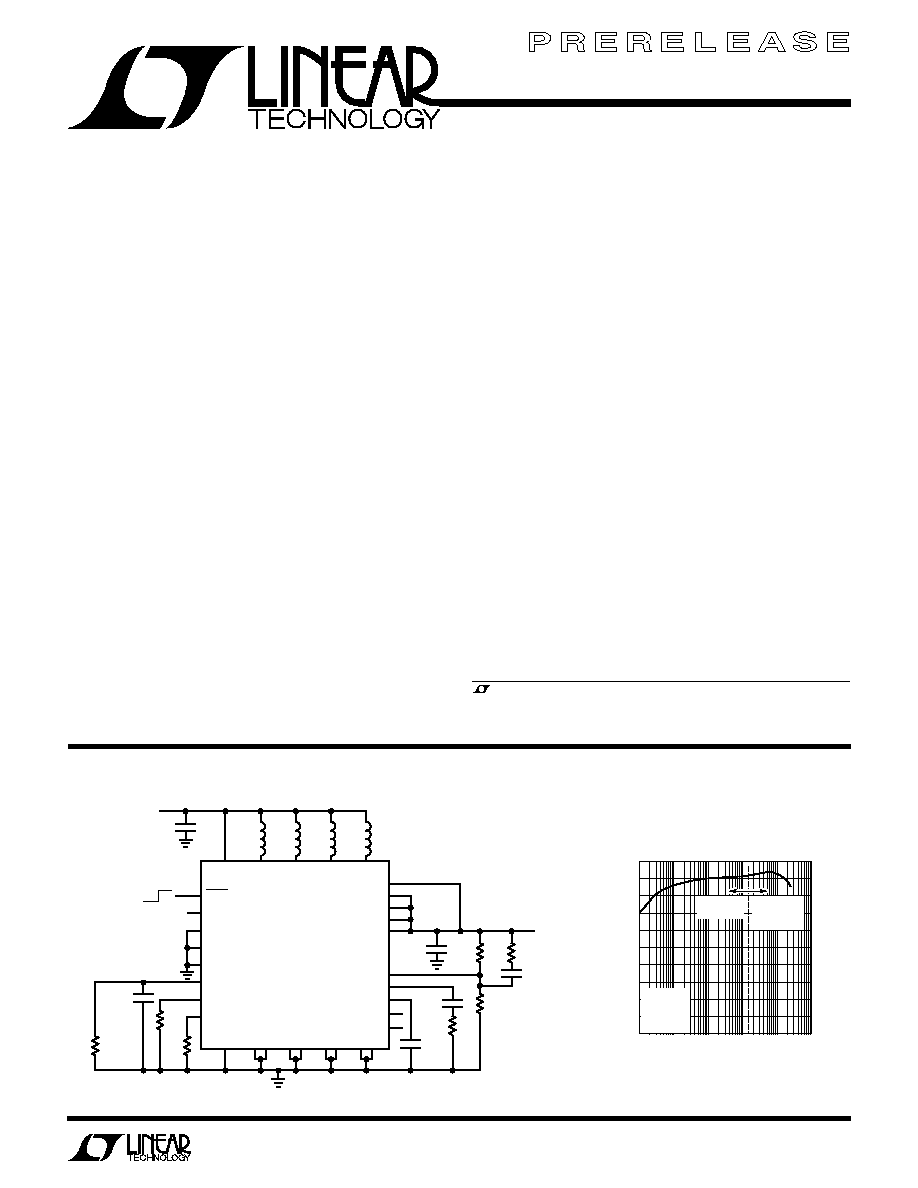

TYPICAL APPLICATIO

U

10MHz, High Current, Very Low Profile, 8-Phase Converter Using Two LTC3425s Operating

in Fixed Frequency Mode with Forced CCM (Max Component Height = 1.6mm)

L5

1

µ

H

C

IN2

2.2

µ

F

R6

75k

R

T2

14.7k

R

F4

17.4k

R

F3

10.2k

L6

1

µ

H

L7

1

µ

H

L8

1

µ

H

C

IN1,2

: TAIYO YUDEN JMK107BJ225MA

C

OUT

: TAIYO YUDEN JMK212BJ475MG (

×

8)

L1 TO L8: MURATA LQH32CN1R0M51

V

IN

SWA

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

C1

330pF

3425 TA05

C

OUT2

4.7

µ

F

×

4

C

SS

0.022

µ

F

R3

33k

R

F2

17.4k

R4

100k

PGOOD

R

F1

10.2k

V

OUT

3.3V

5A

L1

1

µ

H

C

IN1

2.2

µ

F

R5

75k

R

T1

12.1k

L2

1

µ

H

L3

1

µ

H

L4

1

µ

H

V

IN

V

OUT

V

IN

2.5V

SWA

SWB

LTC3425

SWC

SWD

SGND

SHDN

V

OUTS

V

OUTA

V

OUTB

V

OUTC

V

OUTD

REFOUT

CCM

REFEN

SYNCIN

BURST

R

T

I

LIM

PGOOD

SYNCOUT

SS

FB

COMP

GNDA

GNDB

GNDC

GNDD

C

OUT1

4.7

µ

F

×

4

V

OUT

RELATED PARTS

PART NUMBER

DESCRIPTION

COMMENTS

LT

®

1370/LT1370HV

6A (I

SW

) 500kHz, High Efficiency Step-Up DC/DC

V

IN

: 2.7V to 30V, V

OUT(MAX)

: 35V/42V, I

Q

: 4.5mA, I

SD

: <12

µ

A,

Converters

DD, TO220-7

LT1371/LT1371HV

3A (I

SW

) 500kHz, High Efficiency Step-Up DC/DC

V

IN

: 2.7V to 30V, V

OUT(MAX)

: 35V/42V, I

Q

: 4mA, I

SD

: <12

µ

A,

Converters

DD, TO220-7, S20

LT1613

550mA (I

SW

) 1.4MHz, High Efficiency Step-Up DC/DC

90% Efficiency, V

IN

: 0.9V to 10V, V

OUT(MAX)

: 34V, I

Q

: 3mA,

Converter

I

SD

: <1

µ

A, ThinSOT

LT1618

1.5A (I

SW

) 1.25MHz, High Efficiency Step-Up DC/DC

90% Efficiency, V

IN

: 1.6V to 18V, V

OUT(MAX)

: 35V, I

Q

: 1.8mA,

Converter

I

SD

: <1

µ

A, MS10

LTC1700

No R

SENSE

TM

530kHz, Synchronous Step-Up

95% Efficiency, V

IN

: 0.9V to 5V, I

Q

: 200

µ

A, I

SD

: <10

µ

A, MS10

DC/DC Controller

LTC1871

Wide Input Range, 1MHz, No R

SENSE

Current Mode Boost, 92% Efficiency, V

IN

: 2.5V to 36V, I

Q

: 250

µ

A, I

SD

: <10

µ

A, MS10

Flyback and SEPIC Controller

LT1930/LT1930A

1A (I

SW

) 1.2MHz/2.2MHz, High Efficiency Step-Up DC/DC

High Efficiency, V

IN

: 2.6V to 16V, V

OUT(MAX)

: 34V, I

Q

: 4.2mA/5.5mA,

Converters

I

SD

: <1

µ

A, ThinSOT

LT1946/LT1946A

1.5A (I

SW

) 1.2MHz/2.7MHz, High Efficiency Step-Up

High Efficiency, V

IN

: 2.45V to 16V, V

OUT(MAX)

: 34V, I

Q

: 3.2mA,

DC/DC Converters

I

SD

: <1

µ

A, MS8

LT1961

1.5A (I

SW

) 1.25MHz, High Efficiency Step-Up DC/DC

90% Efficiency, V

IN

: 3V to 25V, V

OUT(MAX)

: 35V, I

Q

: 0.9mA,

Converter

I

SD

: 6

µ

A, MS8E

LTC3400/LTC3400B

600mA (I

SW

) 1.2MHz, Synchronous Step-Down DC/DC

92% Efficiency, V

IN

: 0.85V to 5V, V

OUT(MAX)

: 5V, I

Q

: 19

µ

A/300

µ

A,

Converters

I

SD

: <1

µ

A, ThinSOT

LTC3401

1A (I

SW

) 3MHz, Synchronous Step-Up DC/DC Converter

97% Efficiency, V

IN

: 0.5V to 5V, V

OUT(MAX)

: 6V, I

Q

: 38

µ

A, I

SD

: <1

µ

A,

MS10

LTC3701

2-Phase, 550kHz, Low Input Voltage, Dual Step-Down

97% Efficiency, V

IN

: 2.5V to 10V, I

Q

: 460

µ

A, I

SD

: <9

µ

A, SSOP-16

DC/DC Controller