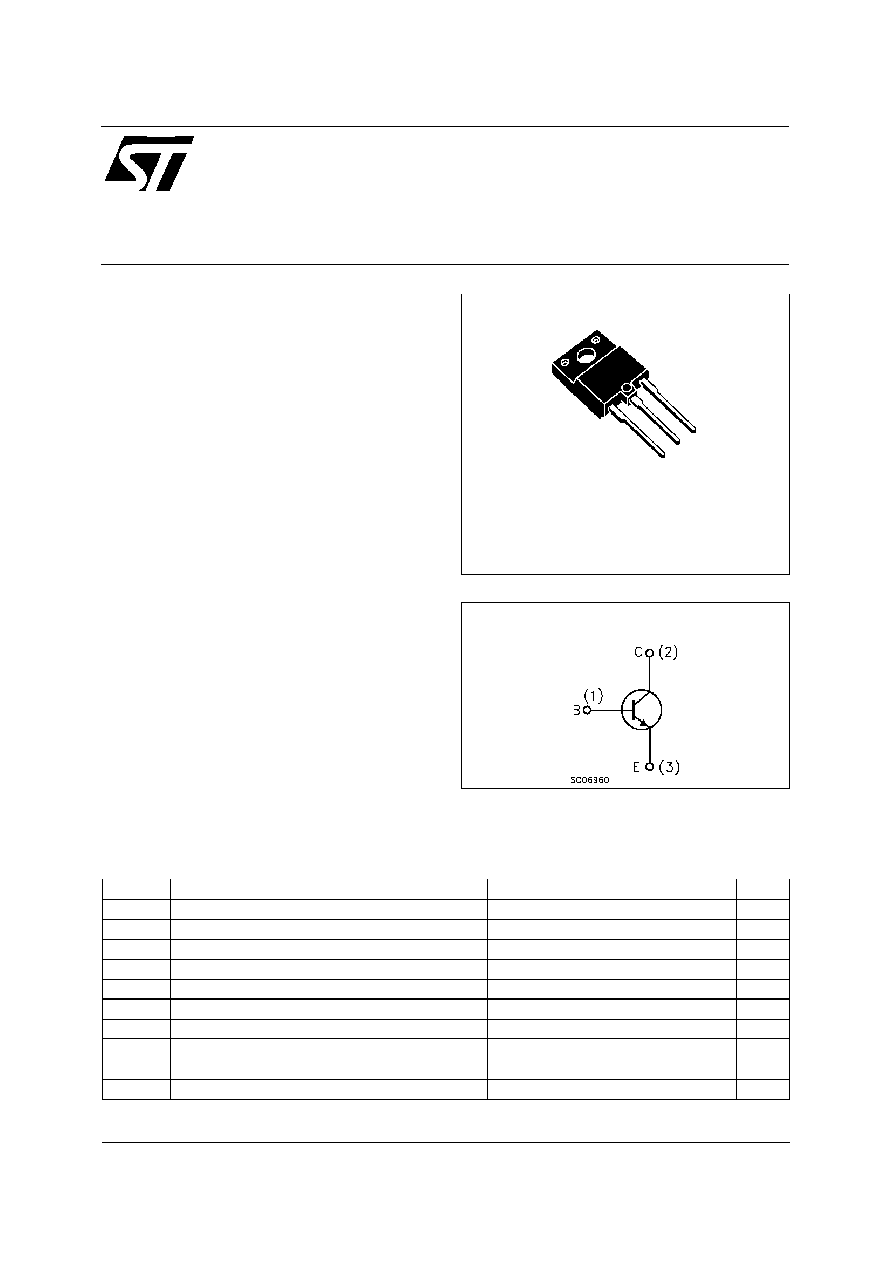

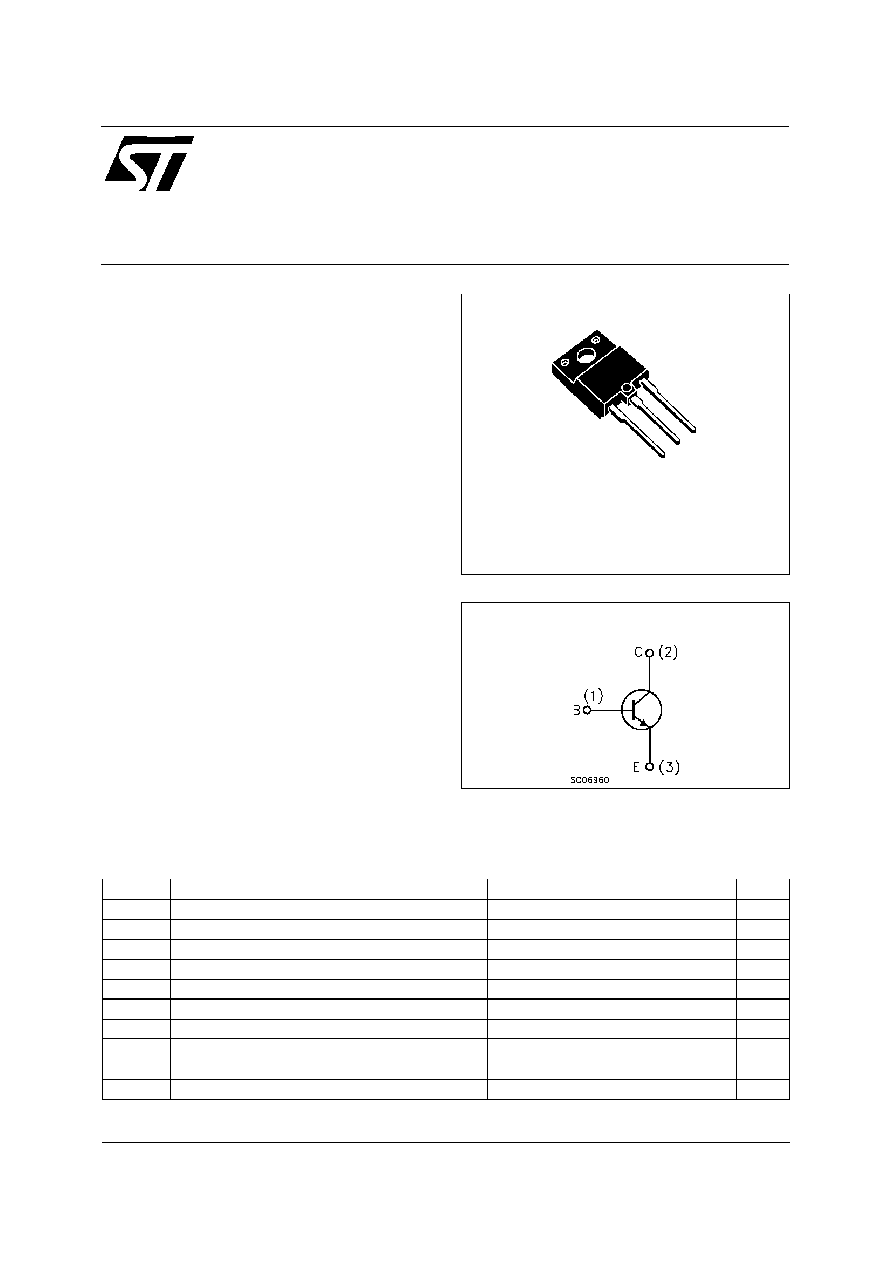

THD200FI

HIGH VOLTAGE FAST-SWITCHING

NPN POWER TRANSISTOR

s

STMicroelectronics PREFERRED

SALESTYPE

s

HIGH VOLTAGE CAPABILITY

s

VERY HIGH SWITCHING SPEED

s

U.L. RECOGNISED ISOWATT218 PACKAGE

(U.L. FILE # E81734 (N))

APPLICATIONS:

s

HORIZONTAL DEFLECTION FOR

MONITORS

DESCRIPTION

The

THD200FI

is

manufactured

using

Multiepitaxial Mesa technology for cost-effective

high performance and uses a Hollow Emitter

structure to enhance switching speeds.

The THD series is designed for use in horizontal

deflection circuits in televisions and monitors.

INTERNAL SCHEMATIC DIAGRAM

December 1999

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Val ue

Uni t

V

CBO

Collect or-Base Voltage (I

E

= 0)

1500

V

V

CEO

Collect or-Emitt er Voltage (I

B

= 0)

700

V

V

EBO

Emitt er-Base Voltage (I

C

= 0)

10

V

I

C

Collect or Current

10

A

I

CM

Collect or Peak Current (t

p

< 5 ms)

20

A

I

B

Base Current

5

A

I

BM

Base Peak Current (t

p

< 5 ms)

10

A

P

t ot

Total Dissipation at T

c

= 25

o

C

57

W

T

stg

St orage Temperature

-65 to 150

o

C

T

j

Max. Operating Junction Temperature

150

o

C

1

2

3

ISOWATT218

®

1/7

THERMAL DATA

R

t hj-ca se

Thermal Resistance Junction-case

Max

2.2

o

C/W

ELECTRICAL CHARACTERISTICS (T

case

= 25

o

C unless otherwise specified)

Symb ol

Parameter

Test Cond ition s

Mi n.

Typ .

Max.

Un it

I

CES

Collect or Cut-off

Current (V

BE

= 0)

V

CE

= 1500 V

V

CE

= 1500 V

T

j

= 125

o

C

0.2

2

mA

mA

I

EBO

Emitt er Cut-off Current

(I

C

= 0)

V

EB

= 5 V

100

µ

A

V

CEO(sus )

Collect or-Emitter

Sustaining Voltage

(I

C

= 0)

I

C

= 100 mA

700

V

V

EBO

Emitt er-Base Voltage

(I

B

= 0)

I

E

= 10 mA

10

V

V

CE(sat )

Collect or-Emitter

Saturat ion Voltage

I

C

= 7 A

I

B

= 1.5 A

1.5

V

V

BE(s at)

Base-Emitt er

Saturat ion Voltage

I

C

= 7 A

I

B

= 1.5 A

1.3

V

h

FE

DC Current G ain

I

C

= 7 A

V

CE

= 5 V

I

C

= 7 A

V

CE

= 5 V

T

j

= 100

o

C

6. 5

4

13

t

s

t

f

RESI STIVE LO AD

St orage Time

Fall T ime

V

CC

= 400 V

I

C

= 7 A

I

B1

= 1.5 A

I

B2

= 3.5 A

2.1

140

3.1

210

µ

s

ns

t

s

t

f

INDUCTIVE LOAD

St orage Time

Fall T ime

I

C

= 7 A

f = 31250 Hz

I

B1

= 1.5 A

I

B2

= -3. 5 A

V

c eflybac k

= 1200 sin

5

10

6

t

V

3.5

320

µ

s

ns

t

s

t

f

INDUCTIVE LOAD

St orage Time

Fall T ime

I

C

= 7 A

f = 64 KHz

I

B1

= 1.5 A

I

B2

= -3. 5 A

V

c eflybac k

= 1200 sin

5

10

6

t

V

1.7

215

µ

s

ns

Pulsed: Pulse duration = 300

µ

s, duty cycle 1.5 %

THD200FI

2/7

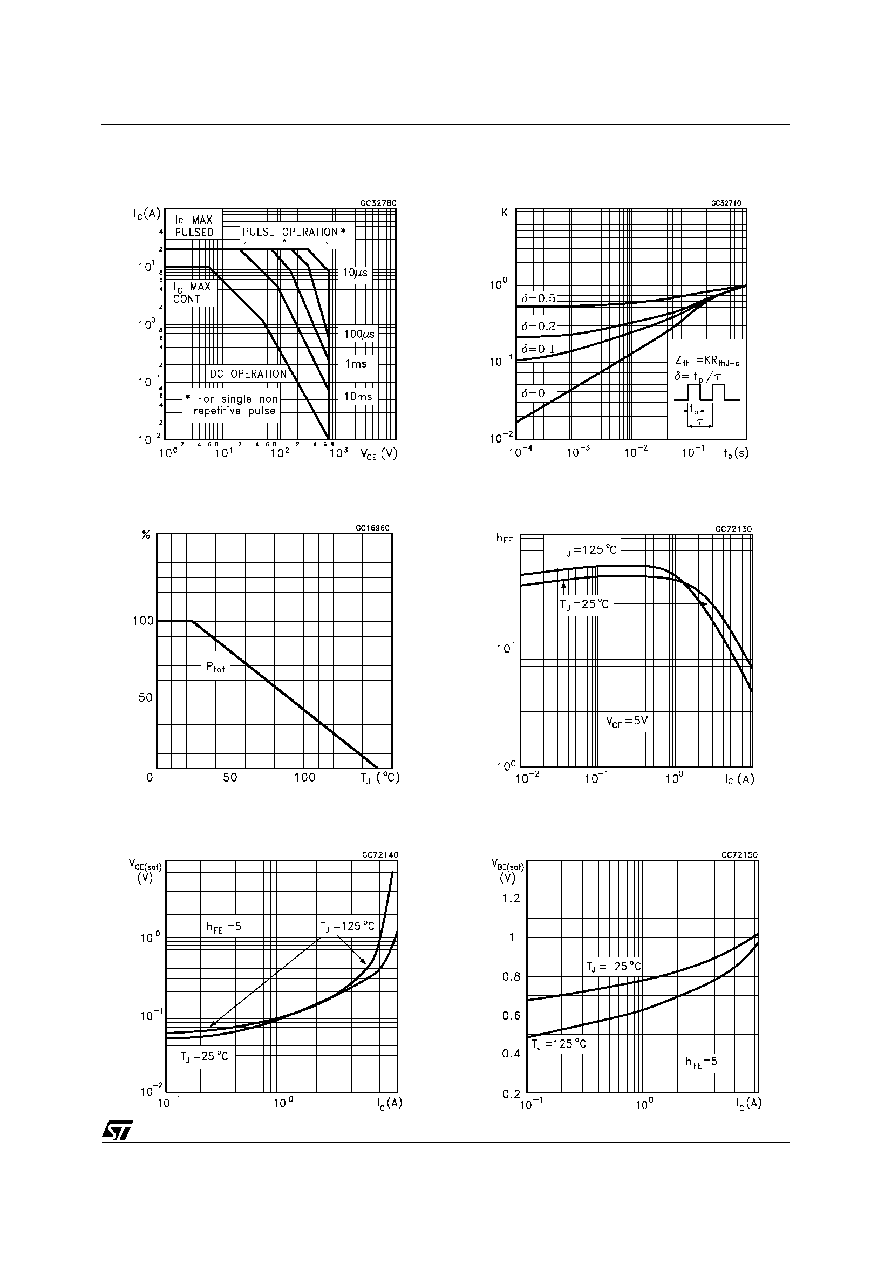

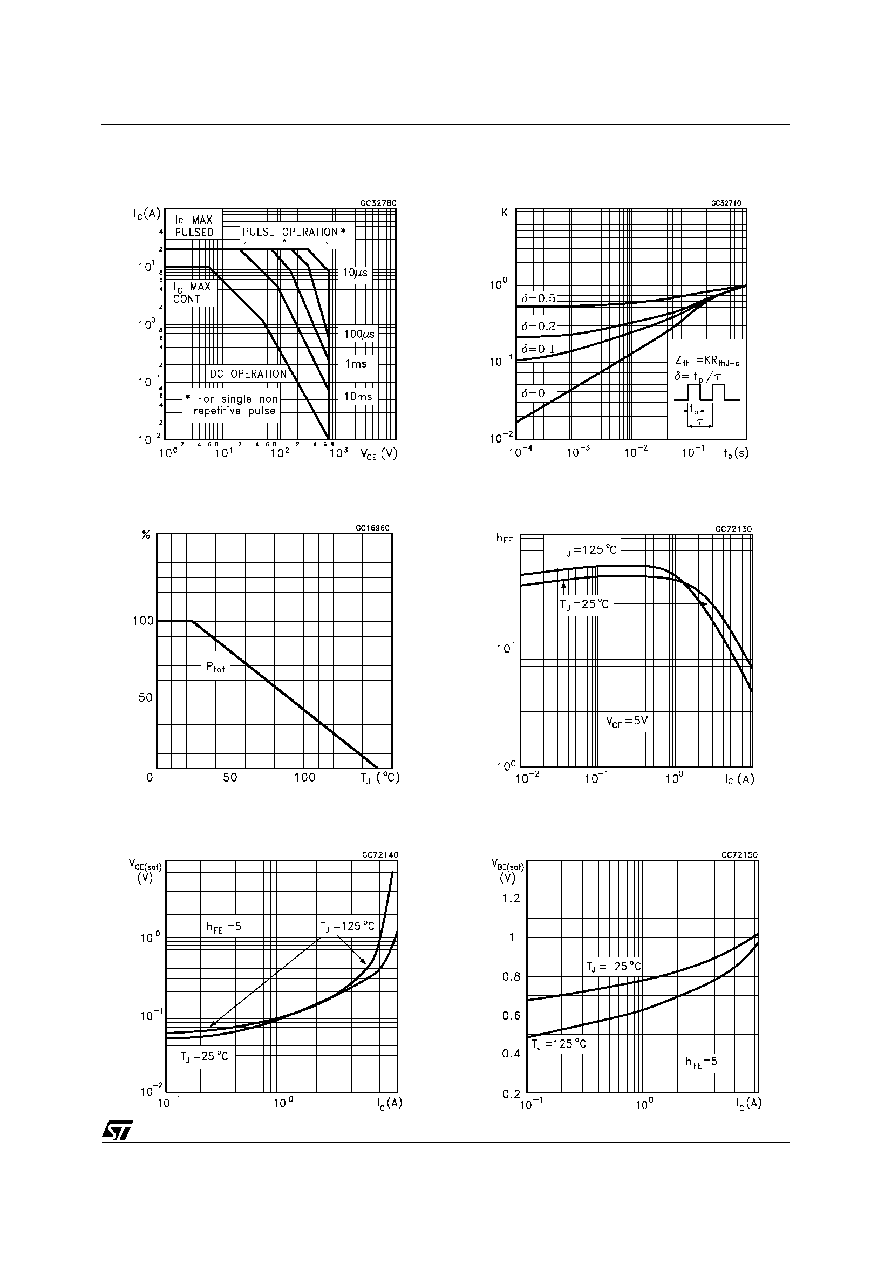

Safe Operating Area

Derating Curve

Collector Emitter Saturation Voltage

Thermal Impedance

DC Current Gain

Base Emitter Saturation Voltage

THD200FI

3/7

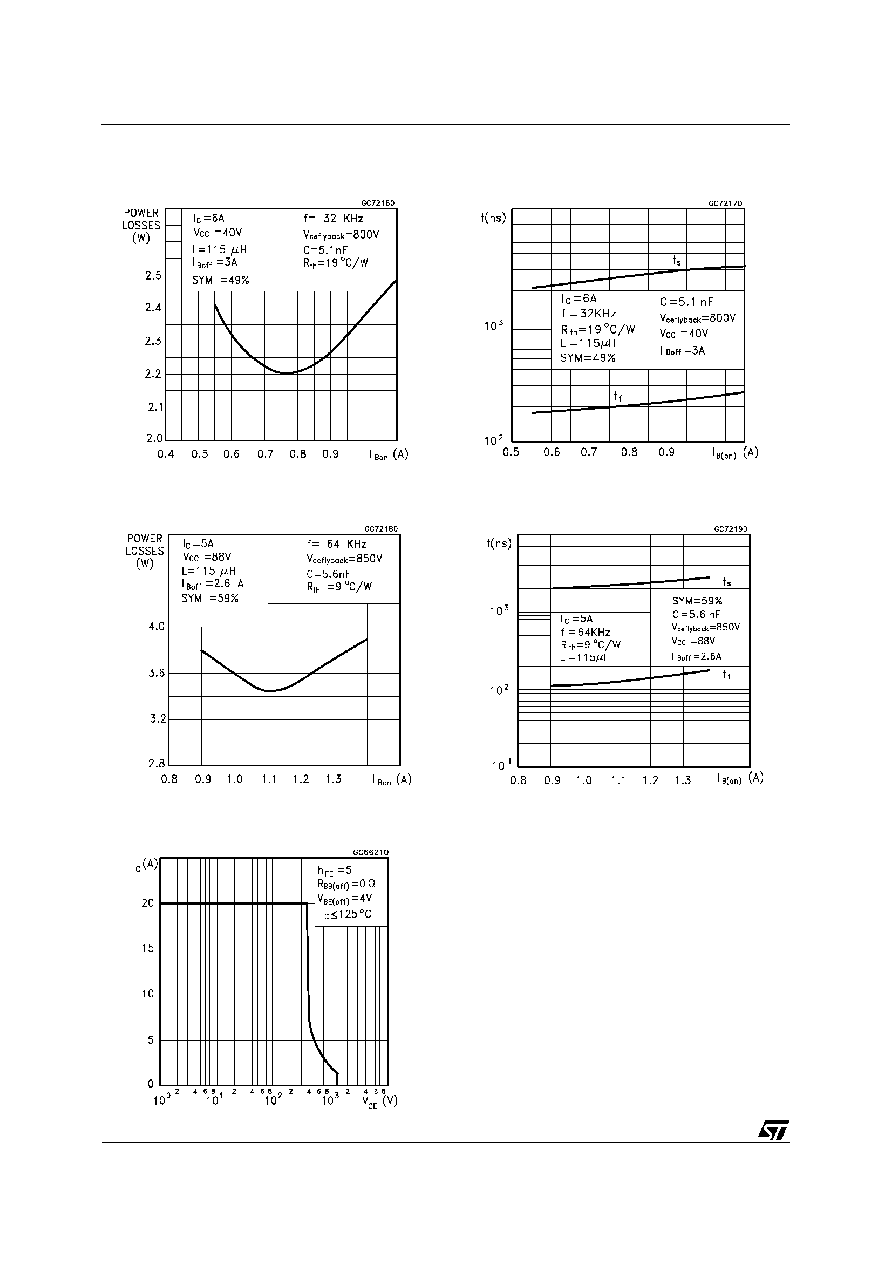

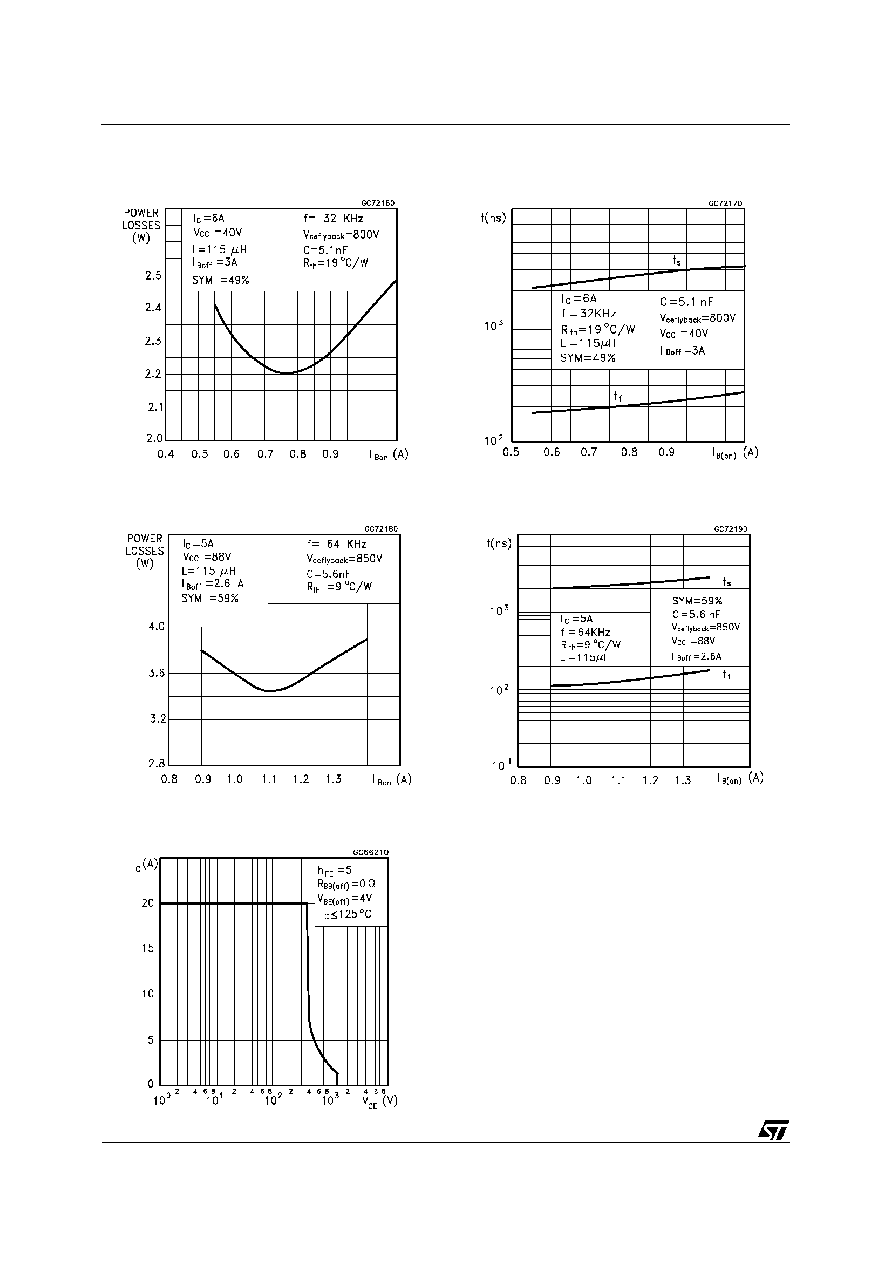

Power Losses at 32 KHz

Power Losses at 64 KHz

Reverse Biased SOA

Switching Time Inductive Load at 32 KHz

(see figure 2)

Switching Time Inductive Load at 64 KHz

(see figure 2)

THD200FI

4/7

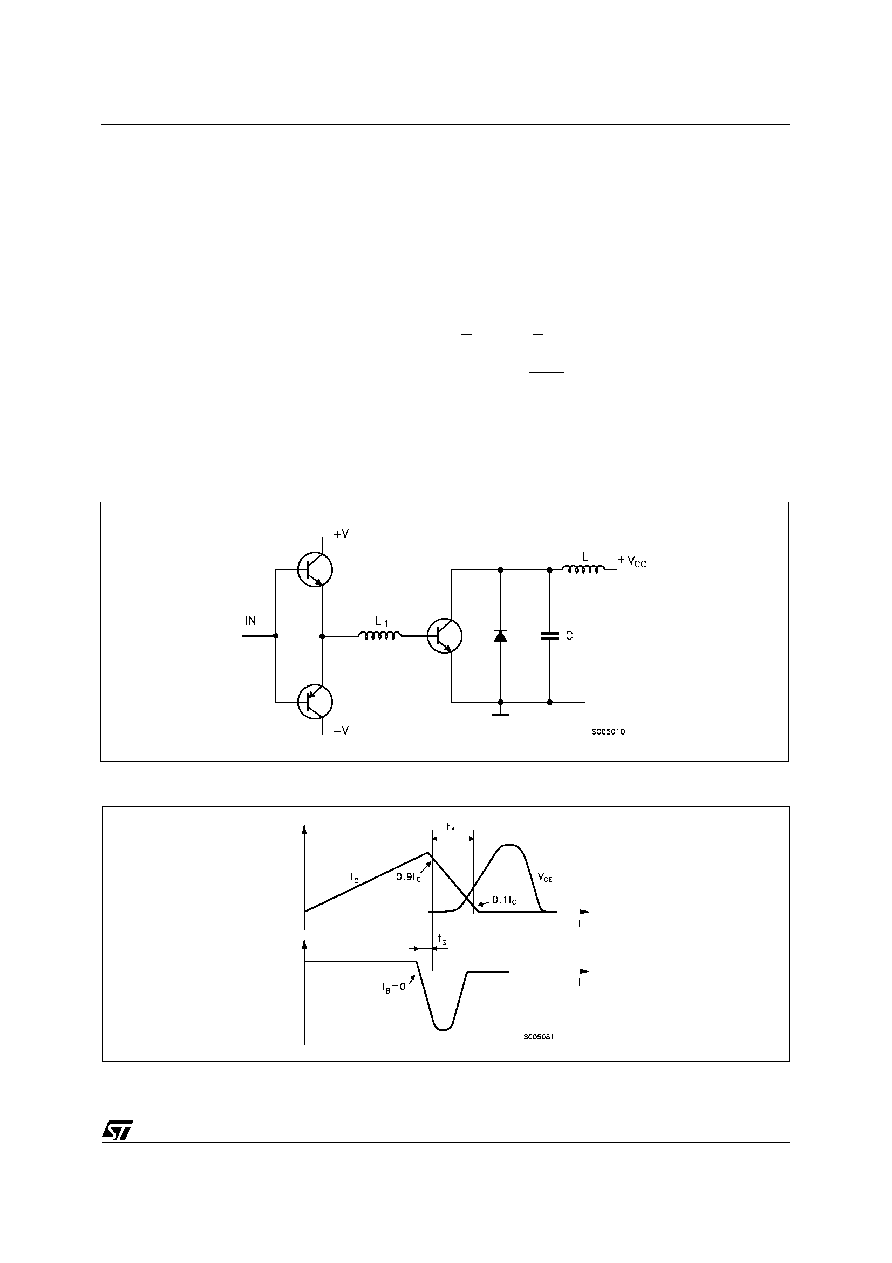

In order to saturate the power switch and reduce

conduction losses, adequate direct base current

I

B1

has to be provided for the lowest gain h

FE

at T

j

= 100

o

C (line scan phase). On the other hand,

negative base current I

B2

must be provided turn

off the power transistor (retrace phase). Most of

the

dissipation, especially in

the

deflection

application, occurs at switch-off so it is essential

to determine the value of I

B2

which minimizes

power losses, fall time t

f

and, consequently, T

j

. A

new set of curves have been defined to give total

power losses, t

s

and t

f

as a function of I

B2

at both

32 KHz and 64 KHz scanning frequencies in

order to choice the optimum negative drive. The

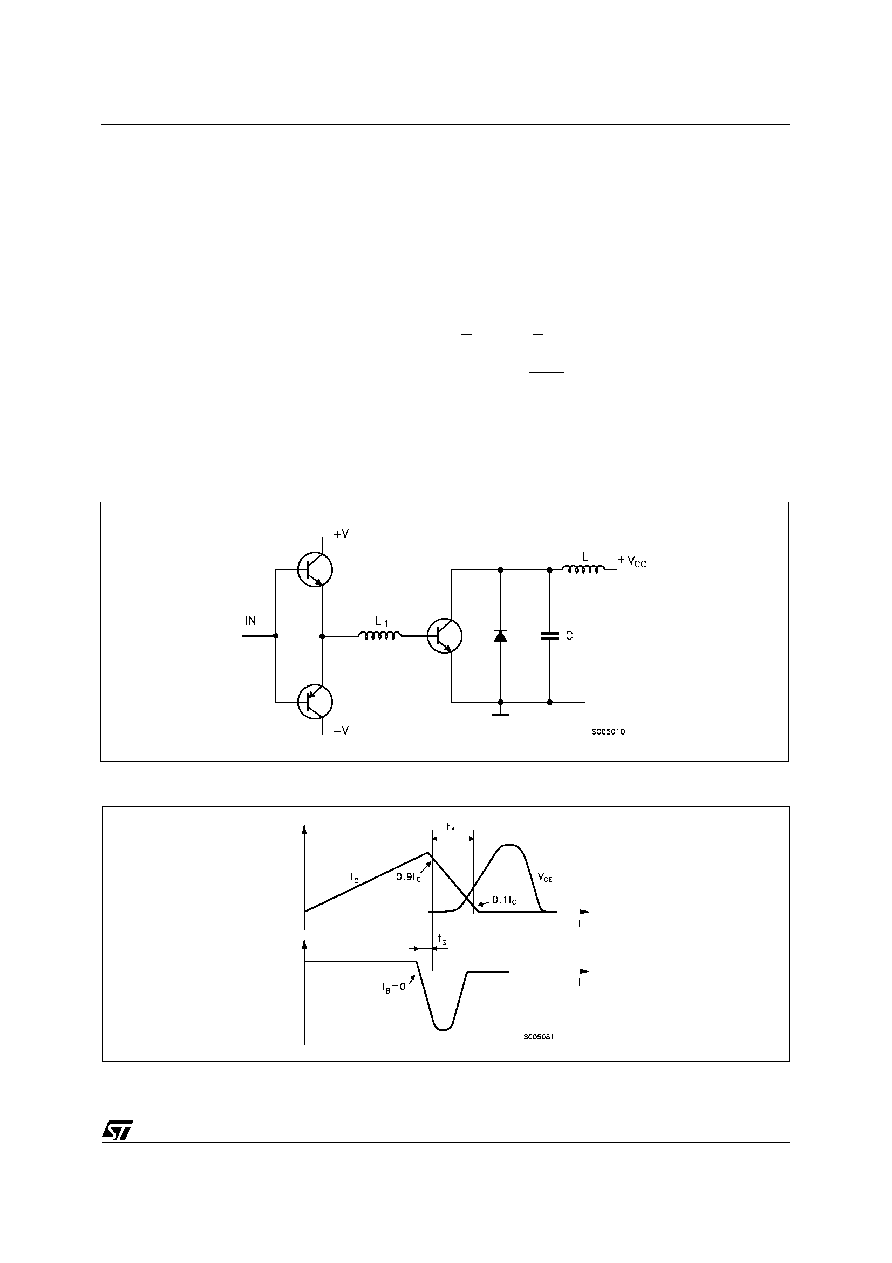

test circuit is illustrated in fig. 1.

Inductance L

1

serves to control the slope of the

negative base current I

B2

in order to recombine

the excess carriers in the collector when base

current is still present, thus avoiding any tailing

phenomenon in the collector current.

The values of L and C are calculated from the

following equations:

1

2

L

(

I

C

)

2

=

1

2

C

(

V

CEfly

)

2

=

2

f

=

1

L

C

Where I

C

= operating collector current, V

CEfly

=

flyback voltage, f= frequency of oscillation during

retrace.

BASE DRIVE INFORMATION

Figure 1: Inductive Load Switching Test Circuit.

Figure 2: Switching Waveforms in a Deflection Circuit.

THD200FI

5/7

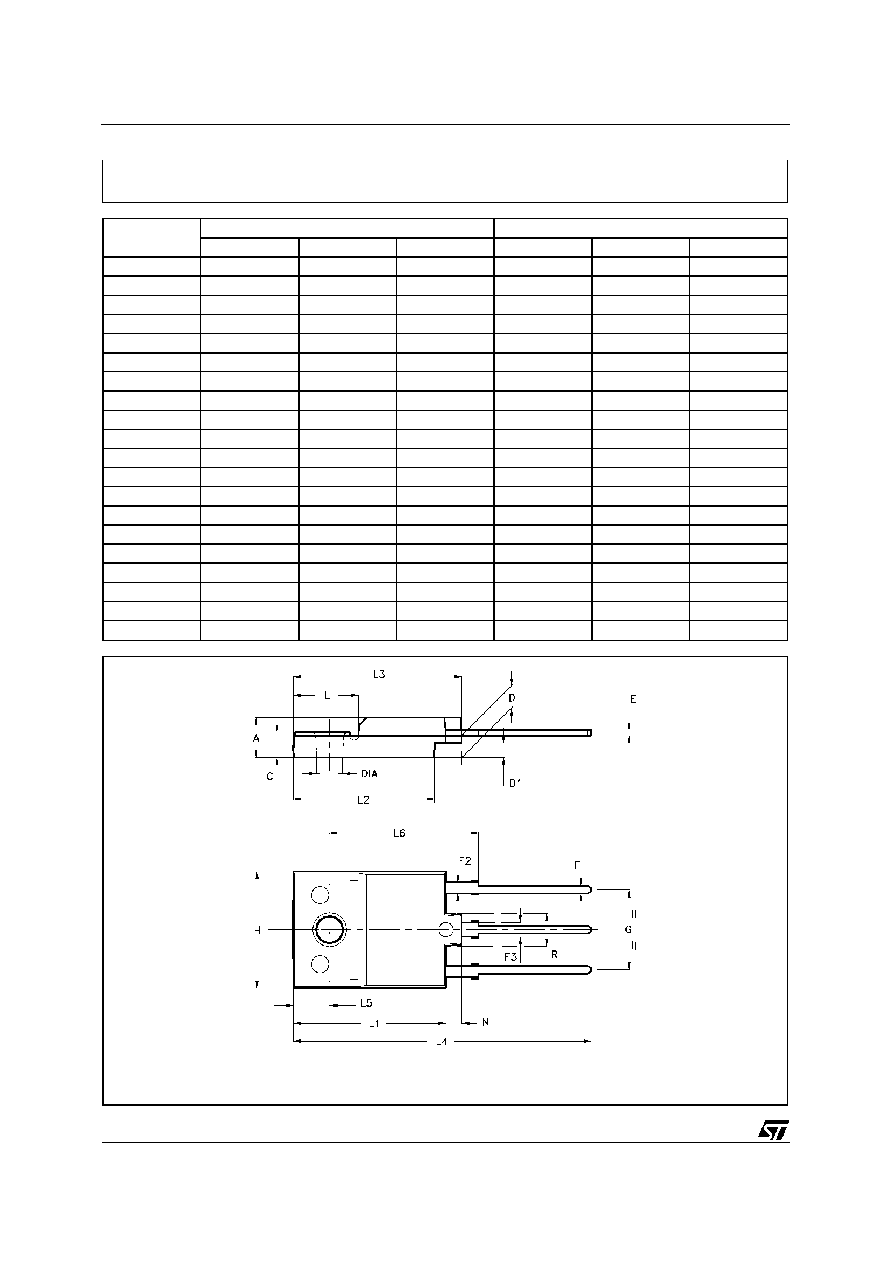

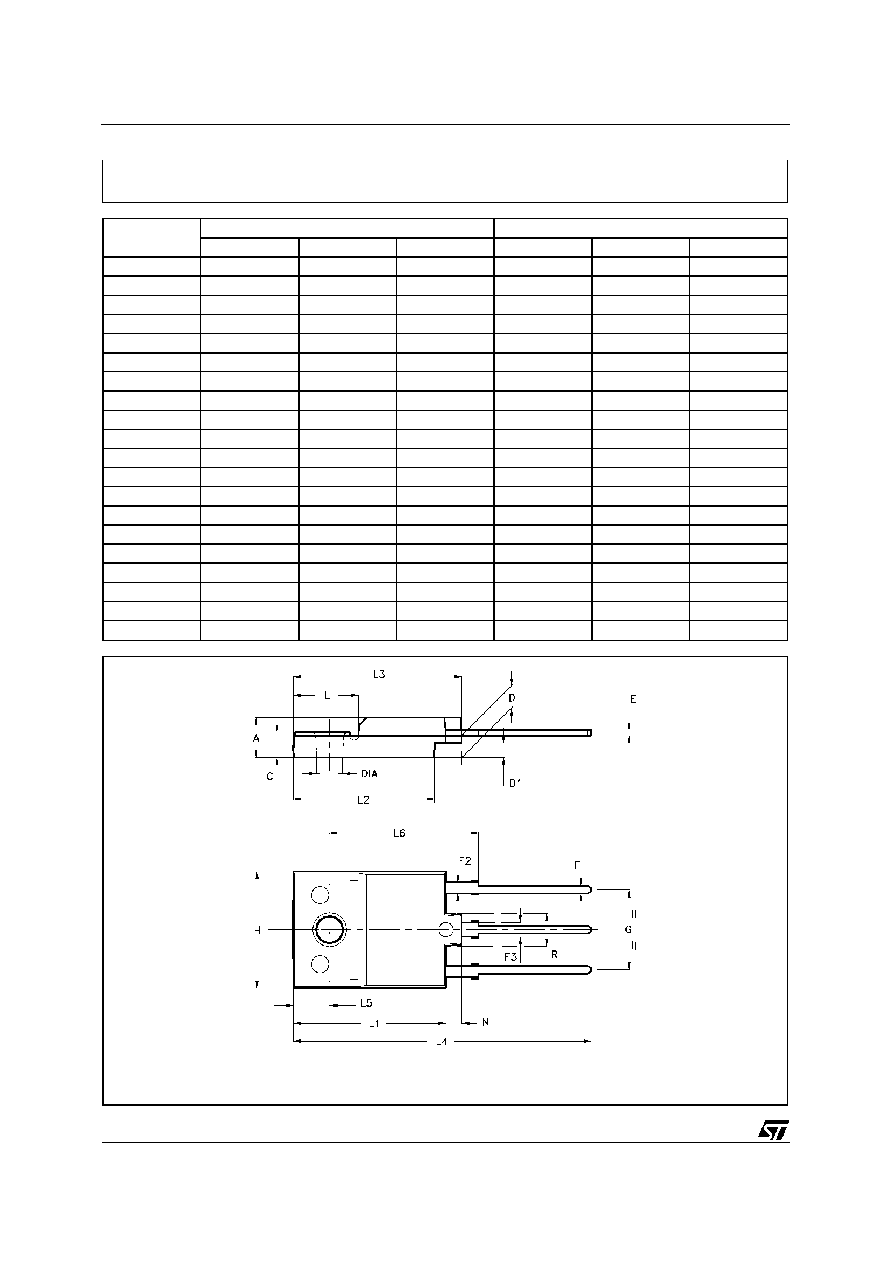

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

5.35

5.65

0.211

0.222

C

3.30

3.80

0.130

0.150

D

2.90

3.10

0.114

0.122

D1

1.88

2.08

0.074

0.082

E

0.75

0.95

0.030

0.037

F

1.05

1.25

0.041

0.049

F2

1.50

1.70

0.059

0.067

F3

1.90

2.10

0.075

0.083

G

10.80

11.20

0.425

0.441

H

15.80

16.20

0.622

0.638

L

9

0.354

L1

20.80

21.20

0.819

0.835

L2

19.10

19.90

0.752

0.783

L3

22.80

23.60

0.898

0.929

L4

40.50

42.50

1.594

1.673

L5

4.85

5.25

0.191

0.207

L6

20.25

20.75

0.797

0.817

N

2.1

2.3

0.083

0.091

R

4.6

0.181

DIA

3.5

3.7

0.138

0.146

P025C/A

ISOWATT218 MECHANICAL DATA

- Weight : 4.9 g (typ.)

- Maximum Torque (applied to mounting flange) Recommended: 0.8 Nm; Maximum: 1 Nm

- The side of the dissipator must be flat within 80

µ

m

THD200FI

6/7

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a trademark of STMicroelectronics

©

1999 STMicroelectronics Printed in Italy All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

.

THD200FI

7/7