1/9

TARGET DATA

September 2003

STP9NK60ZFD - STF9NK60ZFD

STB9NK60ZFD

N-CHANNEL 600V - 0.85

- 7A TO-220/TO-220FP/D

2

PAK

Fast Diode SuperMESHTM MOSFET

s

TYPICAL R

DS

(on) = 0.85

s

HIGH dv/dt CAPABILITY

s

100% AVALANCHE TESTED

s

GATE CHARGE MINIMIZED

s

LOW INTRINSIC CAPACITANCES

s

VERY GOOD MANUFACTURING

REPEATIBILITY

s

FAST INTERNAL RECOVERY DIODE

DESCRIPTION

The Fast SuperMESHTM series associates all ad-

vantages of reduced on-resistance, zener gate pro-

tection and very goog dv/dt capability with a Fast

body-drain recovery diode. Such series comple-

ments the "FDmeshTM" Advanced Technology.

APPLICATIONS

s

HID BALLAST

s

ZVS PHASE-SHIFT FULL BRIDGE

CONVERTERS

ORDERING INFORMATION

TYPE

V

DSS

R

DS(on)

I

D

Pw

STP9NK60ZFD

STF9NK60ZFD

STB9NK60ZFD

600 V

600 V

600 V

< 0.95

< 0.95

< 0.95

7 A

7 A

7 A

104 W

32 W

104 W

SALES TYPE

MARKING

PACKAGE

PACKAGING

STP9NK60ZFD

P9NK60ZFD

TO-220

TUBE

STF9NK60ZFD

F9NK60ZFD

TO-220FP

TUBE

STB9NK60ZFDT4

B9NK60ZFD

D

2

PAK

TAPE & REEL

TO-220

TO-220FP

1

2

3

1

3

D

2

PAK

INTERNAL SCHEMATIC DIAGRAM

STP9NK60ZFD - STF9NK60ZFD - STB9NK60ZFD

2/9

ABSOLUTE MAXIMUM RATINGS

( ) Pulse width limited by safe operating area

(1) I

SD

7A, di/dt

200A/µs, V

DD

V

(BR)DSS

, T

j

T

JMAX.

(*) Limited only by maximum temperature allowed

THERMAL DATA

AVALANCHE CHARACTERISTICS

GATE-SOURCE ZENER DIODE

PROTECTION FEATURES OF GATE-TO-SOURCE ZENER DIODES

The built-in back-to-back Zener diodes have specifically been designed to enhance not only the device's

ESD capability, but also to make them safely absorb possible voltage transients that may occasionally be

applied from gate to souce. In this respect the Zener voltage is appropriate to achieve an efficient and cost-

effective intervention to protect the device's integrity. These integrated Zener diodes thus avoid the usage

of external components.

Symbol

Parameter

Value

Unit

TO-220 / D

2

PAK

TO-220FP

V

DS

Drain-source Voltage (V

GS

= 0)

600

V

V

DGR

Drain-gate Voltage (R

GS

= 20 k

)

600

V

V

GS

Gate- source Voltage

± 30

V

I

D

Drain Current (continuos) at T

C

= 25°C

7

7 (*)

A

I

D

Drain Current (continuos) at T

C

= 100°C

4.3

4.3 (*)

A

I

DM

( )

Drain Current (pulsed)

28

28 (*)

A

P

TOT

Total Dissipation at T

C

= 25°C

104

32

W

Derating Factor

0.83

0.26

W/°C

V

ESD(G-S)

Gate source ESD (HBM-C=100pF, R=1.5K

)

4000

V

dv/dt (1)

Peak Diode Recovery voltage slope

TBD

V/ns

V

ISO

Insulation Withstand Voltage (DC)

-

2500

V

T

j

T

stg

Operating Junction Temperature

Storage Temperature

-55 to 150

°C

TO-220

D

2

PAK

TO-220FP

Unit

Rthj-case

Thermal Resistance Junction-case Max

1.02

3.85

°C/W

Rthj-pcb

Thermal Resistance Junction-pcb Max

(When mounted on minimum Footprint)

30

°C/W

Rthj-amb

Thermal Resistance Junction-ambient Max

62.5

°C/W

T

l

Maximum Lead Temperature For Soldering

Purpose

300

°C

Symbol

Parameter

Max Value

Unit

I

AR

Avalanche Current, Repetitive or Not-Repetitive

(pulse width limited by T

j

max)

7

A

E

AS

Single Pulse Avalanche Energy

(starting T

j

= 25 °C, I

D

= I

AR

, V

DD

= 50 V)

280

mJ

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

BV

GSO

Gate-Source Breakdown

Voltage

Igs=± 1mA (Open Drain)

30

V

3/9

STP9NK60ZFD - STF9NK60ZFD - STB9NK60ZFD

ELECTRICAL CHARACTERISTICS (TCASE =25°C UNLESS OTHERWISE SPECIFIED)

ON/OFF

DYNAMIC

SWITCHING ON

SWITCHING OFF

SOURCE DRAIN DIODE

Note: 1. Pulsed: Pulse duration = 300 µs, duty cycle 1.5 %.

2. Pulse width limited by safe operating area.

3. C

oss eq.

is defined as a constant equivalent capacitance giving the same charging time as C

oss

when V

DS

increases from 0 to 80%

V

DSS

.

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

V

(BR)DSS

Drain-source

Breakdown Voltage

I

D

= mA, V

GS

= 0

600

V

I

DSS

Zero Gate Voltage

Drain Current (V

GS

= 0)

V

DS

= Max Rating

V

DS

= Max Rating, T

C

= 125 °C

1

50

µA

µA

I

GSS

Gate-body Leakage

Current (V

DS

= 0)

V

GS

= ± 20V

±10

µA

V

GS(th)

Gate Threshold Voltage

V

DS

= V

GS

, I

D

= 100µA

3

3.75

4.5

V

R

DS(on)

Static Drain-source On

Resistance

V

GS

= 10V, I

D

= 3.5 A

0.85

0.95

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

g

fs

(1)

Forward Transconductance

V

DS

= 15 V

,

I

D

= 3.5 A

5.3

S

C

iss

C

oss

C

rss

Input Capacitance

Output Capacitance

Reverse Transfer

Capacitance

V

DS

= 25V, f = 1 MHz, V

GS

= 0

1110

135

30

pF

pF

pF

C

oss eq.

(3)

Equivalent Output

Capacitance

V

GS

= 0V, V

DS

= 0V to 480V

72

pF

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

t

d(on)

t

r

Turn-on Delay Time

Rise Time

V

DD

= 300 V, I

D

= 3.5 A

R

G

= 4.7

V

GS

= 10 V

(Resistive Load see, Figure 3)

19

17

ns

ns

Q

g

Q

gs

Q

gd

Total Gate Charge

Gate-Source Charge

Gate-Drain Charge

V

DD

= 480V, I

D

= 7 A,

V

GS

= 10V

38

7

21

53

nC

nC

nC

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

t

d(off)

t

f

Turn-off Delay Time

Fall Time

V

DD

= 300 V, I

D

= 3.5 A

R

G

= 4.7

V

GS

= 10 V

(Resistive Load see, Figure 3)

43

15

ns

ns

t

r(Voff)

t

f

t

c

Off-voltage Rise Time

Fall Time

Cross-over Time

V

DD

= 480V, I

D

= 7 A,

R

G

= 4.7

,

V

GS

= 10V

(Inductive Load see, Figure 5)

11

8

20

ns

ns

ns

Symbol

Parameter

Test Conditions

Min.

Typ.

Max.

Unit

I

SD

I

SDM

(2)

Source-drain Current

Source-drain Current (pulsed)

7

28

A

A

V

SD

(1)

Forward On Voltage

I

SD

= 7 A, V

GS

= 0

1.6

V

t

rr

Q

rr

I

RRM

Reverse Recovery Time

Reverse Recovery Charge

Reverse Recovery Current

I

SD

= 7 A, di/dt = 100A/µs

V

DD

= 30V, T

j

= 150°C

(see test circuit, Figure 5)

150

TBD

TBD

ns

µC

A

STP9NK60ZFD - STF9NK60ZFD - STB9NK60ZFD

4/9

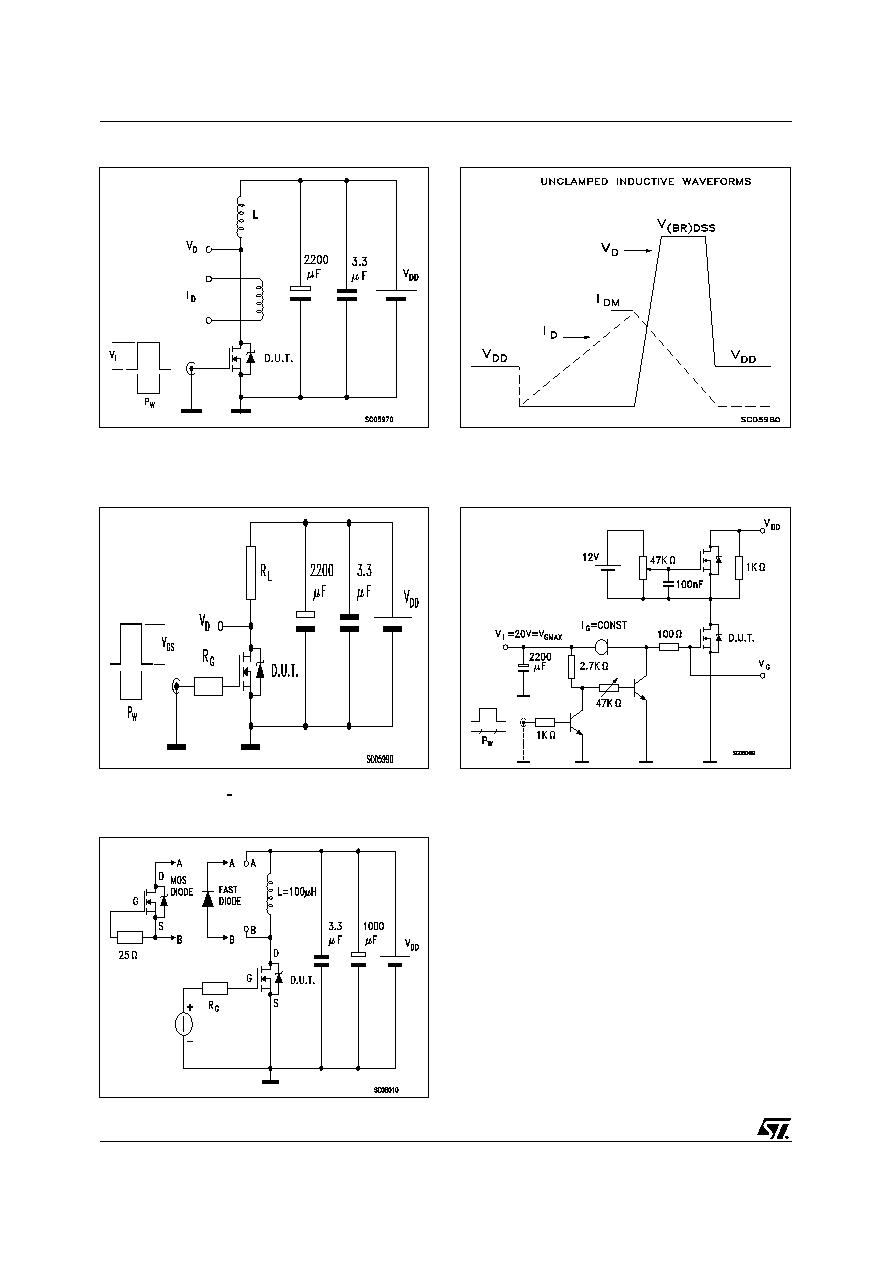

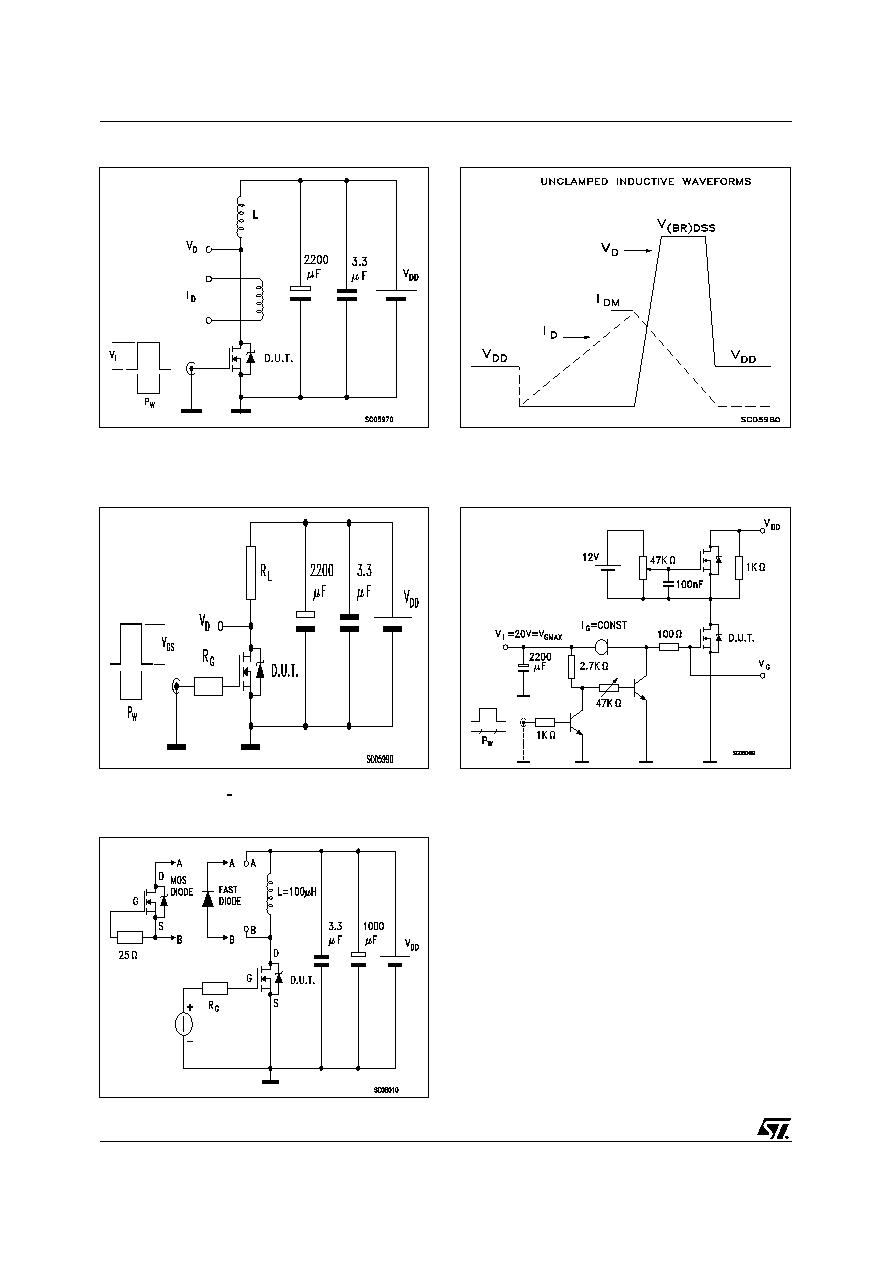

Fig. 5: Test Circuit For Inductive Load Switching

And Diode Recovery Times

Fig. 4: Gate Charge test Circuit

Fig. 2: Unclamped Inductive Waveform

Fig. 1: Unclamped Inductive Load Test Circuit

Fig. 3: Switching Times Test Circuit For

Resistive Load

5/9

STP9NK60ZFD - STF9NK60ZFD - STB9NK60ZFD

DIM.

mm.

inch

MIN.

TYP

MAX.

MIN.

TYP.

MAX.

A

4.40

4.60

0.173

0.181

b

0.61

0.88

0.024

0.034

b1

1.15

1.70

0.045

0.066

c

0.49

0.70

0.019

0.027

D

15.25

15.75

0.60

0.620

E

10

10.40

0.393

0.409

e

2.40

2.70

0.094

0.106

e1

4.95

5.15

0.194

0.202

F

1.23

1.32

0.048

0.052

H1

6.20

6.60

0.244

0.256

J1

2.40

2.72

0.094

0.107

L

13

14

0.511

0.551

L1

3.50

3.93

0.137

0.154

L20

16.40

0.645

L30

28.90

1.137

øP

3.75

3.85

0.147

0.151

Q

2.65

2.95

0.104

0.116

TO-220 MECHANICAL DATA