1/12

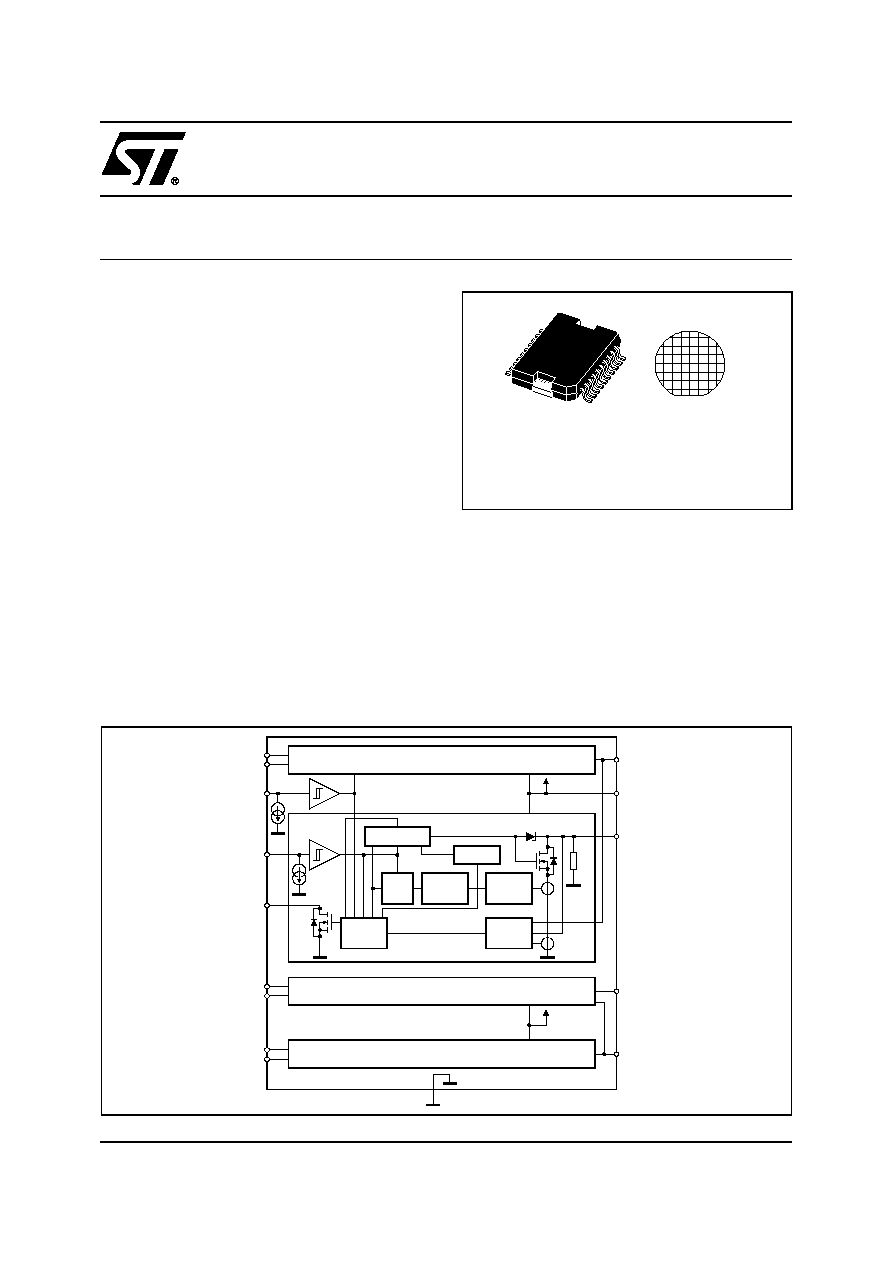

L9349

September 2002

s

Quad power low side driver with 2 x 5A and

2 x 3A output current capability

s

Low R

DSON

typically 200m

and 300m

@ T

j

= 25°C

s

Internal output clamping structures with

V

FB

= 50V for fast inductive load current

recirculation

s

Limited output voltage slew rate for low EMI

s

Protected

µ

P compatible enable and input

s

Wide operating supply voltage range 4.5V to 32V

s

Real time diagnostic functions:

Output shorted to GND

Output shorted to V

SS

Open load detection in ON and OFF condition

Load bypass detection

Overtemperature detection

s

Device protection functions:

Overload disable

Selective thermal shutdown

s

Signal- and Power-Ground-loss shutdown

DESCRIPTION

The L9349 is a monolithic integrated quad low side

driver realized in an advanced MultipowerBCD mixed

technology. The device is intended to drive valves in

automotive environment.

The inputs are

µ

P compatible. Particular care has

been taken to protect the device against failures, to

avoid electromagnetic interferences and to offer ex-

tensive real time diagnostic.

PowerSO20

BARE DIE

ORDERING NUMBERS:

L9349

L9349DIE1

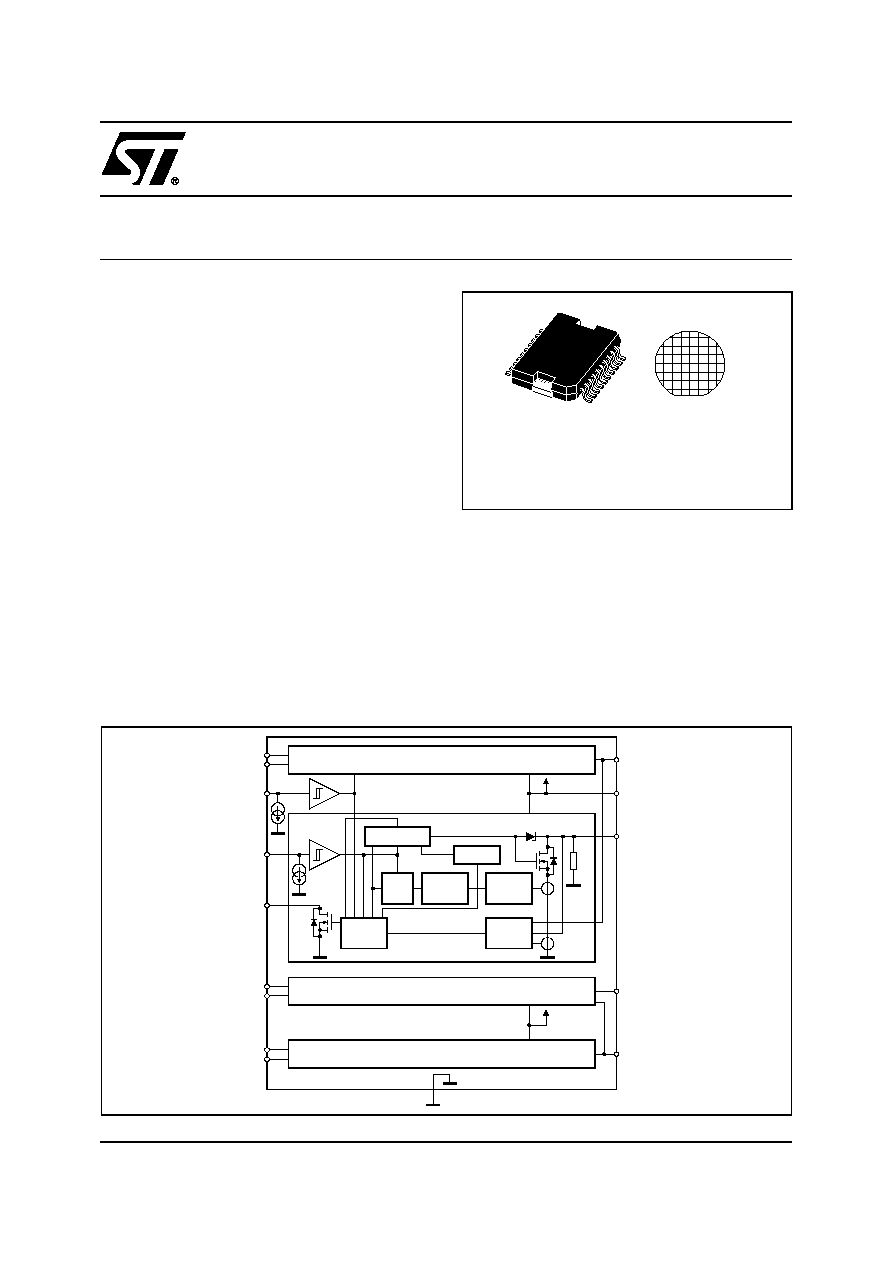

QUAD INTELLIGENT POWER LOW SIDE SWITCH

BLOCK DIAGRAM

Diagnostic

Control

R

Q

S

Delay

Time

Overload

Overtemp

Output Control

Openload

52V

R

IO

Channel 4

Channel 1

Channel 2

Channel 3

OUT3

OUT2

OUT4

VS

OUT1

IN1

D1

EN

IN4

D4

IN2

D2

IN3

D3

GND

00AT0025

L9349

2/12

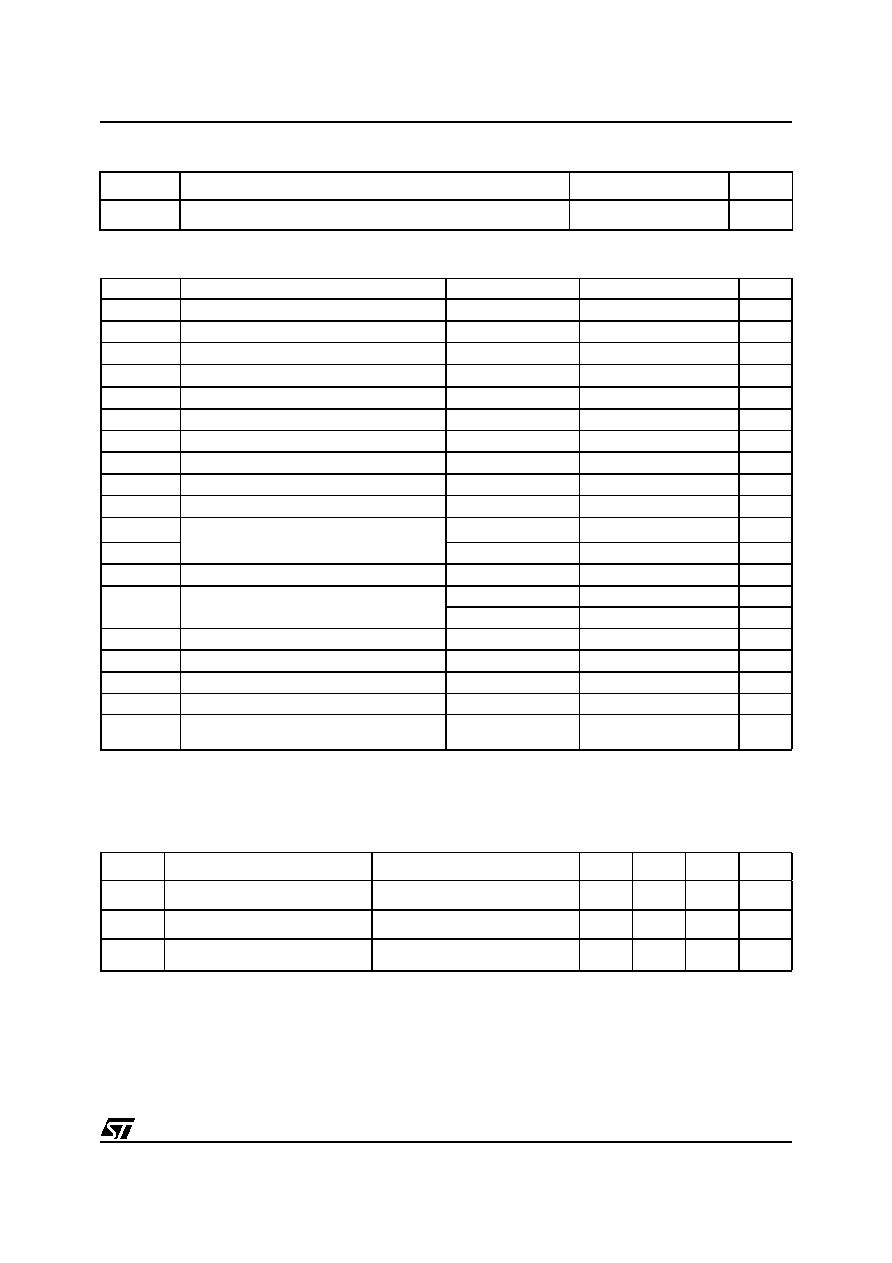

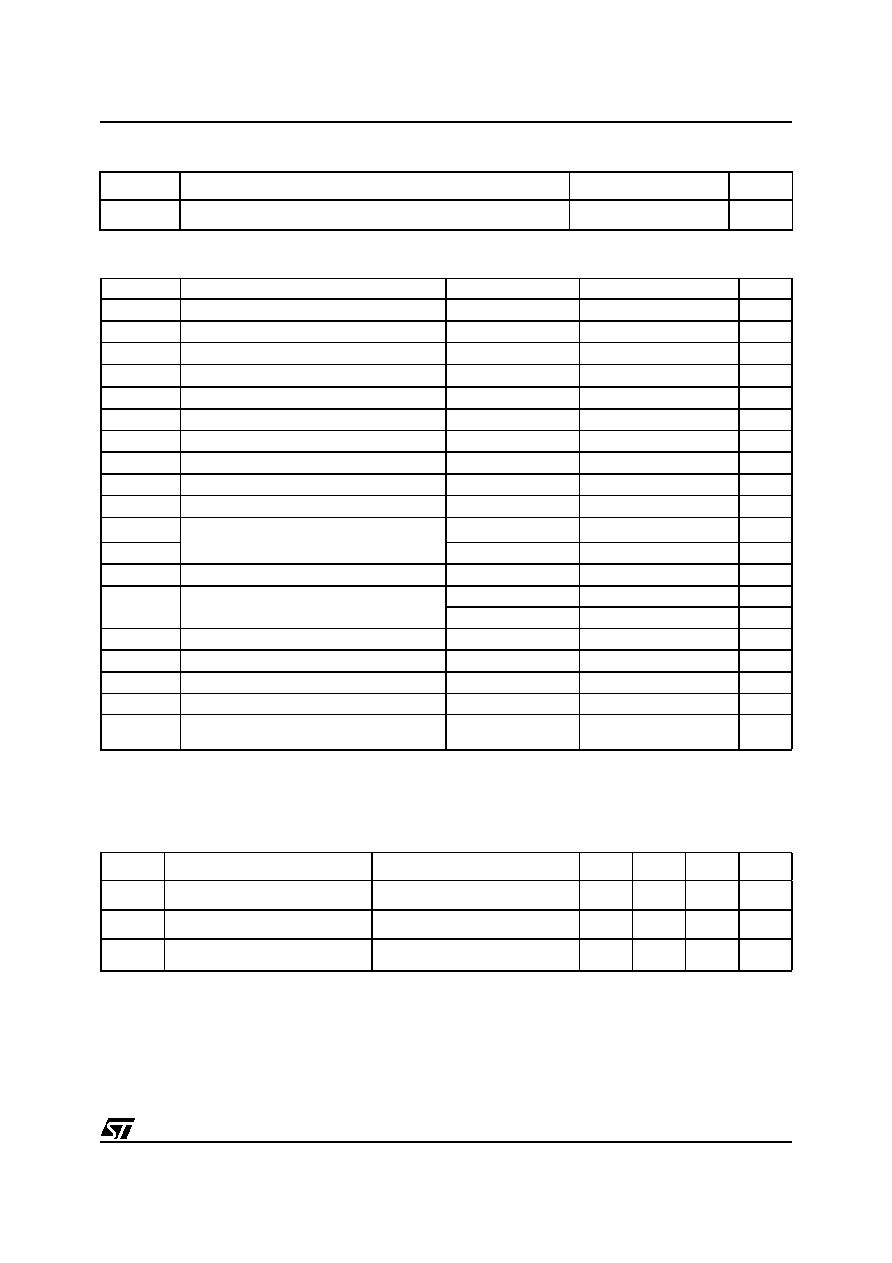

PIN CONNECTION

PIN DESCRIPTION

N°

Pin

Function

1

PGND

Power Ground

2

Out1

Output 1 (5A)

3

D1

Diagnostic 1

4

IN4

Input 4

5

VS

Supply Voltage

6

NC

Not Connected

7

IN3

Input 3

8

D2

Diagnostic 2

9

Out2

Output 2 (5A)

10

PGND

Power Ground

11

PGND

Power Ground

12

Out3

Output 3 (3A)

13

D3

Diagnostic 3

14

IN2

Input 2

15

GND

Signal Ground

16

EN

Common Enable

17

IN1

Input 1

18

D4

Diagnostic 4

19

Out4

Output 4 (3A)

20

PGND

Power Ground

20

PGND

19

OUT4

D4

18

IN1

17

16

EN

GND

15

IN2

14

13

D3

OUT3

12

PGND

11

PGND

1

OUT1

2

3

D1

IN4

4

VS

5

6

NC

IN3

7

D2

8

9

OUT2

PGND

10

00AT0026

Heat sink connected

to pins 1, 10, 11, 20

3/12

L9349

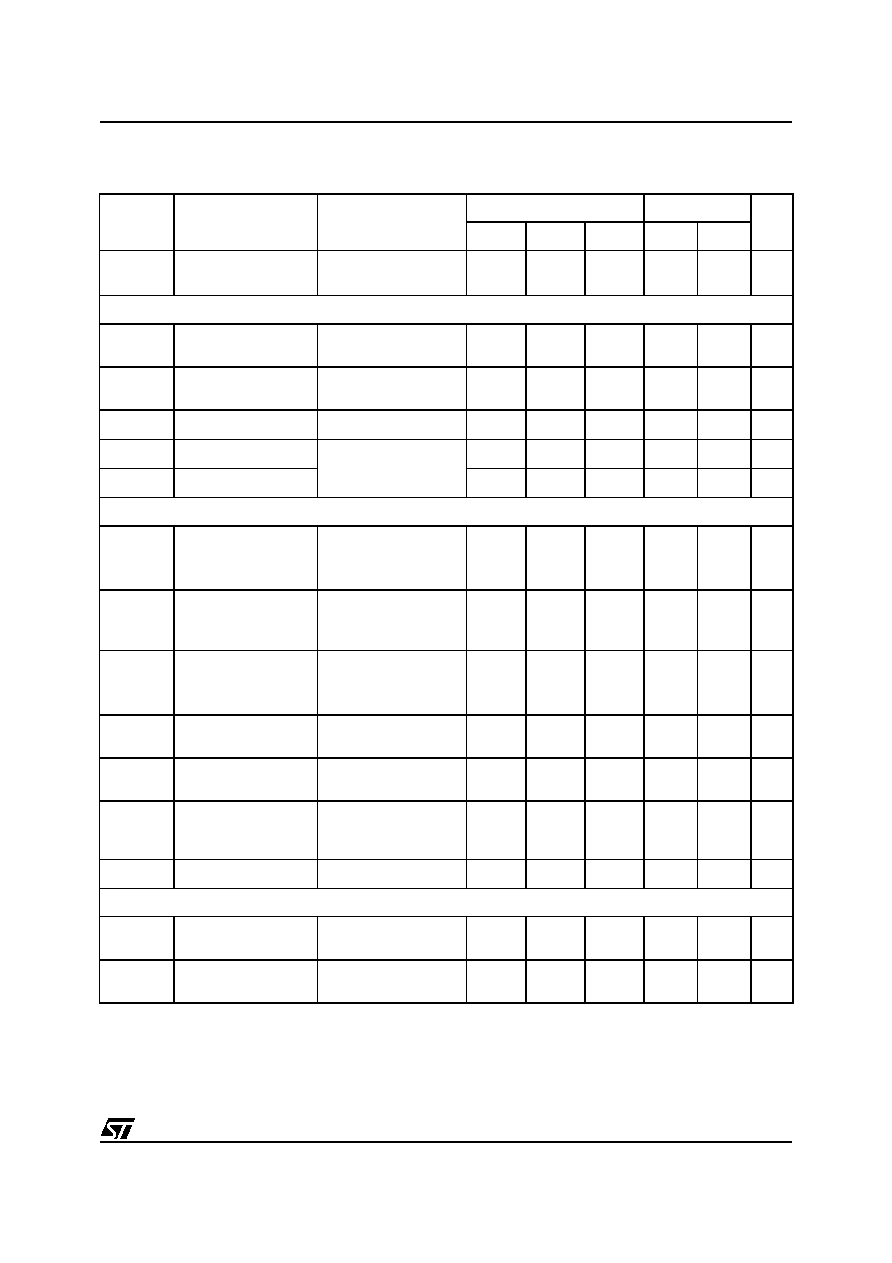

THERMAL DATA

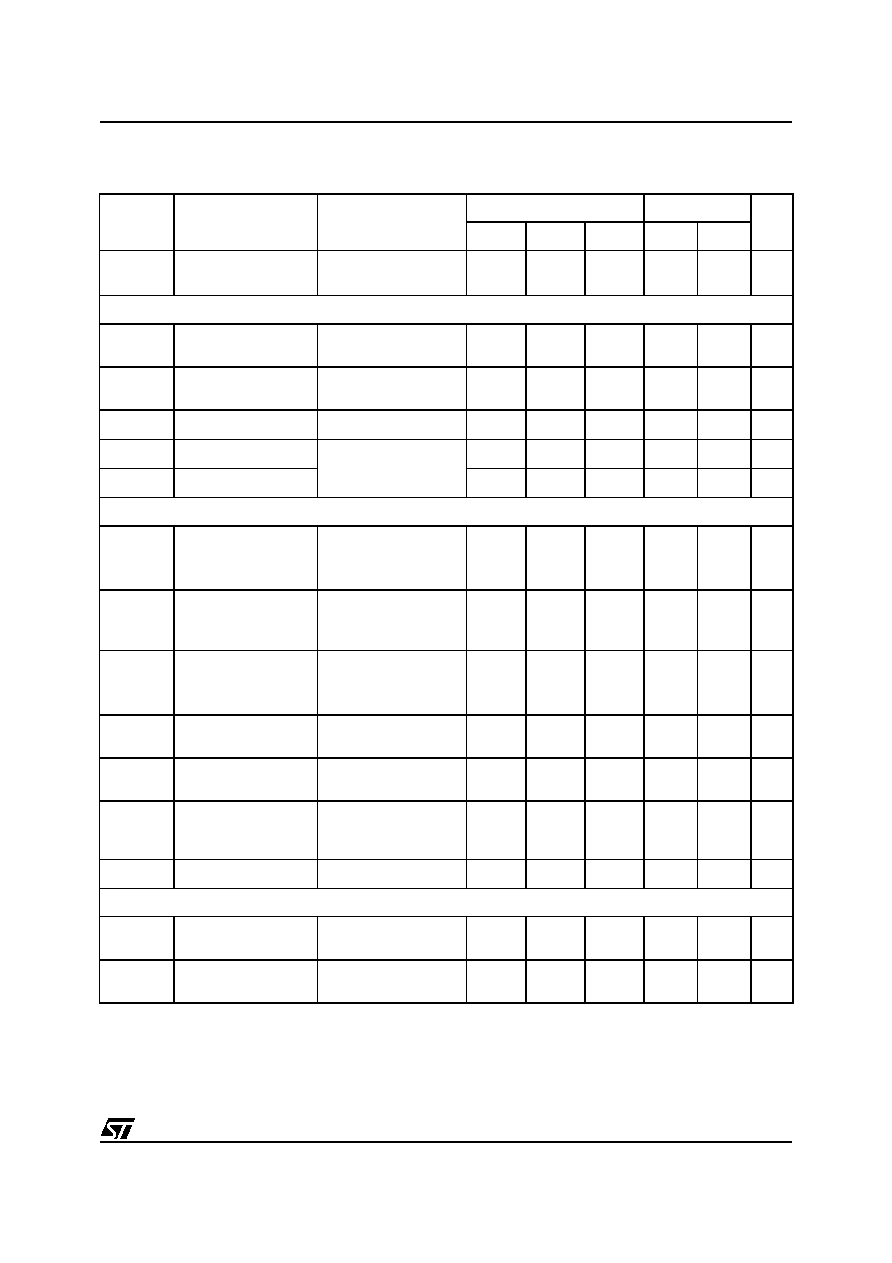

ABSOLUTE MAXIMUM RATINGSI

Electrical Characteristcs (Operating Range)

The electrical characteristics are valid within the below defined operating range, unless otherwise specified.

Symbol

Parameter

Value

Unit

R

Th j-case

Thermal resistance junction to case

3

°C/W

Symbol

Parameter

Conditions

Value

Unit

V

S

DC Supply Voltage

-0.3 to 32

V

V

SP

Supply Voltage Pulse (duration <200ms)

-0.3 to 45

V

dV

S

/dt

Supply Voltage Slope

10

V/

µ

s

V

IN, EN

Input Voltage

I

10mA

-1.5 to 6

V

V

D

Diagnostic DC Output Voltage

I

50mA

-0.3 to 16

V

V

ODC

DC Output Voltage

-0.3 to 45

V

I

O1, 2

DC Output Current Out 1, 2

5

A

I

O3, 4

DC Output Current Out 3, 4

3

A

I

OR1, 2

Reverse Output Current

-5

A

I

OR3, 4

Reverse Output Current

-3

A

E

O1, 2

Switch-off Energy for Inductive Loads

t

EO

= 250

µ

s,

1)

1)

t

EO

is the clamping time (see Figure 1)

50

mJ

E

O3, 4

T = 5ms

30

mJ

V

GND

GND Potential Difference

T

j

= -40 to 150°C

±0.3

V

T

jEO

Junction Temperature During Switch-off

t

30 min

175

°C

t

15 min

190

°C

T

j

Junction Temperature

-40 to T

jDIS

°C

T

stg

Storage Temperature

-55 to 150

°C

T

jDIS

Thermal Disable Junction Temp. Threshold

180 to 210

°C

ESD

Electrostatical Discharging

MIL883C

+-2

kV

ESD

OUT1 - 4

vs. Common-GND

(PGNDs + GND)

+-4

kV

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

V

S

Board Supply Voltage

4.5

12

32

V

T

j1

Junction Temperature

-40

150

°C

T

j2

Junction Temperature

t

15min

1)

over life time

1)

Parameters guaranteed by correlation

150

T

jDIS

°C

L9349

4/12

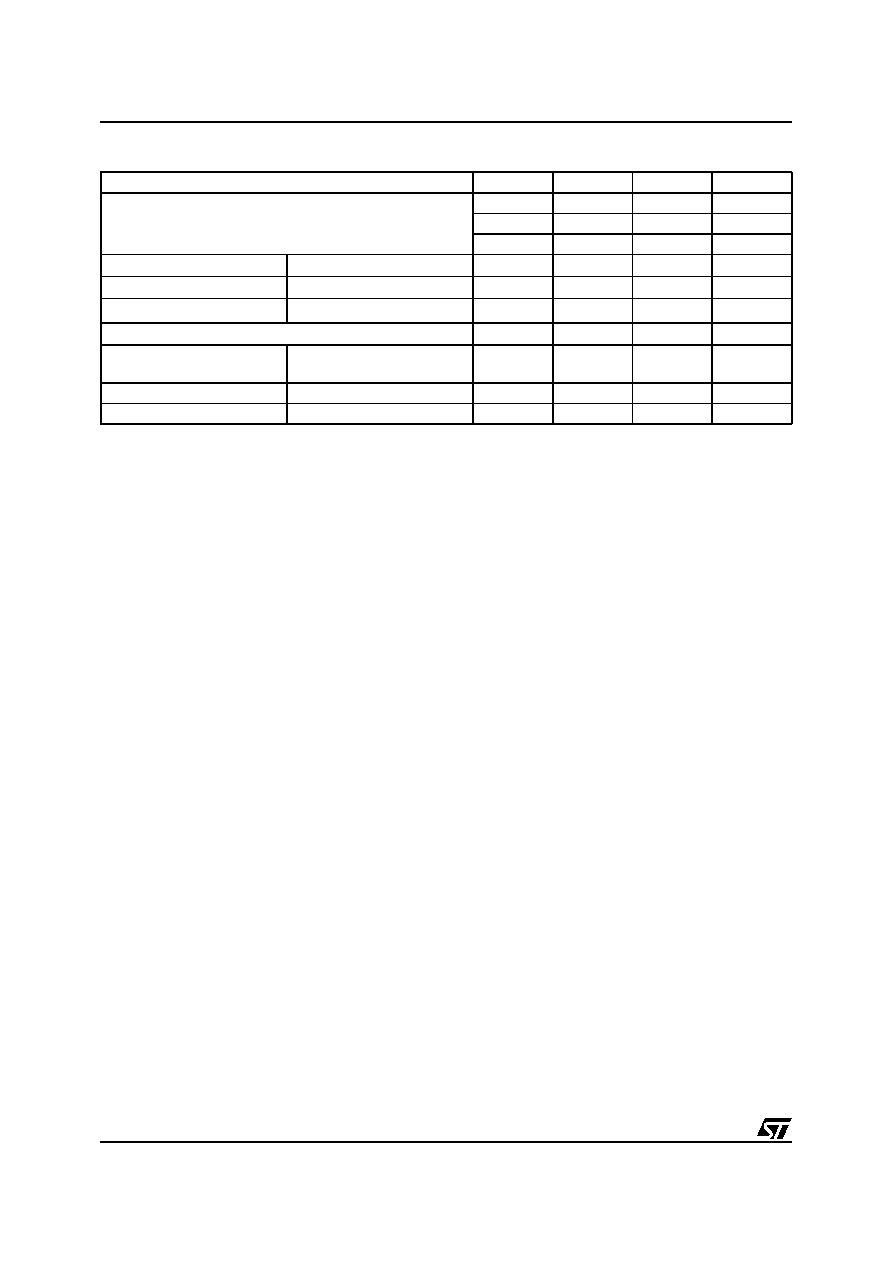

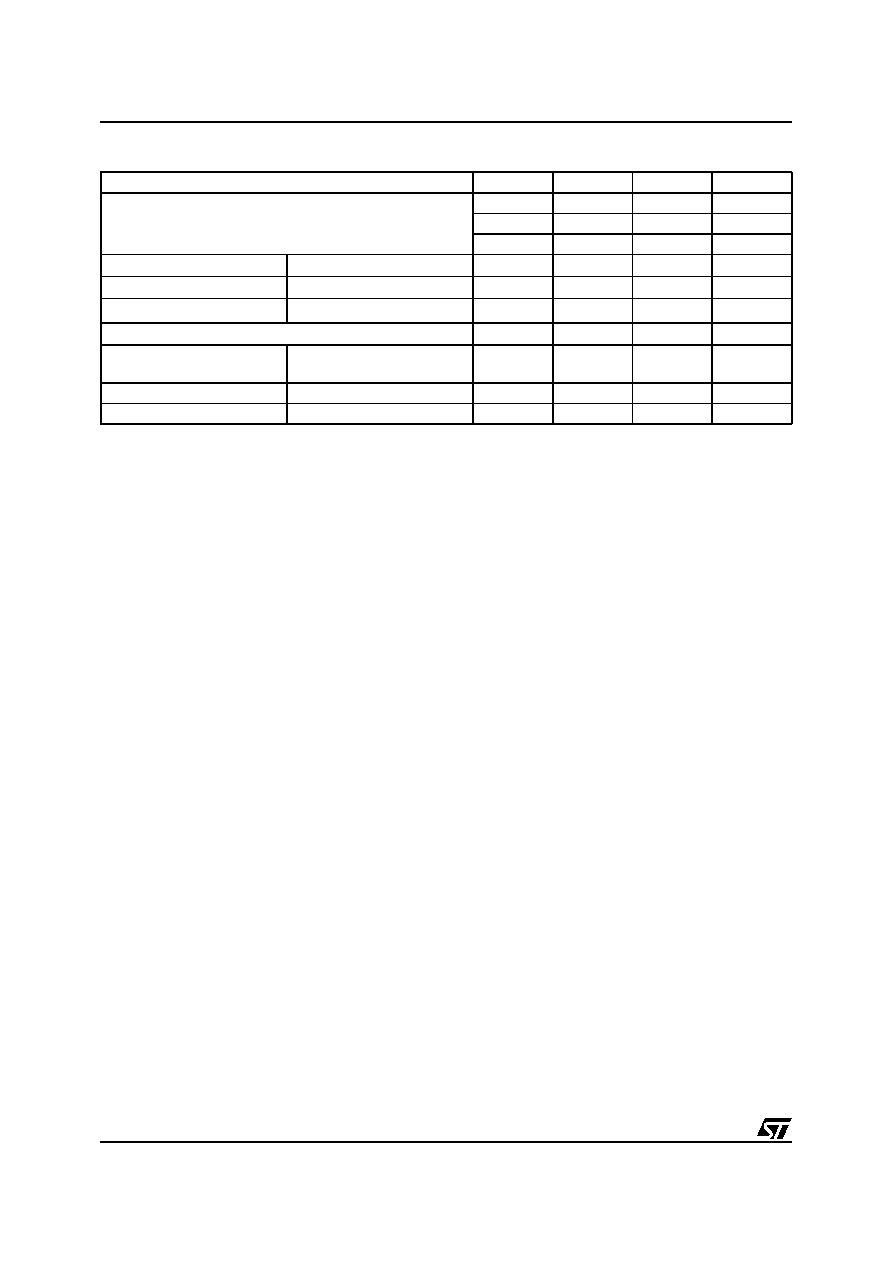

ELECTRICAL CHARACTERISTICS

(V

S

= 4.5 to 32V; -40°C

T

j1

150°C < T

j2

T

jDIS

, unless other-wise specified.)

Symbol

Parameter

Test Conditions

Values T

j1

Values T

j2

Unit

Min.

Typ.

Max.

Min.

Max.

Supply

I

VS OFF

DC Supply Current Off

EN = 1.0V

5

10

mA

I

VS ON

DC Supply Current On

V

S

14V; V

IN

, V

EN

= 2V

8

mA

Diagnostic Outputs D1 - D4

V

DL

Diagnostic Output Low

Voltage

I

D

3mA

0.65

1.0

1.5

V

I

DLE

Diagnostic Output

Leakage Current

V

D

= 14V

1)

0.1

2

20

µ

A

Outputs Out 1 - Out 4

R

DSON 1, 2

Output On Resistance

T

j

= 25°C

T

j

= 150°C

V

S

> 9.5V I

O1,2

= 2A

200

300

500

m

R

DSON 3, 4

T

j

= 25°C

T

j

= 150°C

V

S

> 9.5V

I

O3,4

= 1.3A

300

450

750

m

V

Z

Z-diode clamping

voltage

I

OCL

200mA

45

60

V

R

O

Output pull down

resistor

VS > 9.5V

EN = 0V

10

40

50

k

V

OUV 1-4

Open Load Voltage

Threshold

V

IN

= 1V

0.525 x

V

S

0.55 x

V

S

0.575 x

V

S

V

V

OUV hys 1-

4

Hysteresis

0.003 x

V

S

V

V

OUV 1-4,

2-3, 4-1, 3-2

Open Load Difference

Voltage Threshold

V

IN1,4/2,3

= 1V V

S

16V

VOc S 4.5V

V

OC

= output voltage of

other channel

V

OC

-

1.0V

V

OC

-

1.25V

V

OC

-

1.5V

V

V

OUV hys

1-4, 2-3,

4-1, 3-2

Open Load Hysteresis

40

mV

I

OUC 1, 2, 3,

4

Open Load Current

Threshold

V

EN

=V

IN

=2V;

V

S

=6.5 - 16V

160

320

480

mA

I

OOC 1, 2

Over Load Current

Threshold

V

S

> 6.5V;

V

OUT

= 32V

5

10

A

I

OOC 3, 4

3

6

A

T

SD

Thermal Shut Down

180

195

210

°C

T

SD-hys

Thermal Shut Down

hysteresis

20

°C

5/12

L9349

I

OUT-LE

OUT leakage current

V

OUT

= 20V

V

S

= 0V

5

µ

A

Inputs IN1-4, EN

V

IN,EN L

Logic Input/Enable

Low Voltage

-0.3

1

V

V

IN,EN H

Logic Input/Enable

High Voltage

IN, EN

2.0

6

V

V

EN,IN hys

Logic Input Hysteresis

50

100

mV

I

IN

Input Sink Current

2V < V

IN

, V

EN

< 6V

2)

V

IN

, V

EN

< V

s

10

20

40

µ

A

I

EN

Enable Sink Current

10

20

40

µ

A

Timing

t

ON

Output Delay ON Time I

O

=

1A

V

S

= 12V

3)

)

Fig. 2

4

25

µ

s

t

f,r

Output fall and rise

time

I

O

=

1A

V

S

= 12V

Fig. 2

3

10

30

µ

s

t

OFF

Output Delay OFF

Time

I

O

=

1A

V

S

= 12V

3)

Fig. 2

5

15

30

µ

s

t

DH-L, Diag

Diag. Delay Output

OFF Time

3)

Fig. 2

8

65

90

µ

s

t

D IOU

Diagnostic Open Load

Delay Time

9V< V

S

<16V, Fig 3

8

50

µ

s

t

DOL

Diagnostic Overload

Delay Switch-OFF

Time

9V< V

S

<16V, Fig 3

6

65

µ

s

t

filt

Filter time

4

24

µ

s

PGND

PGND

loss,h

Power GND loss

threshold high

3

V

PGND

loss,l

Power GND loss

threshold low

2

V

1)

The diagnostic output is short circuit protected up to V

D

= 16V

2)

Open pins (EN, IN) are detected as low

3)

V

S

= 9 to 16V

I

OUC

I

O

I

OOC

ELECTRICAL CHARACTERISTICS (continued)

(V

S

= 4.5 to 32V; -40°C

T

j1

150°C < T

j2

T

jDIS

, unless other-wise specified.)

Symbol

Parameter

Test Conditions

Values T

j1

Values T

j2

Unit

Min.

Typ.

Max.

Min.

Max.

L9349

6/12

DIAGNOSTIC TABLE

CIRCUIT DESCRIPTION

The L9349 is a quad low side driver for inductive loads like valves in automotive environment. The internal pull

down current sources at the ENable and INput pins assure in case of open input conditions that the device is

switched off. An output voltage slope limitation for du/dt is implemented to reduce the EMI. An integrated active

flyback voltage limitation clamps the output voltage during the flyback phase to 50 V.

Each driver is protected against short circuit at V

OUT

< 32V and thermal overload. In short circuit condition the

output will be disabled after a short delay time t

DOL

. The thermal disable for T

J

> 180°C of the output will be

reset if the junction temperature decreases about 20°C below the disable threshold temperature.

The overtemperature, overload and groundloss information is stored until IN is low.

For the real time error diagnosis the voltage and the current of the outputs are compared with internal fixed val-

ues V

OUV

for OFF and I

OUC

for ON conditions to recognize open load (R

L

20K

, R

L

> 38

) in OFF and ON

conditions.

Also the output voltages V

O1- 4

are compared to each other output in OFF condition with a fixed offset of

V

OUV

to recognize load bypasses. The

V

OUV

diagnoses is suppressed during the flyback phases of the compared

output. The outputs 1 and 4 are compared for

V

OUV

and also outputs 2 and 3 are compared.

The diagnostic output level in connection with different ENable and INput conditions allows to recognize differ-

ent fail states, like overtemp, short to V

S

, short to GND, bypass to GND and disconnected load (see diagnostic

table).

The diagnostic output is protected against short circuit. Exceeding the over load current threshold I

OOC

, the out-

put current will be limited internally during the diagnostic overload delay switch-off time t

DOL

.

The device complies the I

SO

pulses imposed to the supply voltage of the valves without any failures of the func-

tionality. Therefore some diagnostic functions are internal filtered. The following table shows the corresponding

filter time for each detected signal.

Conditions

EN

IN

OUT

DIAG.

Normal Function

L

X

off

L

H

L

off

L

H

H

on

H

GND short

V

Otyp

< 0.55VS

L

X

off

H

Load bypass

V

O1-4/2-3

1.25V

H

L

off

H

Open Load

I

O1,2,3,4typ

< 320mA

H

H

on

L

T

jtyp

190°C Overtemperature

X

X

off

L

Over Load

I

Omin 1,2

> 5A

I

Omin 3,4

> 3A

H

H

off

L

SGND or PGND loss

channel off

X

L

off

H

SGND or PGND loss

channel on

H

H

off

L

7/12

L9349

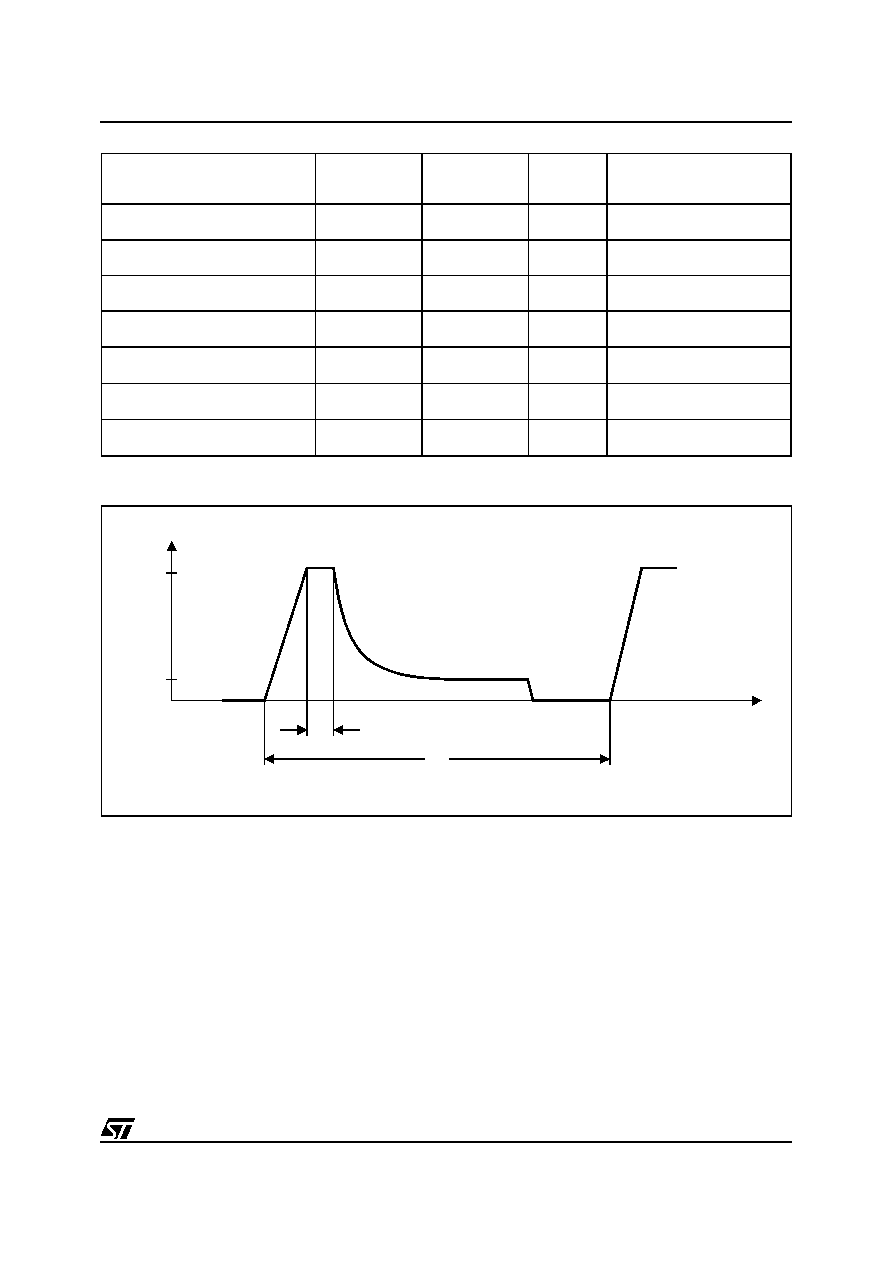

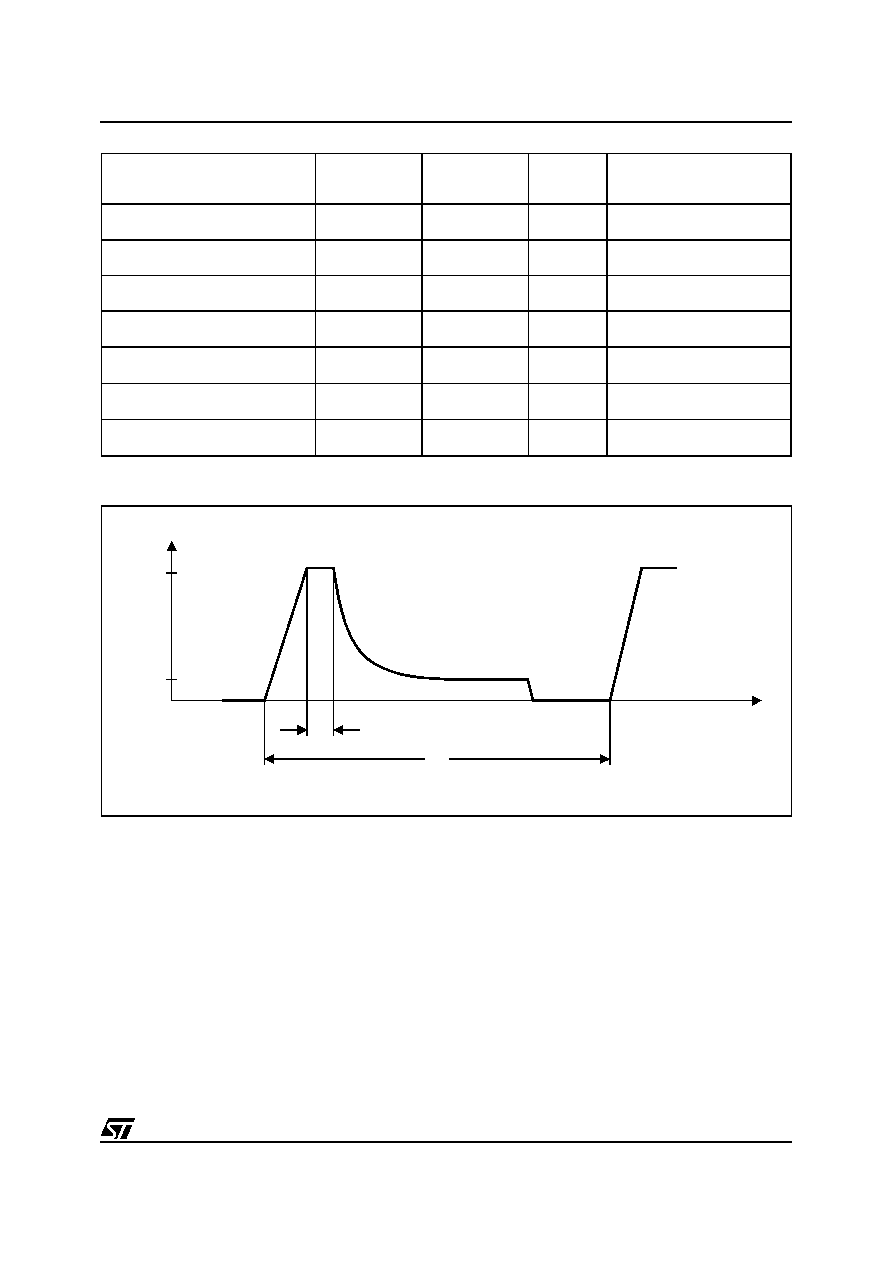

Figure 1. t

EO

Clamping Time

ON State

EN and IN =

HIGH

OFF State

EN or IN,

= LOW

min. Filter

time

Reset done by

Overloading of output

(also shorted load to supply)

X

4

µ

s

INx = "LOW"

Open load

(under voltage detection)

X

-

Open load

(under current detection)

X

-

Overtemperature

X

4

µ

s

INx = "LOW"

Power-Signal GND-loss

X

4

µ

s

INx = "LOW"

Power- Signal-GND-loss

X

4

µ

s

Openload difference

X

4

µ

s

V

O1-4

t

V

OCL

V

S

t

EO

T

00AT0027

L9349

8/12

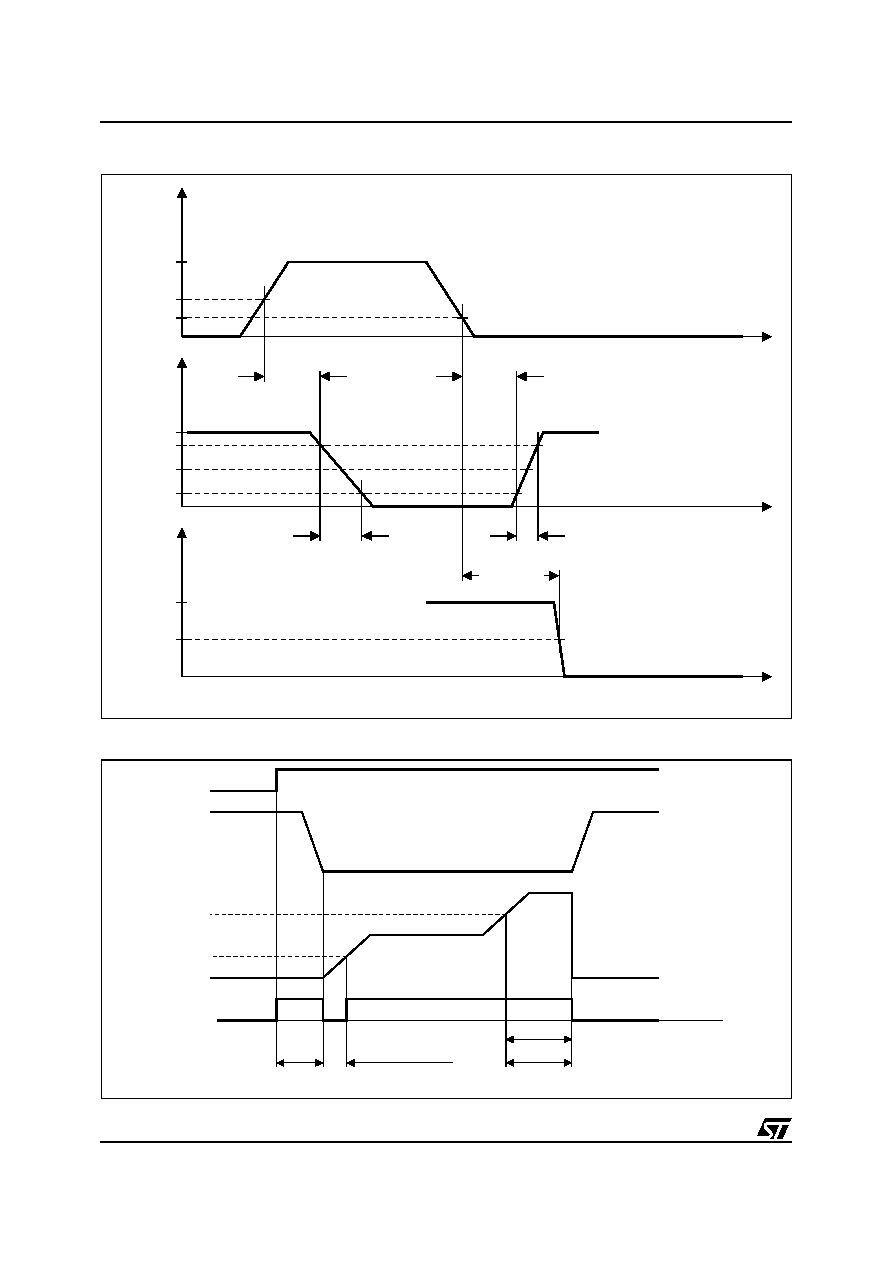

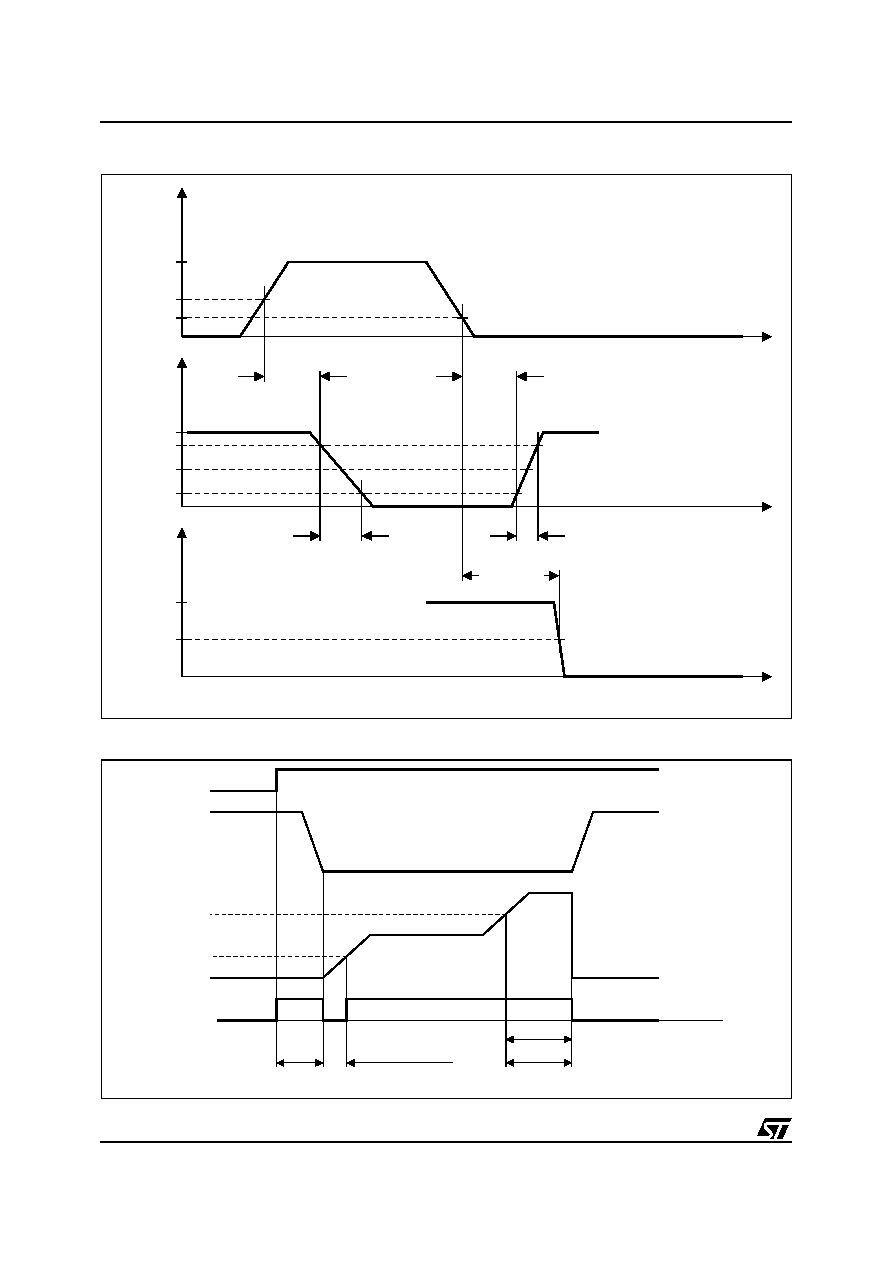

Figure 2. Output Slope (resistive load for testing)

Figure 3. Timing (t

DOL

, t

DIOU

)

V

IN

t

V

H

V

L

5V

V

OUT

t

V

OUV

0.15V

S

t

ON

t

OFF

V

DIAG

0.5V

D

V

D

t

D H-L Diag

00AT0030

V

S

0.85V

S

t

f

t

r

V

EN

IN

V

ON

I

OOC

V

D

I

OUC

Open Load Current

t

DOL

t

DIOU

00AT0032

t

filt

9/12

L9349

Figure 4. Block Diagram - Open Load Voltage Detection

R

IO

R

IO

OUT1

(OUT2)

L

1

(L

2

)

L

4

(L

3

)

V

Batt

OUT4

(OUT3)

+

±

±

+

R

Latch

S

Q

R

Latch

Q

S

V

S

55%

Enable

IN

4

IN

1

VO

UV1

VO

UV4

00AT0033

L9349

10/12

Figure 5. Logic Diagram

Figure 6. Application Circuit Diagram

Open Load Current

Nor

mal

Oper

ation ON

Open Load Current

Open Load Current

Latch Reset

Nor

mal

Oper

ation ON

Open Load

V

oltage

Nor

mal

Oper

ation OFF

Open Load

V

oltage

IO

O

V

IN

VO

U

IO

U

V

D

V

EN

Latched

Ov

er

.

Load

Diagnostic

00AT0034

Diagnostic

Control

R

Q

S

Delay

Time

Overload

Overtemp

Output Control

Openload

52V

R

IO

Channel 4

Channel 1

Channel 2

Channel 3

OUT3

OUT2

OUT4

VS

OUT1

Z

VALVE

Z

VALVE

Z

VALVE

Z

VALVE

+45V

V

Batt

KL30

KL15

IN1

D1

EN

+5V

µ

P

Controller

V

CC

I/O

I/O

I/O

IN4

I/O

D4

I/O

+5V

IN2

D2

I/O

I/O

+5V

IN3

D3

I/O

I/O

+5V

GND

GND

00AT0035

11/12

L9349

OUTLINE AND

MECHANICAL DATA

e

a2

A

E

a1

PSO20MEC

DETAIL A

T

D

1

10

11

20

E1

E2

h x 45

DETAIL A

lead

slug

a3

S

Gage Plane

0.35

L

DETAIL B

R

DETAIL B

(COPLANARITY)

G

C

- C -

SEATING PLANE

e3

b

c

N

N

H

BOTTOM VIEW

E3

D1

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

3.6

0.142

a1

0.1

0.3

0.004

0.012

a2

3.3

0.130

a3

0

0.1

0.000

0.004

b

0.4

0.53

0.016

0.021

c

0.23

0.32

0.009

0.013

D (1)

15.8

16

0.622

0.630

D1

9.4

9.8

0.370

0.386

E

13.9

14.5

0.547

0.570

e

1.27

0.050

e3

11.43

0.450

E1 (1)

10.9

11.1

0.429

0.437

E2

2.9

0.114

E3

5.8

6.2

0.228

0.244

G

0

0.1

0.000

0.004

H

15.5

15.9

0.610

0.626

h

1.1

0.043

L

0.8

1.1

0.031

0.043

N

8° (typ.)

S

8° (max.)

T

10

0.394

(1) "D and E1" do not include mold flash or protusions.

- Mold flash or protusions shall not exceed 0.15mm (0.006")

- Critical dimensions: "E", "G" and "a3".

PowerSO20

0056635

JEDEC MO-166

Weight:

1.9gr

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

©

2002 STMicroelectronics - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

12/12

L9349