SMOOTH DRIVE

TM

SYSTEM

1.8A DRIVE PEAK CAPABILITY

SLEW RATE CONTROL

INDUCTIVE SENSE START-UP ROUTINE

THERMAL SHUTDOWN

SUITABLE FOR 5V AND 12V APPLICATION

ONLY ONE HALL SENSOR IS REQUIRED

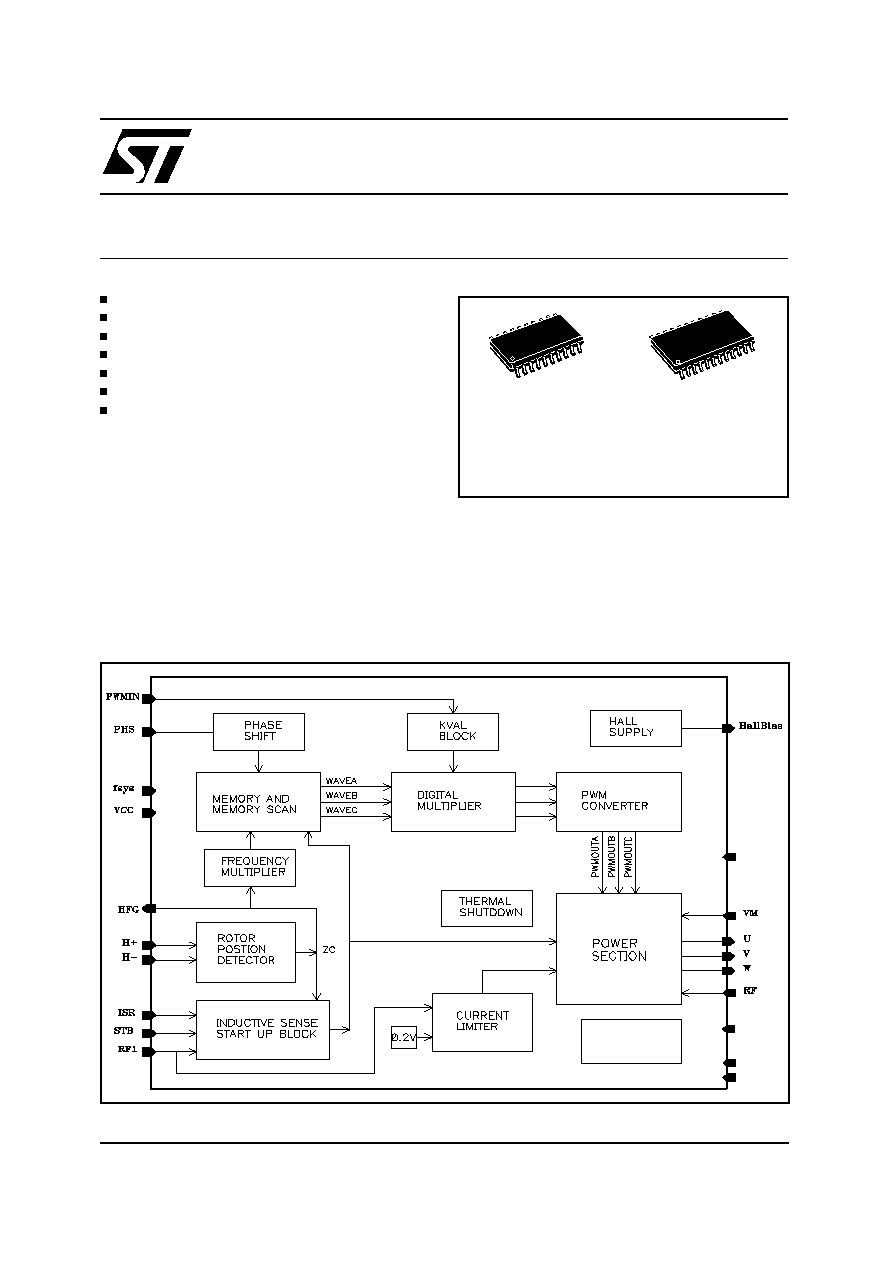

DESCRIPTION

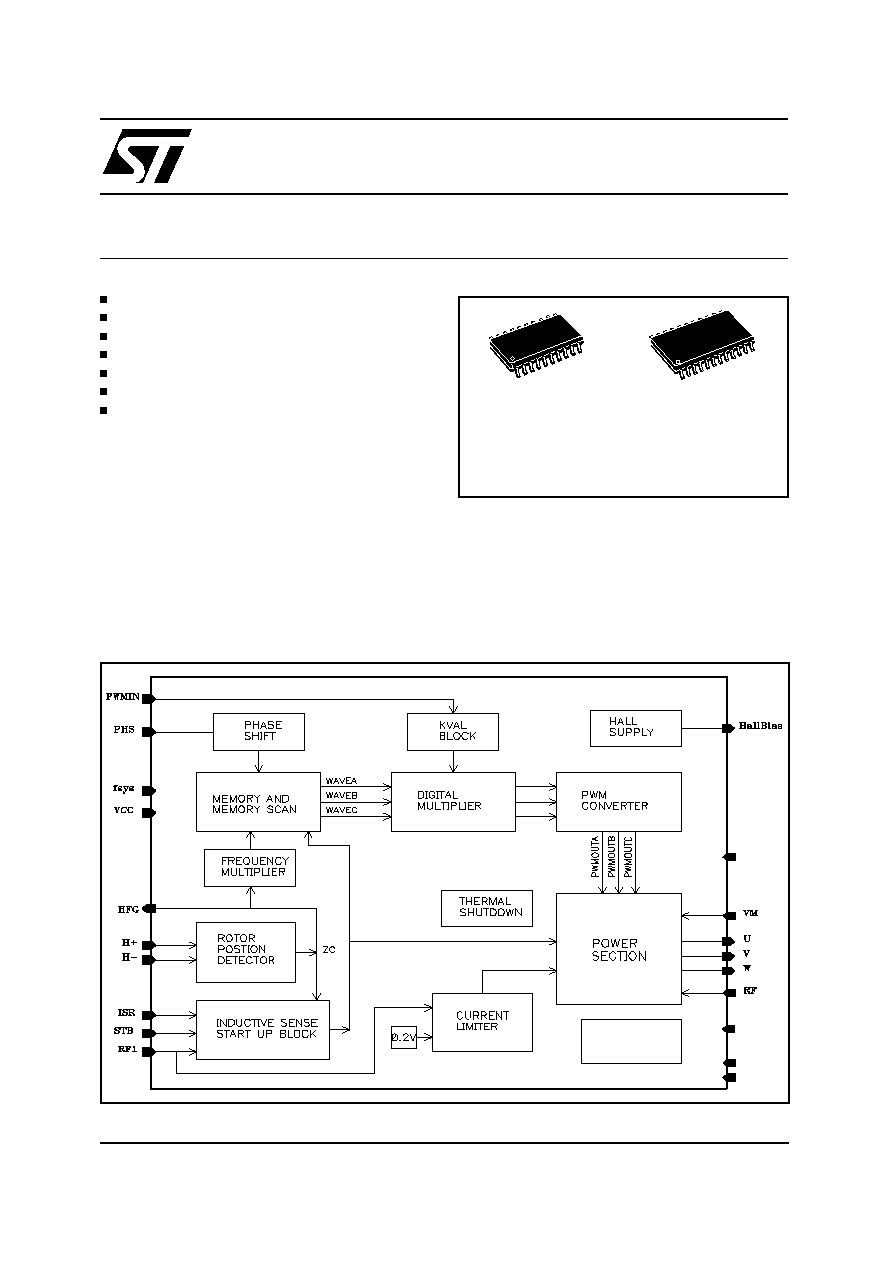

The L7203 SPINDLE MOTOR IC includes a three

phase brushless spindle motor controller and the

power stage in switching mode. The device is de-

signed for both 5V and 12V OPTICAL DRIVE ap-

plication requiring up to 1.8A peak of current.

The device is realized in BCD5, a 0.7

µ

m Mixed

technology.

The spindle motor position detection is carried

out by means of a single comparator with hyster-

esis. In the start-up phase the "inductive sense

start up method" is used to detect the rotor posi-

tion, determining the direction of starting rotation.

This procedure is implemented by a logic circuit

on chip.

The device applies three sinusoidal voltages to

the motor coils.

This is obtained through the application of the

April 2001

LOW VOLTAGE

DETECTOR

PRS

SRC

AGND

DGND

BLOCK DIAGRAM

ORDERING NUMBERS: L7203 (SO20)

L7203S (SSO24)

L7203

SMOOTH DRIVE SPINDLE MOTOR FOR OPTICAL DRIVE

APPLICATION WITH POWER INTEGRATED

®

SO20

SSO24

1/13

SMOOTH DRIVING concept.

It is based on the idea of driving the motor wind-

ing through 3 sinusoidal voltages dephased of

120 degrees. The motor is controlled in voltage

mode, so no current control compensation net-

work is required.

Each profile is digitally described by 36 bytes

stored in a ROM memory.

These sinusoidal signals are modulated by multi-

plying each sample by a value stored in the KVAL

register. Using this kind of profiles it is possible to

obtain great advantages such as torque ripple

and acoustic noise reduction and lower EMI. An

easier track following is ensured, since vibration

are reduced.

The clock signal on the chip can be synchronized

to the external application clock signal.

An internal circuit can limit the current. The

threshold is fixed with a internal 0.2 V reference.

The device generates:

- a current generator to define output voltage

slew rate

- a 3.3 V reference to bias hall sensor.

- the HFG open drain output signal for speed

regulation.

The device includes :

- a circuit for thermal shutdown with hysteresis.

- a low voltage detector

In the STANDBY state the main functions of the

device are turned off, in order to minimize the

power consumption.

The STANDBY state of the device is imposed by:

- Thermal shutdown

- stand by signal from

µ

P

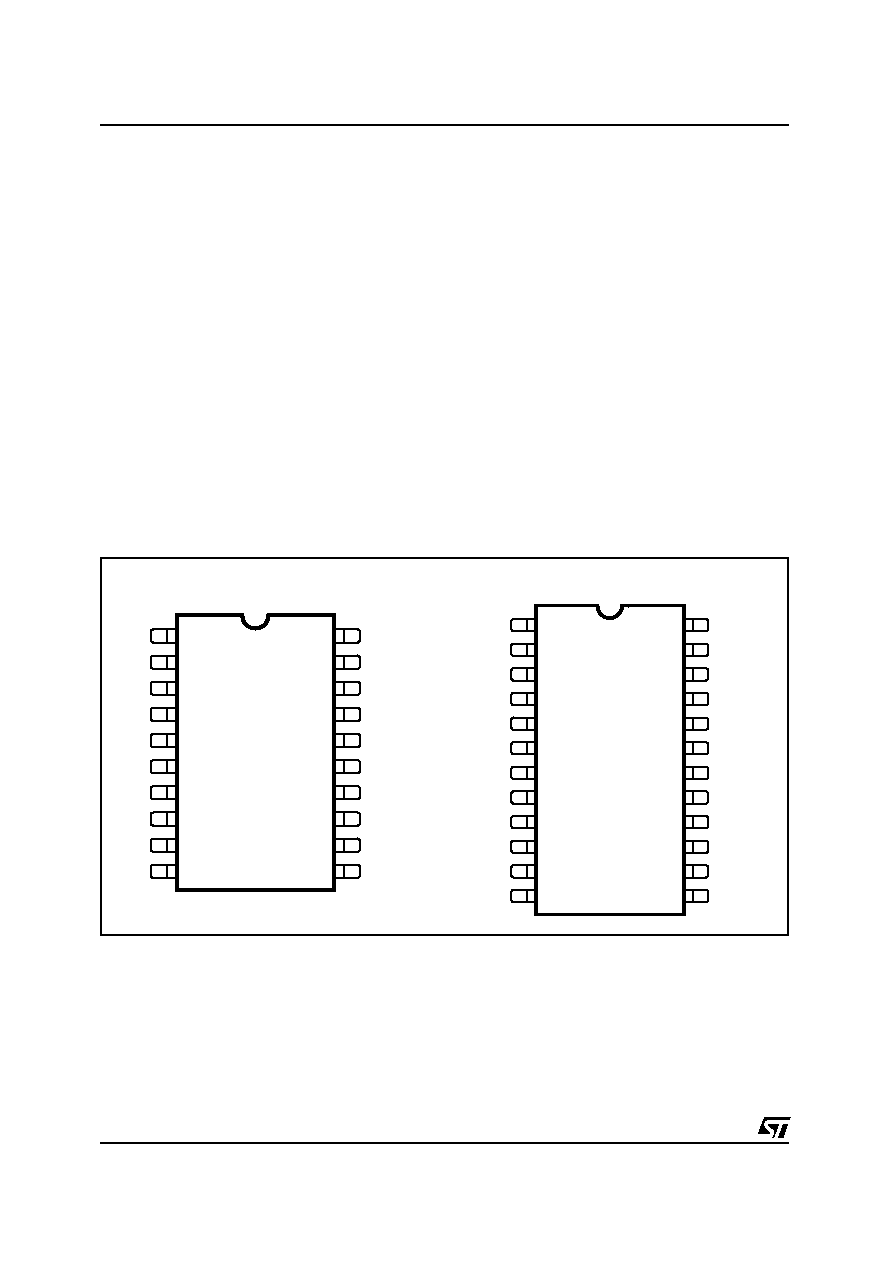

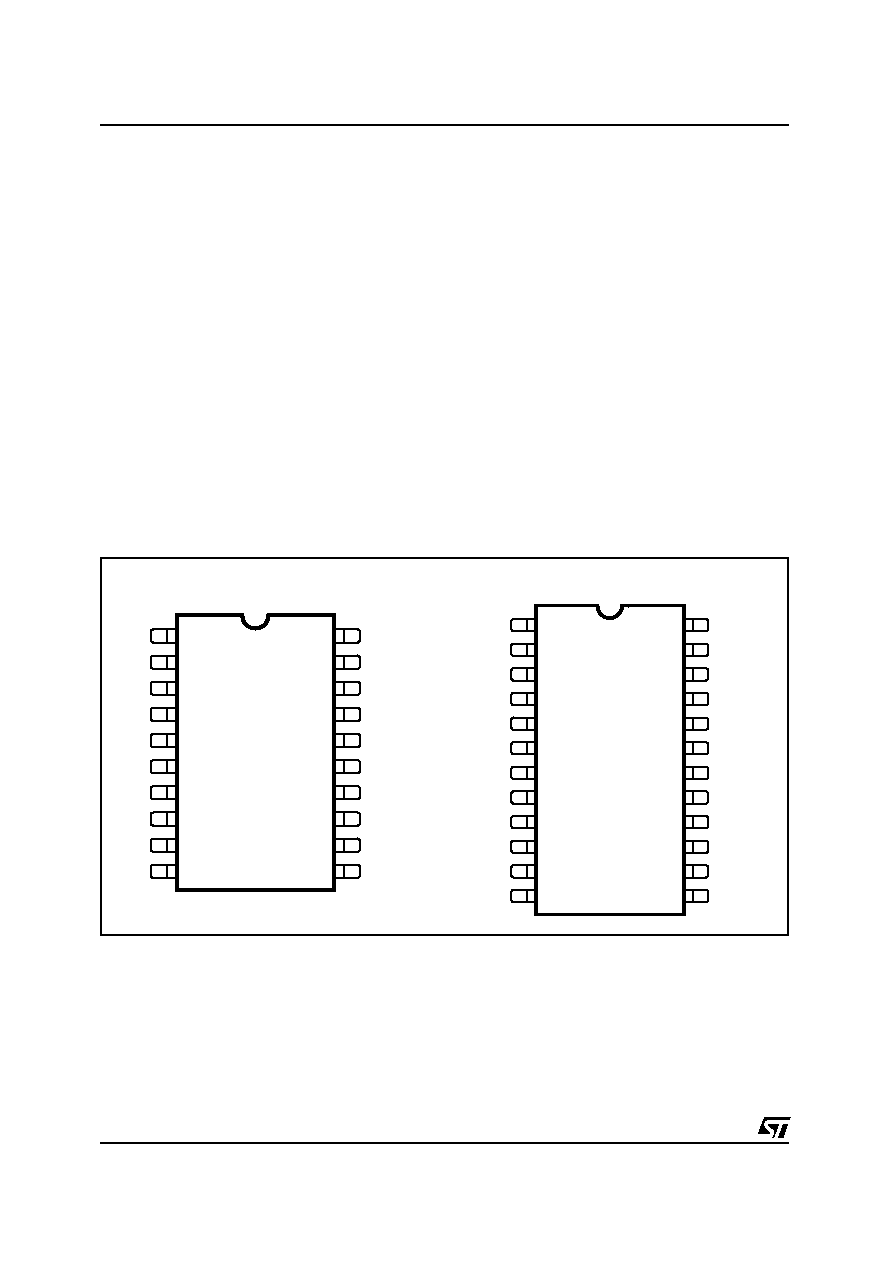

PIN CONNECTIONS

DESCRIPTION (continued)

PRS

N.C.

N.C.

VM

U

N.C.

V

W

RF

H BIAS

ISR

V

CC

DGND

AGND

SRC

HFG

FSYS

STB

1

3

2

4

5

6

7

8

9

22

21

20

19

18

16

17

15

23

10

24

N.C.

PHS

D01IN1174

RF1

PWMIN

11

14

13

12

H+

H-

STB

PRS

VM

U

V

RF

W

RF1

H+

PHS

HBIAS

ISR

AGND

VCC

DGND

SRC

HFG

FSYS

1

3

2

4

5

6

7

8

9

18

17

16

15

14

12

13

11

19

10

20

H-

PWMIN

D98IN928A

SO20

SSO24

L7203

2/13

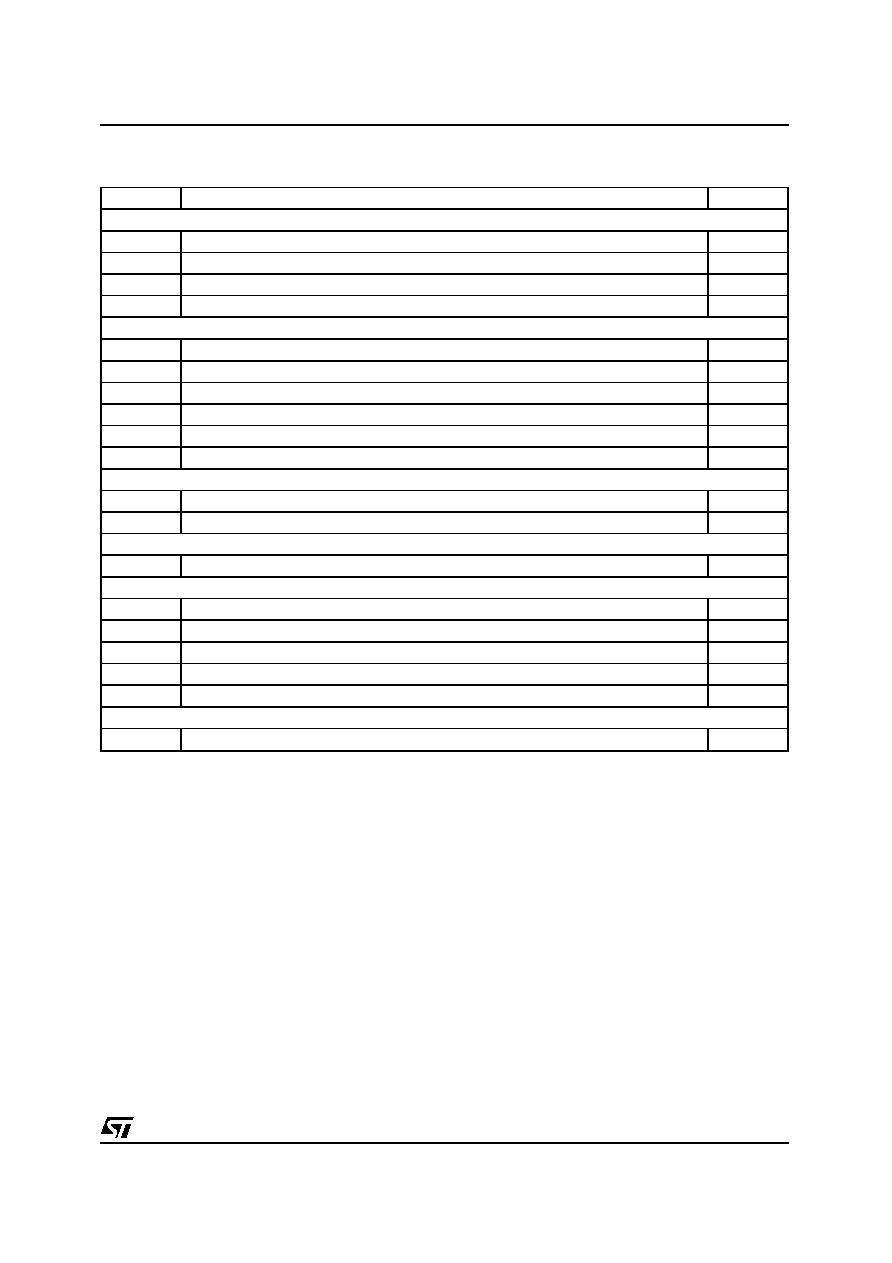

PIN DESCRIPTION

PIN

DESCRIPTION

TYPE

POWER AND GROUND

VM

Supply voltage for power stages +12/5V

P12

VCC

Supply for 5V core

P5

DGND

Logic ground

G

AGND

Analog ground

G

DIGITAL PIN

PWMIN

PWM input signal to calculate kval

IC5

Fsys

System frequency

IC5

PHS

Phase Shift Pin

IC5

PRS

Prescaler Pin

IC5

STB

Start and Stop signal

ZD5

HFG

Open Drain F-Generator signal from Spindle Motor

OD5

HALL SENSOR

BIAS

3.3V reference to bias Hall sensor

OA5

H+, H-

Hall sensor differential input

IA5

INDUCTIVE SENSE REFERENCE

ISR

Inductive sense reference

IA5

MOTOR CONTROL

OUTV

Winding output U

OA12

OUTV

Winding output V

OA12

OUTW

Winding output W

OA12

RF

Current sense resistor (force)

OA12

RF1

Current sense resistor (sense)

IA5

SLEW RATE CONTROL

SRC

Slew Rate Control

OA5

INPUT DEFINITION

IC5 Input CMOS, 3.3-5V capability with hysteresis

ZD5 Bidirectional, open drain, 3.3-5V capability

OD5 Output, open drain, 3.3-5V capability

IA5 Input, Analog, 5V

OA5 Output, Analog, 5V

OA12 Output, Analog, 12V

P12 Power 12V / 5V

P5 Power 5V

G Ground

L7203

3/13

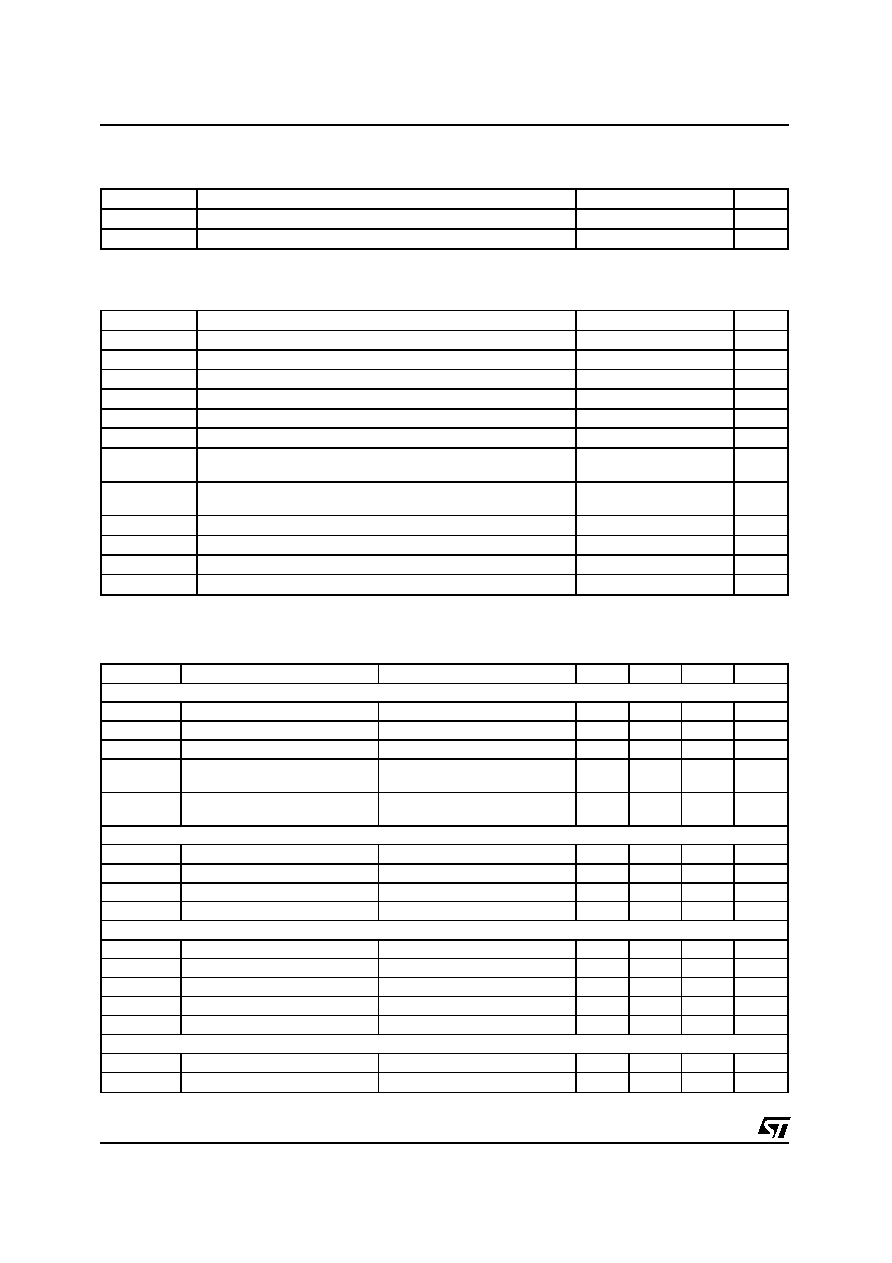

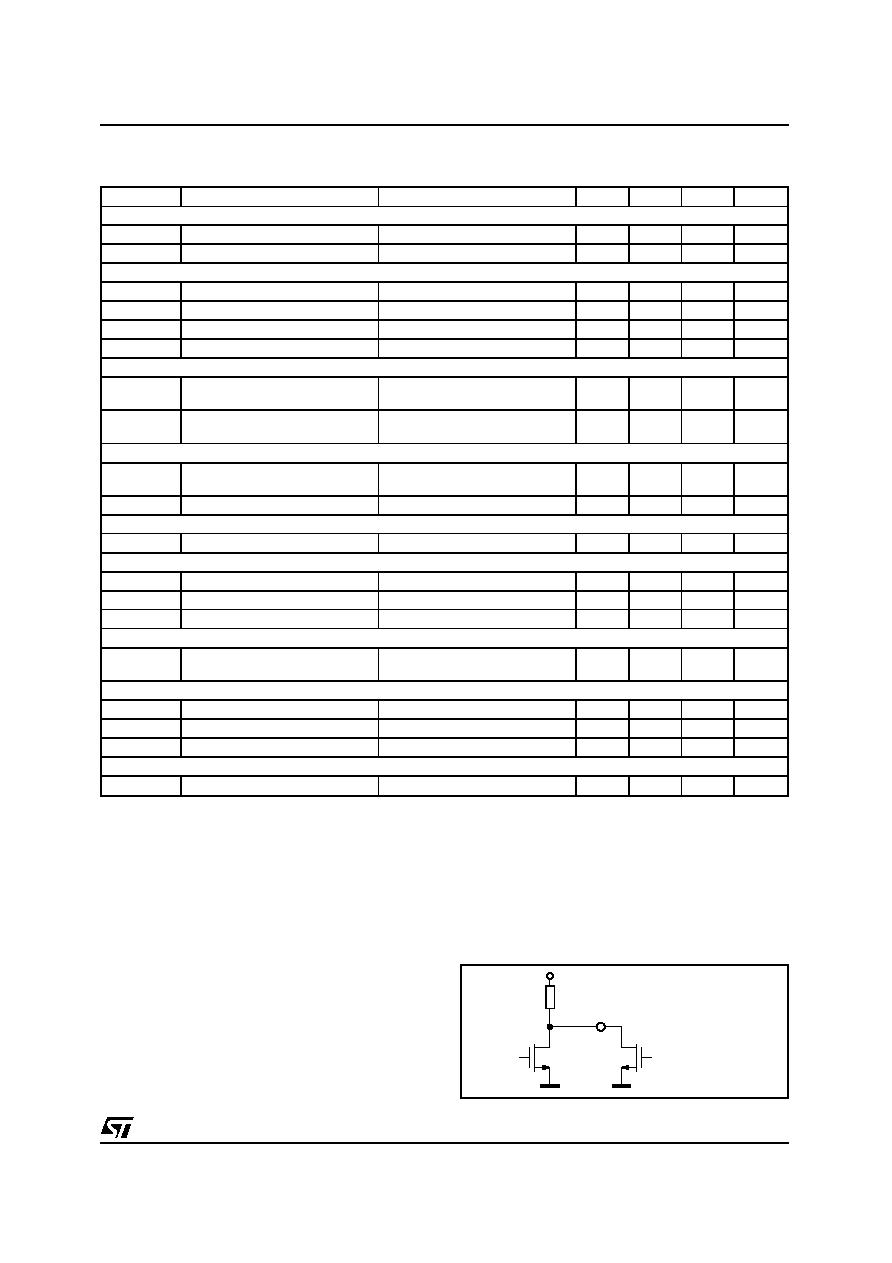

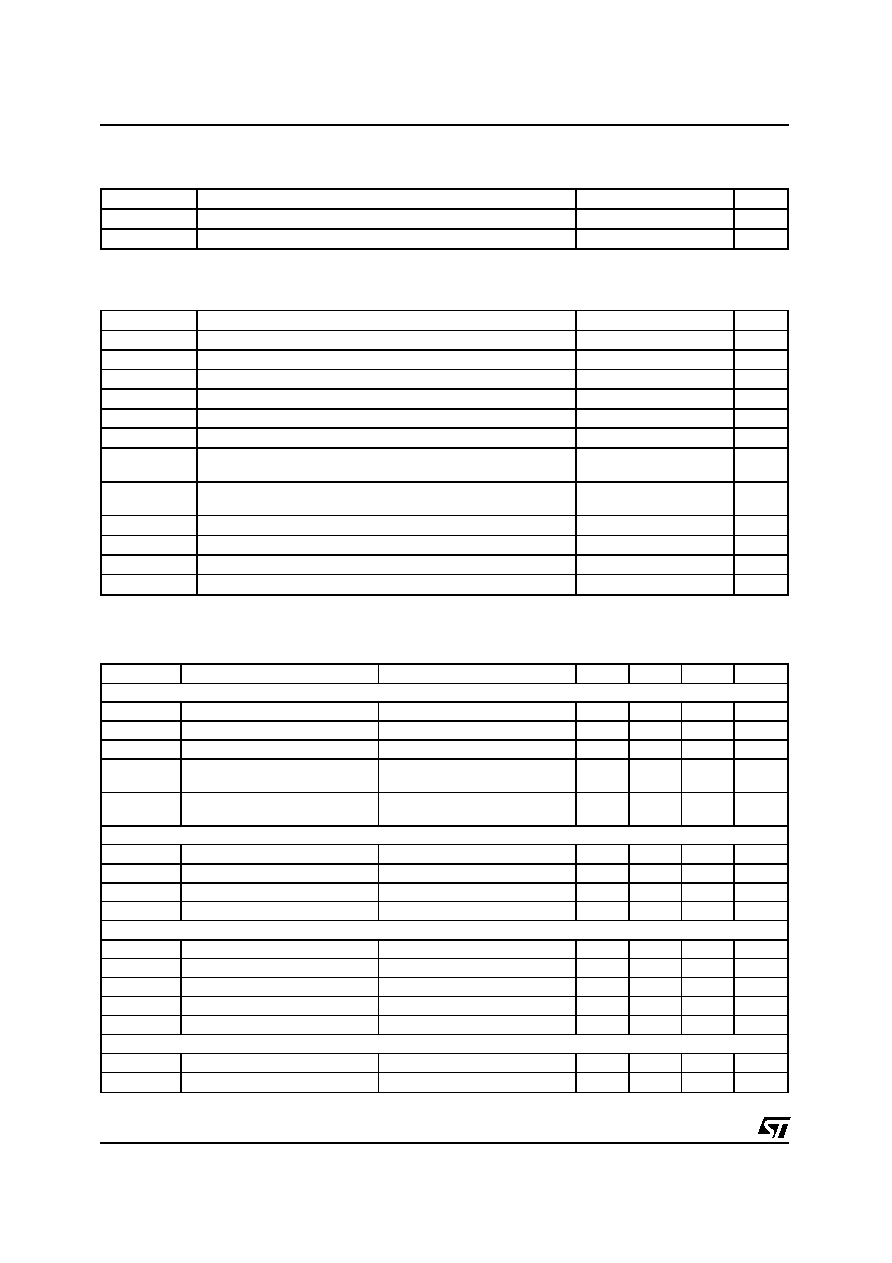

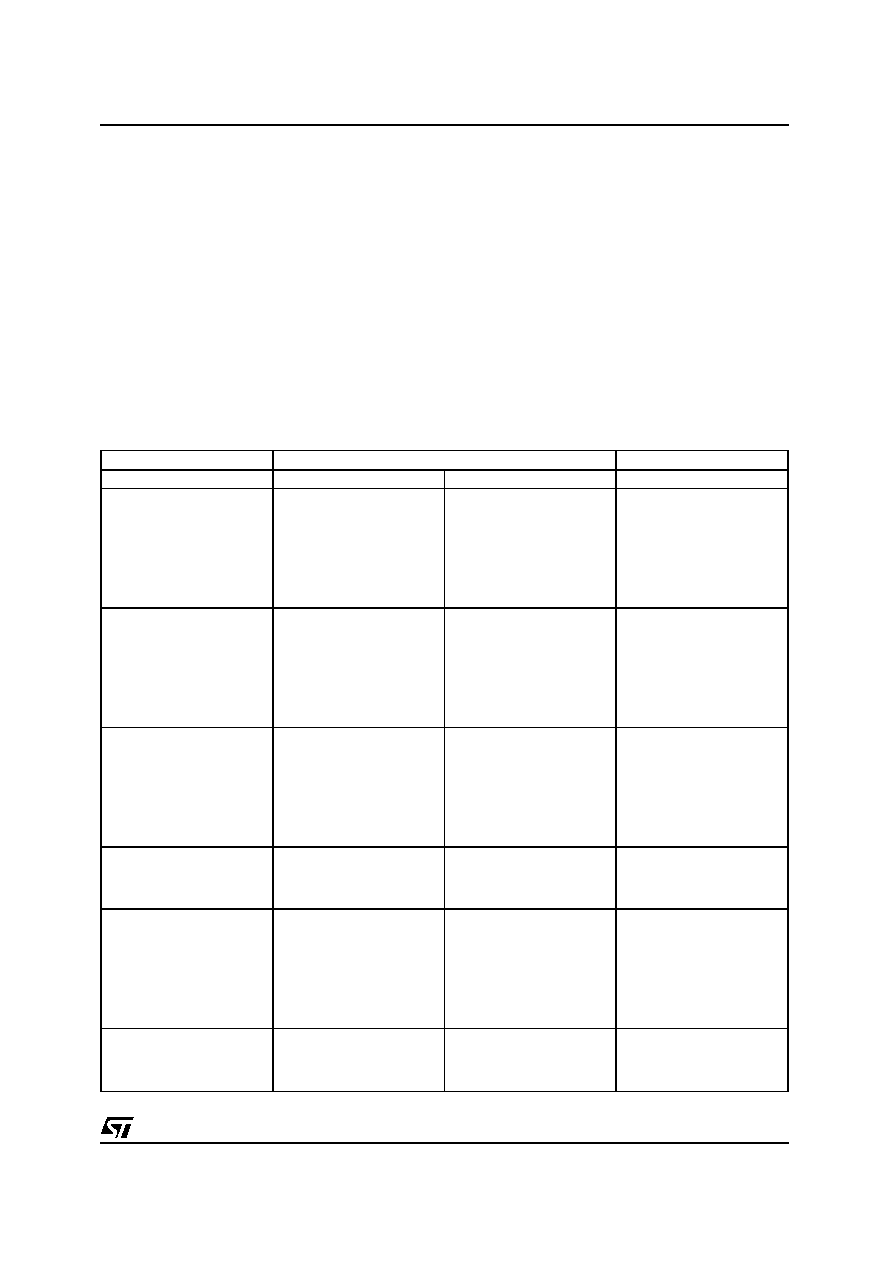

DC ELECTRICAL CHARACTERISTICS ( V

CC

= 5V; V

M

= 12V; T

amb

= 25°C unless otherwise specified)

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

SUPPLY

V

CC

Supply 5V operating range

4.25

5.75

V

V

M

Supply 12V operating range

(note 1)

10.2

13.8

V

V

M

Supply 5V operating range

4.25

5.75

V

I

Vcc

V

CC

Supply Current

V

CC

= 5.75; f

sys

= 20MHz STB = 0

(bias pin open) STB =1

1.3

20

mA

mA

V

VM

V

M

Supply Current

V

M

= 13.8 STB = 0

STB =1

1

7

mA

mA

PWMIN, PHS, PRS, Fsys

V

iL

Input Low Voltage

1

V

V

iH

Input High Voltage

2.2

V

V

iHYS

Input Hysteresis

100

mV

I

z

Leakage Current

V

CC

= 5.75

-10

+10

µ

A

STB

V

iL

Input Low Voltage

1

V

V

iH

Input High Voltage

2.2

V

V

OL

Open Drain Output

IOL = 2mA V

CC

= 4.25V

0.4

V

V

iHYS

Input Hysteresis

100

mV

I

z

Leakage Current

V

CC

= 5.75, Therm off

-10

+10

µ

A

HFG

V

OL

Open Drain Output

IOL = 2mA V

CC

= 5V

0.4

V

I

z

Leakage Current

V

CC

= 5.75, HFG hiz

-10

+10

µ

A

THERMAL DATA

Symbol

Parameter

Value

Unit

R

th j-pins

Thermal Resistance Junction to Pins Max.

16

°C/W

R

th j-amb

Thermal Resistance Junction to Ambient Max.

90

°C/W

ABSOLUTE MAXIMUM RATINGS

Symbol

Parameter

Value

Unit

T

amb

Ambient Temperature

-20 to 80

°C

T

op

Operating Temperature

0 to 150

°C

T

smin

Minimum Thermal Circuit Threshold

140

°C

V

M

-0.3 to 15

Vdc

V

CC

-0.3 to 7

Vdc

U, V, W, (low side drive =off)

-0.3 to 17

Vdc

PWMIN, PHS, FSYS, TEST, STB, HFG, BIAS, H+, H-, RF1,

RF, ISR, PORPin

-0.3 to V

CC

+0.3

Vdc

P

D1

Power dissipation at sustained operation with a package R

thj-amb

at 90°C

1

W

ESD

Susceptibility

2000

Vac

T

STG

Storage Temperature

-55 to 150

°C

I

OLHFG

HFG open drain current

10

mA

I

Peak

Motor Peak Current

1.8

A

L7203

4/13

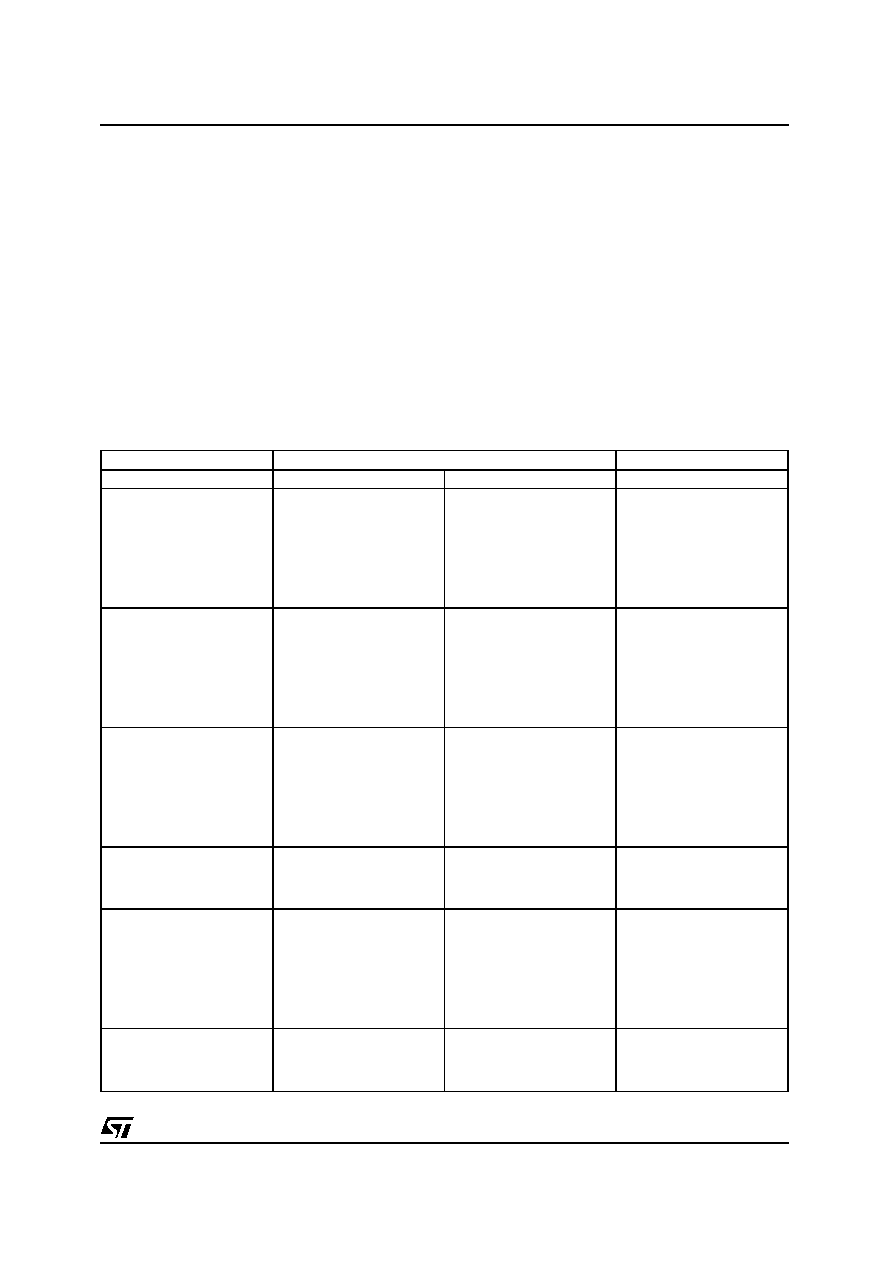

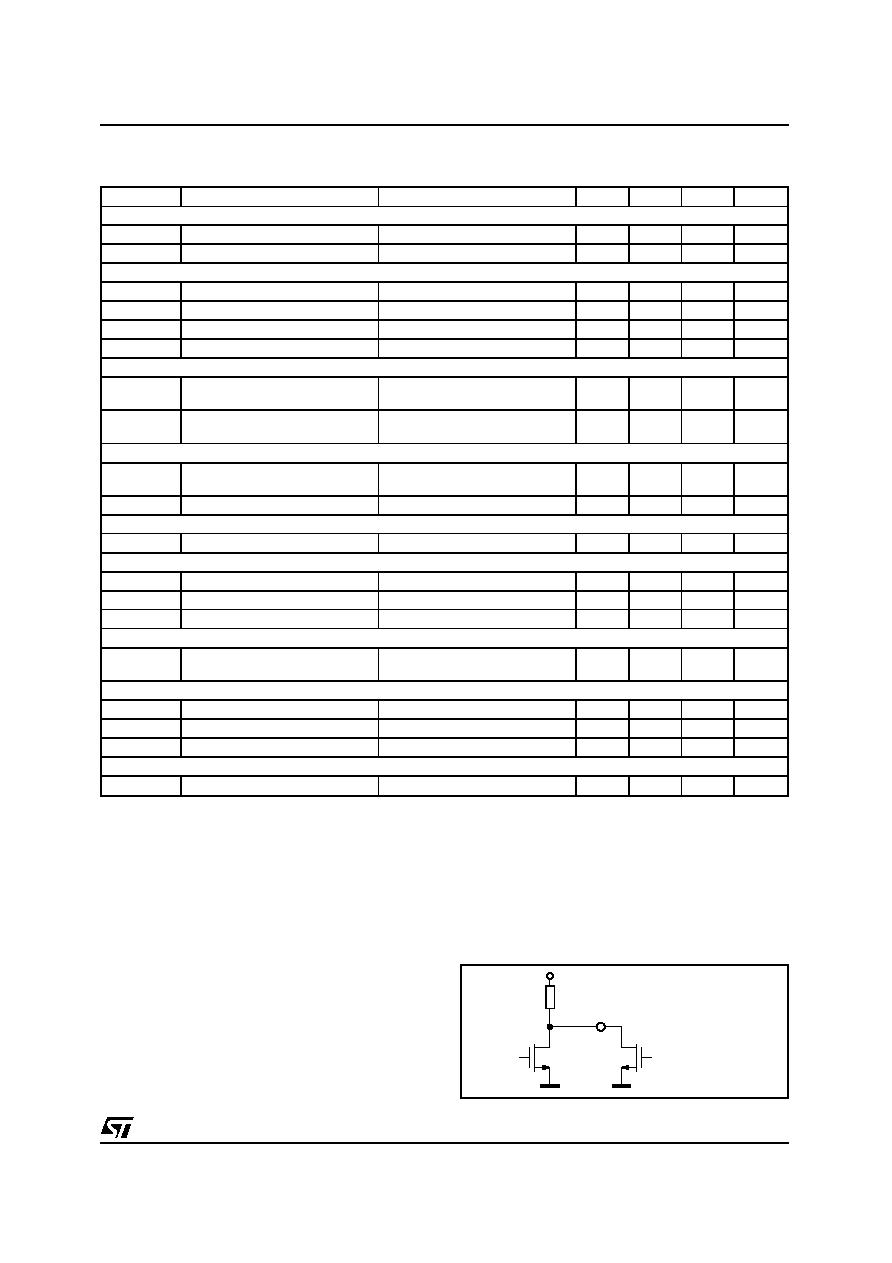

FUNCTIONAL DESCRIPTION

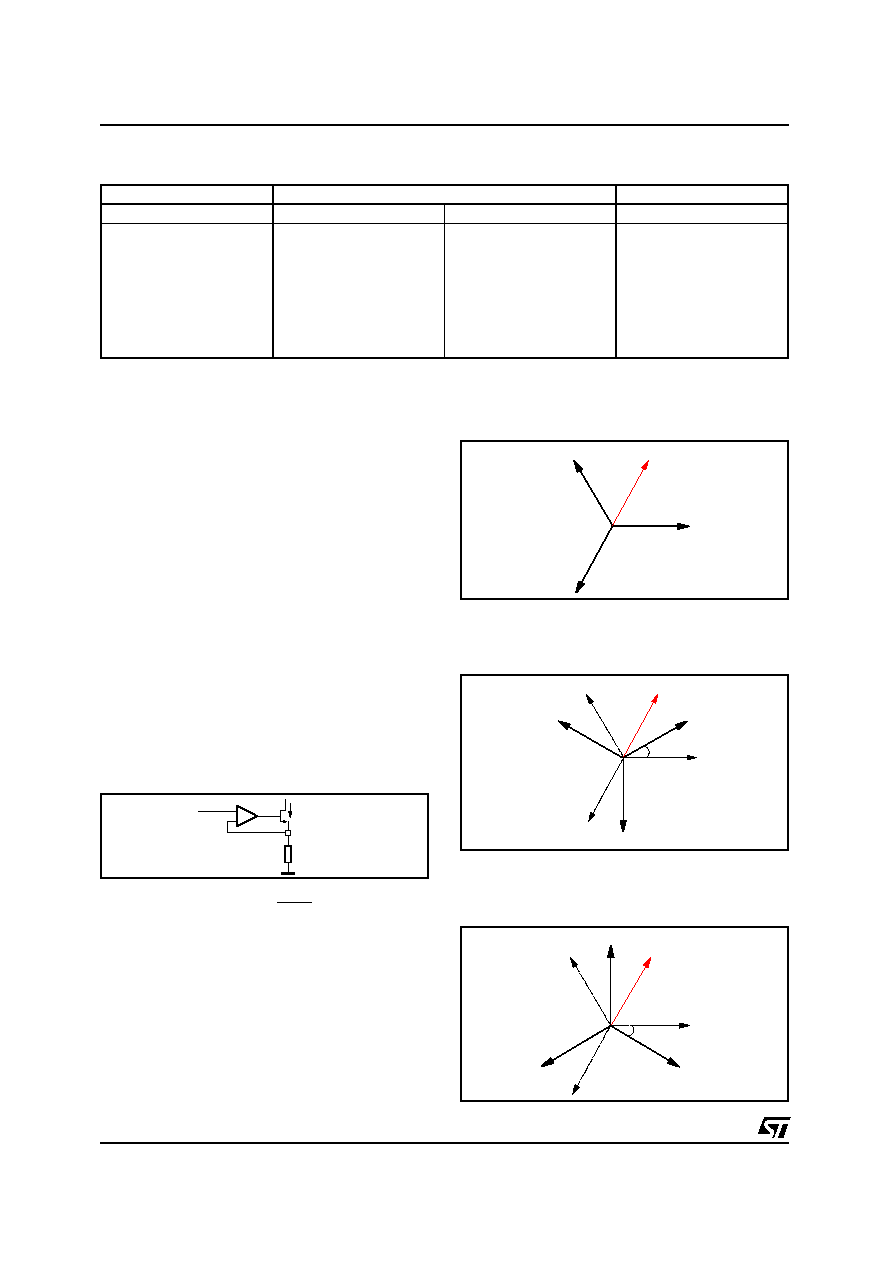

STB-Thermal protection

Controller drive STB pin by open drain.

When Thermal Shutdown is excited, the device

force this pin LOW.

Controller will manage STB to do a re-start.

When STB is LOW all the drivers are shut off.

Hall Sensor Bias

A regulator on chip supply a 3.3V+-10% refer-

ence on pin Bias. This regulator can supply an

output current up-to 15 mA.

Symbol

Parameter

Test Condition

Min.

Typ.

Max.

Unit

BIAS

V

BIAS

BIAS Output Voltage

V

CC

= 5V; 5mA < I < 15mA

3.25

3.75

V

I

Bmax

Max Output Current

15

mA

H+, H-

V

H

±

H+ H- Input Voltage Range

0

2.5

V

I

H

±

Input Leakage Current

V

in

= 0, +V

CC

-10

+10

µ

A

V

OFFISR

Comparator Offset

-15

+15

mV

VHy

Comparator Hysteresys

4

15

mV

MOTOR POWER STAGE

R

DSON

High and Low side FET on

Resistance

T

j

= 125; V

M

= 4.25V

I = 1.2A

2

I

U/V/W

Spindle Output Leakage

Current

V

M

= 15V

100

µ

A

CURRENT LIMITER

V

Lim

Internal Reference Voltage for

current limitation

220

240

260

mV

V

OFFLim

Comparator Offset

-15

+15

mV

THERMAL PROTECTION

T

S

Shutdown temperature

130

170

°C

UNDERVOLTAGE

V

ccth (fall)

Undervoltage threshold (fall)

2.9

-

-

V

V

ccth (rise)

Undervoltage threshold (rise)

-

-

3.4

V

V

ccth (hys)

Undervoltage threshold (hys)

-

0.1

-

V

SYSTEM FREQUENCY

f

sys

System frequency

PRS = 0

PRS = 1

10

20

20

34

MHz

MHz

SLEW RATE CONTROL

V

SRC

SRC Output Voltage

1.25

V

I

SRC

Output Current

500

µ

A

R

SRC

External Resistor on pin SRC

10

K

ISR

V

ISR

Input Range

0

2

V

Note 1: An SMBJIZAVCL-TR is recommended to clamp V

M

in case of high impedance on power supply line.

DC ELECTRICAL CHARACTERISTICS (continued)

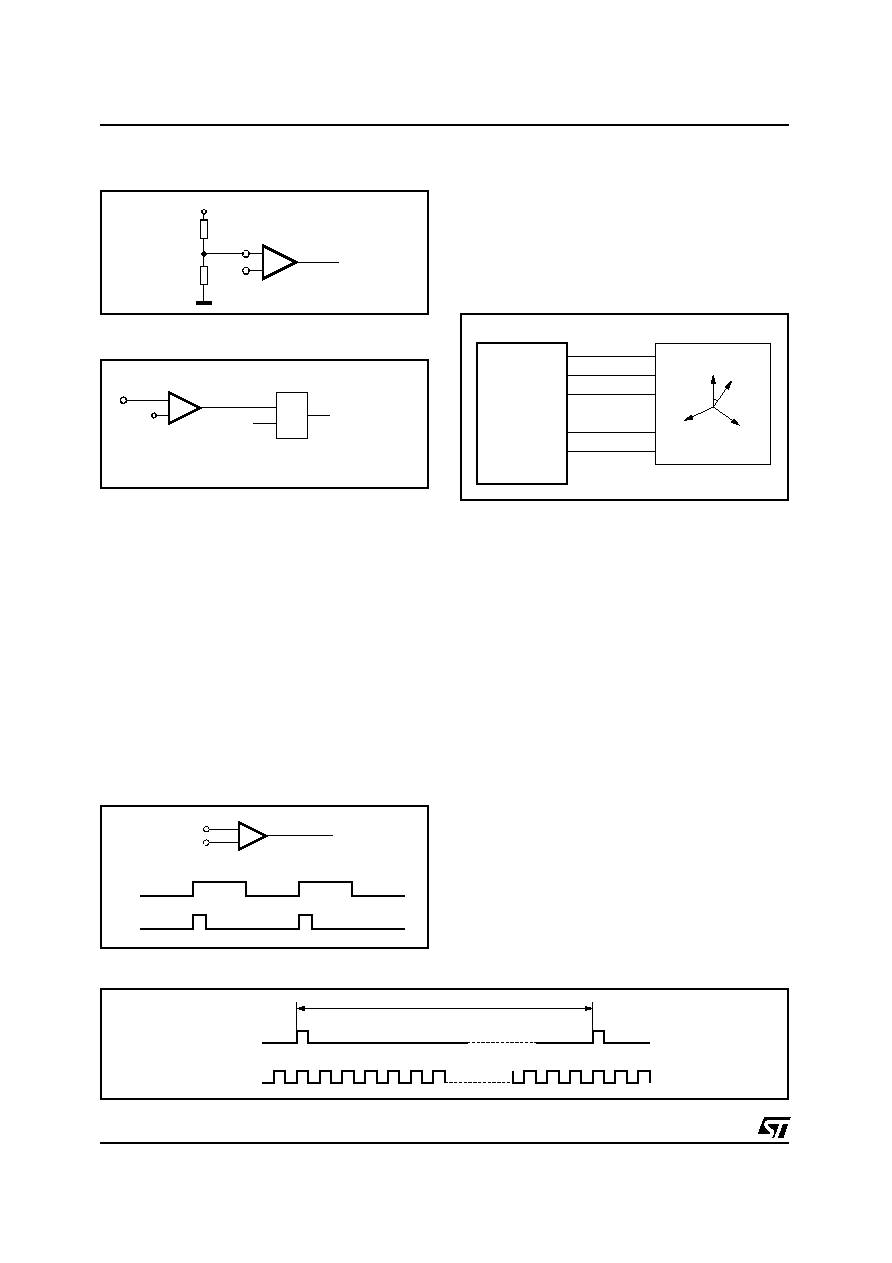

R PULL UP

OVER TEMP

STB

D98IN880

Figure 1.

L7203

5/13

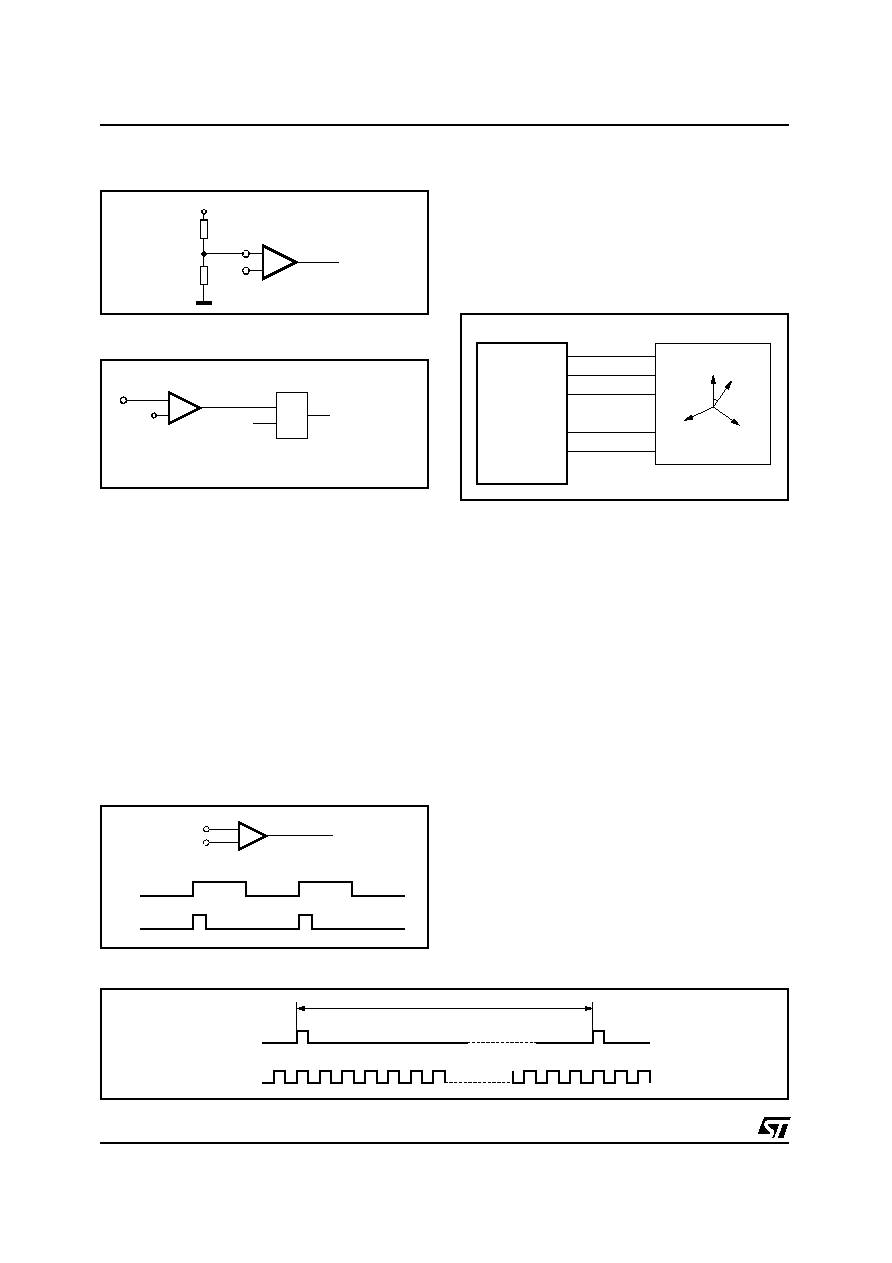

Inductive Sense Start Up Block

The inductive sense method allows to determine

the position and the direction of the starting rota-

tion of the motor.

With the rotor at rest, a voltage Vn is applied sub-

sequently to two motor phases, according to this

sequence: UW, VW, VU, WU, WV, UV.

A timer measures the rise time dT to reach the

reference current ISR in each phase.

This reference is fixed on the pin ISR with a resis-

tor divider between the pin BIAS and GND.

Through a comparator is possible to determine

the phase which has the minimum rise time and

so the rotor position is univocally determinated.

The start up is a procedure allowing to start the

motor avoiding any backrotation. This procedure

is realized by a customized logic on chip (no

modification required in the external microproces-

sor software).

For the Motor Connection please refer to the Fig. 4.

Current Limiter

The current limiter aim is to avoid that the current

in the motor winding overides a fixed threshold

value. The voltage input at the pin RF1 is com-

pared with an internal 0.2V reference.

When the current exceeds the Ilimit value a flip-

flop is reset masking (through a combinational

logic) the signal to the power windings.

Rotor Position Detector

This block is connected to the Hall Sensor Out-

put. A comparator with hysteresis receives the

sinusoidal hall-sensor signal and generates a

squared signal HOUT.

The Zero-Cross signal is generated starting from

the HOUT signal as in fig. 5.

The HOUT signal can be read from the micro-

processor on the output open drain pin HFG.

Frequency multiplier

The Frequency Multiplier generates the memory

scan frequency (Fscan) starting from the Zero-

Cross (ZC) signal from the Rotor Position Detec-

tor block. The scan frequency relates to the rate

of the samples of the input signals.

The number of wave samples in a period T is 36,

so this circuit generates 36 pulses between 2

Zero Crossing.

CURRENT LIMIT

RF1

D98IN882

0.2V

-

+

R

S

TO THE POWER STAGE

SET EVERY

255 CLOCK

CYCLE

INTERNAL

REFERENCE

Figure 3.

HOUT

H+

D98IN883A

-

+

COMPARATOR WITH HYSTERESIS

H-

HOUT

ZC

Figure 5.

T

ZC

Fscan

1

2

3

4

5

6

7

8

35

36

D98IN879

Figure 6.

R1

TIMER

ISR

D98IN881

BIAS

RF1

R2

-

+

Figure 2.

L7203

30°

Bemf coil B

Hall sensor

Bemf coil C

Bemf coil A

MOTOR COIL A

MOTOR COIL B

MOTOR COIL C

U

V

W

H+

H-

H+

H-

MOTOR

D01IN1175

Figure 4. Motor Connections.

L7203

6/13

Fscan has a frequency 36 times of (1/T). The

Fscan is generated from the Zero-cross fre-

quency measured at the previous cycle.

So, if the motor speed changes, the zero-cross is

not constant, the Frequency Multiplier adjusts the

scan clock, ensuring the synchronization between

the Zero-Cross signal and the sinusoidal output

voltage.

Memory and Memory Scan

The memory stores 3x36 samples describing 3

signals. As each sample is represented in a byte,

it may have a value in the range 0 to 255.

The shape of these three signals are designed in

order to generate three sinusoidal voltages

across the Motor coils ensuring the highest per-

formances in term of power losses and motor

speed. The shape of the signals are reported in

fig. 7.

In Fig 8 is swown the "differential" voltage across

the motor coil U and the motor coil V. Obviously,

the voltage shape across the motor coil U and W

and the voltage across the motor coil V and W

are also sinusoidal and dephased of 120 and 240

degrees respect the voltage shown in fig. 8.

The Memory and Memory scan block receives

the scan clock, and at each clock provides the

sample addressed by an internal address regis-

ter.

This register is initialized with the memory ad-

dress of the wave sample synchronized with the

Zero-Cross signal. The maximum efficiency (i.e.

the maximum motor speed for a particular value

of current) for the motor driving may be reached

ensuring a particular value PH of dephase be-

tween the Zero-Cross signal and the voltage out-

put signal.

This value is written by the external controller us-

ing PHS pin (see Phase Shift Block section).

Kval Block and PWM interface

This unit contains a register storing the Kval

value. The Kval value represents a multiplying

factor to modulate the 3 profile signals amplitude

and it is generated starting from the PWMIN sig-

nal coming from the external system controller.

The Kval block receives the PWMIN signals and

calculates the Kval value through the reference

triangular signal.

This signal is generated by a 10 bit counter that

starts counting from 1023 to 0 at Fsys rate, and

then restart up to 1023. The resolution is

±

1LSB.

Internal triangular wave is synchronized with the

PWMIN falling edge.

The PWMIN signal contains information regard-

ing both the amplitude and to the sign of the con-

trol variable. If the duty cycle is less than 50% the

Kval is in the range (-1023, -1), while if the duty

cycle is equal or greater than 50% the kval is in

the range (0, 1023).

A negative Kval value (i.e. PWM duty cycle from

0 to 50%) indicates an active brake and gener-

ates a 180 degree shift in the voltage profile

scan.

The rising edge of the PWMIN signal determines

the kval on the reference triangular waveform.

If the PWMIN signal is stable during the entire cy-

cle, the Kval is evaluated according to the follow-

ing rule:

- PWMIN signal stable to 1 -> Kval = +1023

- PWMIN signal stable to 0 -> Kval = -1023

In order to ensure the synchronization between

INTERNAL

REFERENCE

SIGNAL

PWMIN

0

1023

KVAL < 0

KVAL > 0

KVAL < 0

D98IN884

Figure 9.

U-W

D98IN931

Figure 8.

V

U

W

D98IN930

Figure 7.

L7203

7/13

the PWMIN signal and the internal signals, the

PWMIN signal rate must be calculated by the ex-

ternal microcontroller using the same frequency

signal provided to the chip through the pin fsys.

Digital Multiplier

This unit contains a multiplier executing the multi-

plication of each sample provided by the memory

by the value stored in kval register.

The output value is a 10-bit word, plus the sign bit.

PWM Converter

The PWM converter receives from the digital mul-

tiplier three 10 bit digital number and converts it

into three PWM signals.

A counter counts up (from 0 to 255) and down

(from 255 to 0) at the Fsys rate in continuos

mode. Three 8-bit input registers are written with

the 8 most significant bit of the word to be con-

verted and compared to the counter value. The

comparator output is:

COMPARATOR

8 MSB

OUTPUT MULTIPLIER

D98IN886

OUTPUT

OUTPUT PWM:

LSB

00

01

10

11

WHERE:

A HALF FSYS PERIOD

A FSYS PERIOD

Figure 11.

COUNTER

OUTPUT COMPARATOR

0

255

D98IN885A

510 Tsys

Figure 10.

L7203

8/13

- 0, if the input value is smaller than the counter

output

- 1, if the input value is equal or greater than the

counter output

The comparator output is "adjusted" with a com-

binational logic with the 2 low significant bit of the

word to be converted in order to reach a 10 bit

precision.

The comparator output duty cycle is extended

with a half fsys period for every low bit step how

is showed in the figure 11.

Phase Shift Block

This block regulates the phase of the driving sig-

nal to control the dephasing between the Zero-

Cross signal and the voltage sinusoidal output

signal.

It is possible to demonstrate that the maximum

efficiency for the motor driving may be reached

ensuring a particular value PH of dephase be-

tween the Zero-Cross signal and the voltage out-

put signal.

The Phase Shift BLock, starting from the PHS in-

put signal synchronize the wave output with the

Zero-Cross signal to ensure the optimum

dephase.

The PHS signal expresses the phase shift

through the duration of its value according to the

following rule:

Table 1.

PHS on

NPhase

Phase Shift (degree)

time

µ

s (Tsys = 50ns)

decimal

bit

0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0

1

2

3

4

5

6

7

00000 000

00000 001

00000 010

00000 011

00000 100

00000 101

00000 110

00000 111

LATCH

1.25

2.50

3.75

5.00

6.25

7.50

8.75

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

8

9

10

11

12

13

14

15

00001 000

00001 001

00001 010

00001 011

00001 100

00001 101

00001 110

00001 111

10

11.25

12.50

13.75

15.00

16.25

17.50

18.75

3.2

3.4

3.6

3.8

4.0

4.2

4.4

4.6

16

17

18

19

20

21

22

23

000010 000

000010 001

000010 010

000010 011

000010 100

000010 101

000010 110

000010 111

20

21.25

22.50

23.75

25.00

26.25

27.50

28.75

.

.

.

.

.

.

.

.

.

.

.

.

16.0

16.2

16.4

16.6

16.8

17.0

17.2

17.4

80

81

82

83

84

85

86

87

001010 000

001010 001

001010 010

001010 011

001010 100

001010 101

001010 110

001010 111

100

101.25

102.50

103.75

105.00

106.25

107.50

108.75

.

.

.

.

.

.

.

.

.

.

.

.

L7203

9/13

PHS on = tsys * 4 * Nphase

where: tsys = 50ns if fsys = 20MHz

The resulting PHASE SHIFT value is:

PHASE SHIFT = Nphase(8:3) x 10 +

Nphase(2:0) x 1.25

For istance if Nphase = 00011 110

PHASE SHIFT = 3 x 10 + 6 x 1.25 = 37.5

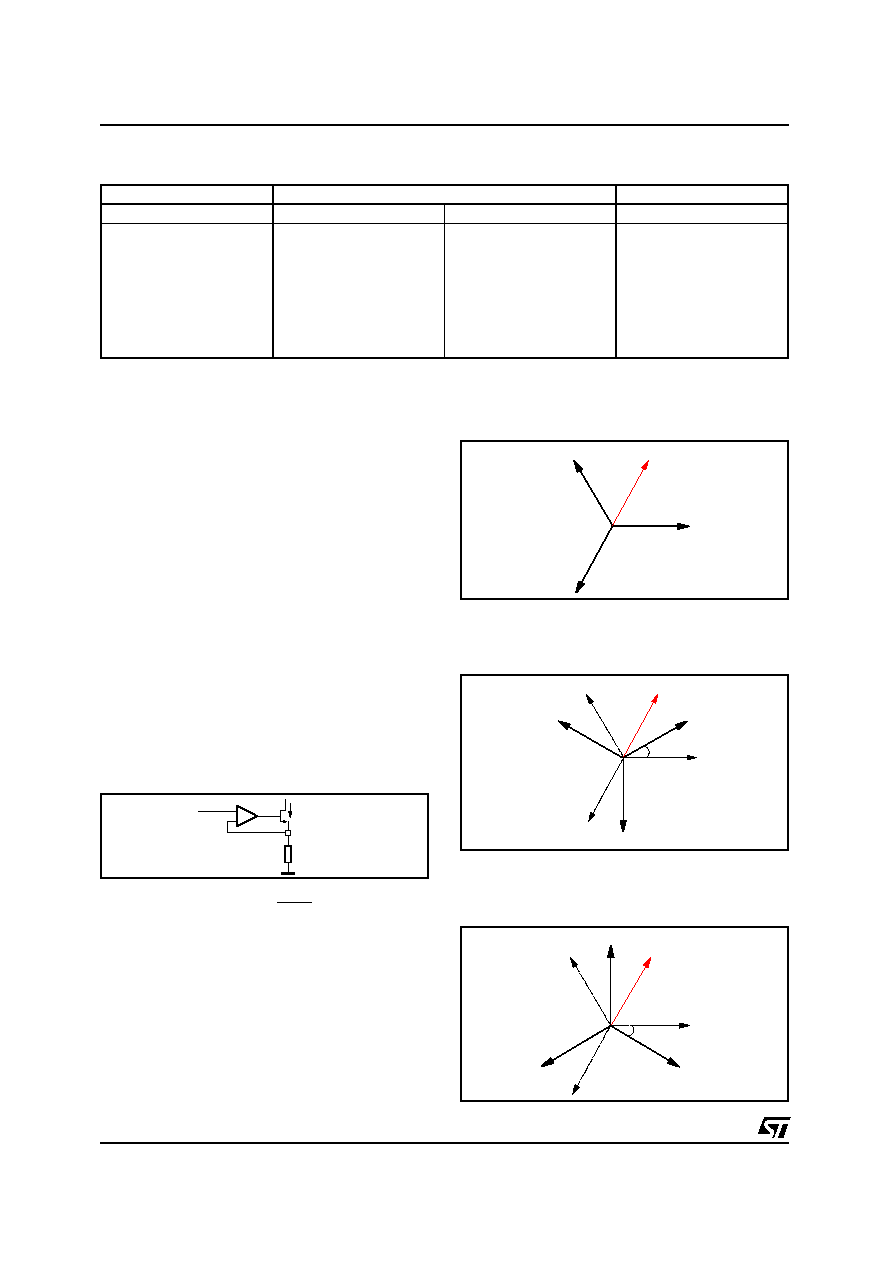

Low Voltage Detector

This circuit detects if V

CC

is lower than a fixed

threshold. If this event happens the internal logic

is resetted and the output FETS are forced in

High impedance.

Slew Rate Control Circuit

This circuit fixes the slew rate for the output stage

in order to reduce EMI.

A reference current is generated by means of an

internal reference voltage and an external resis-

tor.

The I

SRC

is used to fix slew rate with a linear law:

SLEW RATE = R

SLR/ISRC

V

REF

R

EXT

R

ext

recommended value >10K

Prescaler Pin

The PRS Pin should be forced to ground when

the FSYS frequency is lower (or equal) than

20MHz and should be forced to V

CC

when FSYS

frequency is higher than 20MHz, in order to set

the correct timing during the inductive sense,

start up and resynchronization phases.

Example of different phase shift settings are

shown in the following pictures.

PHS on

NPhase

Phase Shift (degree)

time

µ

s

decimal

bit

56.0

56.2

56.4

56.6

56.8

57.0

57.2

57.4

> 57.6

280

281

282

283

284

285

286

287

288

100011 000

100011 001

100011 010

100011 011

100011 100

100011 101

100011 110

100011 111

100100 000

350

351.25

352.50

353.75

355.00

356.25

357.50

358.75

0

Table 1. (continued)

V

REF

V

REF

I

SRC

=

SRC

R

ext

/

R

ext

+

-

Figure 12.

Hall sensor

OUT V

OUT U

OUT W

Figure 13. Phase relation between OUTPUT

sinusoidal voltage (PWM_IN > 50%)

and Hall sensor signal writin Phase

shift = 0° (default value)

Hall sensor

OUT V

OUT U

OUT W

30°

Figure 14. Phase relation between OUTPUT

sinusoidal voltage (PWM_IN > 50%)

and Hall sensor signal writing Phase

shift = 30°

Hall sensor

30°

OUT V

OUT U

OUT W

Figure 15. Phase relation between OUTPUT

sinusoidal voltage (PWM_IN > 50%)

and Hall sensor signal writing Phase

shift = 330°

L7203

10/13

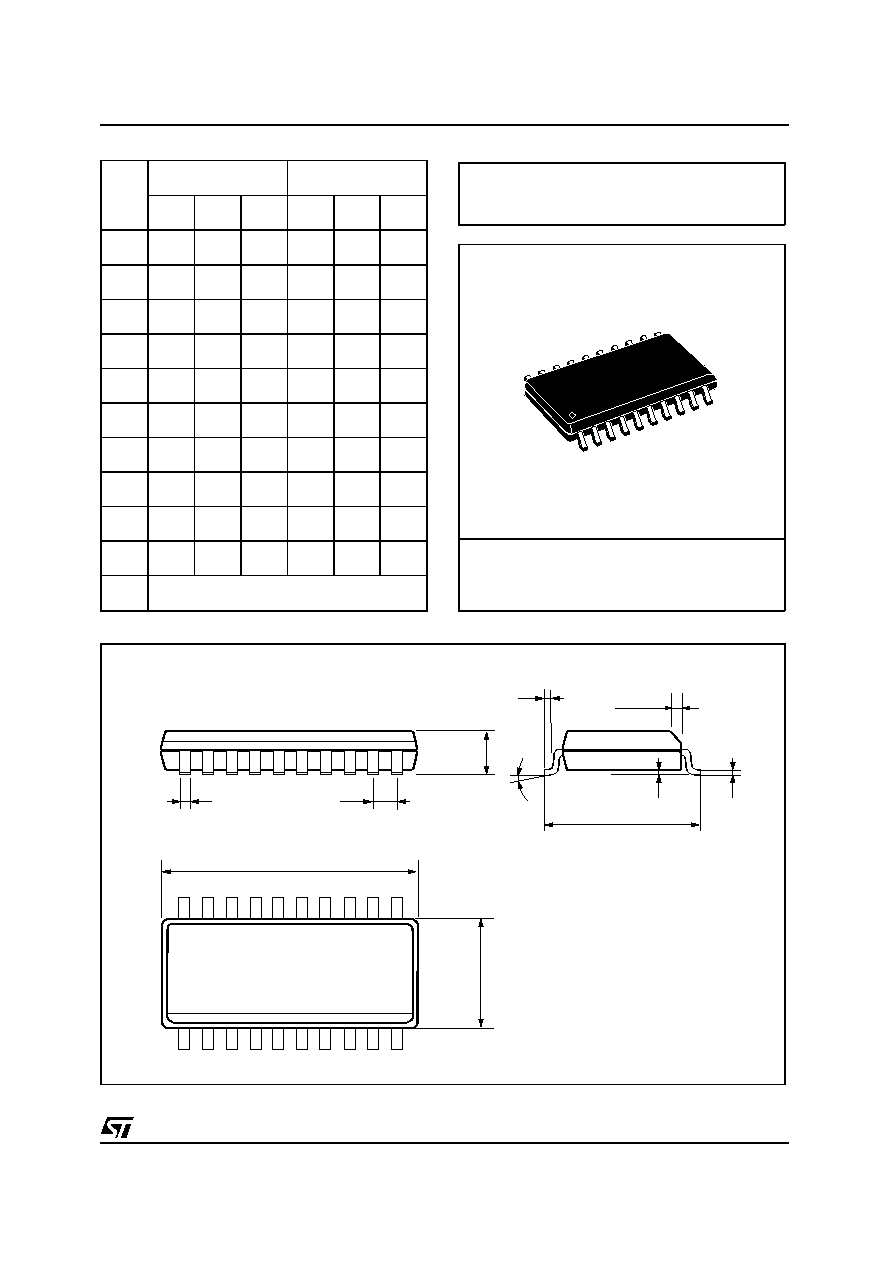

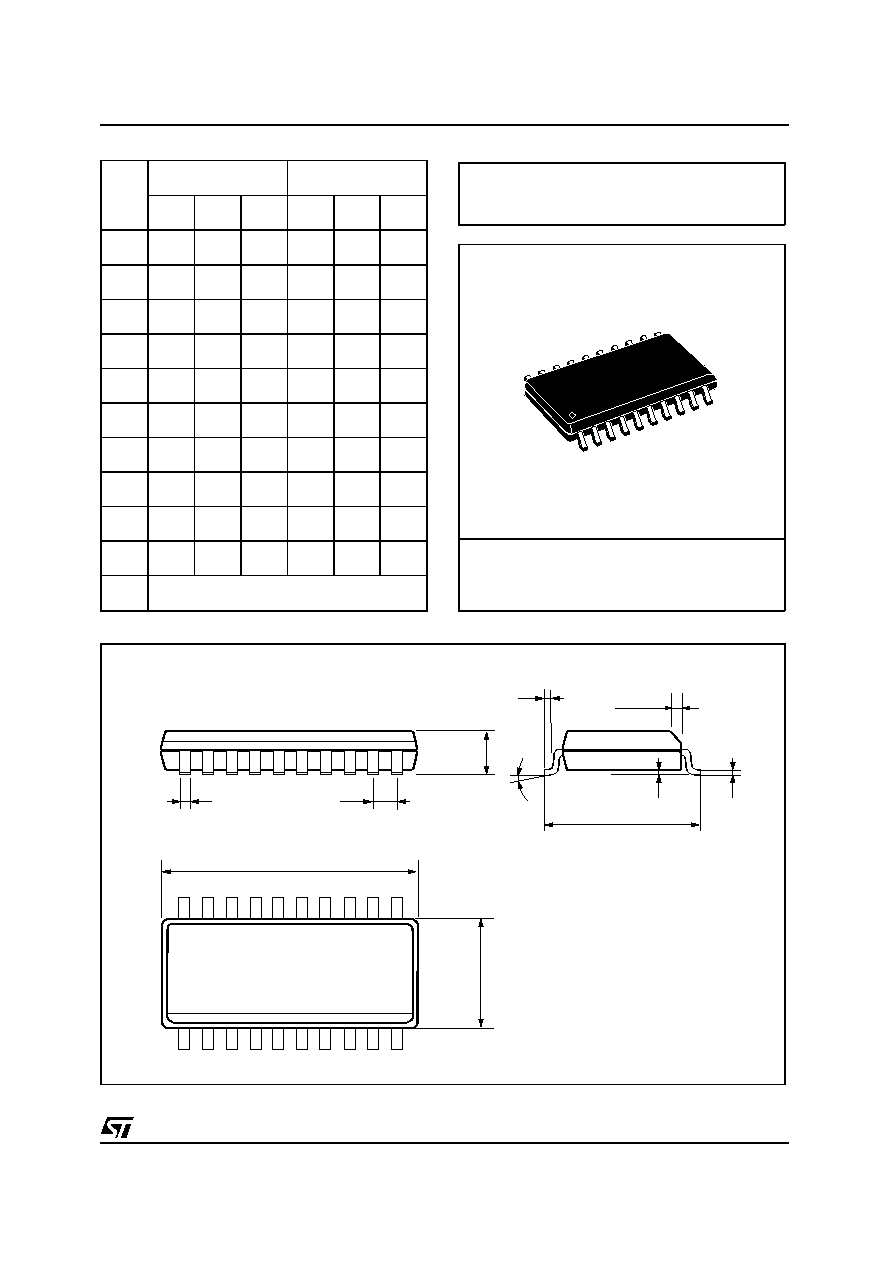

1

1

0

11

20

A

e

B

D

E

L

K

H

A1

C

SO20MEC

h x 45°

SO20

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

2.35

2.65

0.093

0.104

A1

0.1

0.3

0.004

0.012

B

0.33

0.51

0.013

0.020

C

0.23

0.32

0.009

0.013

D

12.6

13

0.496

0.512

E

7.4

7.6

0.291

0.299

e

1.27

0.050

H

10

10.65

0.394

0.419

h

0.25

0.75

0.010

0.030

L

0.4

1.27

0.016

0.050

K

0° (min.)8° (max.)

OUTLINE AND

MECHANICAL DATA

L7203

11/13

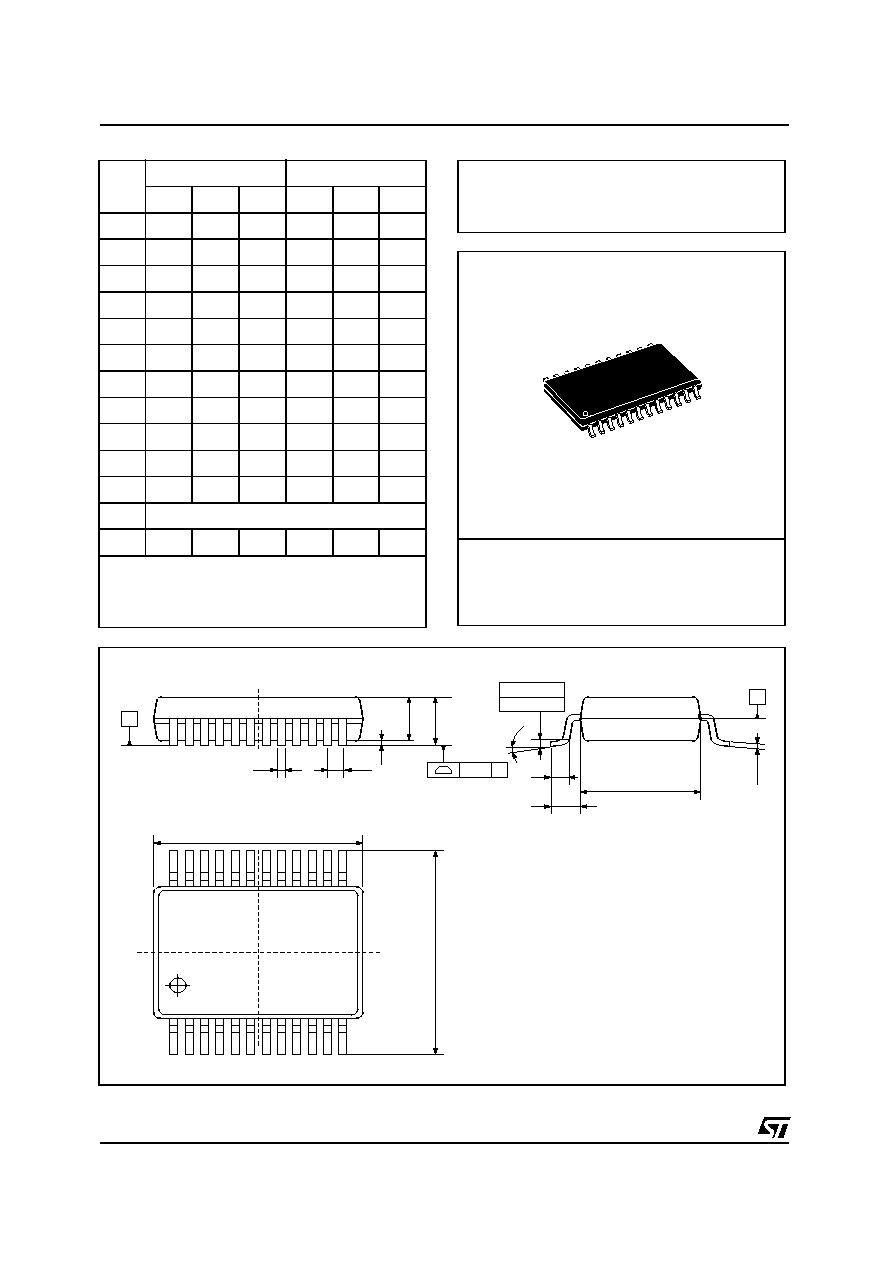

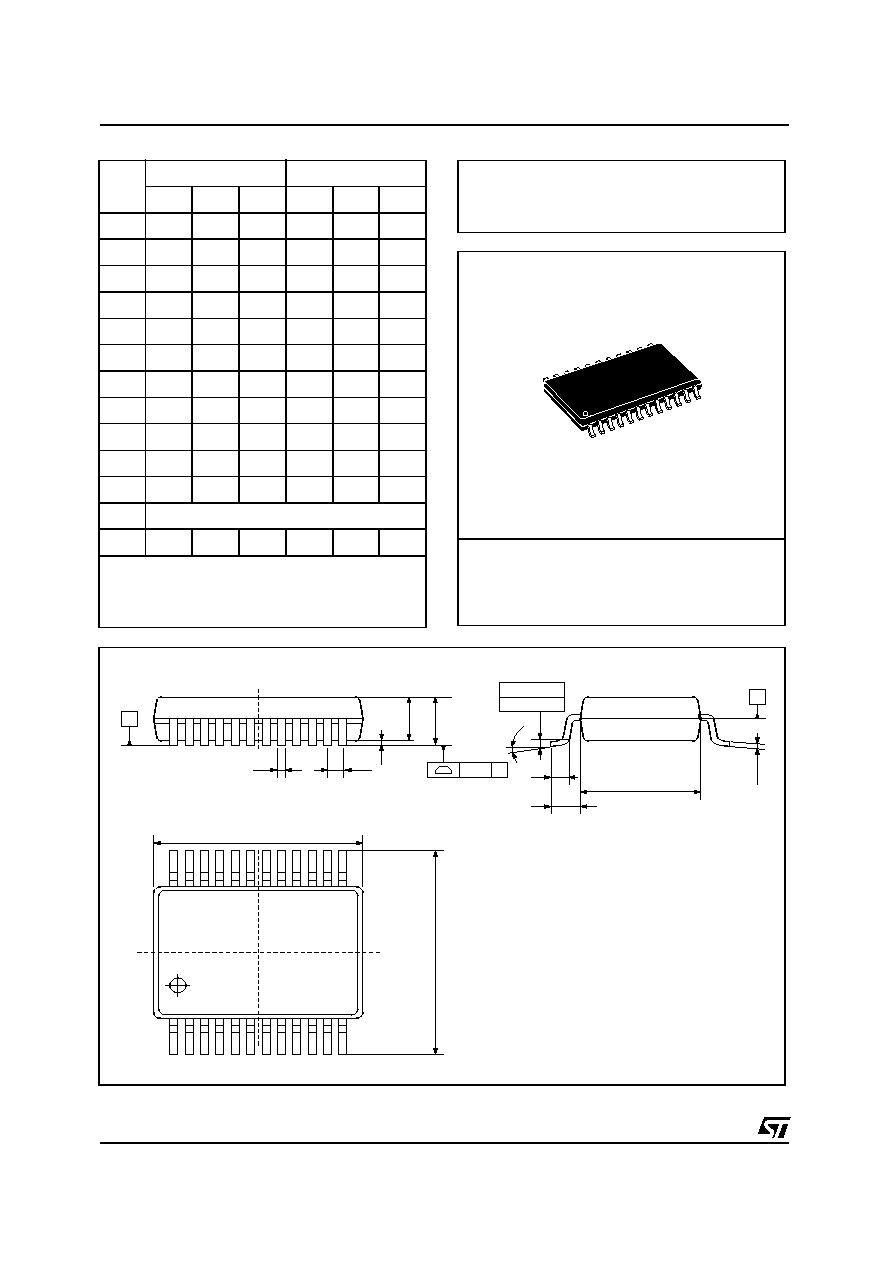

OUTLINE AND

MECHANICAL DATA

DIM.

mm

inch

MIN.

TYP.

MAX.

MIN.

TYP.

MAX.

A

2.00

0.079

A1

0.05

0.002

A2

1.65

1.75

1.85

0.060

0.079

B (2)

0.22

0.38

0.009

0.015

C

0.09

0.25

0.003

0.01

D (1)

7.9

8.2

8.5

0.31

0.32

0.33

E

7.4

7.8

8.2

0.29

0.30

0.32

E1 (1)

5.0

5.3

5.6

0.20

0.21

0.22

e

0.65

0.025

L

0.55

0.75

0.95

0.022

0.029

0.004

L1

1.25

0.05

k

0° (min), 4° (typ), 8° (max)

ddd

0.1

0.004

(1) "D and E1" dimensions do not include mold flash or protu-

sions, but do include mold mismatch and are mesaured at

datum plane "H". Mold flash or protusions shall not exceed

0.20mm in total (both side).

(2) "B" dimension does not include dambar protusion/intrusion.

SSO24

0053237

B

e

A2

A

1

1

2

13

24

D

L

L1

E1

C

E

K

SSO24ME

SEATING

PLANE

C

A1

ddd

C

0.25mm

GAGE PLANE

DATUM

PLANE

H

Shrink Small Outline Package

L7203

12/13

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2001 STMicroelectronics Printed in Italy All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

L7203

13/13