/home/web/htmldatasheet/RUSSIAN/html/sharp/177825

P

RODUCT

S

PECIFICATIONS

Mobile Liquid Crystal Displays Group

LQ057Q3DC12

TFT-LCD Module

Spec. Issue Date:

May 30, 2005

No: LA1-

05016

LCP-0

5016-1

NOTICE

This publication is the proprietary of SHARP and is copyrighted, with all rights reserved. Under the copyright laws, no part of

this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical for any purpose, in

whole or in part, without the express written permission of SHARP Express written permission is also required before any use of

this publication may be made by a third party.

The application circuit examples in this publication are provided to explain the representative applications of SHARP's devices

and are not intended to guarantee any circuit design or permit any industrial property right or other rights to be executed. SHARP

takes no responsibility for any problems related to any industrial property right or a third party resulting from the use of

SHARP's devices, except for those resulting directly from device manufacturing processes.

In the absence of confirmation by device specification sheets, SHARP takes no responsibility for any defects that occur in

equipment using any of SHARP's devices, shown in catalogs, data books, etc. Contact SHARP in order to obtain the latest

device specification sheets before using any SHARP's device.

SHARP reserves the right to make changes in the specifications, characteristics, data, materials, structures and other contents

described herein at any time without notice in order to improve design or reliability. Contact SHARP in order to obtain the latest

specification sheets before using any SHARP's device. Manufacturing locations are also subject to change without notice.

Observe the following points when using any device in this publication. SHARP takes no responsibility for damage caused by

improper use of the devices.

The appropriate design measures should be taken to ensure reliability and safety when SHARP's devices are used for equipment

such as:

· Transportation control and safety equipment (i.e., aircraft, trains, automobiles, etc.)

· Traffic signals

· Gas leakage sensor breakers

· Alarm equipment

· Various safety devices etc.

SHARP's devices shall not be used for equipment that requires extremely high level of reliability, such as:

· Military and space applications

· Nuclear power control equipment

· Medical equipment for life support

Contact a SHARP representative, in advance, when intending to use SHARP's devices for any "specific" applications other than

those recommended by SHARP.

Contact and consult with a SHARP representative if there are any questions about the contents of this publication.

LA1-05016-2

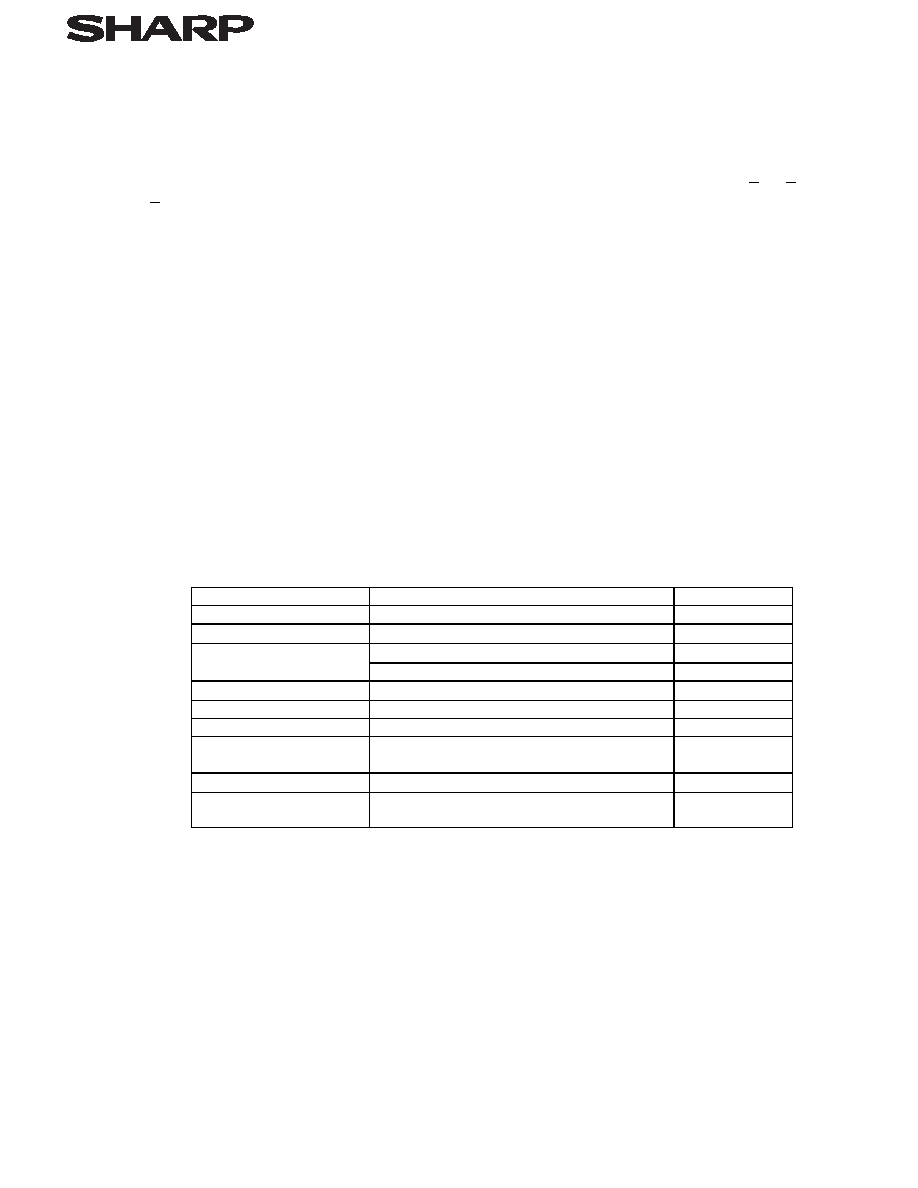

1. Application

This specification applies to color TFT-LCD module, LQ057Q3DC12.

2. Summary and Features

This module is a color active matrix LCD module incorporating amorphous silicon TFT (Thin Film

Transistor). It is composed of a color TFT-LCD panel, driver ICs, control circuit (PWB), FPC, front

and back polarizer, sealed case, backlight unit. Graphics and texts can be displayed on a 320×RGB×

240 dots panel with 262,144 colors by suitable control supplying from the outside.

It isn't composed DC/AC inverter for a backlight drive.

The input of QVGA and VGA signal is possible.

Wide Viewing Angle technology is adopted. (The most suitable viewing angle is in the 12

o'clock direction.)

By adopting an active matrix drive, a picture with high contrast is realized.

Reflection due to external light is minimized through the use of a low reflection black matrix .

A thin, light and compact module is accomplished through the use of COG mounting

technology.

Through the use of high color purity color filter and TN-normally white mode excelled in

color reproducibility, an image with highly natural color reproduction is realized.

High viewing angle and high brightness (500cd/m2).

An inverted video display in the vertical / horizontal directions is possible.

This module is adapted to RoHS compliance.

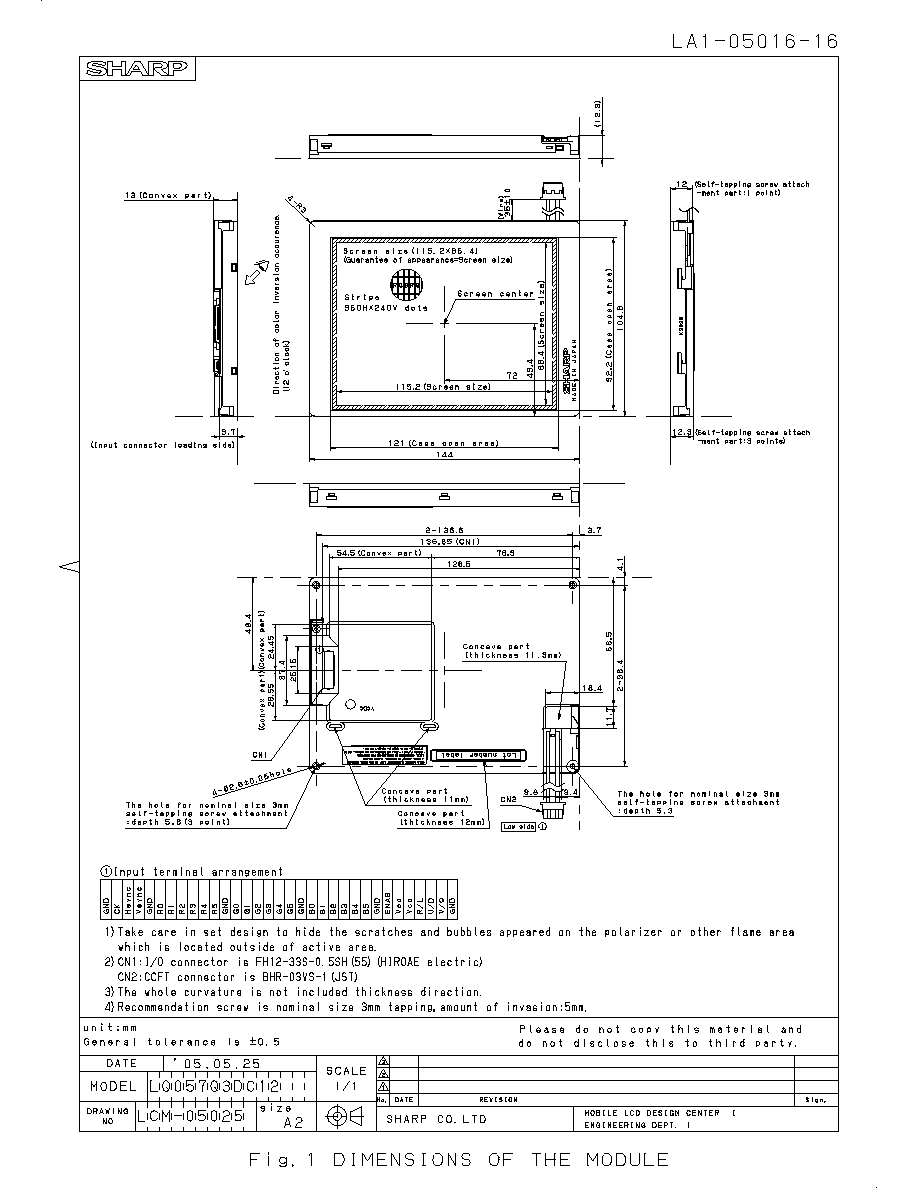

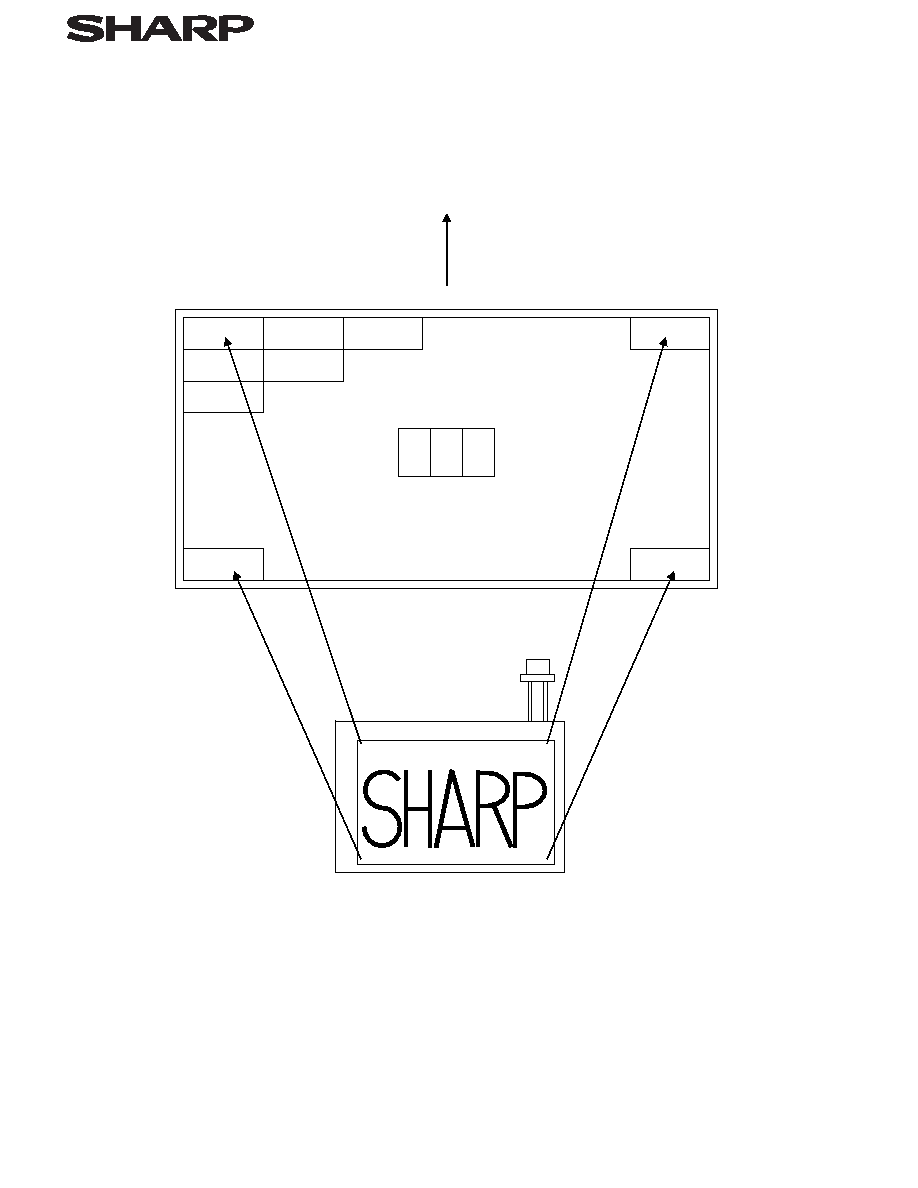

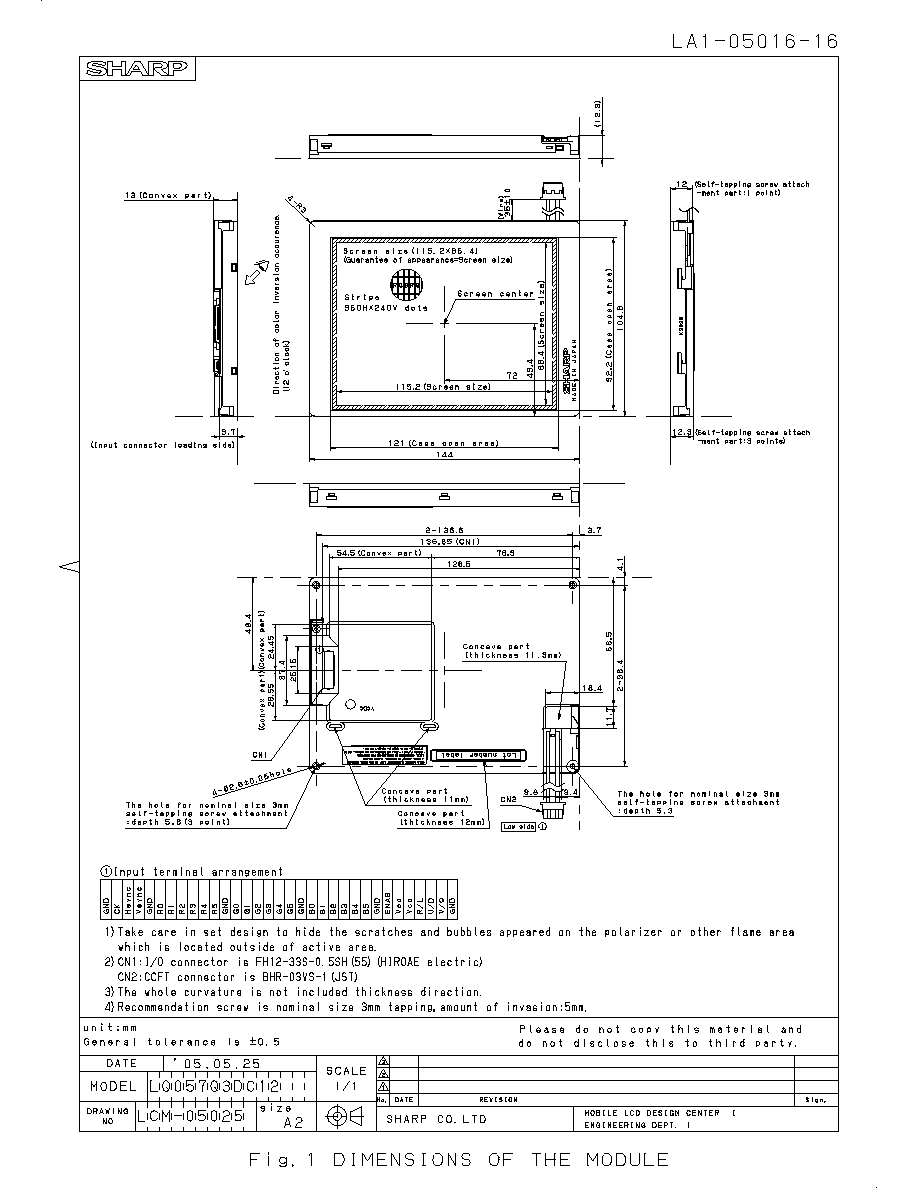

3. Mechanical specifications

table 3-1

Parameter Specifications

Units

Screen size

14.4 (5.7 inch) diagonal

cm

Active area

115.2 (H) × 86.4 (V)

mm

Display format

320(H)×240(V)

pixels

(1 pixel = R + G + B dots)

Dot pitch

0.360 (H) × 0.360 ()

mm

Pixel configuration

R,G,B Stripe configuration

Display mode

Normally white

Outline dimension

Note1-1

144.0 (W)×104.6 (H)×13.0(D)

mm

Mass

220±20

Surface treatment

(Surface hardness)

Hard coat (3H)

Note 1-1

A connector of backlight is excepted.

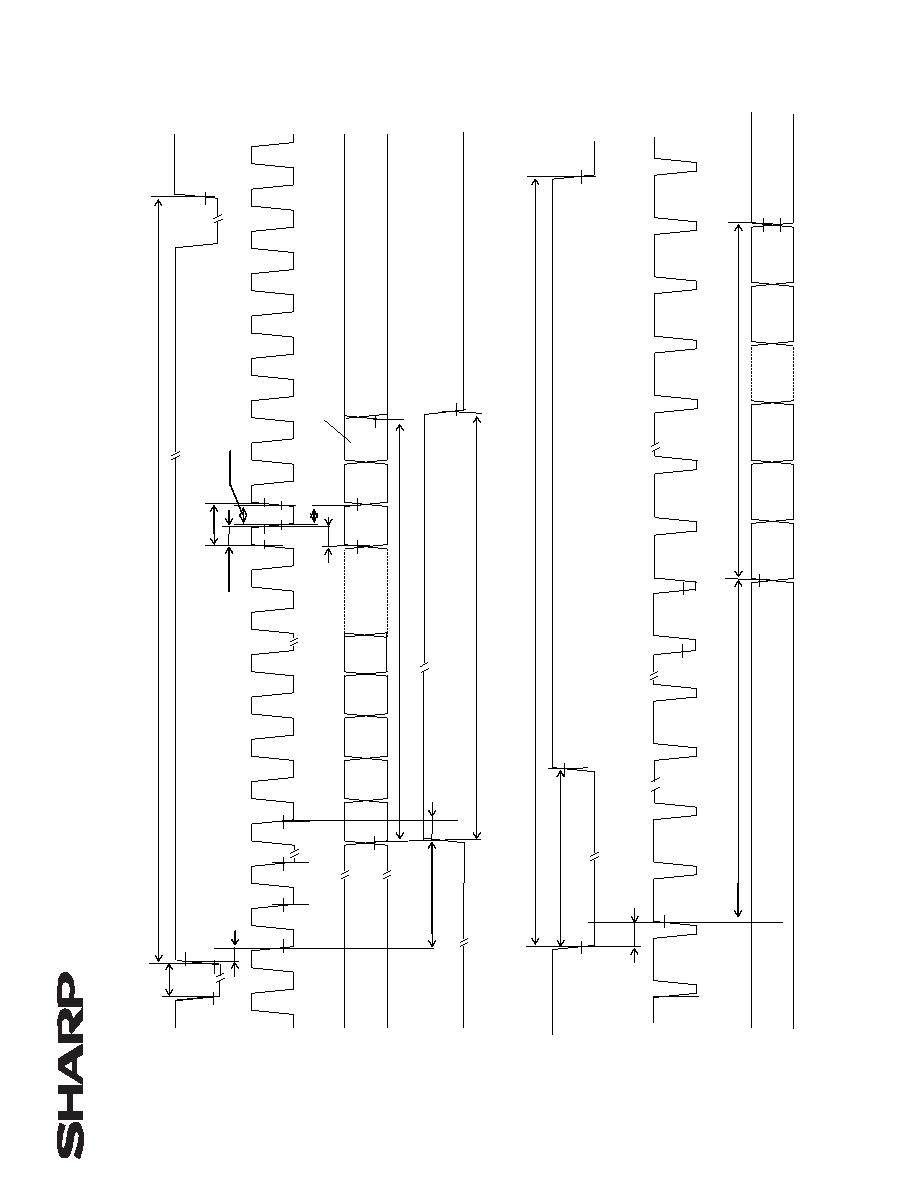

A figure of outline dimension is shown in Fig. 1.

LA1-05016-3

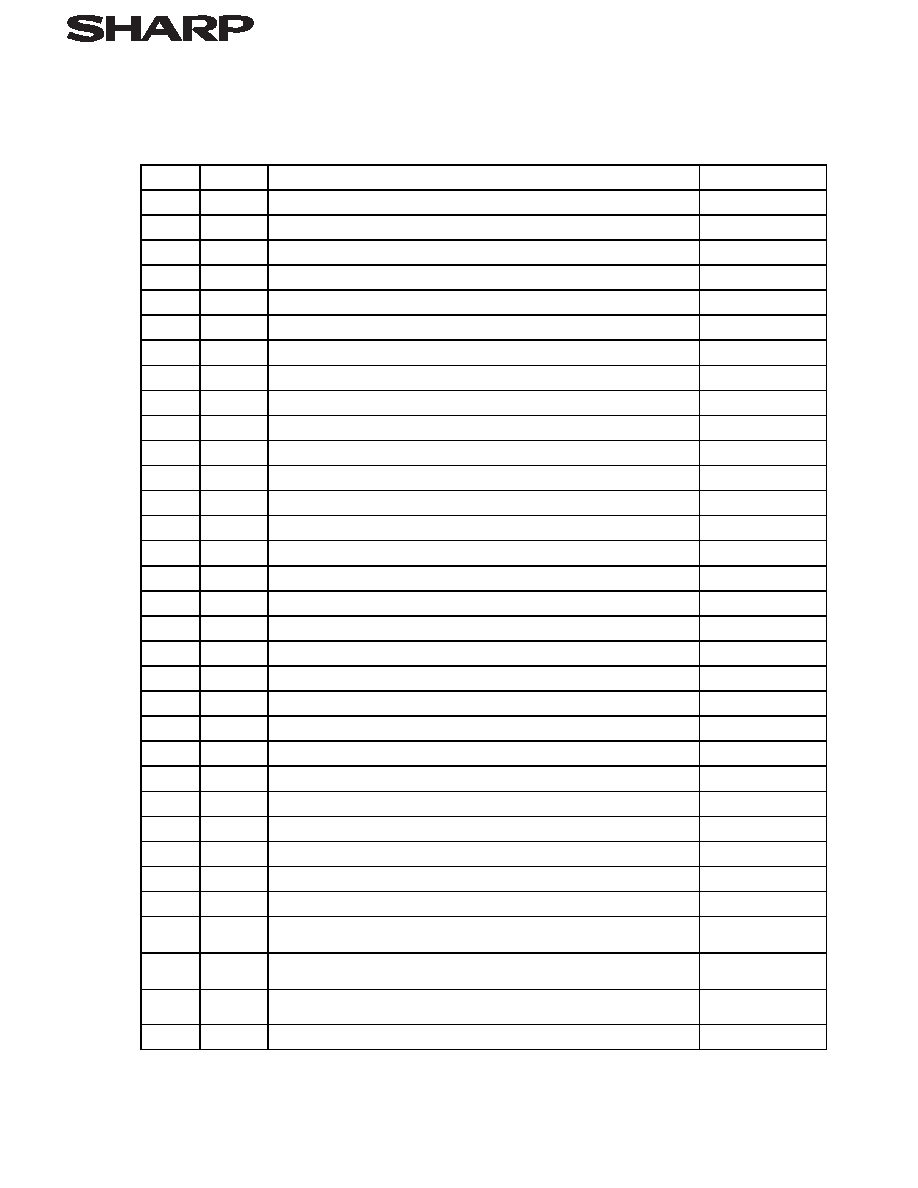

. Input terminal

4-1. TFT-LCD panel driving part

CN1 Used connector: FH12-33S-0.5SH(55) (HIROSE ELECTRIC C0.,LTD.)

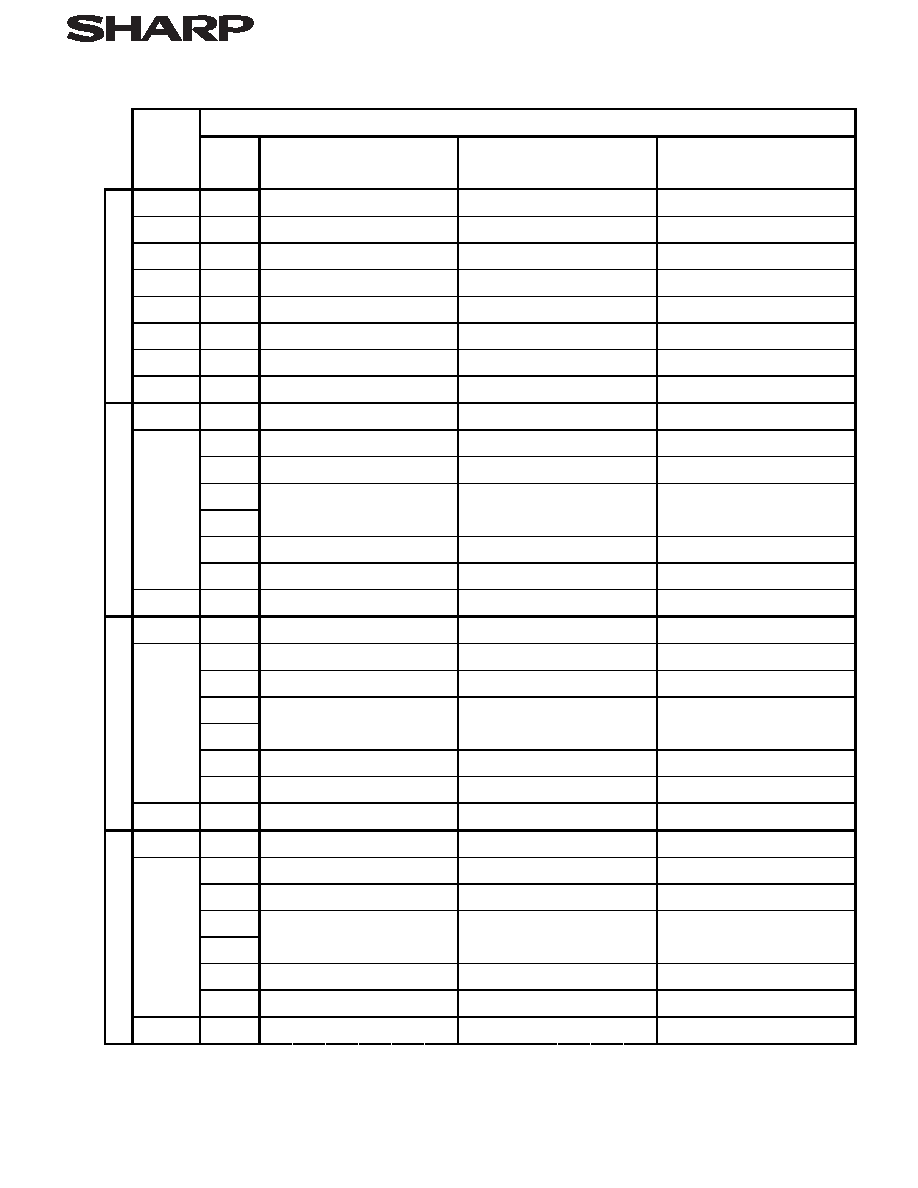

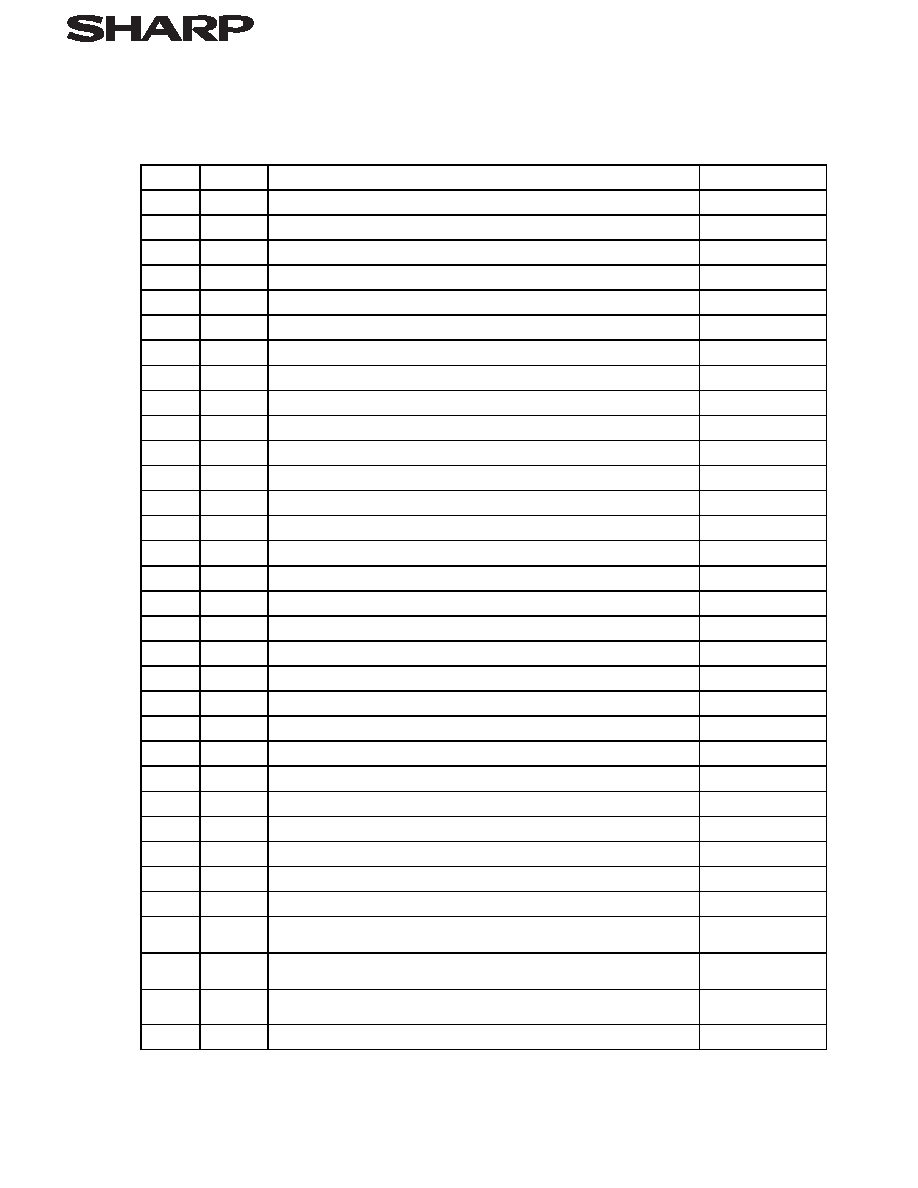

Table 4-1 Functional table of CN1 terminals

Pin No. Symbol

Description Polarity

GND

ground

CK

Clock signal for sampling each data signal

Hsync

Horizontal synchronous signal

Negative

Vsync

Vertical synchronous signal

Negative

GND

ground

R0

RED data signal(LSB)

R1

RED data signal

R2

RED data signal

R3

RED data signal

R4

RED data signal

R5

RED data signal(MSB)

GND

ground

G0

GREEN data signal(LSB)

G1

GREEN data signal

G2

GREEN data signal

G3

GREEN data signal

G4

GREEN data signal

G5

GREEN data signal(MSB)

GND

ground

B0

BLUE data signal(LSB)

B1

BLUE data signal

B2

BLUE data signal

B3

BLUE data signal

B4

BLUE data signal

B5

BLUE data signal(MSB)

GND

ground

ENAB

Signal to settle the horizontal display positionNote4-1

Positive

Vcc

+3.3V power supply

Vcc

+3.3V power supply

R/L

Selection signal for horizontal scanning directionNote4-2

("L" : Normally , "H" : Right-and-Left reversal)

U/D

Selection signal for vertical scanning directionNote4-2

("H" : Normally , "L" : Up-and-Down reversal)

V/Q

Selection signal for VGA or QVGA

("H" : VGA , "L" : QVGA)

GND

ground

LA1-05016-4

Note 4-1 The horizontal display start timing is settled in accordance with a rising timing of

ENAB signal. In case ENAB is fixed "Low", the horizontal start timing is determined as

described in Fig7. Don't keep ENAB "High" during operation.

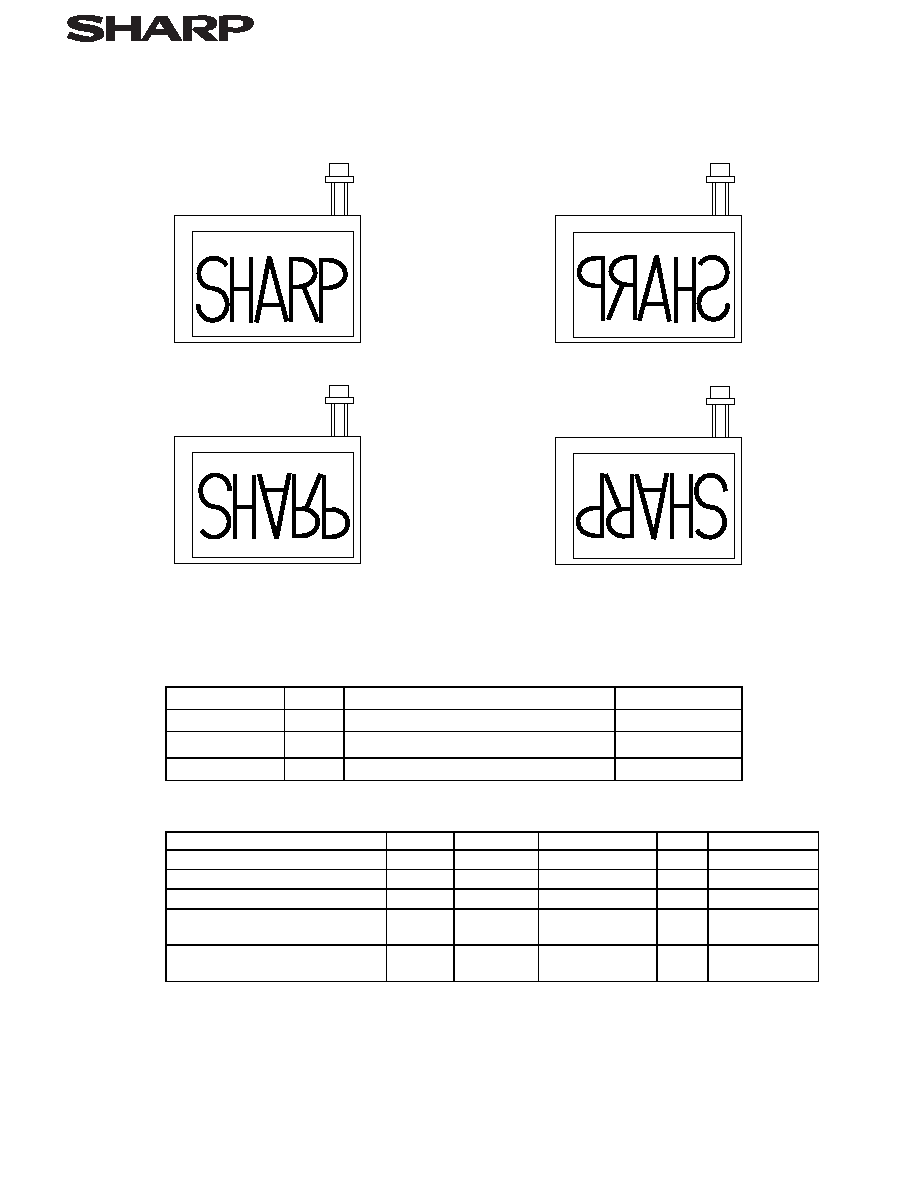

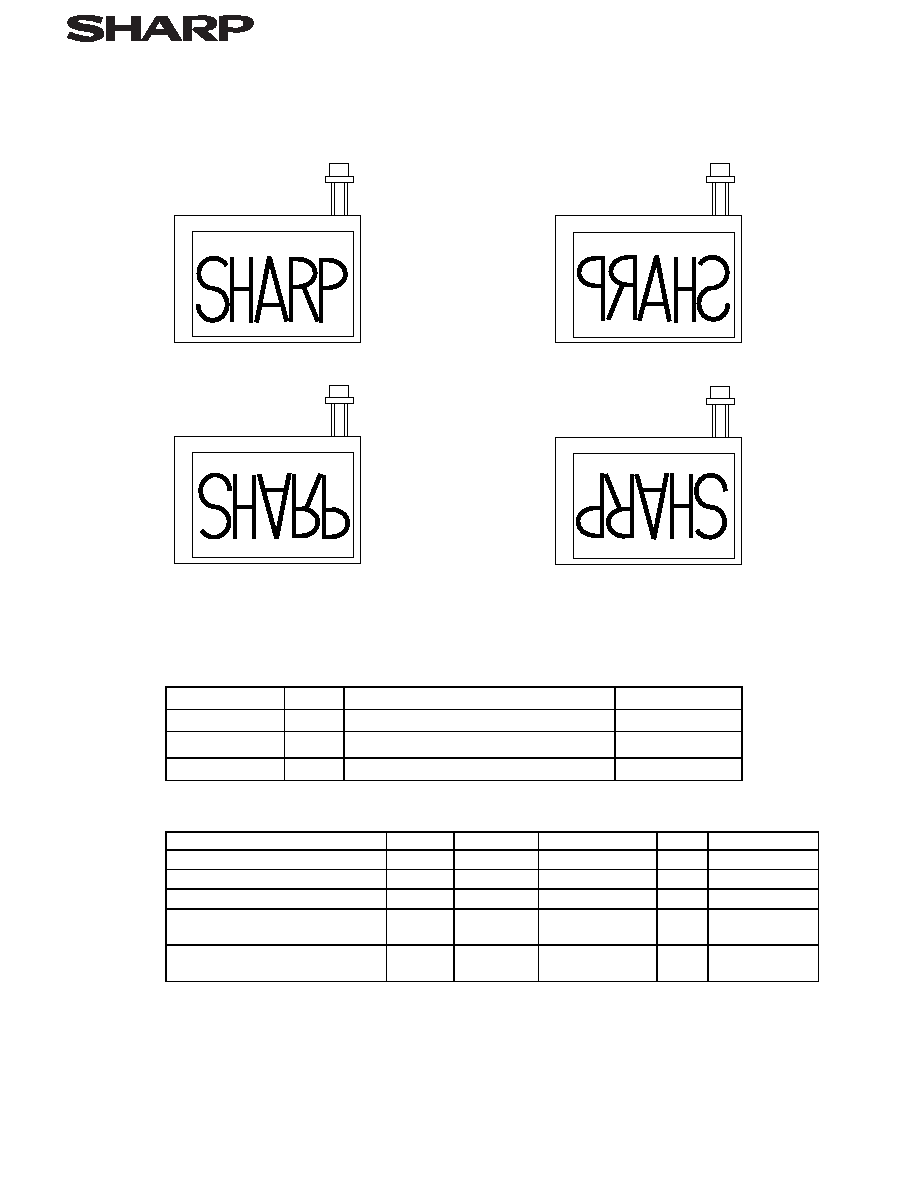

Note 4-2

R/L = LU/D = H R/L = HU/D = H

R/L = LU/D = L R/L = HU/D = L

4-2. Backlight fluorescent tube driving part

CN2 Used connector BHR-03VS-1 (JST Co. , Ltd.)

Suitable connector SM02(8.0)B-BHS-1N-TB (JST Co. , Ltd.)

Table 4-2 Functional table of CN2 terminals

Terminal

No.

symbol function

Color of FL cable

1 V

LOW

input

terminal (Low Voltage Side)

White

2 NC

Non connection

-

3 V

HIGH

input

terminal (High Voltage Side)

Red

5. Absolute maximum ratings

Table 5-1

Parameter Symbol

Condition

Ratings

Unit

Note

Input voltage

V

I

Ta=25

-

0.3 6.0V

V

Note 5-1

+3.3V power supply voltage

cc Ta=25 0

+.0

Storage temperature

stg --

-

30 80

Note 5-2,3

Operating temperature

Panel surface temperature

opr1 --

-

10 70

Note5-2,3,4

Operating temperature

Ambient temperature

opr2 --

-

10 +70

Note 5-5

Note 5-1 CK,

R0R5, G0G5, B0B5, Hsync, Vsync, ENAB, R/L, U/D, V/Q

Note 5-2

This rating applies to all parts of the module and should not be exceeded.

Note 5-3

Maximum wet-bulb temperature is less than 39. Condensation of dew must be

avoided as electrical current leaks will occur, causing a degradation of performance

specifications.

Note 5-4

The operating temperature only guarantees operation of the circuit. For contrast,

speed response, and other factors related to display quality, judgment is done using the

ambient temperature Ta =25.

Note 5-5

Ambient temperature when the backlight is lit (reference value).

LA1-05016-5

6. Electrical characteristics

6-1. TFT-LCD panel driving section

Table 6-1 Ta=25

Parameter Symbol

Unit Remarks

+3.3V Supply

voltage

Vcc +3.0 +3.3 +3.6 V

Note 6-1

power suply Current dissipation

Icc

-

130

160

mA Note 6-2

Permissive input ripple

V

RF

-

-

100

MVp-p Vcc=+3.3V

Input Low voltage

V

IL

0 -

0.3Vcc V

Input High voltage

V

IH

0.7Vcc -

+5.5

Note 6-3

Input leak current (Low)

I

OL

-

-

10

A V

I

=0V

Note 6-3

I

OH1

-

-

10

A V

I

=3.35.0V

Note 6-4

Input leak current (High)

I

OH2

-

-

100

A V

I

=3.35.0V

Note 6-5

Note 6-1

Vcc turn-on/off conditions.

t120ms

0<t250ms

0<t31s

1s<t4

Vcc-dip conditions

1) 2.4V Vcc 3.0V

td 20msec

2) At Vcc 2.4V

Vcc-dip conditions should also follow the Vcc turn-on/off

conditions.

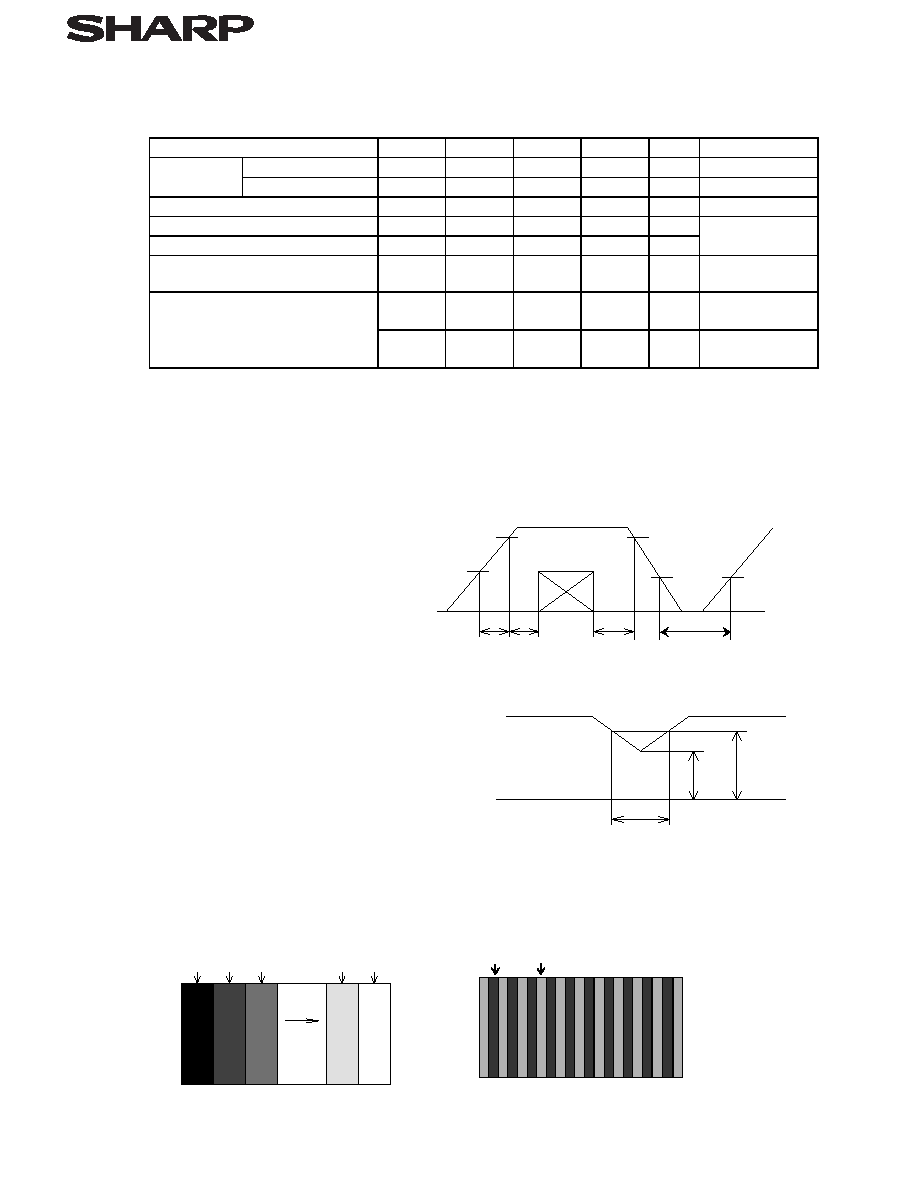

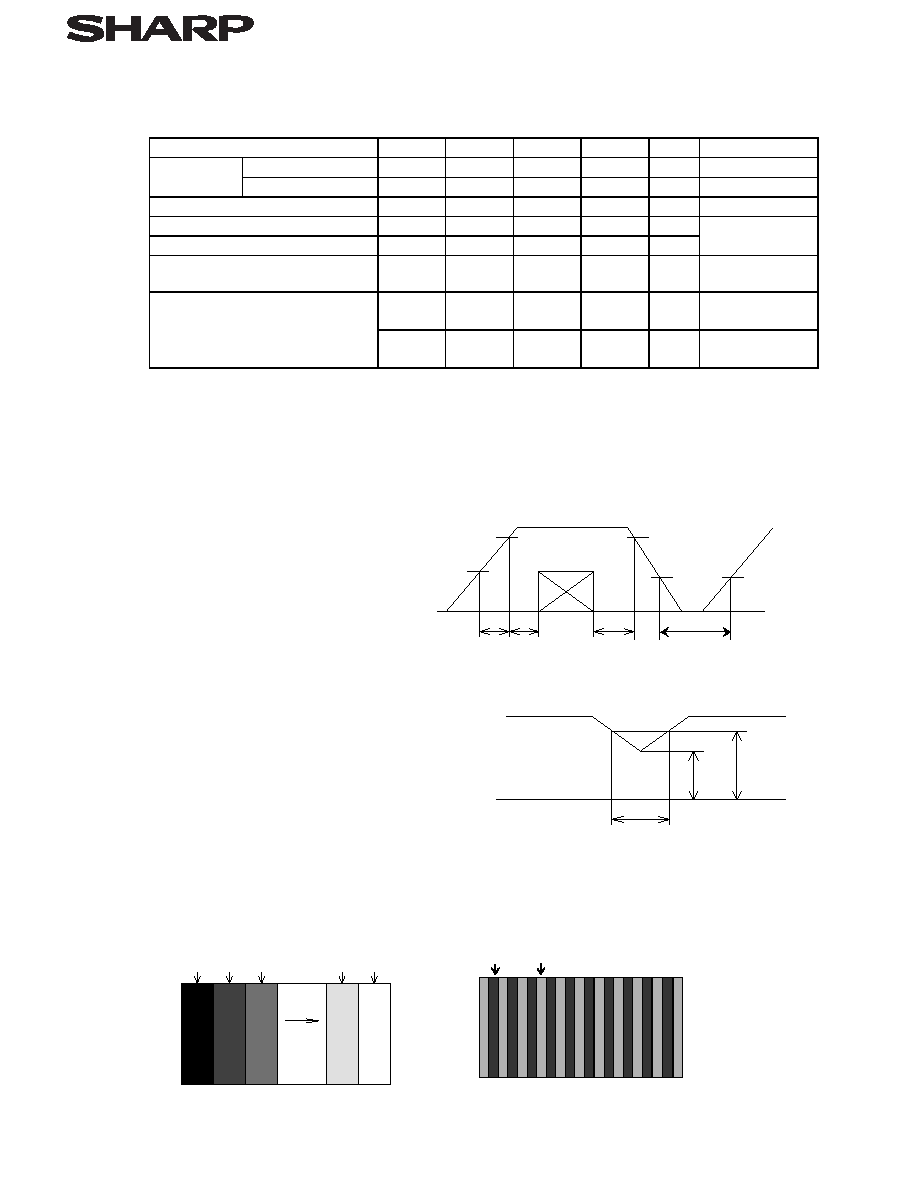

Note 6-2 Vcc = 3.3VV/Q = ""

Typical current situation: Timing; Typical64-gray-bar pattern.

Max current situation: Timing; TypicalVertical stripe pattern alternating

0 gray scale (GS0) with 42 gray scale (GS42) every 1 dot.

Typical current situation Max current situation

RGB

GS0

RGB

GS3

RGB

GS7

RGB

GS59

RGB

GS63

....

td

2.4V

3.0V

Vcc

GS0

GS42

t1

t2

t3

0.3V

3.0V

3.0V

Vcc

data

t4

0.3V

0.3V

LA1-05016-6

Note 6-3 CK,R0R5,G0G5,B0B5,Hsync,Vsync,ENAB,R/L,U/D,V/Q

Note 6-4 CK,R0R5,G0G5,B0B5,Hsync,Vsync,R/L,U/D

Note 6-5 ENABV/Q

6-2. Backlight driving section

The backlight system is an edge-lighting type with single CCFT (Cold Cathode Fluorescent Tube).

The characteristics of Lamp are shown in the following table.

Table 6-2

Parameter Symbol

Unit Remarks

lamp voltage

620

690 760 Vrms

5 mArms

lamp current

4.5 5.0 5.5

mArms

ordinary

state

lamp power

WL

-

3.5

-

W ratings

lamp frequency

30

-

60 kHz

kick-off Ta=+25

-

-

1350

voltage

Ta=-10

-

-

1470

Vrms

A shield is

connected to GND.

( Inverter HIU-288 [ Output condenser : 22pF ] TOSHIBA HARISON LIGHTING co. Ltd.)

Caution

Use the inverter providing symmetrical sine-wave in positive/negative polarity with no spike.

A shield(module's metal shield) should be connected to GND of inverter circuit.

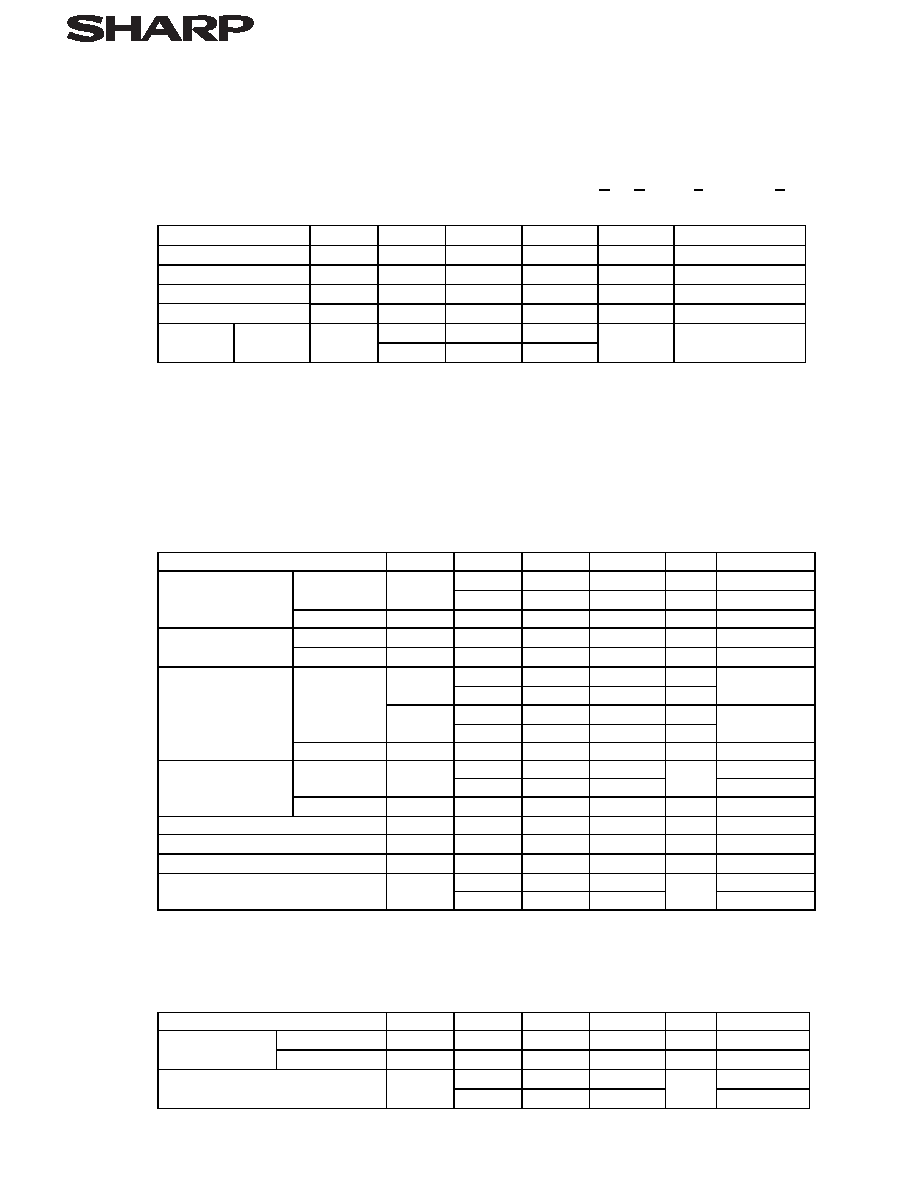

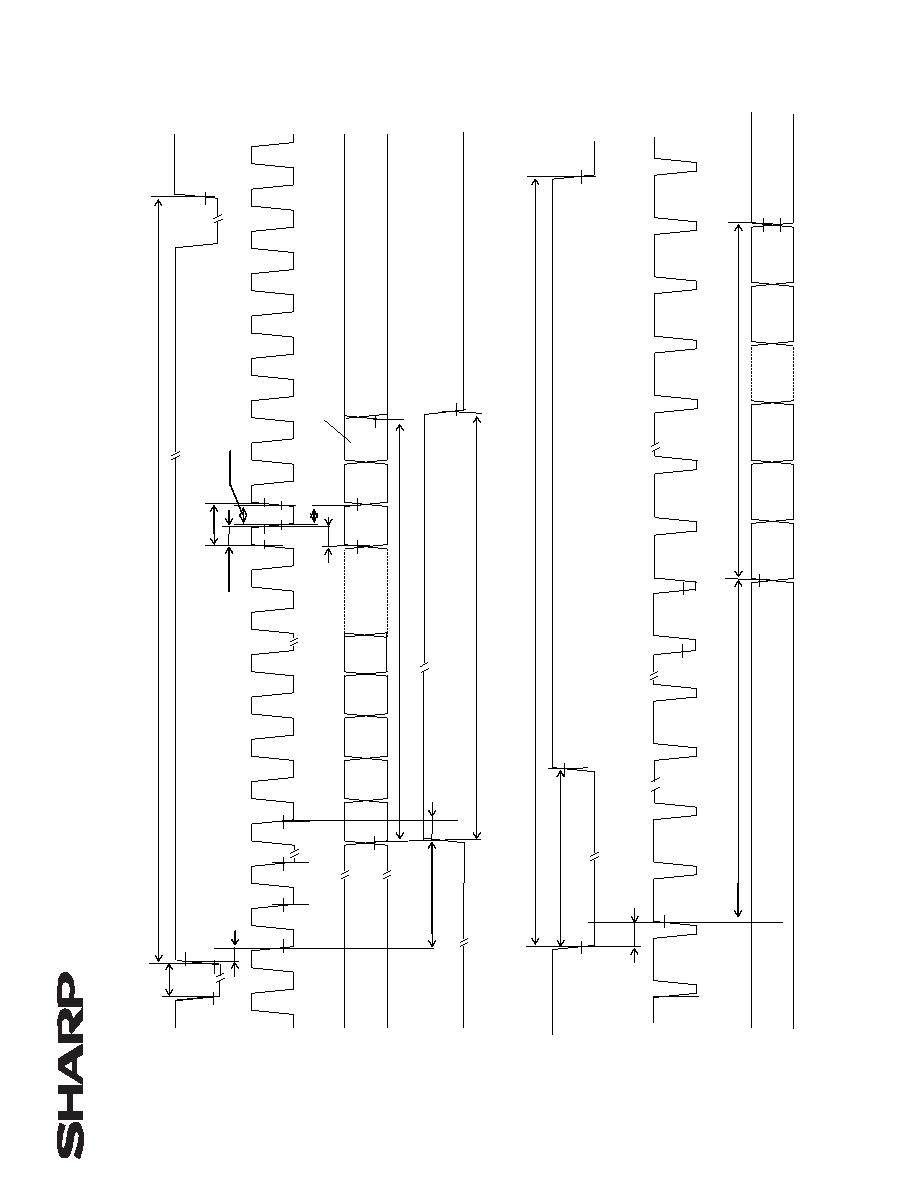

7. Timing Characteristics of input signals

Timing diagrams of input signal are shown in Fig.7

7-1. Timing characteristics

Table 7-1

Parameter

Symbol

MIN

TYP

MAX

Unit

Remarks

Clock

-

25.18

28.33

MHz V/Q = H

frequency 1/Tc

-

6.3

7.0

V/Q = L

Duty

ratio

TH/T

40

50

60

%

Data Setup

time

Tds

5

-

-

ns

Hold

time

Tdh

10

-

-

ns

TH 30.0 31.8 -

s V/Q = H

770

800 900

clock

TH 50.0 63.6 -

s V/Q = L

Cycle

360

400 450

clock

Horizontal sync.

signal

Pulse width

THp

2

96

200

clock

Vertical sync.

Cycle

TV

515

525

560

line V/Q = H

signal

251

262

280

V/Q = L

Pulse

width

TVp

2

-

34 line

Horizontal display period

THd

320

320

320

clock

Hsync-Clock phase difference

THc

10

-

Tc-10

ns

Hsync-Vsync phase difference

TVh

0

-

TH-THp s

Vertical display start position

TVs

34

34

34

line V/Q = H

7

7

7

V/Q = L

Note) In case of lower frequency, the deterioration of display quality, flicker etc., may be occurred.

7-2. Horizontal display position

The horizontal display position is determined by the rising edge of ENAB signal.

Table 7-2

Parameter symbol

Min.

Typ.

Max.

Unit

Remark

Enable signal

Setup time

Tes

5

-

Tc-10

ns

Pulse

width

Tep

2

320

TH-10

clock

The 44 - TH-664 clock V/Q = H

Hsync-Enable signal phase

difference

2

TH-340

V/Q = L

Note) When ENAB is fixed "Low", the display starts from the following data as shown in Fig.7.

V/Q = "H" C104 (clock) V/Q = "L" C52 (clock)

LA1-05016-7

7-3. Vertical display position

The Vertical display start position (TVs) is fixed 34 line (V/Q =H) and 7 line (V/Q = L).

ENAB signal has no relation to the vertical display position.

7-4. Input Data Signals and Display Position on the screen

Display position of input data (H,V)

D1,DH1

D1,DH2

D1,DH3

D1,DH240

D2,DH1

D320,DH240

D320,DH1

D2,DH2

R

D3,DH1

G B

LA1-05016-8

Horizontal sync.

signal

Hsync

Clock signal

CK

DataR05

G05B05

Data Enable signal

ENAB

Vertical Sync

signal

Vsync

Horizontal sync

signal

Hsync

DataR05

G05B05

Fig 7. Input signal waveforms

0.3Vcc

0.7Vcc

TVp

TV

0.3Vcc

TVh

Vertical invalid data period

DH1 DH2 DH3

Vertical invalid

data

period

DH239 DH240

TVs

THp

0.7Vcc

0.3Vcc

Tch

Tcl

Tc

0.3Vcc

TH

THc

0.3Vcc

Horizintal invalid data period

Horizontal invalid data period

D2

D1

D3

D318 D319

Tds

Tdh

Tes

0.7Vcc

Tep

0.3Vcc

THd

The

C104(V/Q=H)

C52(V/Q=L)

(Number of clock)

C2

C1

Only when enable terminal is fixed "Low"

0.7Vcc

Line1 Line2

D4

D320

D5

0.3Vcc

Line34(V/Q=H)

Line7(V/Q=L)

(Number of Vertical count)

0.3Vcc 0.3Vcc 0.3Vcc

TVd

Number of Horizontal data

0.7Vcc

LA1-05016-9

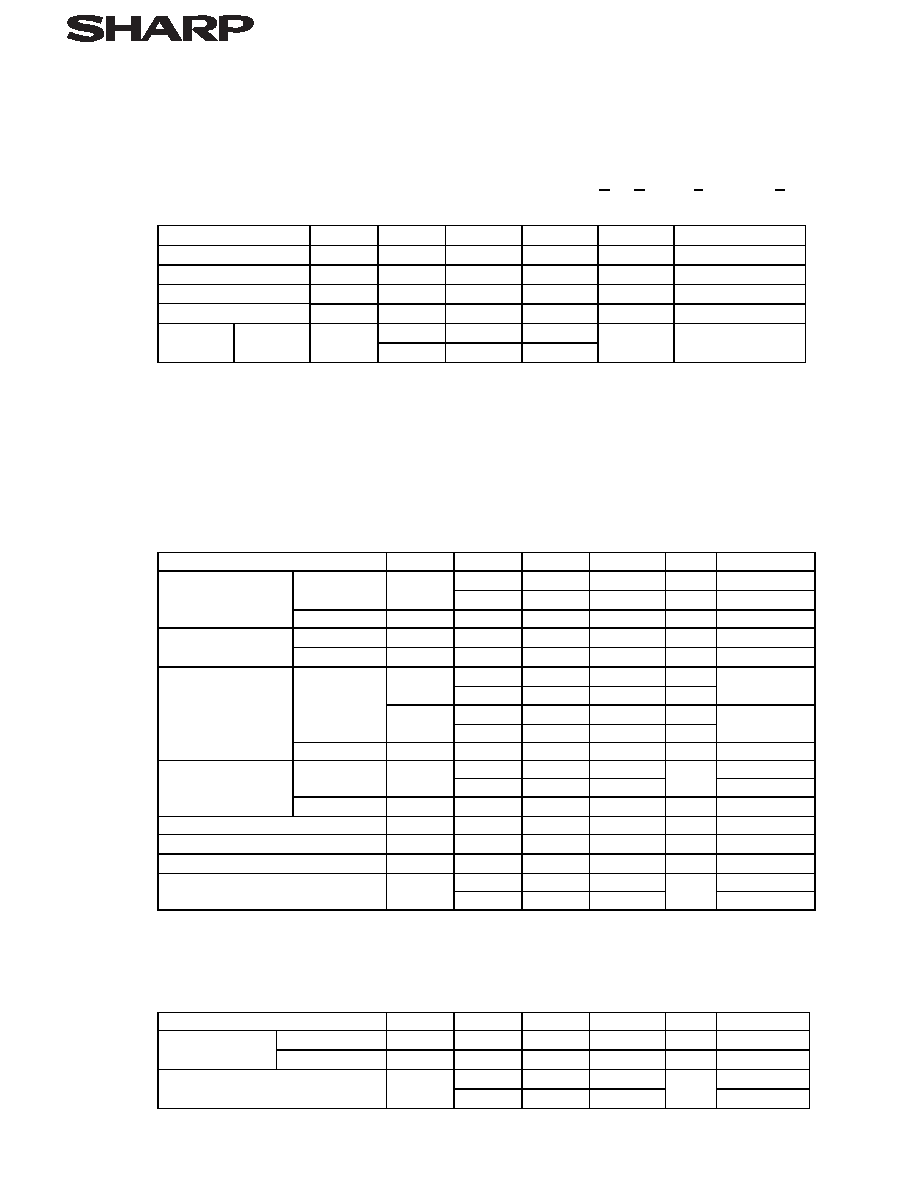

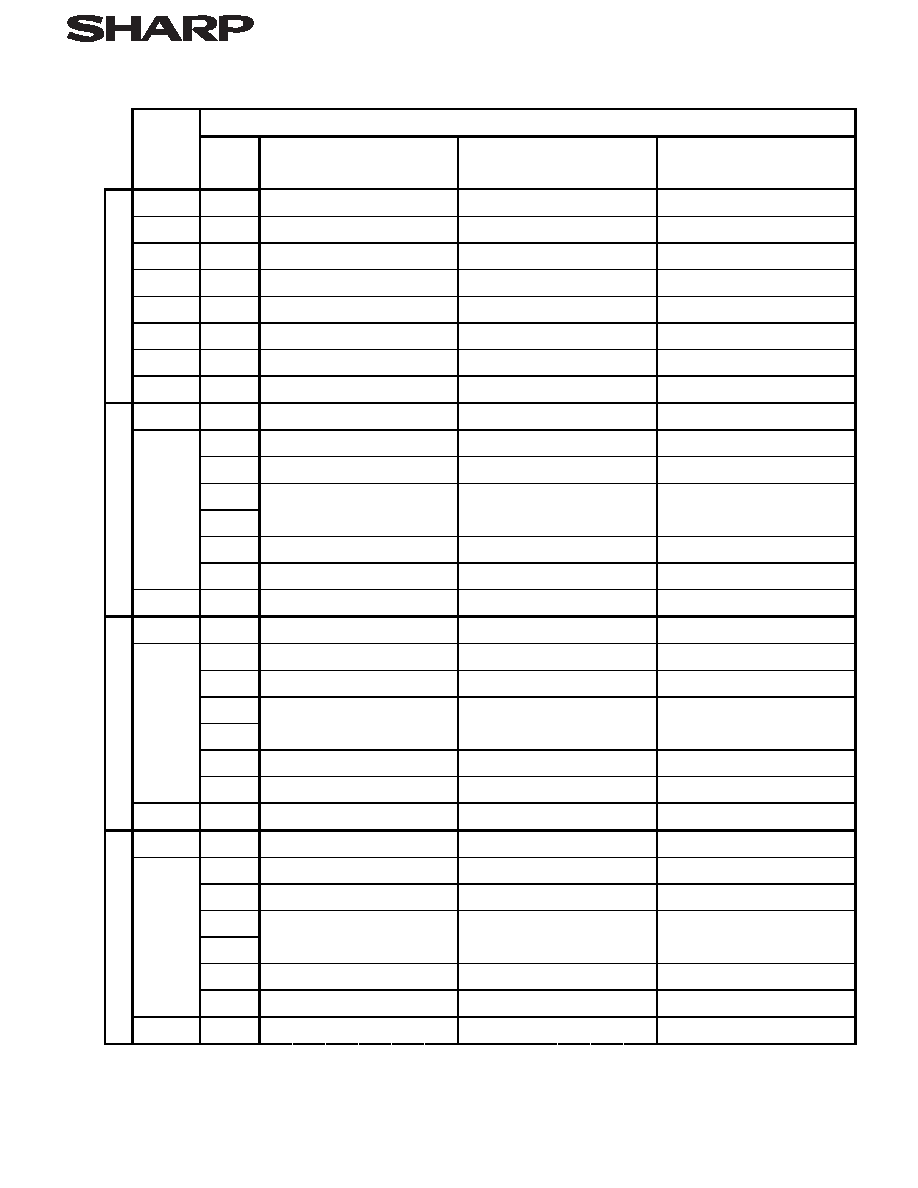

() Input Signals, Basic Display Color and Gray Scale of Each Color

Colors & Data signal

Gray scale Gray

Scale

R0 R1 R2 R3 R4 R5 G0 G1 G2 G3 G4 G5 B0 B1 B2 B3 B4 B5

Black

-

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Blue

-

0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

Green

-

0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

Cyan

-

0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1

Red

-

1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Magenta

-

1 1 1 1 1 1 0 0 0 0 0 0 1 1 1 1 1 1

Yellow

-

1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0

Basic color

White

-

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Brighter GS61 1 0 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

GS62 0 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Gra

y

Scale of red

Red GS63 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0

Brighter GS61 0 0 0 0 0 0 1 0 1 1 1 1 0 0 0 0 0 0

GS62 0 0 0 0 0 0 0 1 1 1 1 1 0 0 0 0 0 0

Gra

y

Scale of

g

reen

Green GS63 0 0 0 0 0 0 1 1 1 1 1 1 0 0 0 0 0 0

Black GS0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

GS1 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0

Darker GS2 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0

Brighter GS61 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1

GS62 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1

Gra

y

Scale of bleu

Bleu GS63 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1

0 :Low level voltage 1 :High level voltage

Each basic color can be displayed in 64 gray scales from 6 bit data signals. According to the

combination of total 18 bit data signals, the 262,144-color display can be achieved on the screen.

LA1-05016-10

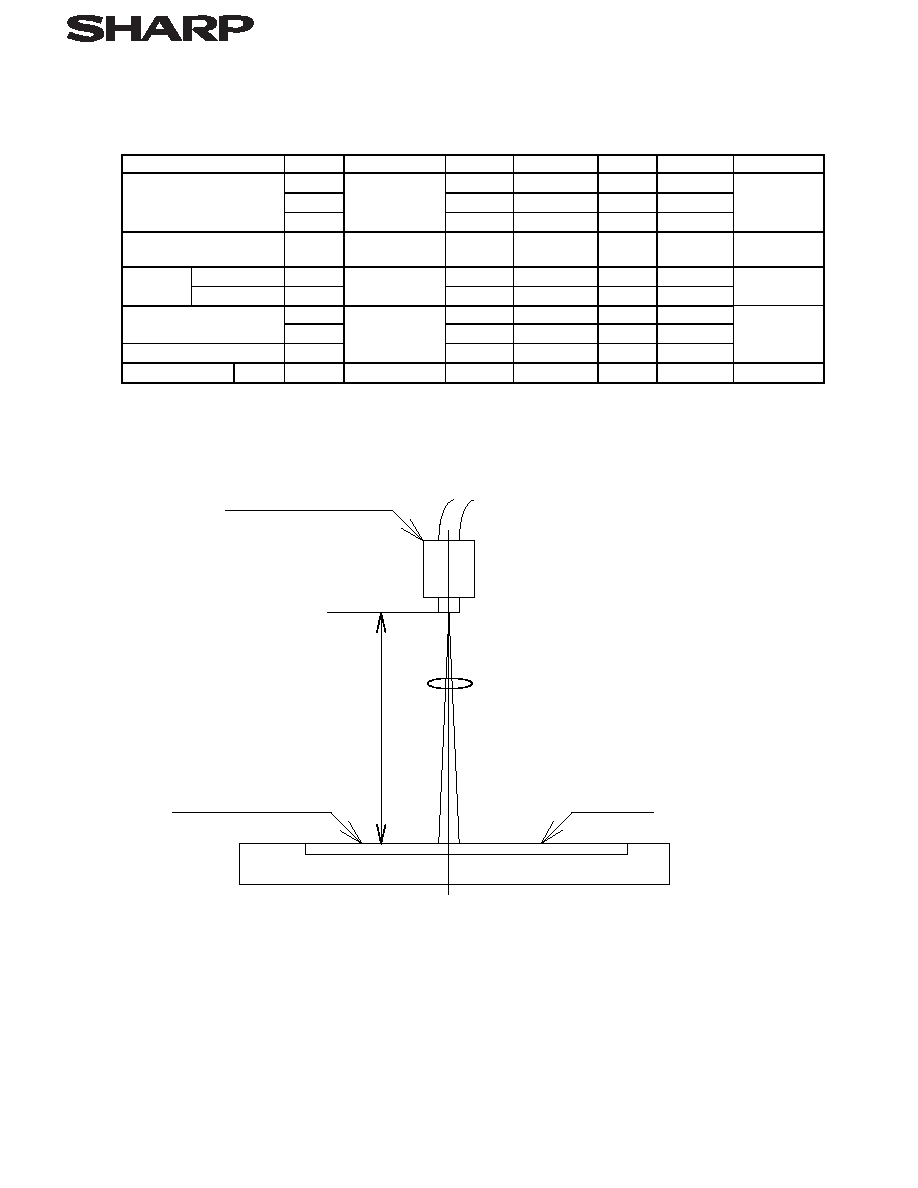

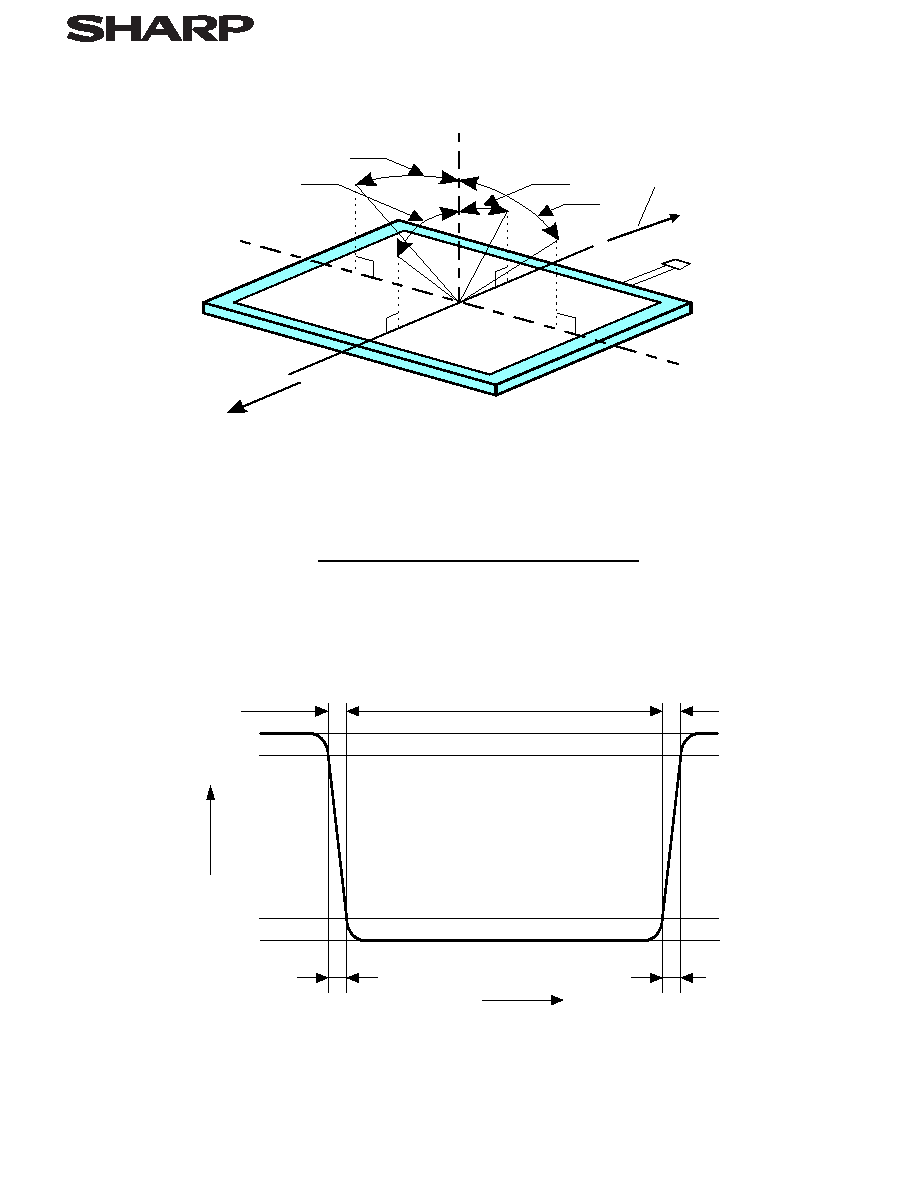

9. Optical characteristics

Table 9-1 Ta=25VCC = 3.3V

Parameter Symbol

Condition

Min

Typ

Max

Unit

Remarks

21, 22

60 65 -

°

(degree) Note 9-1

Viewing angle range

11 CR5

60 65 -

°

(degree)

12

35 40 -

°

(degree)

Contrast ratio

CRmax

Optimal

viewing angle

250 350 -

Note 9-2

Response Rise

r

°

-

8 20

ms

Note 9-3

time Fall

d

-

21 40 ms

White chromaticity

x

0.263

0.313

0.363

y

IL=5mArms

0.279

0.329

0.379

Note 9-4

Luminance Y

350

500

-

cd/m

2

lamp life time +25

- continuation

40,000 50,000 -

hour

Note 9-5

Lamp test in the module is made with the following inverter:.

HIU-288 [ Output condenser : 22pF ] TOSHIBA HARISON LIGHTING co. Ltd.

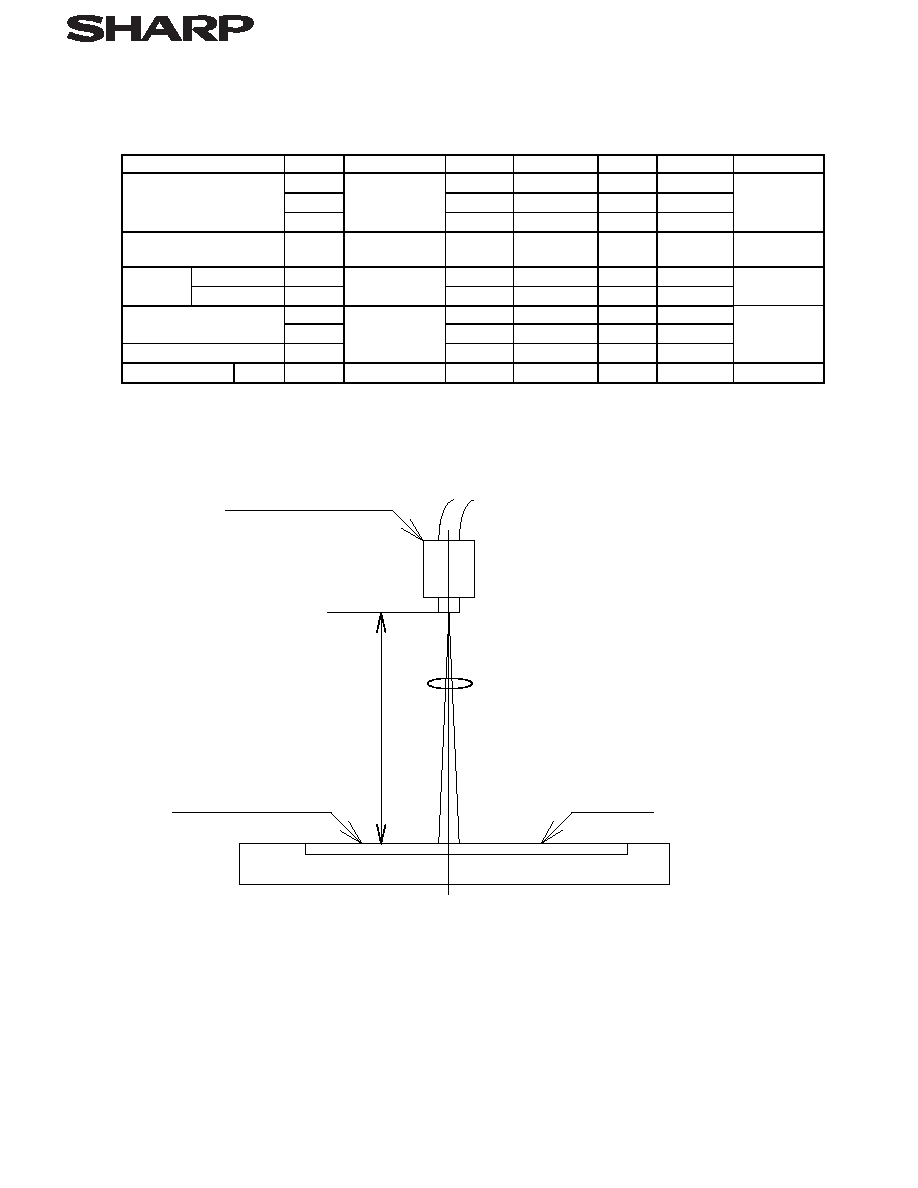

The optical specifications are measured 30 minute after turing lamp on and in a dark room or

equivalent condition, according to the method shown in Fig.9-1 below.

Fig.9-1 Optical characteristics measurement method

Photodetector (BM-5A : TOPCON)

Center of the screen

TFT-LCD Module

LCD panel

Field=2°

400

LA1-05016-11

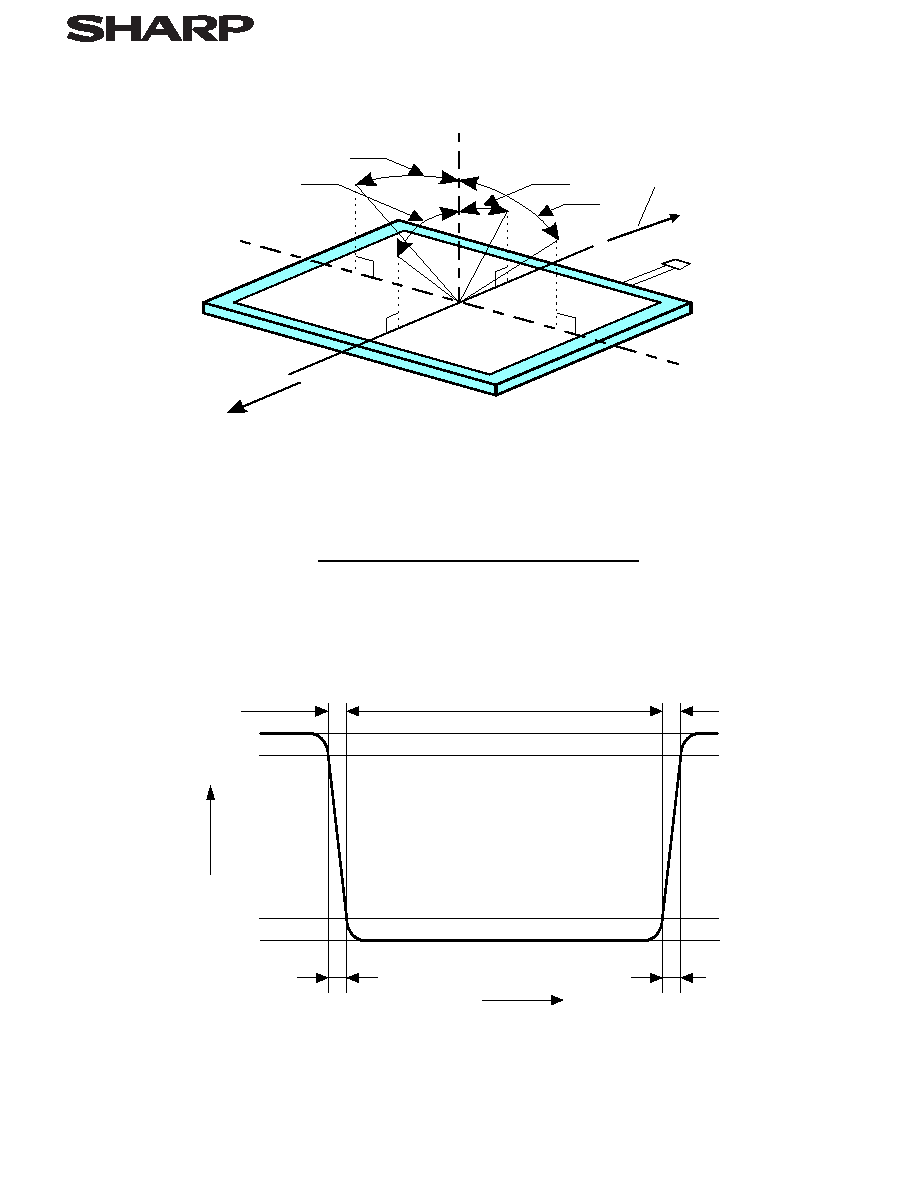

Note 9-1 Viewing angle range is defined as follows.

12 o'clock

direction

6 o'clock direction

Normal line

21

22

11

12

The best viewing angle of this module is slightly leaned to 12 o'clock from normal line.

Where

11

max

, gray scale is reversed partially.

Where

11

max

, or in

12

direction, gray scale isn't reversed.

Note 9-2 Contrast ratio is defined as follows:

Luminance (brightness) with all pixels white

Contrast ratio(CR)=

Luminance (brightness) with all pixels black

Measurement point : Center of the active area

Note 9-3 Response time is obtained by measuring the transition time of photo detector

output, when input signals are applied so as to make the area "black" to and

from "white".

Black White

White

Time

P

h

o

t

o

d

e

t

e

c

t

e

r

o

u

t

p

u

t

(

R

e

l

a

t

i

v

e

v

a

l

u

e

)

Note 9-4 This parameter should be measured at the center of the screen and 30 minutes after turn-

on.

Inverter frequency: 49kHz

The characteristics are measured when the driver circuit is not powered.

Note 9-5 The data for lamp is for your reference, because lamp is consumable component.

LA1-05016-12

a)

Lamp life time is defined by either 1 or 2 below.

(Continuous turning on at Ta=25, IL=5mA rms)

When a brightness of lamp surface become 50% of the initial value under the

standard condition.

When a kick-off voltage in Ta=-10 exceeded maximum value(1470 Vrms)

at the output of inverter circuitry.

b)

In case of operating under lower temp. environment, the lamp exhaustion is accelerated

and the brightness becomes lower.

(Continuous operating for around 1 month under lower temp. condition may reduce the

brightness to half of the original brightness.)

LA1-05016-13

10. Handling instructions

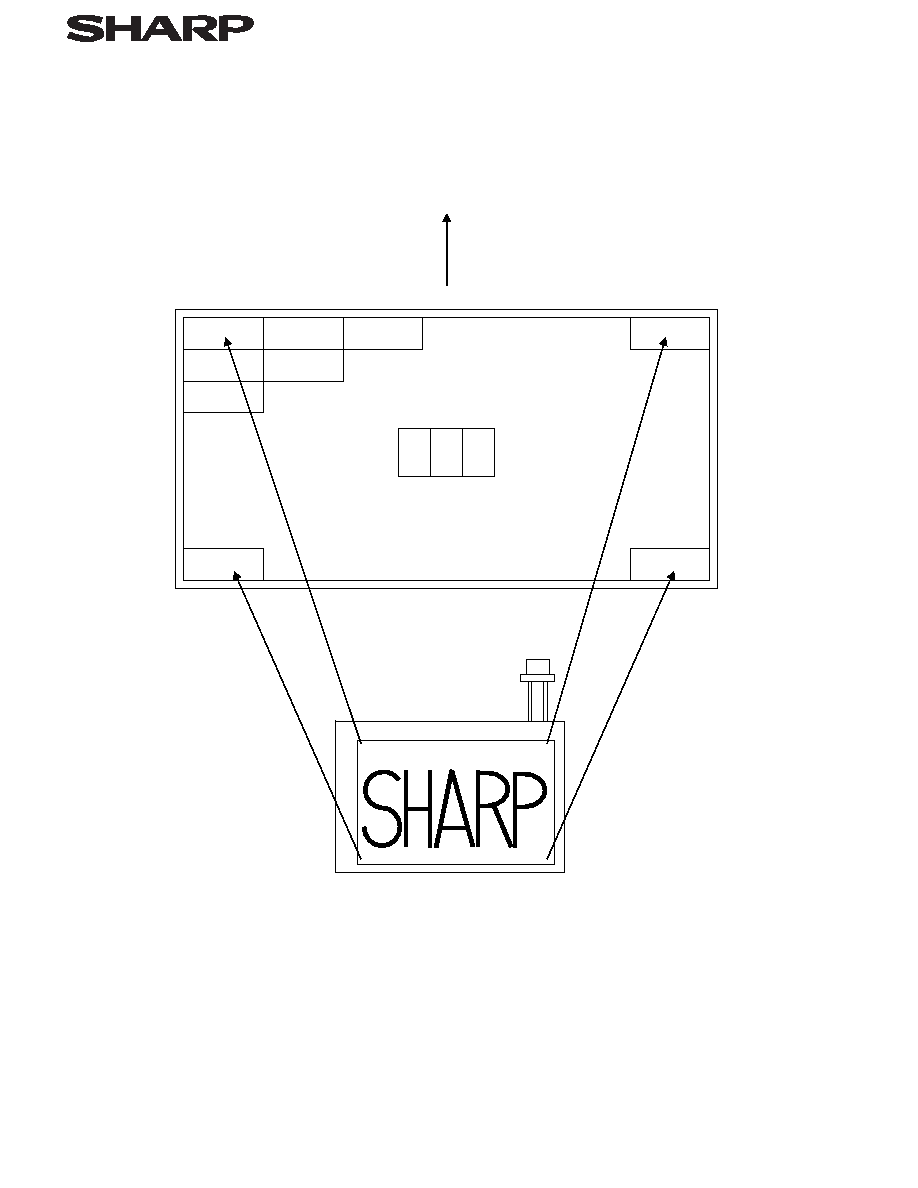

10-1. Mounting of modules

The TFT-LCD module is designed to be mounted on equipment using the mounting

tabs in the four corners of the module at the rear side. On mounting the module, as the

nominal diameter 3.0mm tapping screw (fastening torque is 0.25 through

0.30 Nm) is recommended, be sure to fix the module on the same plane, taking care not

to wrap or twist the module. The depth of tapping screw embedded into LCD module must

be less than 5mm.

The pressing module, (ex. touching switch etc.) causes disordered image. So taking care

for pressure not to conduct directly to LCD module.

Please power off the module before you connect or disconnect input connector.

Connect the metallic shielding cases of the module and the ground pattern of the inverter

circuit firmly. If that connection is not perfect, there may be a possibility that the following

problems happen.

a) The noise from the backlight unit will increase.

b) The output from inverter circuit will be unstable.

c) In some cases, a part of module will heat up.

10-2. Precautions in mounting

Polarizer which is made of soft material and susceptible to flaw must be handled carefully.

Method of removing dust from polarizer.

Blow off dust with N2 blower for which static electricity preventive measure has

been taken.

Since the polarizer is easily damaged, wiping should be avoided. If the panel has stain

or finger grease, we recommend to use adhesive tape to softly remove them from the panel.

Inevitable, wipe off by cleaning cloth for a lens with carefully, breathing on it.

When metal part of the TFT-LCD module (shielding lid and rear case) is soiled, wipe it

with soft dry cloth. For stubborn dirties, wipe the part, breathing on it.

Wipe off water drop or finger grease immediately. Long contact with water may cause

discoloration or spots.

TFT-LCD module uses glass which breaks or cracks easily if dropped or bumped on hard surface.

handle with care.

Since CMOS LSIs are incorporated in this module, take care of electrostatic and earth human

body while handling.

10-3. Caution of product design

The notes and cautions below should be followed when product is designed with this module.

The LCD module should be protected against water salt-water by the waterproof cover.

Take enough shielding countermeasure not to interfere to peripheral electric device.

10-4. Others

Do not expose the module to direct sunlight or intensive ultraviolet rays for many hours;

liquid crystal is deteriorated by ultraviolet rays.

If stored at the temperature lower than rated temperature, the liquid crystal may freeze and

it may cause LCD panel damage. If storage temperature exceeds the specified rating, the

molecular orientation of the liquid crystal may change to that of a liquid, and they may not

revert to their original state. Store the module in normal room temperature.

The voltage of beginning electric discharge may over the normal voltage because of leakage

current from approach conductor by to draw lump lead line around.

If LCD panel breaks, there may be a possibility that the liquid crystal escapes from the panel.

If the liquid crystal drip into the eyes or mouth washes it out immediately.

The caution to other ordinal electronic component should be followed also.

LA1-05016-14

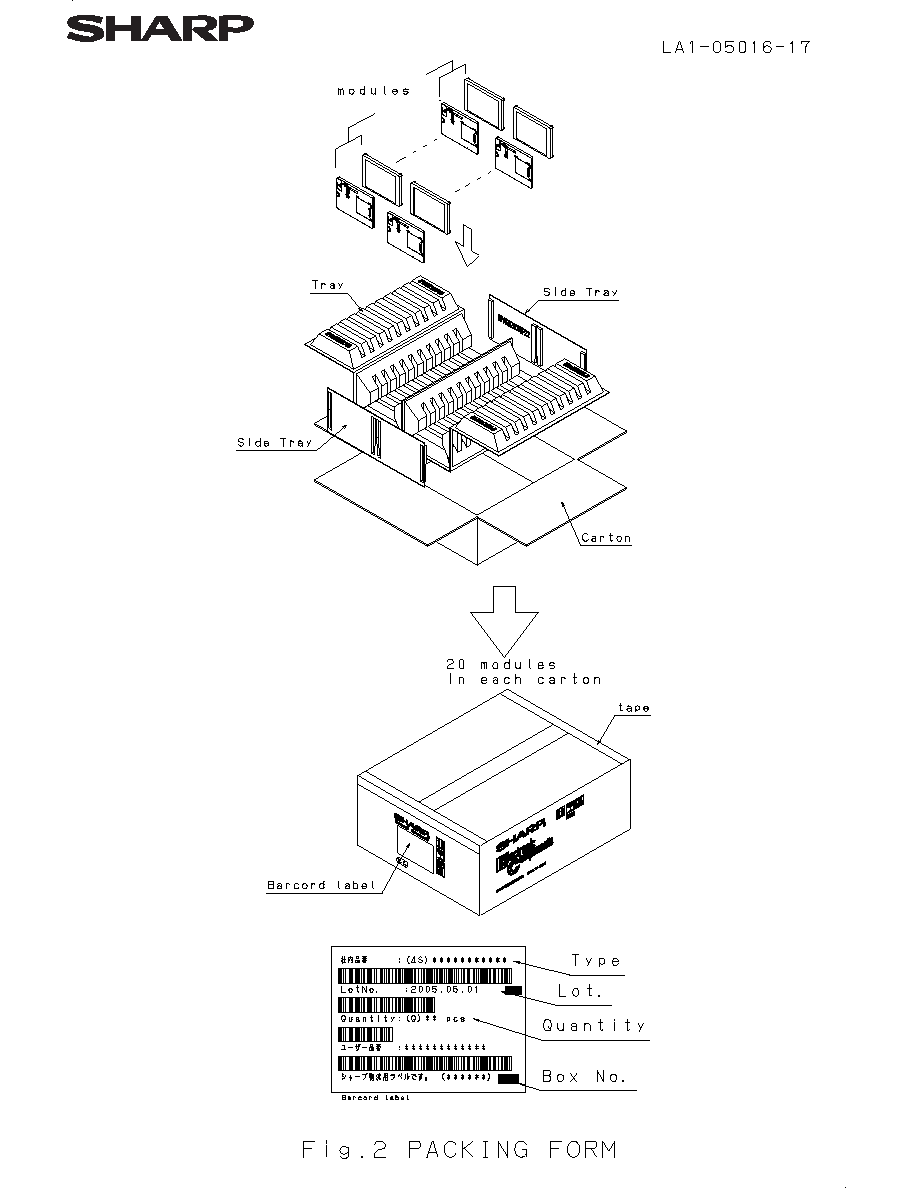

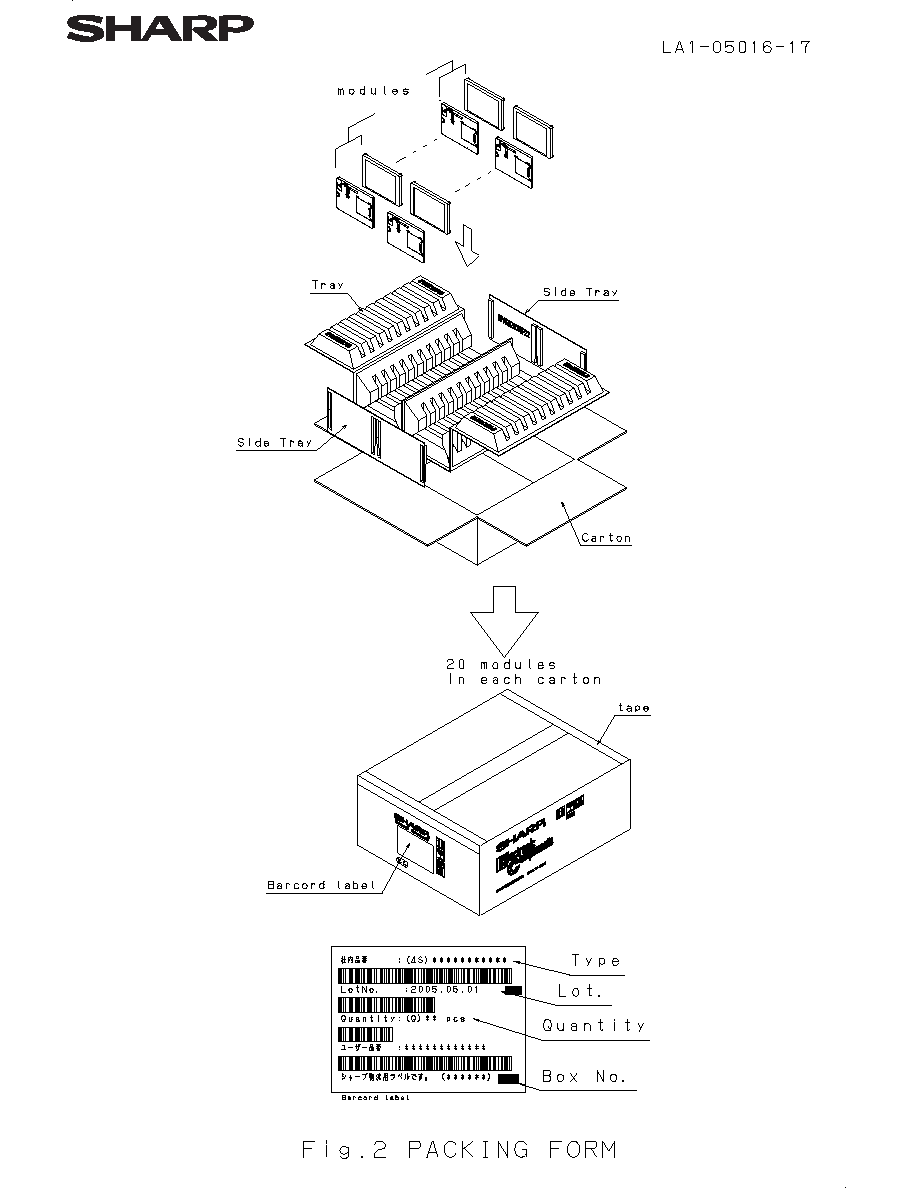

11. Shipping requirements

a) Number of layers of cartons in pile : 12 layers max.

b) Maximum number of product contained: 20 units per 1 carton.

c) Carton size : 442mm(W)×390mm(H)×170mm(D)

d) Total mass ( for 20 units ) : Approximately 5.5

e) Carton stock environment :

Temperature 0 to 40

Humidity 60%RH or less

Atmosphere Harmful gases such as acid and alkali which corrode electric

components and wires must not be detected.

Storage period Approximately 3 months

Opening of package To prevent TFT-LCD module from being damaged by electrostatic,

adjust the humidity to 50%RH or higher and provide

an appropriate measure for electrostatic earthing before

opening the package.

12. Others

a) Adjusting volumes have been set optimally before shipment. Therefore, do not change any

adjusted values. If adjusted values are changed, the specifications described here may not be

satisfied.

b) Disassembled the module, it may cause malfunction.

c) Be careful since image retention may occur when a fixed pattern is displayed for a long time.

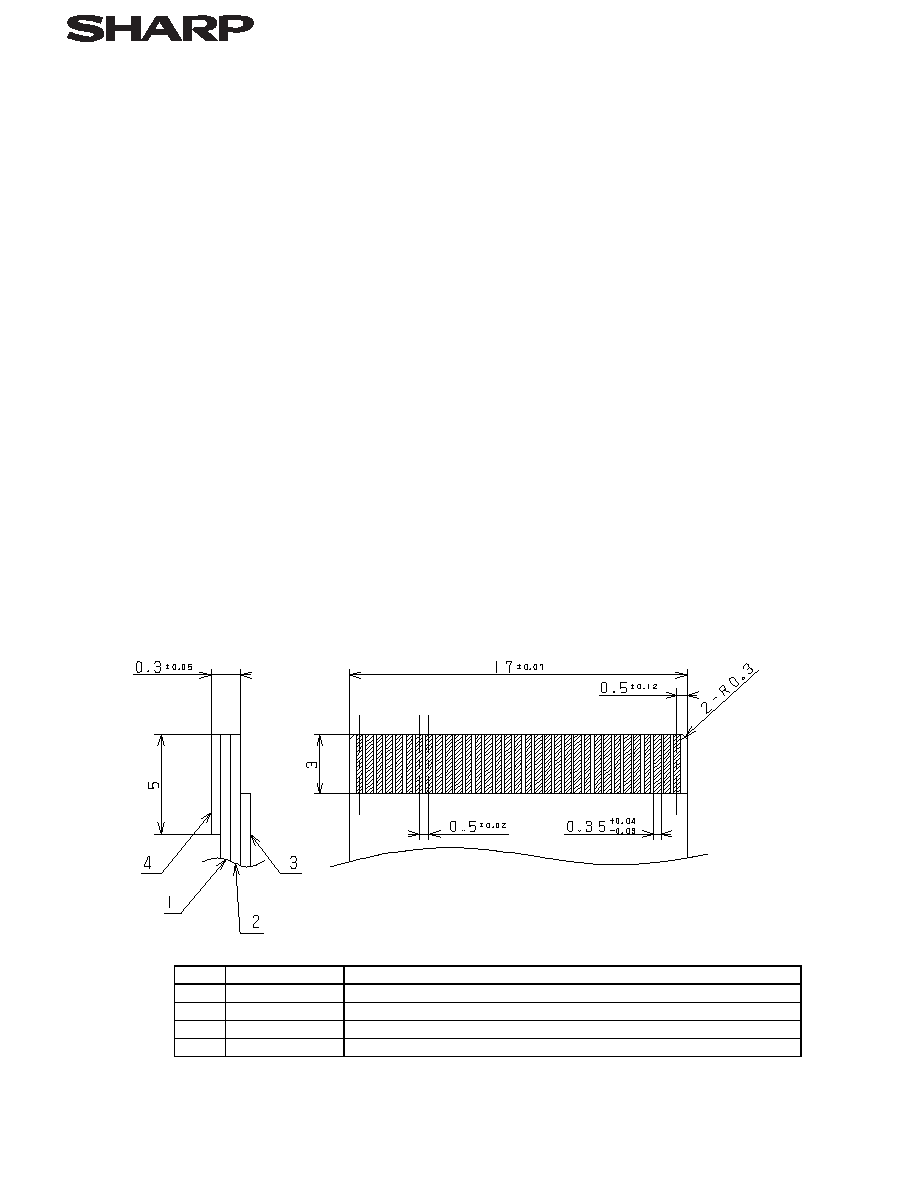

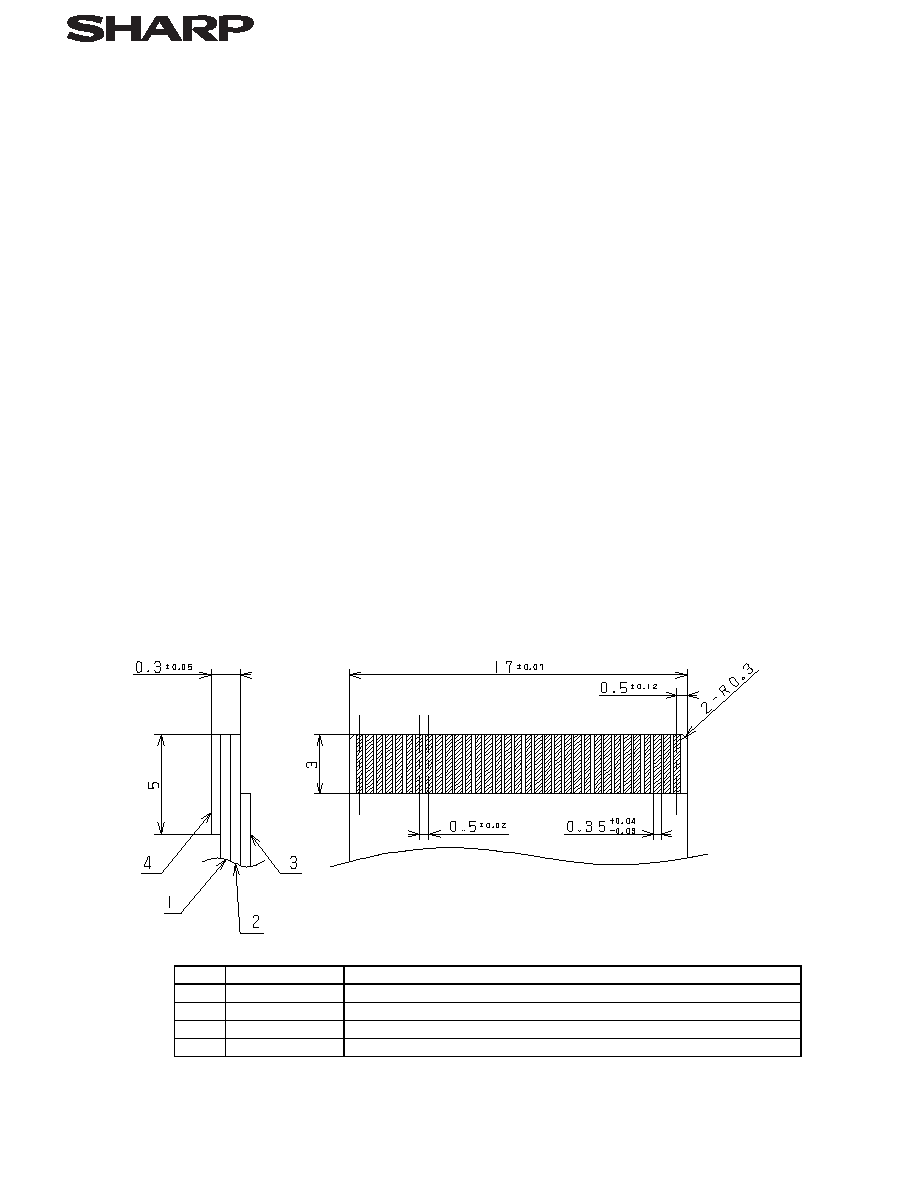

d) Input/Output connector for TFT-LCD panel driving part

Used connector : FH12-33S-0.5SH(55) (HIROSE ELECTRIC C0.,LTD.)

1) Fit FPC : Refer to the following figure

2) Keeping power of terminal : 0.9N/pin or more

[ Every terminal is pulled out 25±3mm/minute ]

3) Endurance of insert/pull out : Less than double of the initial resistance value

[ The electrical resistance value of the contact changed by the repeated insertion/pulling

out by 20 times to and from the matching FPC ]

No. Parameter

Material

1

Base material

Polyimide or the equivalent [ 25um thickness ]

2

Copper leaf

Copper leaf [ 35um thickness ] gold leaf[ 2um or more thickness ]

3

Coverlay

Polyimide or the equivalent

4

Reinforced sheet Polyester, polyimide or the equivalent [ 188um thickness ]

Fit FPC for Input/Output connector : 0.5mm pitch

LA1-05016-15

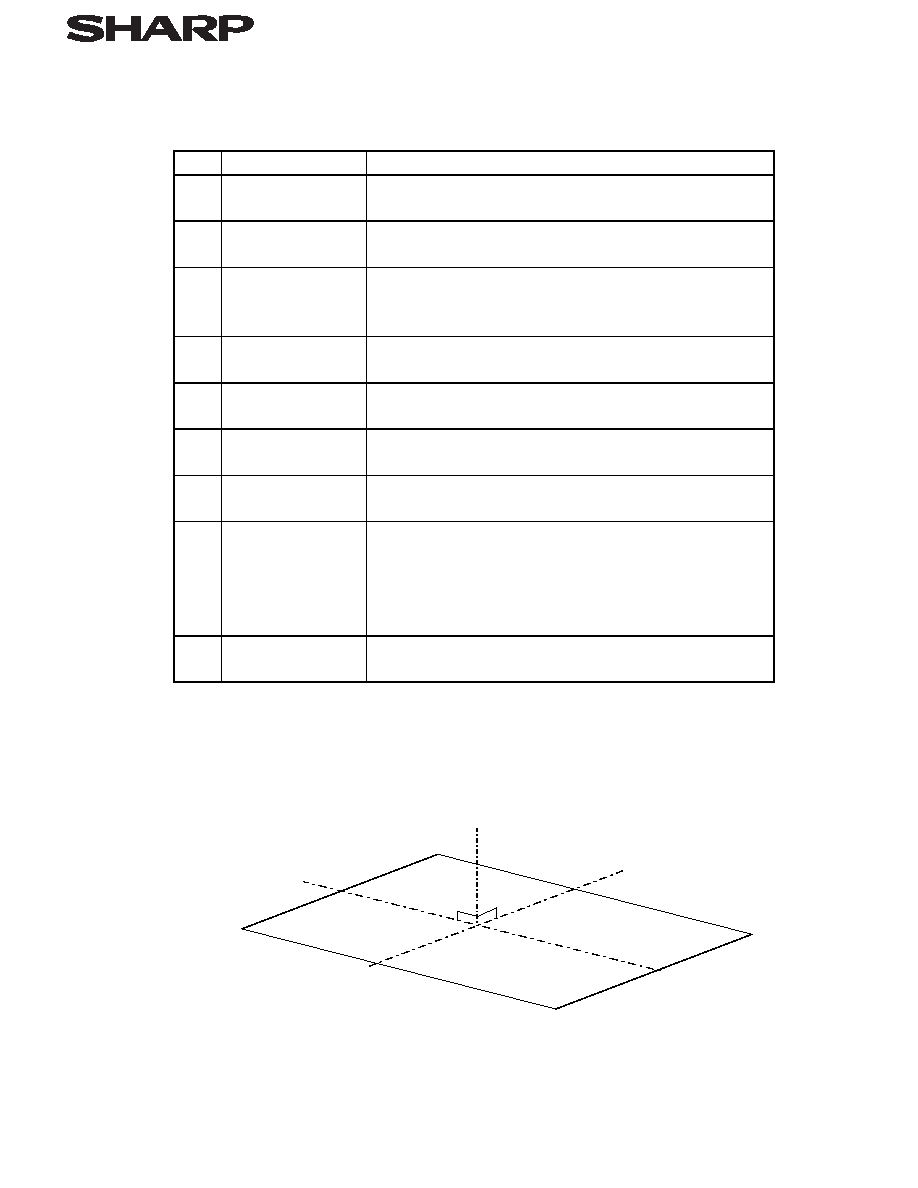

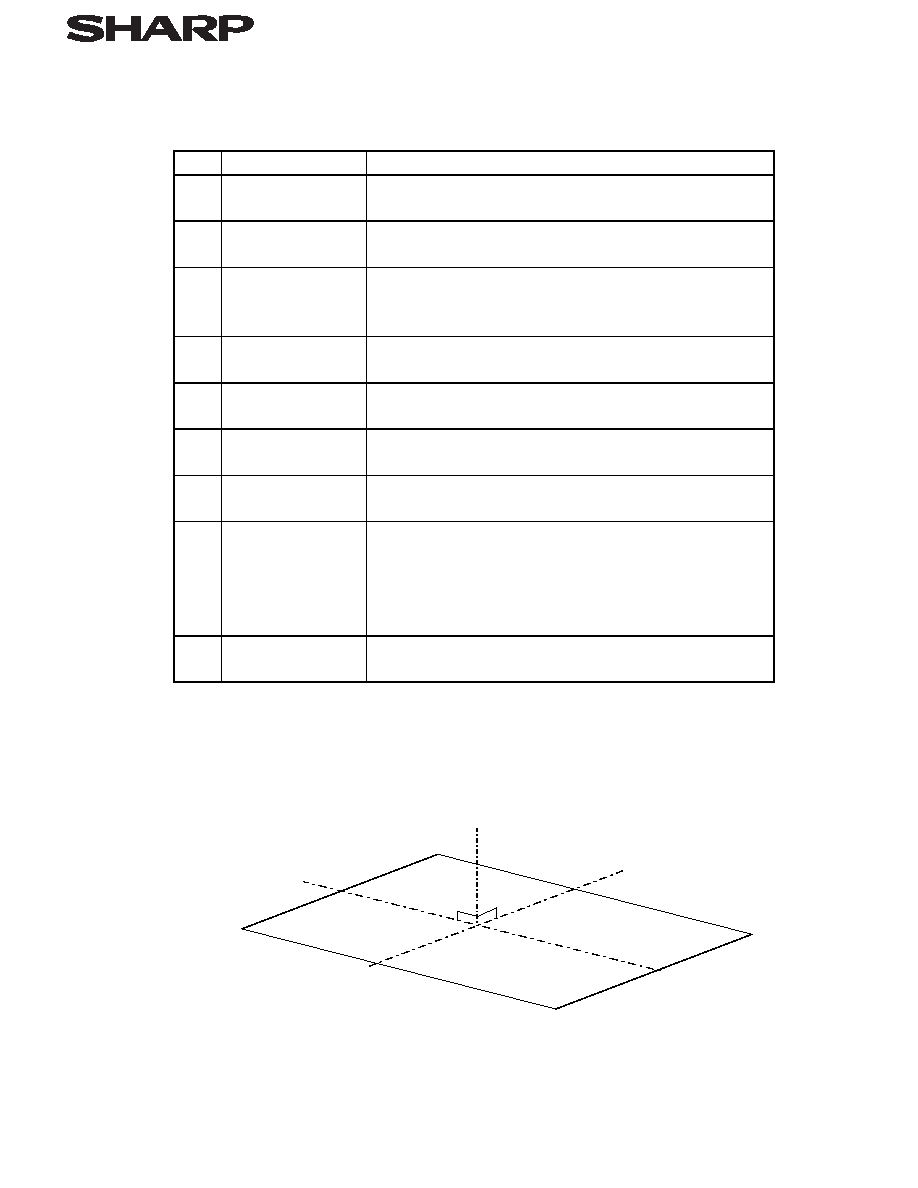

13. Reliability Test Conditions for TFT-LCD Module

Table 13-1

No.

Test items

Test conditions

High temperature

storage test

Leaves the module at Ta = +80 for 240h Note 1

Low temperature

storage test

Leaves the module at Ta=-30 for 240h Note 1

High temperature

and high humidity

operating test

Operates the module at Tp= +40, 95%RH for 240h

(No condensation) Note 1

High temperature

operating test

Operates the module at Tp= +70 for 240h Note 1

Low temperature

operating test

Operates the module at Ta=-10 for 240h Note 1

(The lifetime of a CCFT is not included)

Strength against

ESD

±

200V200pF(0) 1 time for each terminals

Shock test

(non-operating)

490m/s26ms, ±X±Y±Z 3 times for each direction

JIS C0041, A-7 Condition C

Vibration test

(non-operating)

Frequency557Hz, Stroke0.15mm

Frequency58500Hz, Acceleration9.8m/s

2

Sweep cycle11 minutes

X,Y,Z 1 hours for each directions ( total 3 hours ) Note 2

JIS D1601

Thermal shock test Ta=-30+80 , 200 cycles

(0.5h) (0.5h)

Result evaluation criteria

Under the display quality test conditions with normal operation state, these shall be

no change which may affect practical display function.

Note 1 Ta= Ambient temperature, Tp= Panel surface temperature

Note 2 X,Y,Z directions are shown as follows:

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Suggested applications (if any) are for standard use; See Important Restrictions for limitations on special applications. See Limited

Warranty for SHARP's product warranty. The Limited Warranty is in lieu, and exclusive of, all other warranties, express or implied.

ALL EXPRESS AND IMPLIED WARRANTIES, INCLUDING THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR USE AND

FITNESS FOR A PARTICULAR PURPOSE, ARE SPECIFICALLY EXCLUDED. In no event will SHARP be liable, or in any way responsible,

for any incidental or consequential economic or property damage.

NORTH AMERICA

EUROPE

JAPAN

SHARP Microelectronics of the Americas

5700 NW Pacific Rim Blvd.

Camas, WA 98607, U.S.A.

Phone: (1) 360-834-2500

Fax: (1) 360-834-8903

Fast Info: (1) 800-833-9437

www.sharpsma.com

SHARP Microelectronics Europe

Division of Sharp Electronics (Europe) GmbH

Sonninstrasse 3

20097 Hamburg, Germany

Phone: (49) 40-2376-2286

Fax: (49) 40-2376-2232

www.sharpsme.com

SHARP Corporation

Electronic Components & Devices

22-22 Nagaike-cho, Abeno-Ku

Osaka 545-8522, Japan

Phone: (81) 6-6621-1221

Fax: (81) 6117-725300/6117-725301

www.sharp-world.com

TAIWAN

SINGAPORE

KOREA

SHARP Electronic Components

(Taiwan) Corporation

8F-A, No. 16, Sec. 4, Nanking E. Rd.

Taipei, Taiwan, Republic of China

Phone: (886) 2-2577-7341

Fax: (886) 2-2577-7326/2-2577-7328

SHARP Electronics (Singapore) PTE., Ltd.

438A, Alexandra Road, #05-01/02

Alexandra Technopark,

Singapore 119967

Phone: (65) 271-3566

Fax: (65) 271-3855

SHARP Electronic Components

(Korea) Corporation

RM 501 Geosung B/D, 541

Dohwa-dong, Mapo-ku

Seoul 121-701, Korea

Phone: (82) 2-711-5813 ~ 8

Fax: (82) 2-711-5819

CHINA

HONG KONG

SHARP Microelectronics of China

(Shanghai) Co., Ltd.

28 Xin Jin Qiao Road King Tower 16F

Pudong Shanghai, 201206 P.R. China

Phone: (86) 21-5854-7710/21-5834-6056

Fax: (86) 21-5854-4340/21-5834-6057

Head Office:

No. 360, Bashen Road,

Xin Development Bldg. 22

Waigaoqiao Free Trade Zone Shanghai

200131 P.R. China

Email: smc@china.global.sharp.co.jp

SHARP-ROXY (Hong Kong) Ltd.

3rd Business Division,

17/F, Admiralty Centre, Tower 1

18 Harcourt Road, Hong Kong

Phone: (852) 28229311

Fax: (852) 28660779

www.sharp.com.hk

Shenzhen Representative Office:

Room 13B1, Tower C,

Electronics Science & Technology Building

Shen Nan Zhong Road

Shenzhen, P.R. China

Phone: (86) 755-3273731

Fax: (86) 755-3273735