1.

General description

The PCA9502 is an 8-bit I/O expander with I

2

C-bus/SPI host interface. The device comes

in a very small HVQFN24 package, which makes it ideally suitable for hand-held, battery

operated applications.

The device also supports software reset, which allows the host to reset the device at any

time, independent of the hardware reset signal.

2.

Features

2.1 General features

I

Selectable I

2

C-bus or SPI interface

I

3.3 V or 2.5 V operation

I

Industrial temperature range:

-

40

°

C to +85

°

C

I

Eight programmable I/O pins

I

Software reset

I

Industrial and commercial temperature ranges

I

Available in HVQFN24 package

I

16 hardware-selectable slave addresses

2.2 I

2

C-bus features

I

Noise filter on SCL/SDA inputs

I

400 kbit/s (maximum)

I

Compliant with I

2

C-bus Fast-mode

I

Slave mode only

2.3 SPI features

I

15 Mbit/s maximum speed

I

Slave mode only

I

SPI Mode 0

3.

Applications

I

Factory automation and process control

I

Portable and battery operated devices

I

Cellular data devices

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

Rev. 02 -- 3 August 2006

Product data sheet

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

2 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

4.

Ordering information

5.

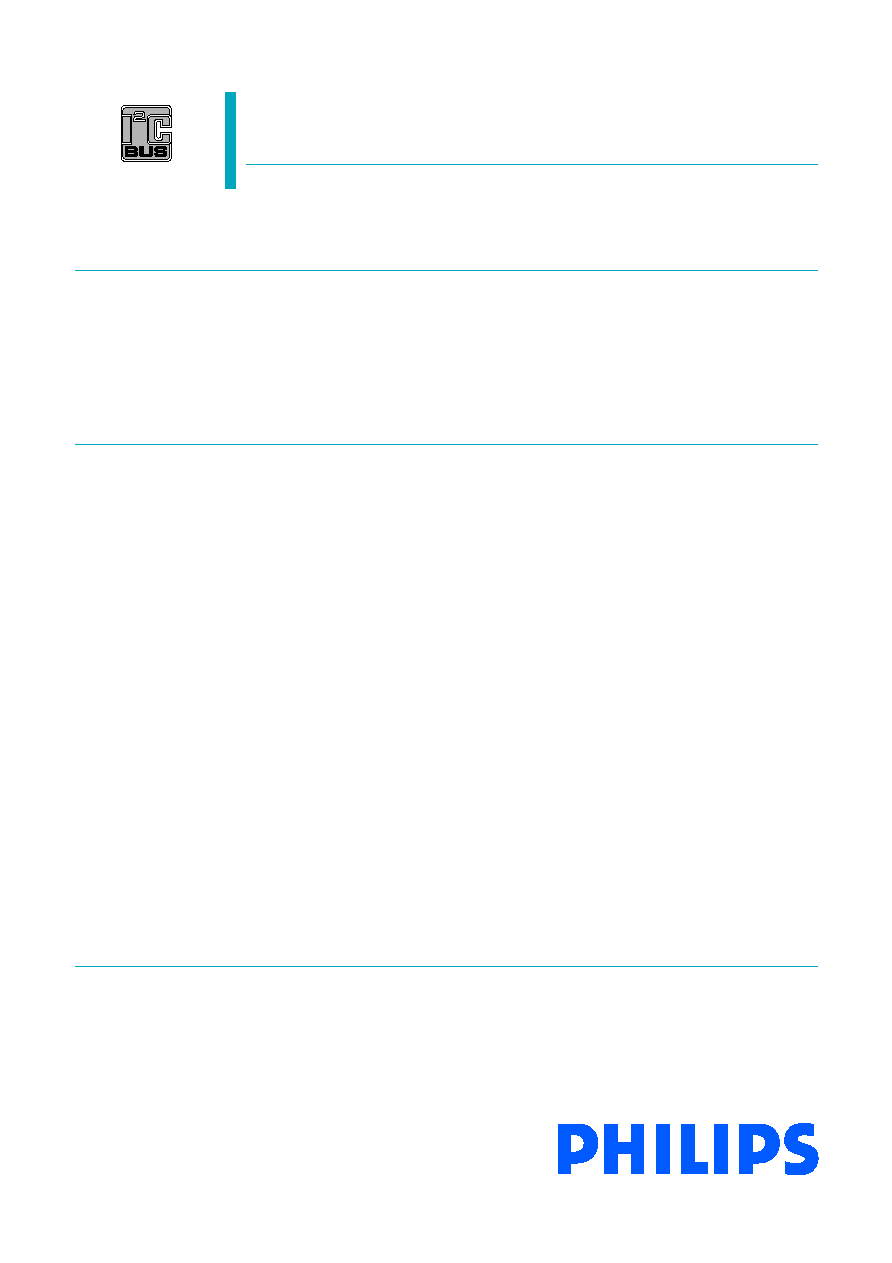

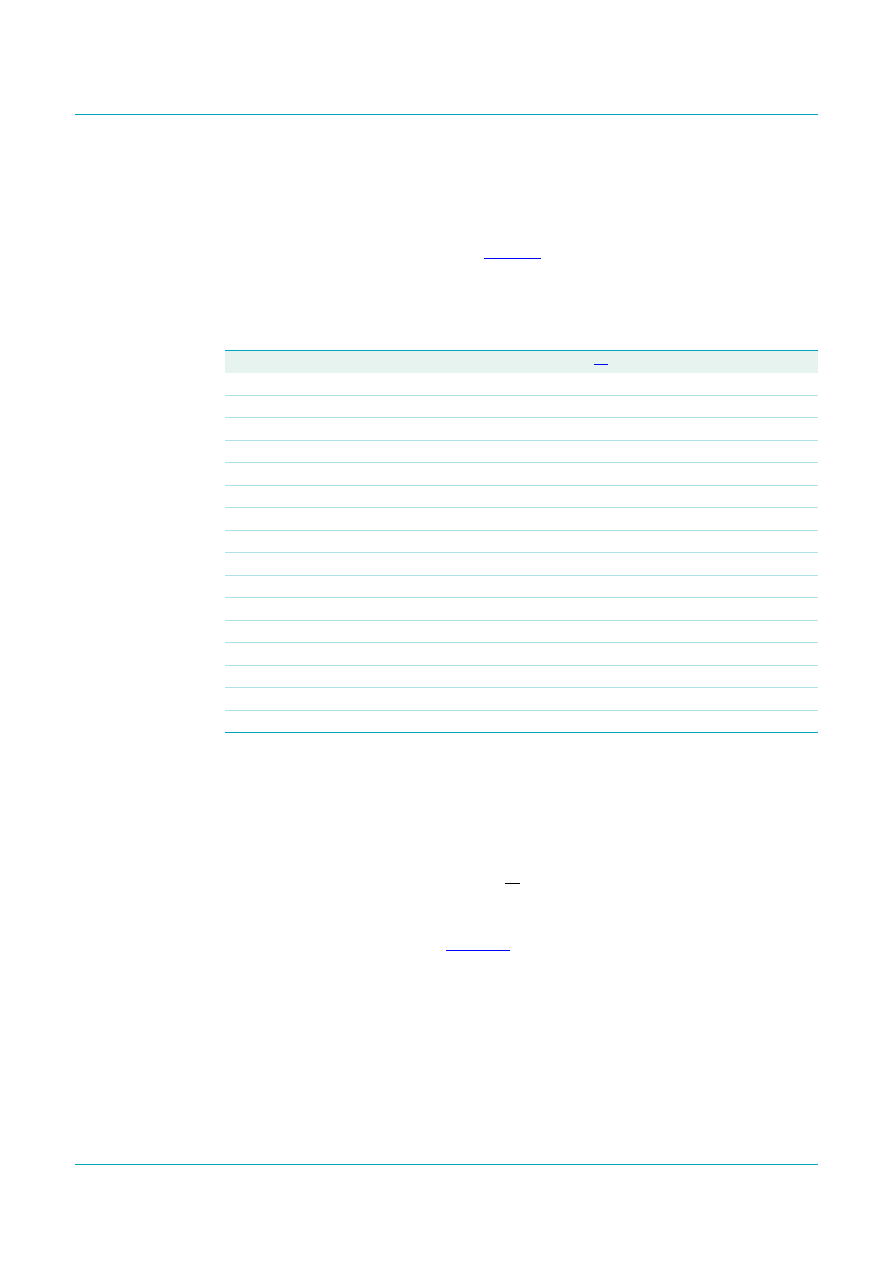

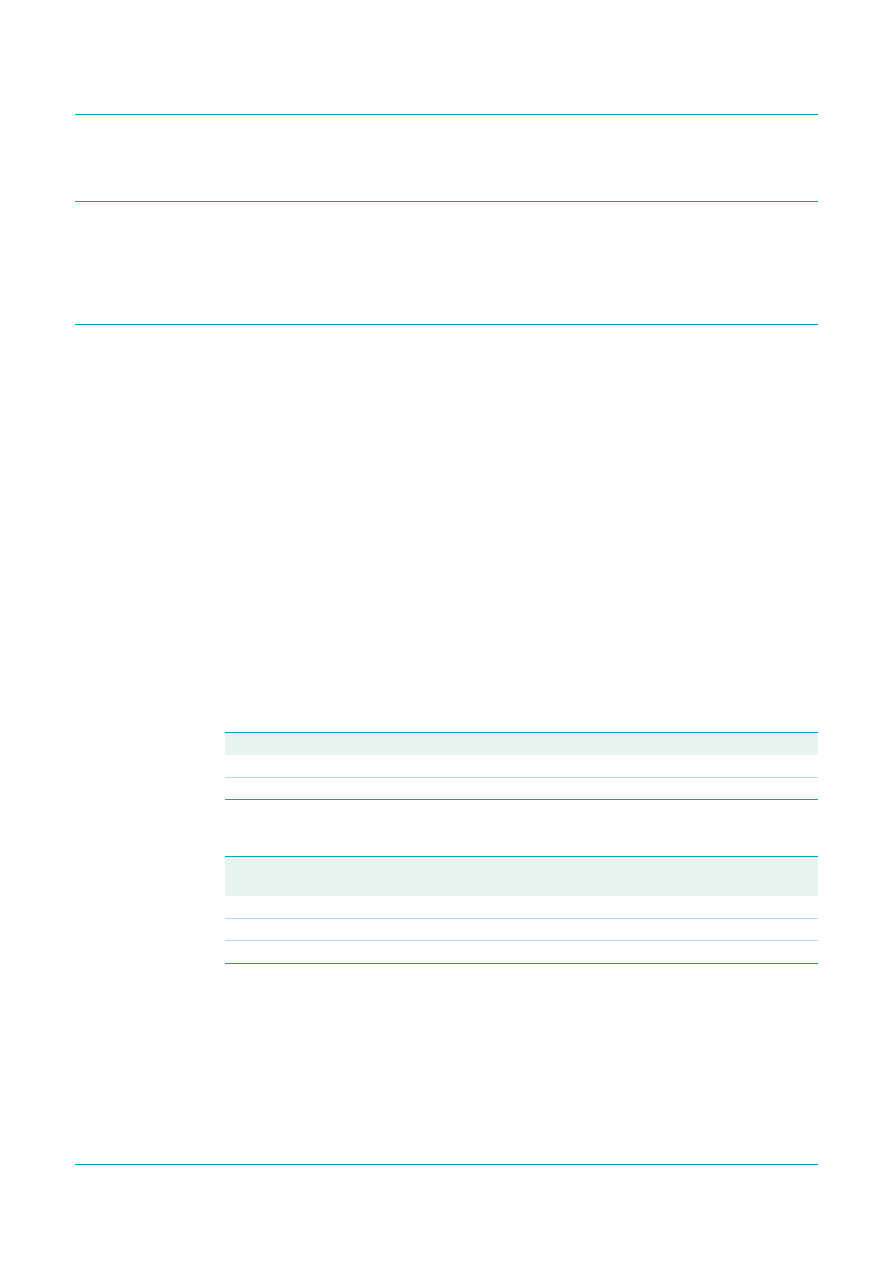

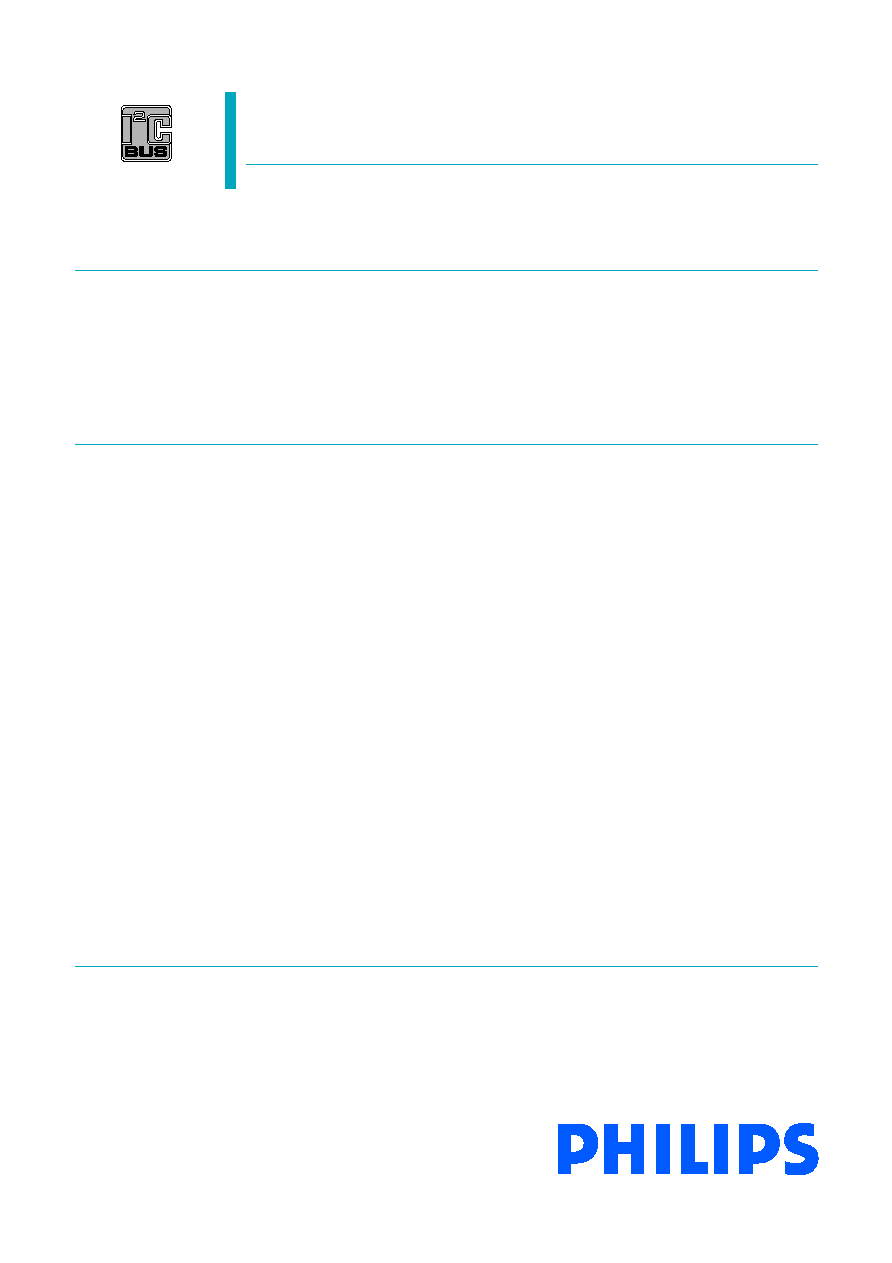

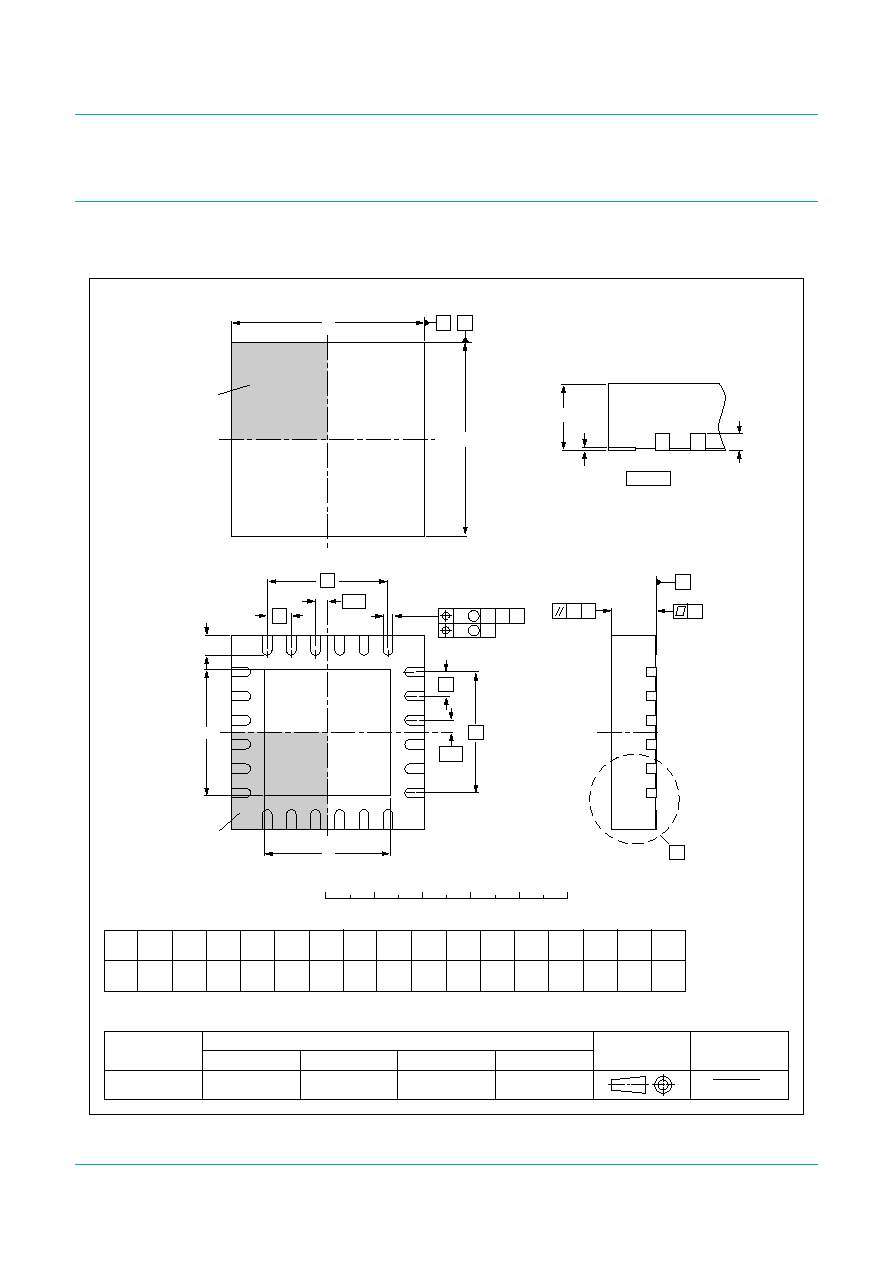

Block diagram

Table 1.

Ordering information

Type number

Package

Name

Description

Version

PCA9502BS

HVQFN24

plastic thermal enhanced very thin quad flat package;

no leads; 24 terminals; body 4

×

4

×

0.85 mm

SOT616-3

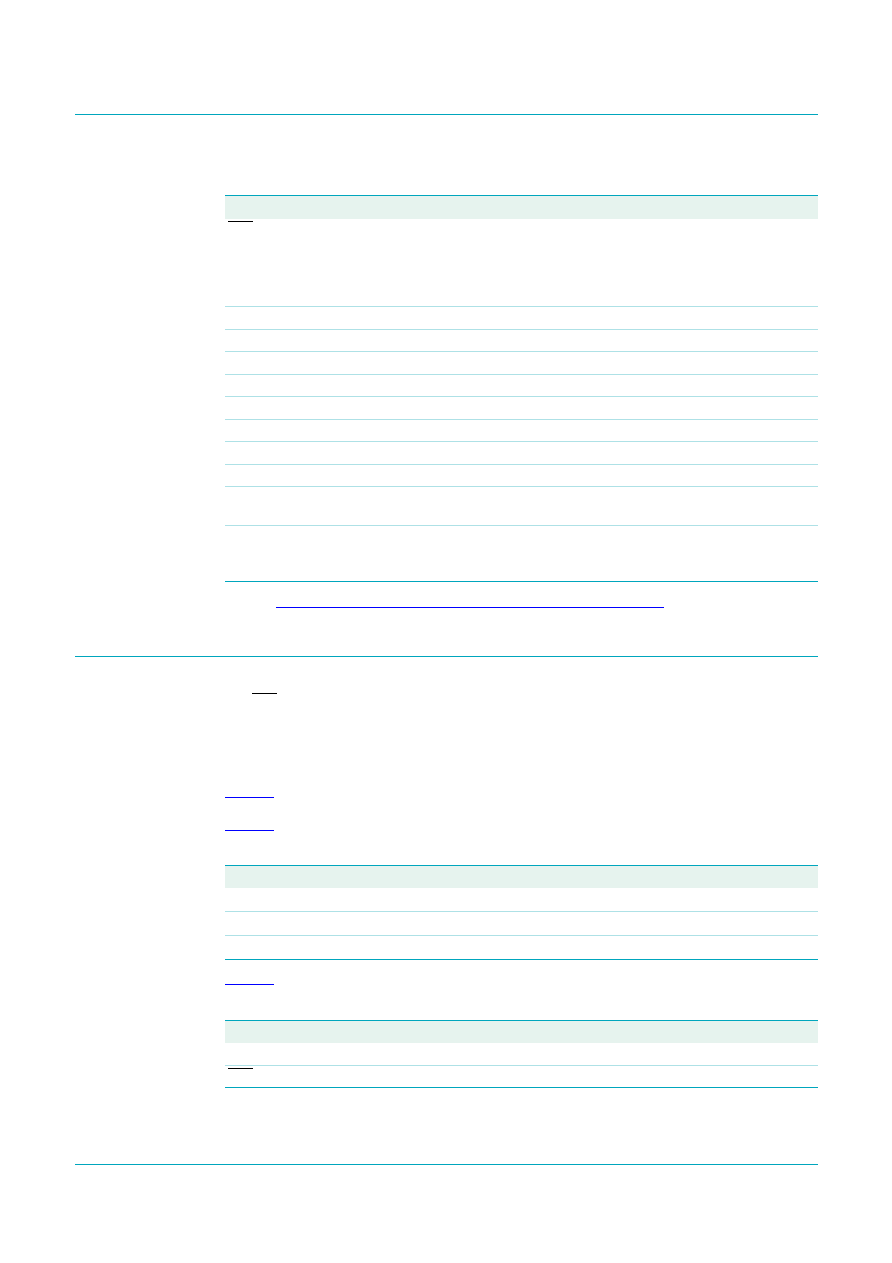

Fig 1.

Block diagram of PCA9502 I

2

C-bus interface

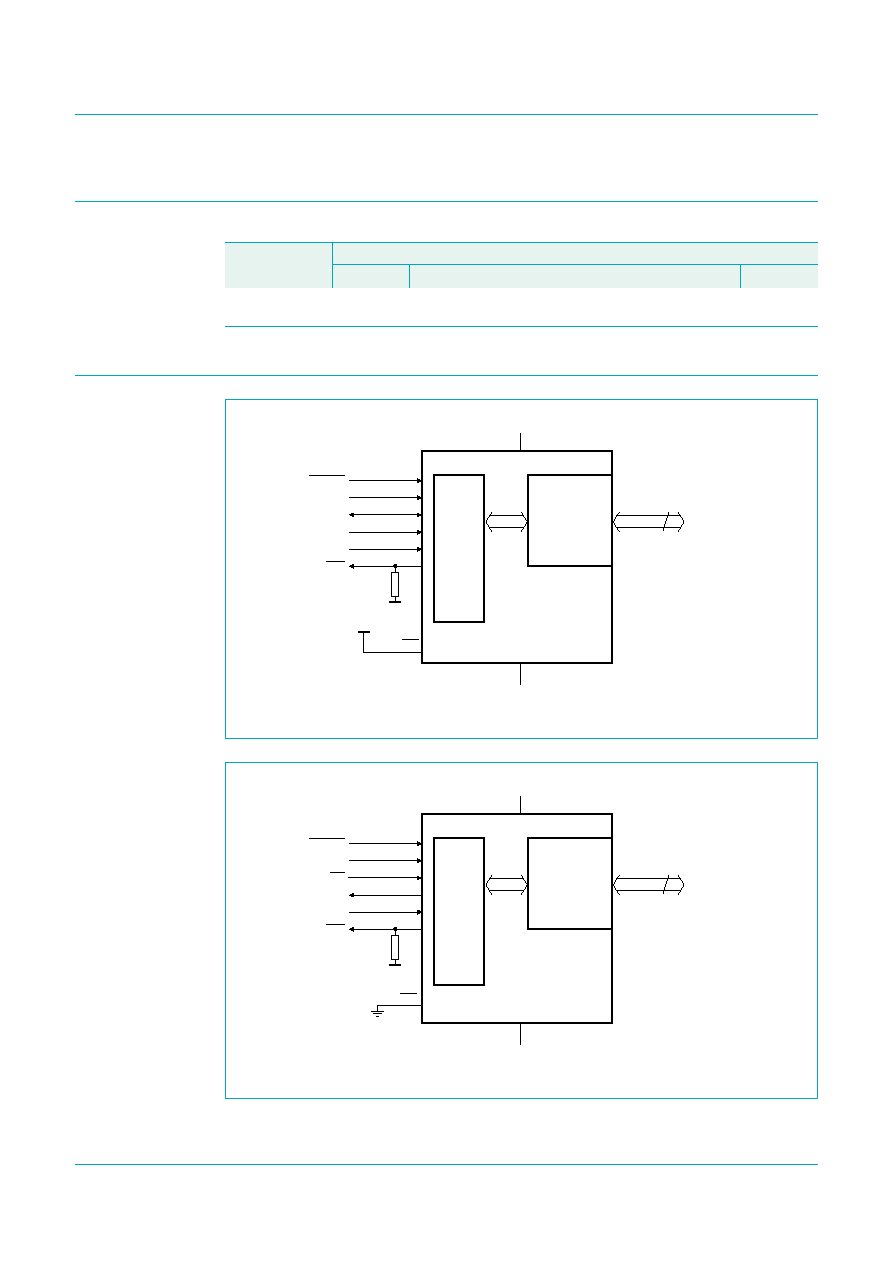

Fig 2.

Block diagram of PCA9502 SPI interface

PCA9502

002aab837

V

DD

I

2

C-BUS

GPIO

REGISTER

GPIO[7:0]

SCL

SDA

A0

IRQ

I2C/SPI

8

A1

RESET

V

DD

V

SS

V

DD

1 k

(3.3 V)

1.5 k

(2.5 V)

CS

PCA9502

002aab838

SPI

GPIO

REGISTER

GPIO[7:0]

SCLK

SO

IRQ

I2C/SPI

8

SI

RESET

V

DD

V

SS

V

DD

1 k

(3.3 V)

1.5 k

(2.5 V)

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

3 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

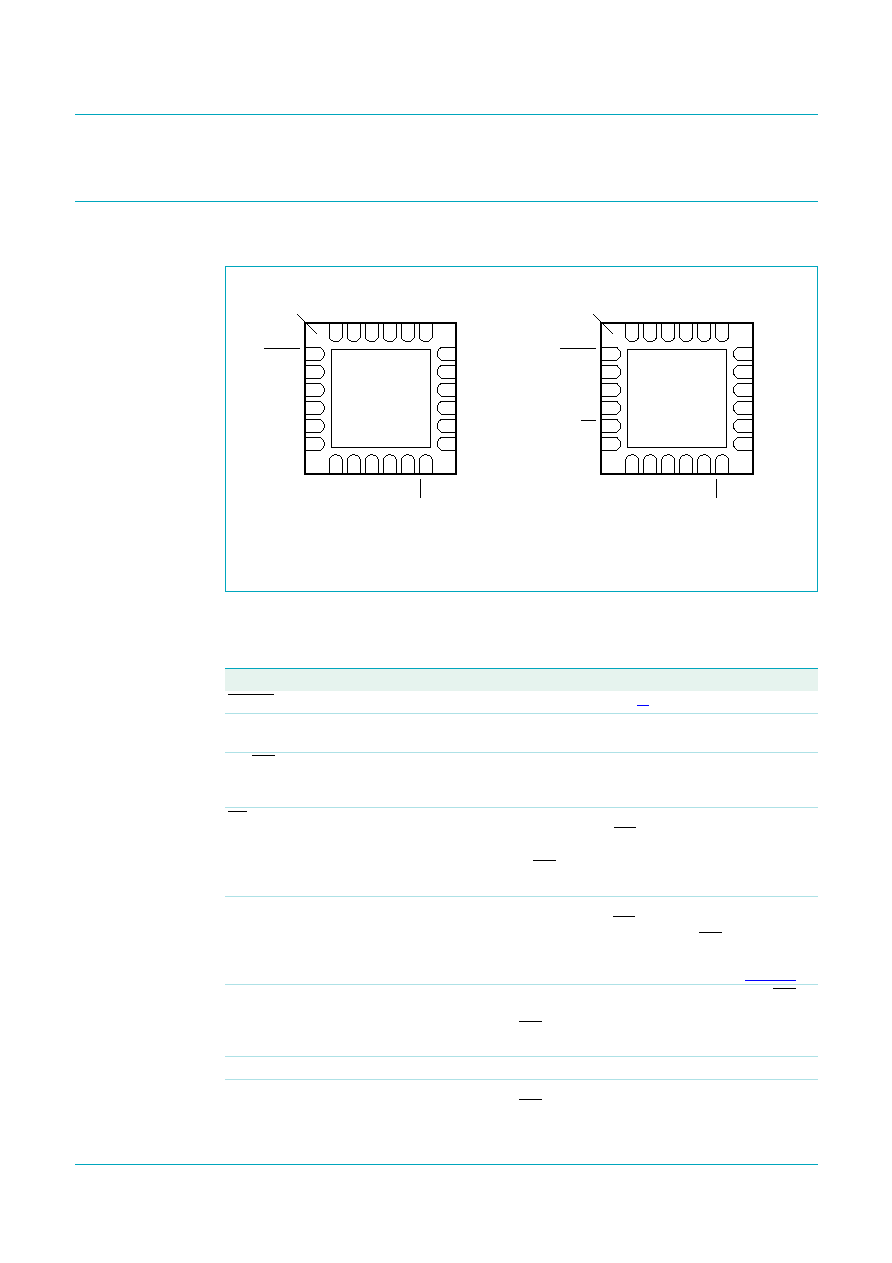

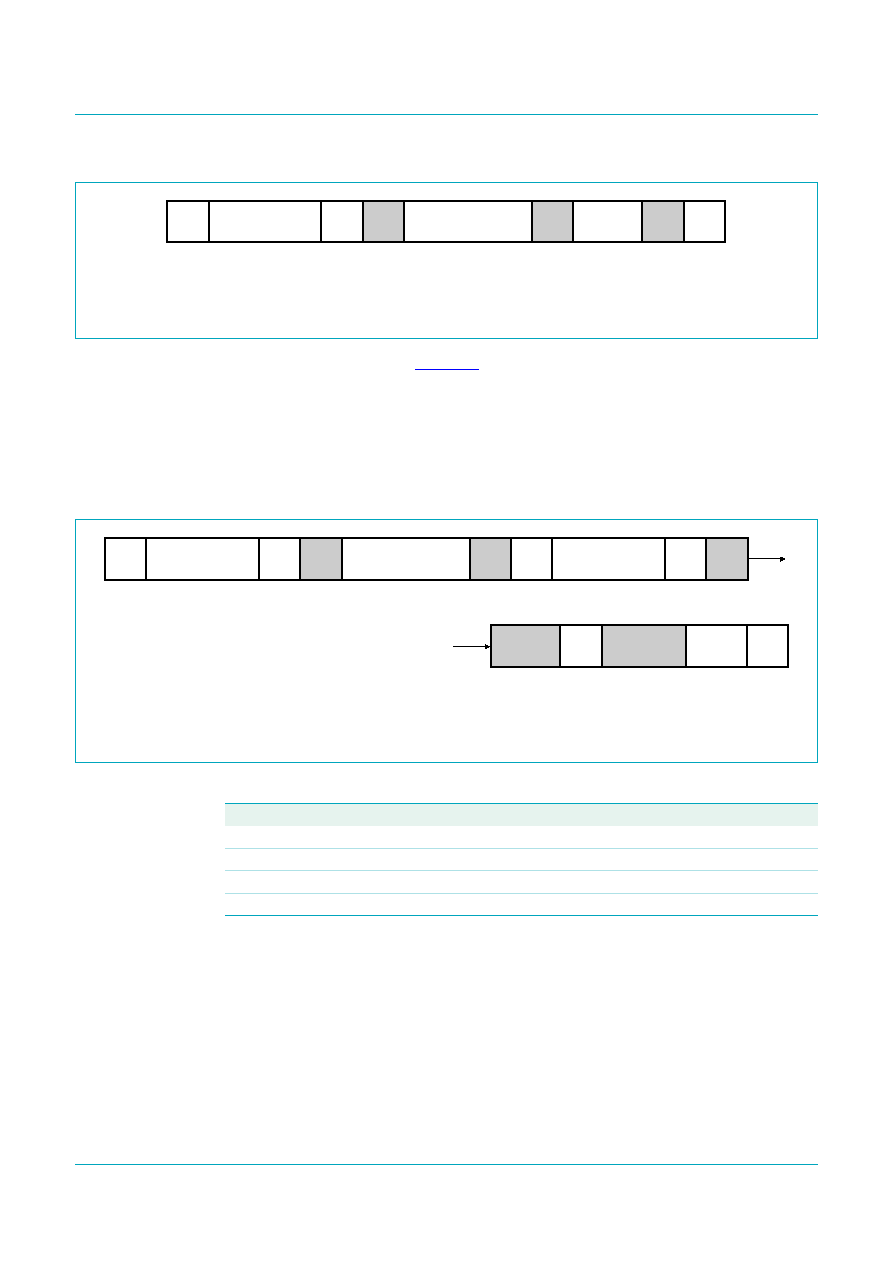

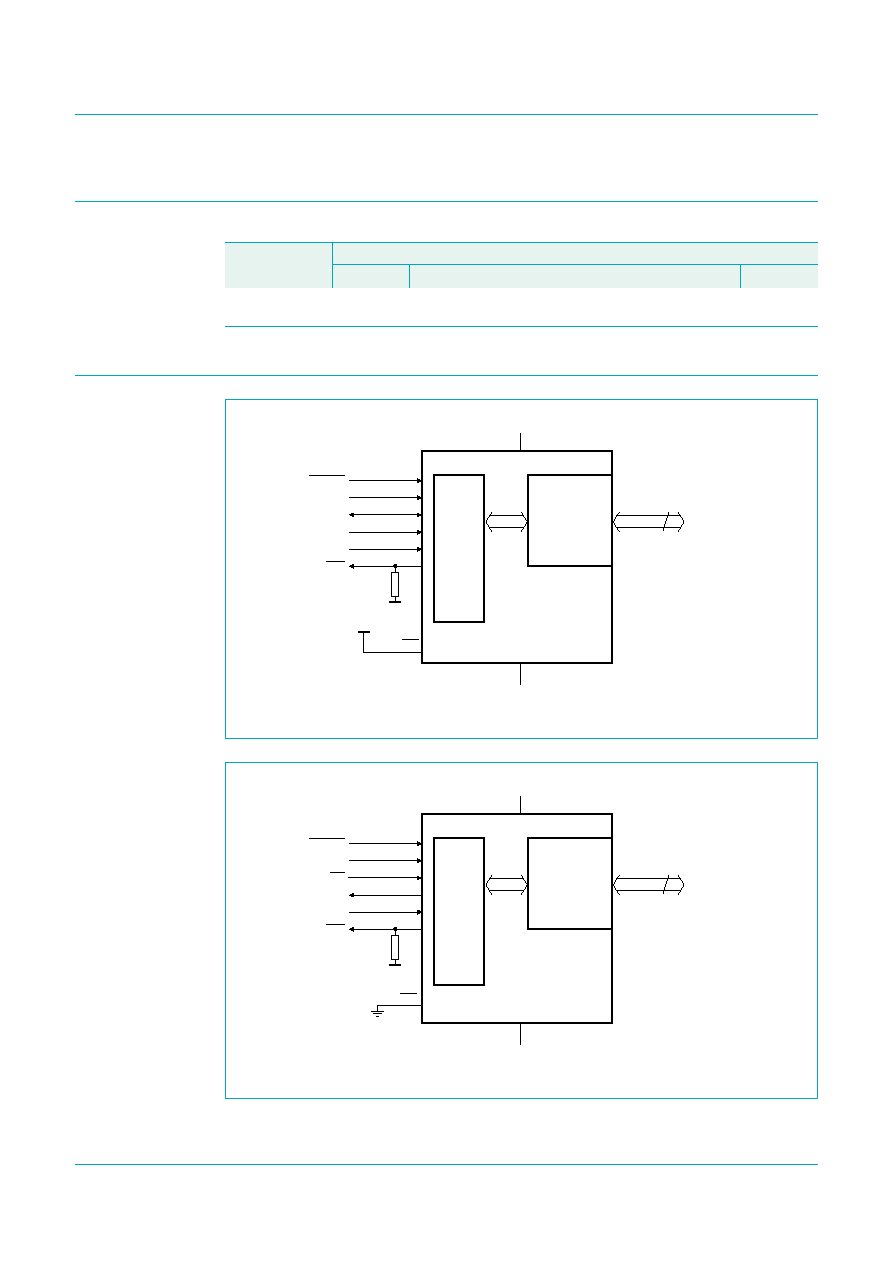

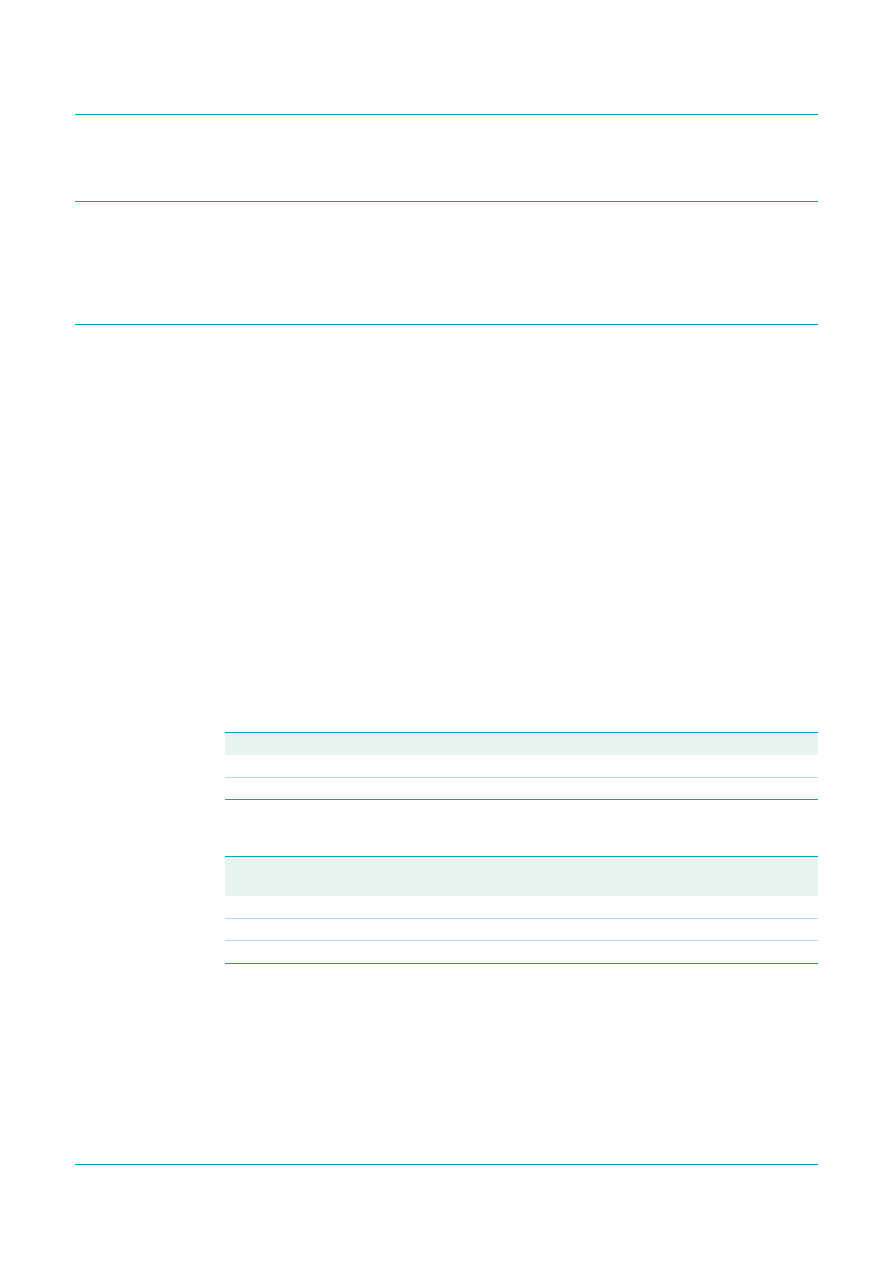

6.

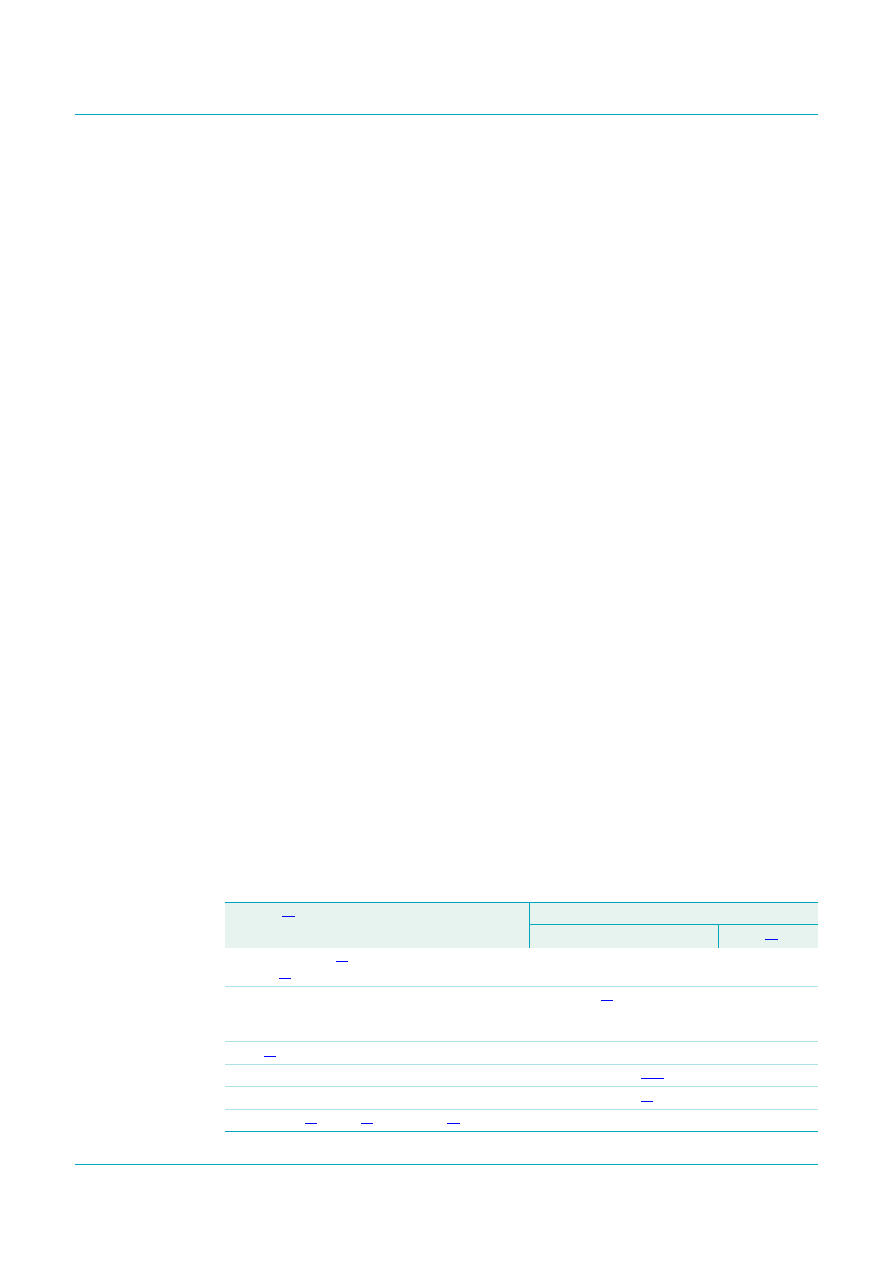

Pinning information

6.1 Pinning

6.2 Pin description

a. I

2

C-bus interface

b. SPI interface

Fig 3.

Pin configuration for HVQFN24

GPIO7

GPIO6

GPIO5

GPIO4

V

SS

GPIO2

GPIO1

GPIO0

SCL

n.c.

A1

A0

V

DD

V

DD

RESET

V

DD

GPIO3

V

DD

V

SS

SDA

002aab839

Transparent top view

V

DD

V

SS

V

DD

terminal 1

index area

6

13

5

14

4

15

3

16

2

17

1

18

7

8

9

10

11

12

24

23

22

21

20

19

PCA9502BS

IRQ

GPIO7

GPIO6

GPIO5

GPIO4

V

SS

GPIO2

GPIO1

GPIO0

SCLK

SO

SI

CS

V

SS

V

DD

RESET

V

DD

GPIO3

V

DD

V

SS

V

SS

002aab840

Transparent top view

V

DD

V

SS

V

DD

terminal 1

index area

6

13

5

14

4

15

3

16

2

17

1

18

7

8

9

10

11

12

24

23

22

21

20

19

PCA9502BS

IRQ

Table 2.

Pin description

Symbol

Pin

Type

Description

RESET

1

I

device hardware reset (active LOW)

[1]

V

DD

2, 3, 11,

22, 24

-

power supply

I2C/SPI

4

I

I

2

C-bus or SPI interface select. I

2

C-bus interface is selected if this

pin is at logic HIGH. SPI interface is selected if this pin is at logic

LOW.

CS/A0

5

I

SPI chip select or I

2

C-bus device address select A0. If SPI

configuration is selected by I2C/SPI pin, this pin is the SPI chip

select pin (Schmitt trigger, active LOW). If I

2

C-bus configuration

is selected by I2C/SPI pin, this pin along with A1 pin allows user

to change the device's base address.

SI/A1

6

I

SPI data input pin or I

2

C-bus device address select A1. If SPI

configuration is selected by I2C/SPI pin, this is the SPI data input

pin. If I

2

C-bus configuration is selected by I2C/SPI pin, this pin

along with A0 pin allows user to change the device's base

address. To select the device address, please refer to

Table 11

.

SO

7

O

SPI data output pin. If SPI configuration is selected by I2C/SPI

pin, this is a 3-stateable output pin. If I

2

C-bus configuration is

selected by I2C/SPI pin, this pin function is undefined and must

be left as n.c. (not connected).

SCL/SCLK

8

I

I

2

C-bus or SPI input clock.

SDA

9

I/O

I

2

C-bus data input/output, open-drain if I

2

C-bus configuration is

selected by I2C/SPI pin. If SPI configuration is selected then this

pin is an undefined pin and must be connected to V

SS

.

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

4 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

[1]

See

Section 7.1 "Hardware reset, Power-On Reset (POR) and software reset"

7.

Functional description

The device interfaces to a host through either I

2

C-bus or SPI interface (selectable through

I2C/SPI pin), and provides the host with eight programmable GPIO pins.

7.1 Hardware reset, Power-On Reset (POR) and software reset

These three reset methods are identical and will reset the internal registers as indicated in

Table 3

.

Table 3

summarizes the state of registers after reset.

Table 4

summarizes the state of hardware pins after reset.

IRQ

12

O

Interrupt (open-drain, active LOW). Interrupt is enabled when

interrupt sources are enabled in the I/O Interrupt Enable register

(IOIntEna). The interrupt condition is the change of state of the

input pins. An external resistor (1 k

for 3.3 V, 1.5 k

for 2.5 V)

must be connected between this pin and V

DD

.

GPIO0

13

I/O

programmable I/O pin

GPIO1

14

I/O

programmable I/O pin

GPIO2

15

I/O

programmable I/O pin

GPIO3

16

I/O

programmable I/O pin

GPIO4

18

I/O

programmable I/O pin

GPIO5

19

I/O

programmable I/O pin

GPIO6

20

I/O

programmable I/O pin

GPIO7

21

I/O

programmable I/O pin

V

SS

10, 17,

23

-

ground

V

SS

center

pad

-

The center pad on the back side of the HVQFN24 package is

metallic and should be connected to ground on the printed-circuit

board.

Table 2.

Pin description

...continued

Symbol

Pin

Type

Description

Table 3.

Registers after reset

Register

Reset state

I/O direction

all bits cleared

I/O interrupt enable

all bits cleared

I/O control

all bits cleared

Table 4.

Signals after reset

Signal

Reset state

I/Os

inputs

IRQ

HIGH by external pull-up

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

5 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

7.2 Interrupts

The PCA9502 has interrupt generation capability. The interrupt enable register (IOIntEna)

enables interrupts due to I/O pin change of state, and the IRQ signal in response to an

interrupt generation.

8.

Register descriptions

The programming combinations for register selection are shown in

Table 5

.

[1]

Other addresses 0x00 through 0x09, 0x0F are reserved and should not be accessed (read or write).

[2]

These bits are reserved and should be set to 0.

8.1 Programmable I/O pins Direction register (IODir)

This register is used to program the I/O pins direction. Bit 0 to bit 7 control GPIO0 to

GPIO7.

Remark: If there is a pending input (GPIO) interrupt and IODir is written, this pending

interrupt will be cleared, that is, the interrupt signal will be negated.

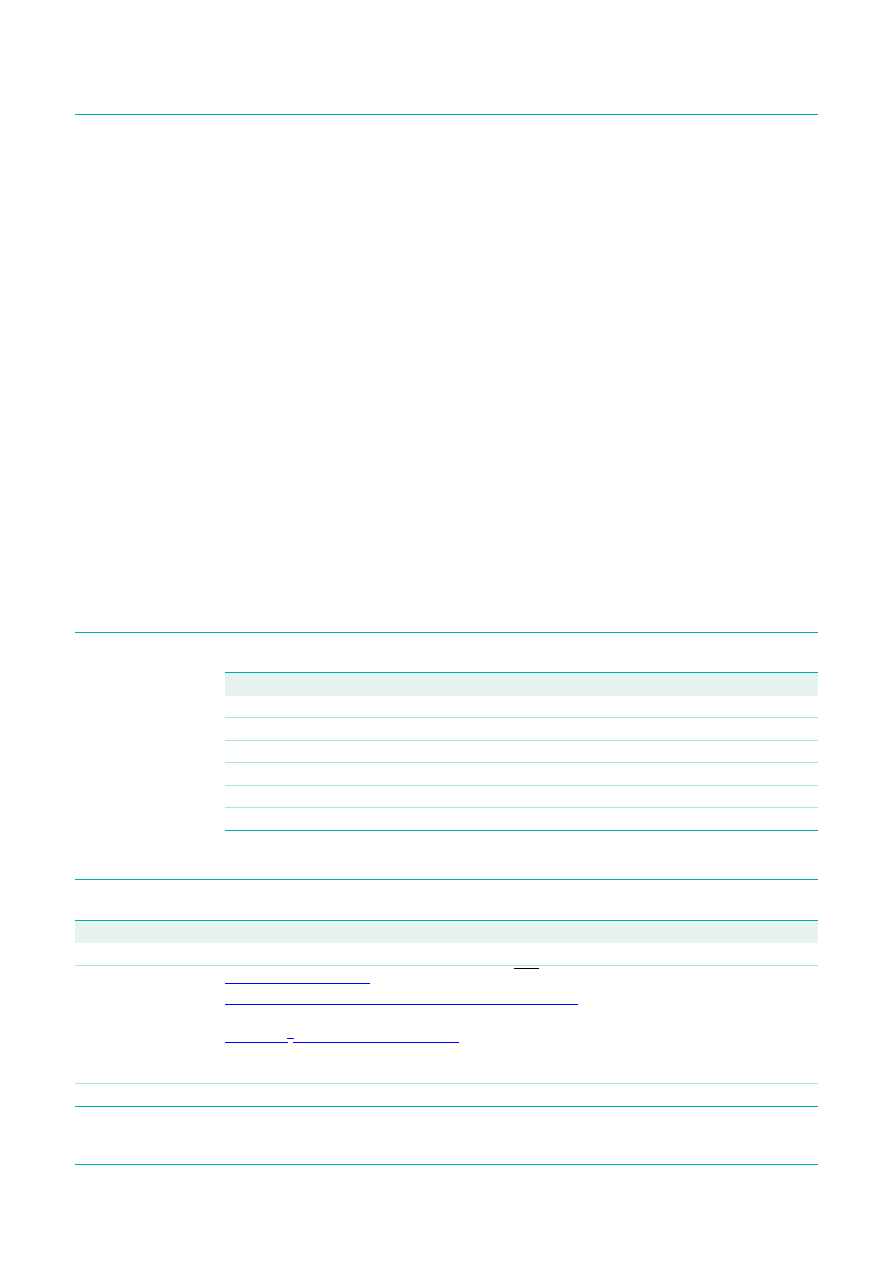

Table 5.

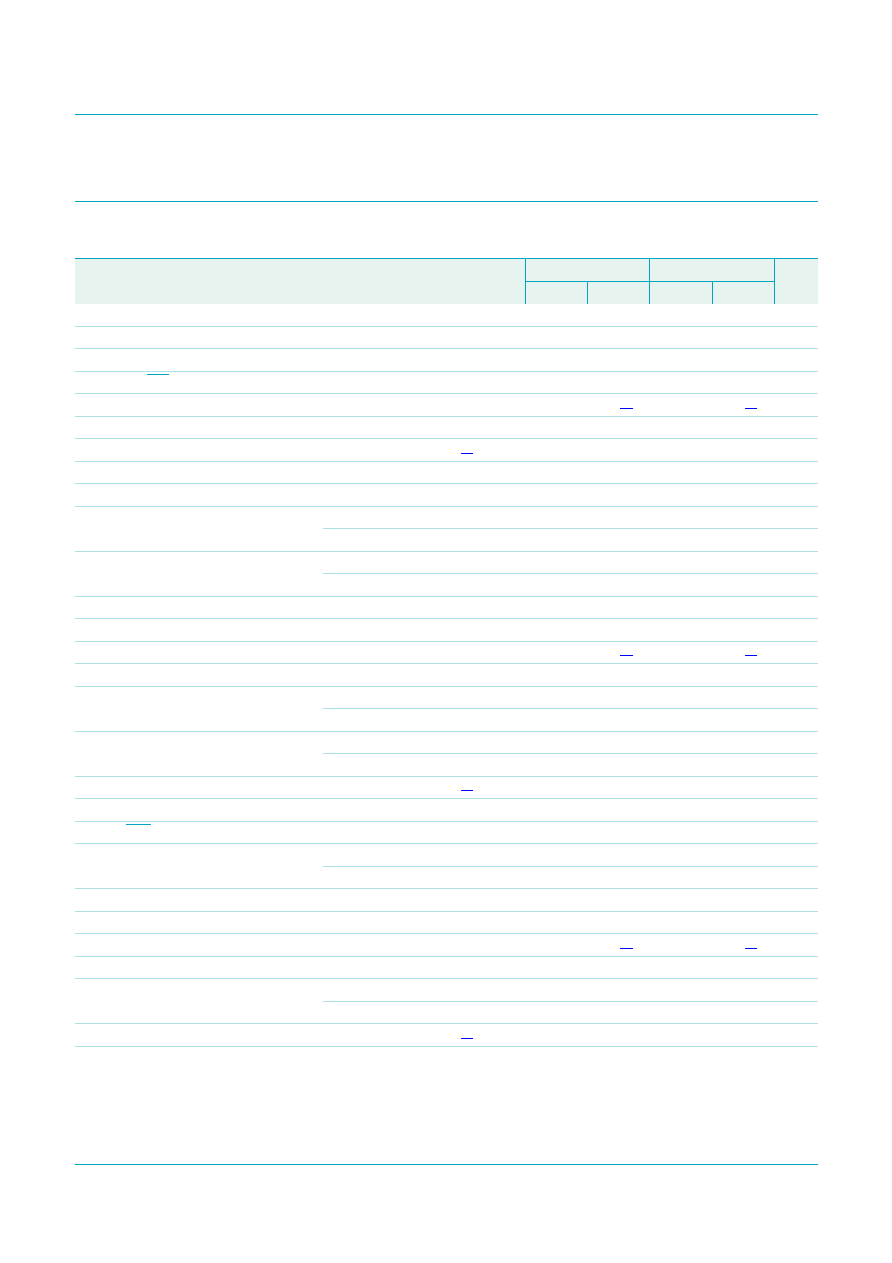

Register map - read/write properties

Register name

Read mode

Write mode

IODir

I/O pin direction

I/O pin direction

IOState

I/O pin states

n/a

IOIntEna

I/O interrupt enable register

I/O interrupt enable register

IOControl

I/O pins control

I/O pins control

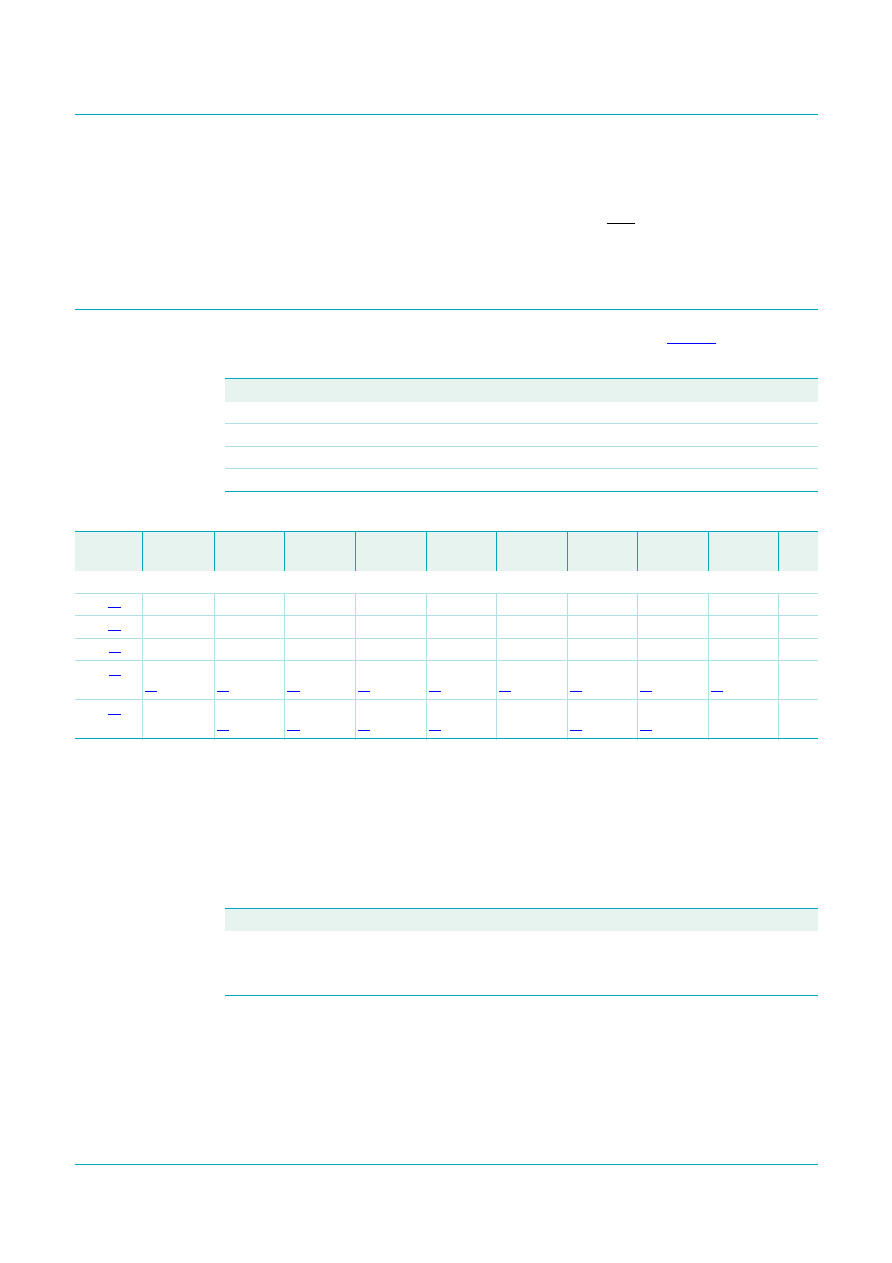

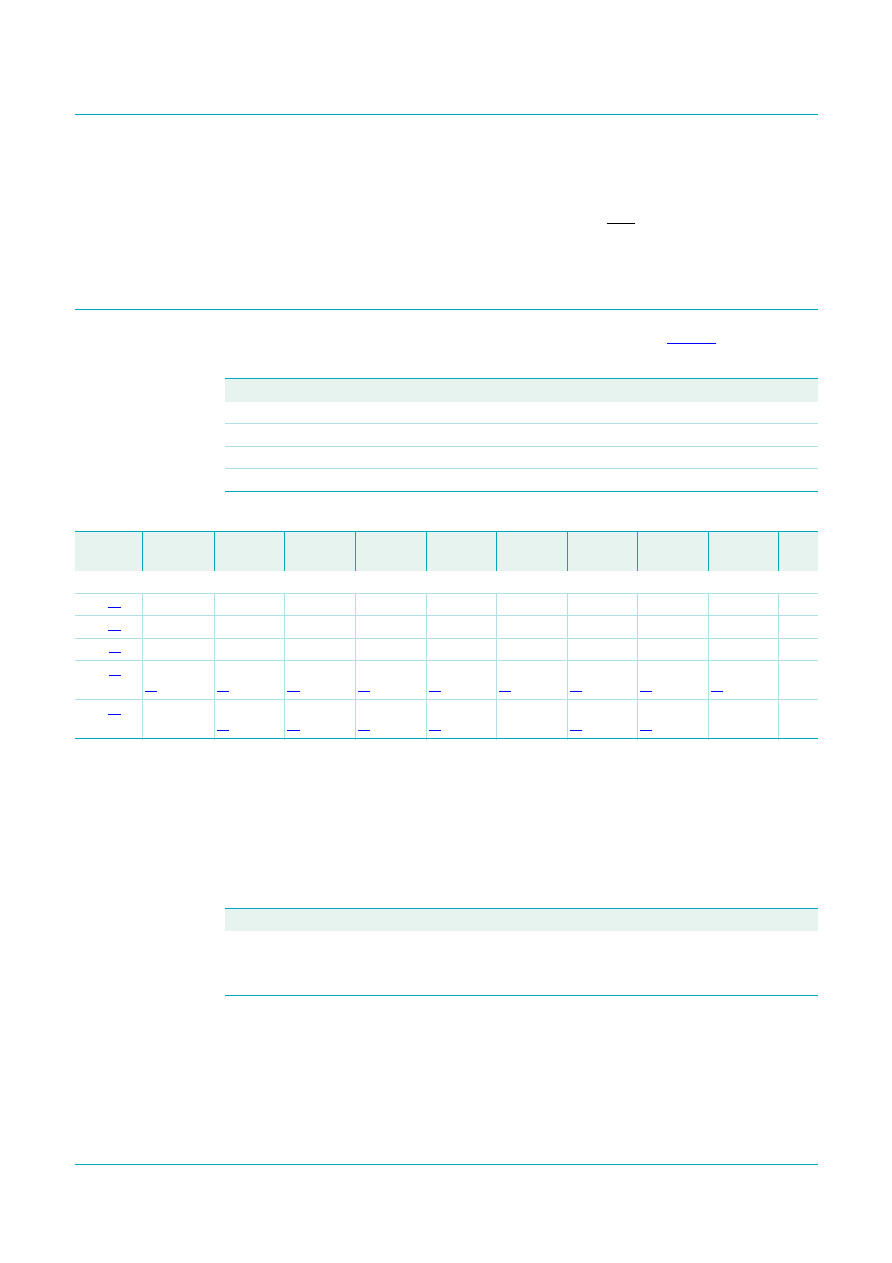

Table 6.

PCA9502 internal registers

Register

address

Register

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

R/W

General Register Set

0x0A

[1]

IODir

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

R/W

0x0B

[1]

IOState

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

R/W

0x0C

[1]

IOIntEna

bit 7

bit 6

bit 5

bit 4

bit 3

bit 2

bit 1

bit 0

R/W

0x0D

[1]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

0x0E

[1]

IOControl

reserved

[2]

reserved

[2]

reserved

[2]

reserved

[2]

SReset

reserved

[2]

reserved

[2]

IOLatch

R/W

Table 7.

IODir register (address 0x0A) bit description

Bit

Symbol

Description

7:0

IODir

set GPIO pins 7:0 to input or output

0 = input

1 = output

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

6 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

8.2 Programmable I/O pins State register (IOState)

When `read', this register returns the actual state of all I/O pins. When `write', each

register bit will be transferred to the corresponding IO pin programmed as output.

8.3 I/O Interrupt Enable register (IOIntEna)

This register enables the interrupt due to a change in the I/O configured as inputs.

8.4 I/O Control register (IOControl)

Table 8.

IOState register (address 0x0B) bit description

Bit

Symbol

Description

7:0

IOState

Write this register: set the logic level on the output pins

0 = set output pin to zero

1 = set output pin to one

Read this register: return states of all pins

Table 9.

IOIntEna register (address 0x0C) bit description

Bit

Symbol

Description

7:0

IOIntEna

input interrupt enable

0 = a change in the input pin will not generate an interrupt

1 = a change in the input will generate an interrupt

Table 10.

IOControl register (address 0x0E) bit description

Bit

Symbol

Description

7:4

-

reserved for future use

3

SReset

software reset

A write to this bit will reset the device. Once the device is reset this

bit is automatically set to 0.

2:1

-

reserved for future use

0

IOLatch

enable/disable inputs latching

0 = input values are not latched. A change in any input generates an

interrupt. A read of the input register clears the interrupt. If the input

goes back to its initial logic state before the input register is read,

then the interrupt is cleared.

1 = input values are latched. A change in the input generates an

interrupt and the input logic value is loaded in the bit of the

corresponding input state register (IOState). A read of the IOState

register clears the interrupt. If the input pin goes back to its initial

logic state before the interrupt register is read, then the interrupt is

not cleared and the corresponding bit of the IOState register keeps

the logic value that initiates the interrupt.

Example: If GPIO4 input was as logic 0 and the input goes to logic 1

then back to logic 0, the IOState register will capture this change and

an interrupt is generated (if enabled). When the read is performed on

the IOState register, the interrupt is de-asserted, assuming there were

no additional input(s) that changed, and bit 4 of the IOState register

will read `1'. The next read of the IOState register should now read `0'.

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

7 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

9.

I

2

C-bus operation

The two lines of the I

2

C-bus are a serial data line (SDA) and a serial clock line (SCL). Both

lines are connected to a positive supply via a pull-up resistor, and remain HIGH when the

bus is not busy. Each device is recognized by a unique address whether it is a

microcomputer, LCD driver, memory or keyboard interface and can operate as either a

transmitter or receiver, depending on the function of the device. A device generating a

message or data is a transmitter, and a device receiving the message or data is a

receiver. Obviously, a passive function like an LCD driver could only be a receiver, while a

microcontroller or a memory can both transmit and receive data.

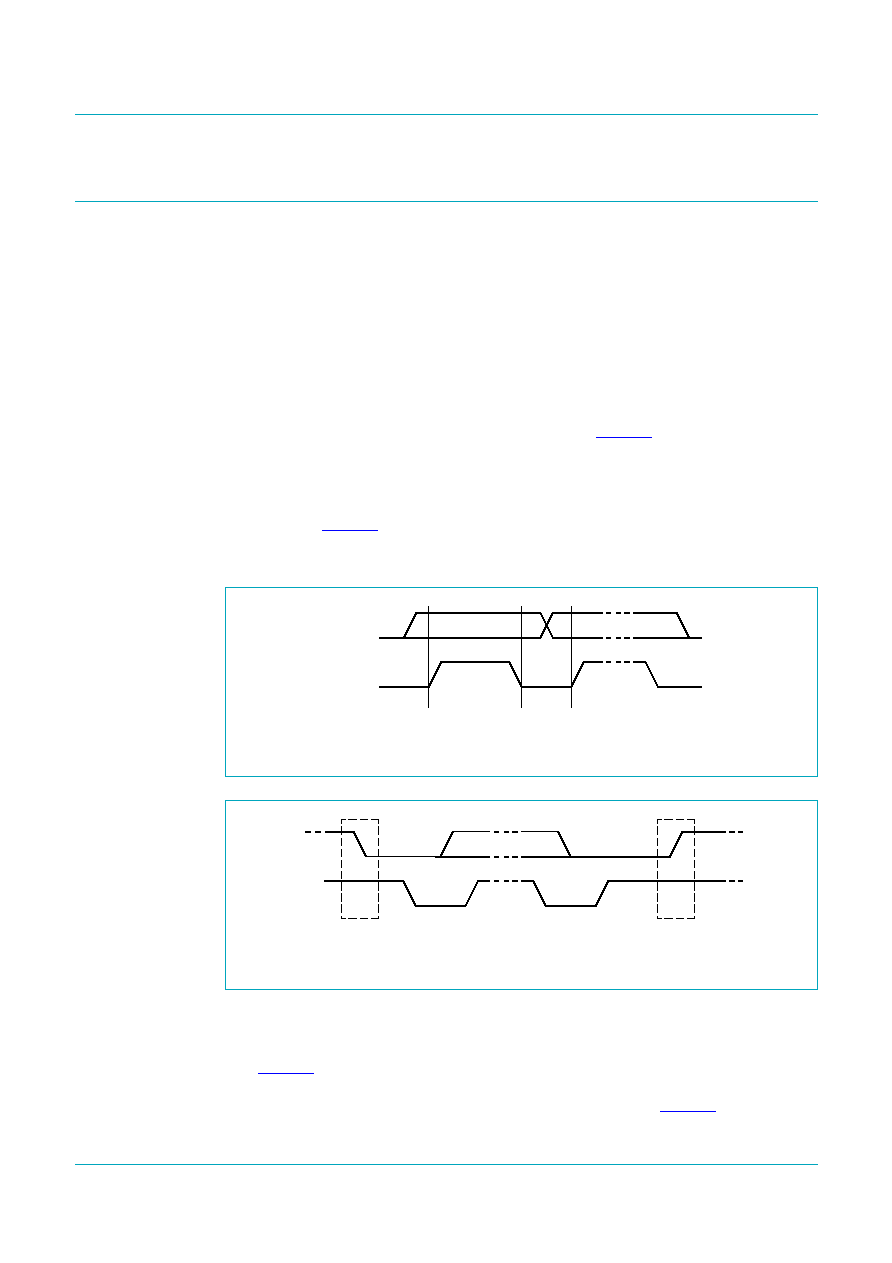

9.1 Data transfers

One data bit is transferred during each clock pulse (see

Figure 4

). The data on the SDA

line must remain stable during the HIGH period of the clock pulse in order to be valid.

Changes in the data line at this time will be interpreted as control signals. A HIGH-to-LOW

transition of the data line (SDA) while the clock signal (SCL) is HIGH indicates a START

condition, and a LOW-to-HIGH transition of the SDA while SCL is HIGH defines a STOP

condition (see

Figure 5

). The bus is considered to be busy after the START condition and

free again at a certain time interval after the STOP condition. The START and STOP

conditions are always generated by the master.

The number of data bytes transferred between the START and STOP condition from

transmitter to receiver is not limited. Each byte, which must be eight bits long, is

transferred serially with the most significant bit first, and is followed by an acknowledge bit.

(see

Figure 6

). The clock pulse related to the acknowledge bit is generated by the master.

The device that acknowledges has to pull down the SDA line during the acknowledge

clock pulse, while the transmitting device releases this pulse (see

Figure 7

).

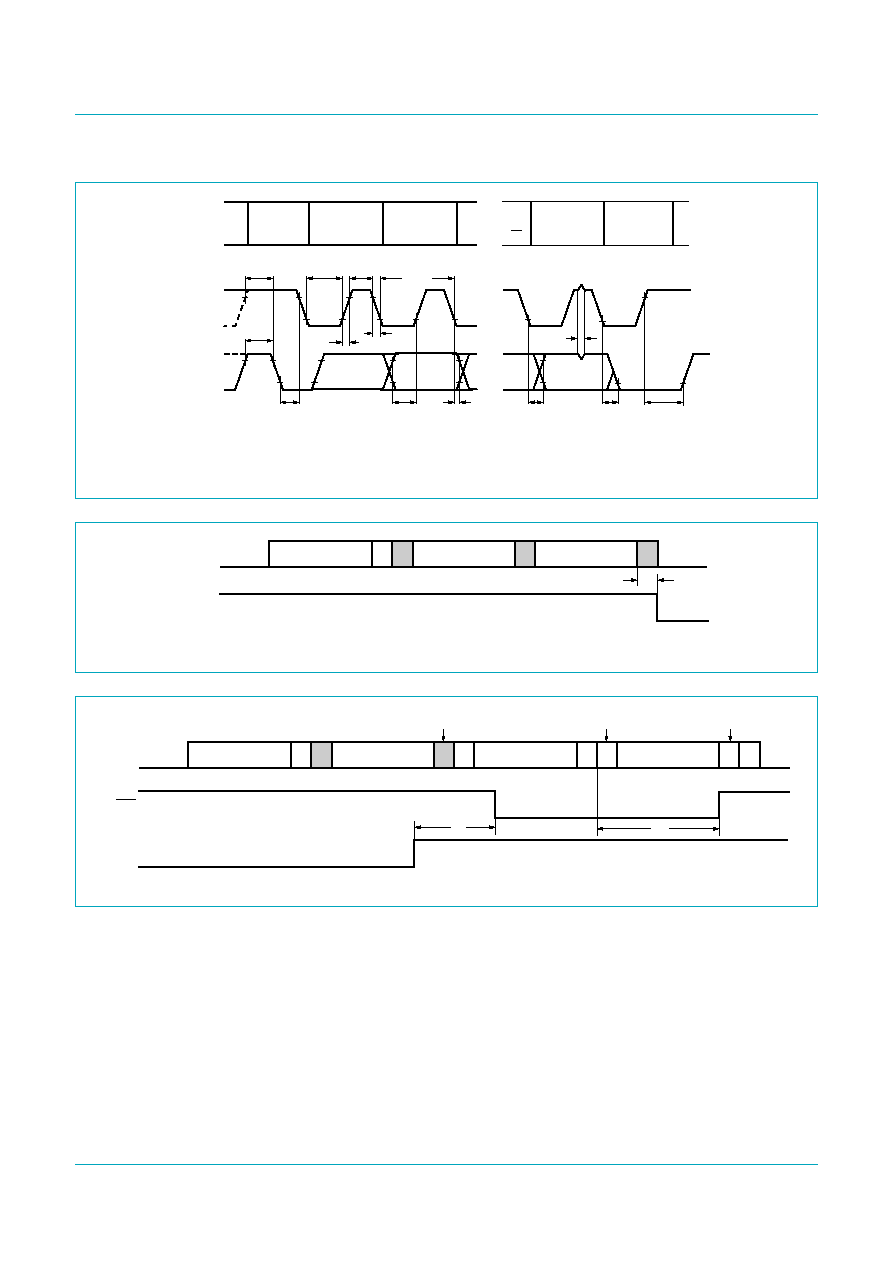

Fig 4.

Bit transfer on the I

2

C-bus

Fig 5.

START and STOP conditions

mba607

data line

stable;

data valid

change

of data

allowed

SDA

SCL

mba608

SDA

SCL

P

STOP condition

SDA

SCL

S

START condition

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

8 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

A slave receiver must generate an acknowledge after the reception of each byte, and a

master must generate one after the reception of each byte clocked out of the slave

transmitter.

There is an exception to the `acknowledge after every byte' rule. It occurs when a master

is a receiver: it must signal an end of data to the transmitter by not signalling an

acknowledge on the last byte that has been clocked out of the slave. The acknowledge

related clock, generated by the master should still take place, but the SDA line will not be

pulled down. In order to indicate that this is an active and intentional lack of

acknowledgement, we shall term this special condition as a `negative acknowledge'.

9.2 Addressing and transfer formats

Each device on the bus has its own unique address. Before any data is transmitted on the

bus, the master transmits on the bus the address of the slave to be accessed for this

transaction. A well-behaved slave with a matching address, if it exists on the network,

should of course acknowledge the master's addressing. The addressing is done by the

first byte transmitted by the master after the START condition.

An address on the network is seven bits long, appearing as the most significant bits of the

address byte. The last bit is a direction (R/W) bit. A `0' indicates that the master is

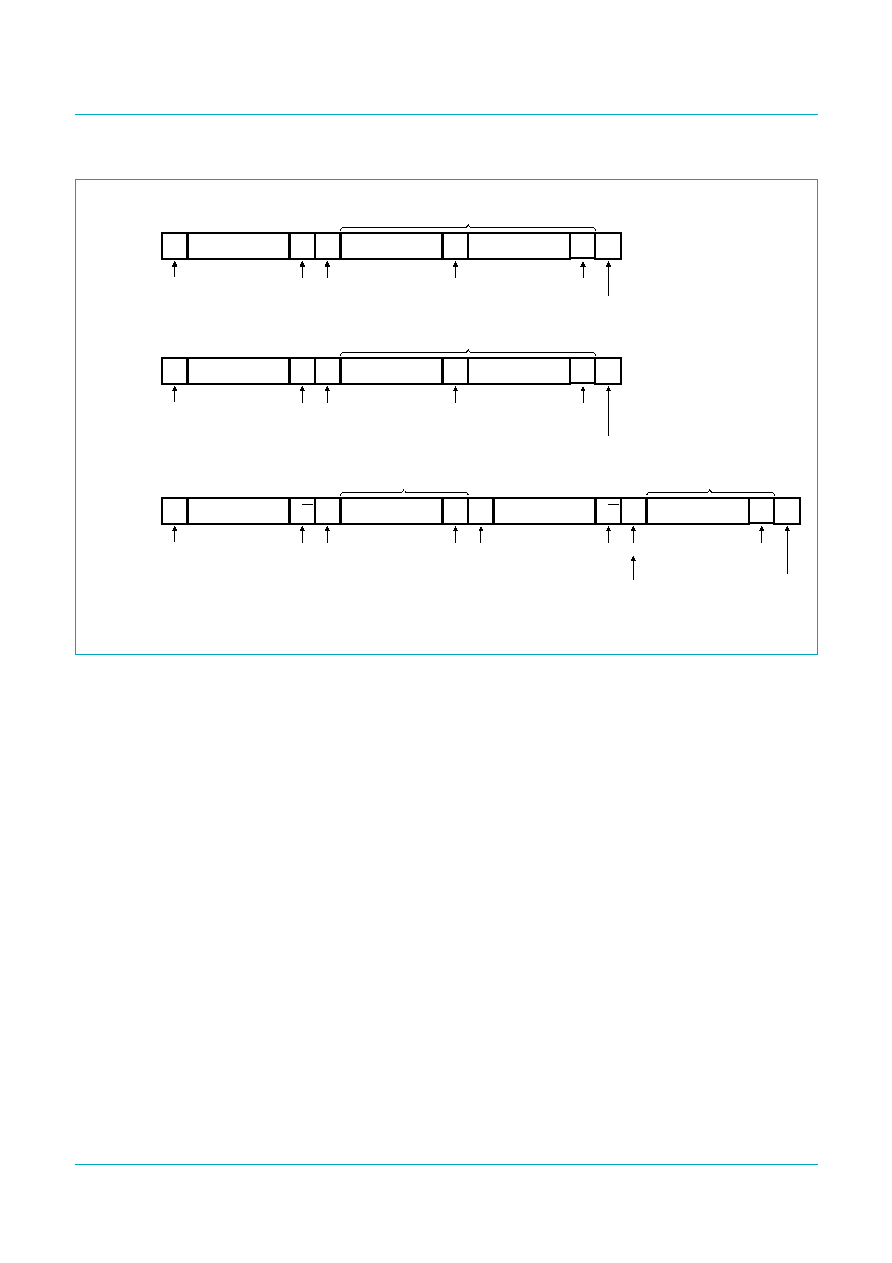

transmitting (write) and a `1' indicates that the master requests data (read). A complete

data transfer, comprised of an address byte indicating a `write' and two data bytes is

shown in

Figure 8

.

Fig 6.

Data transfer on the I

2

C-bus

S

P

SDA

SCL

MSB

0

1

6

7

8

0

1

2 to 7

8

ACK

ACK

002aab012

START

condition

STOP

condition

acknowledgement signal

from receiver

byte complete,

interrupt within receiver

clock line held LOW

while interrupt is serviced

Fig 7.

Acknowledge on the I

2

C-bus

S

0

1

6

7

8

002aab013

data output

by transmitter

data output

by receiver

SCL from master

START

condition

transmitter stays off of the bus

during the acknowledge clock

acknowledgement signal

from receiver

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

9 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

When an address is sent, each device in the system compares the first seven bits after the

START with its own address. If there is a match, the device will consider itself addressed

by the master, and will send an acknowledge. The device could also determine if in this

transaction it is assigned the role of a slave receiver or slave transmitter, depending on the

R/W bit.

Each node of the I

2

C-bus network has a unique seven-bit address. The address of a

microcontroller is of course fully programmable, while peripheral devices usually have

fixed and programmable address portions.

When the master is communicating with one device only, data transfers follow the format

of

Figure 8

, where the R/W bit could indicate either direction. After completing the transfer

and issuing a STOP condition, if a master would like to address some other device on the

network, it could start another transaction by issuing a new START.

Another way for a master to communicate with several different devices would be by using

a `repeated START'. After the last byte of the transaction was transferred, including its

acknowledge (or negative acknowledge), the master issues another START, followed by

address byte and data, without effecting a STOP. The master may communicate with a

number of different devices, combining `reads' and `writes'. After the last transfer takes

place, the master issues a STOP and releases the bus. Possible data formats are

demonstrated in

Figure 9

. Note that the repeated START allows for both change of a slave

and a change of direction, without releasing the bus. We shall see later on that the change

of direction feature can come in handy even when dealing with a single device.

In a single master system, the repeated START mechanism may be more efficient than

terminating each transfer with a STOP and starting again. In a multimaster environment,

the determination of which format is more efficient could be more complicated, as when a

master is using repeated STARTs it occupies the bus for a long time and thus preventing

other devices from initiating transfers.

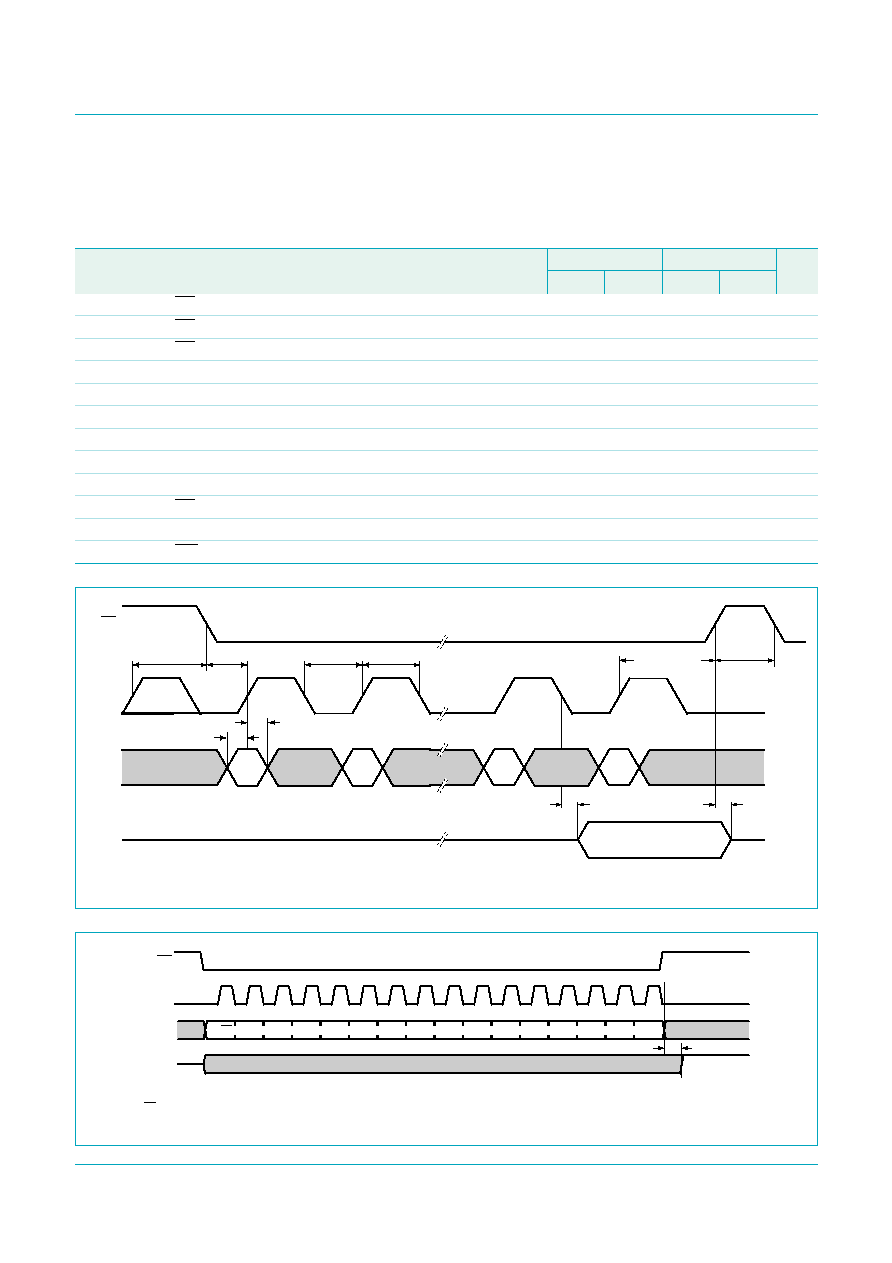

Fig 8.

A complete data transfer

S

P

SDA

SCL

0 to 6

7

8

ACK

002aab046

START

condition

STOP

condition

address

R/W

0 to 6

7

8

data

ACK

0 to 6

7

8

data

ACK

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

10 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

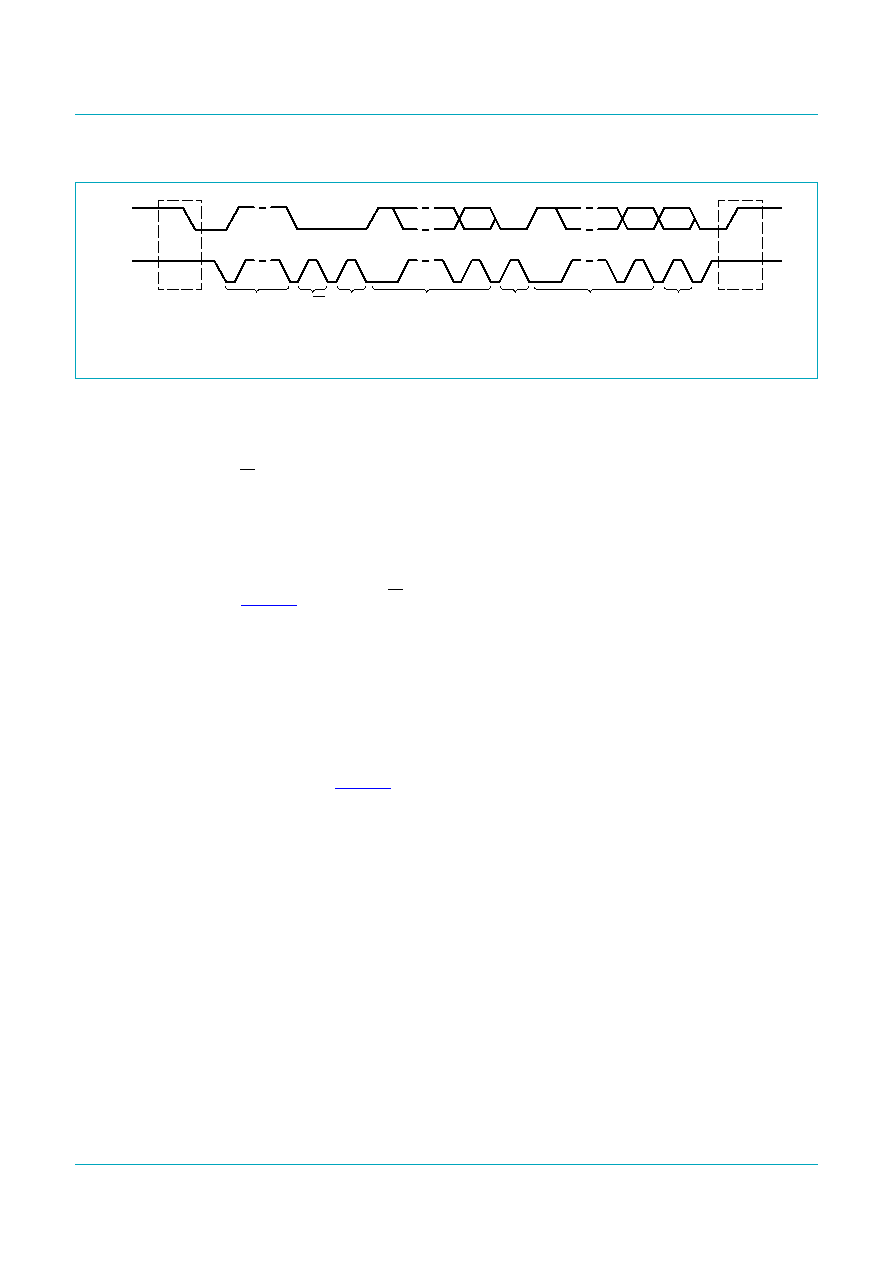

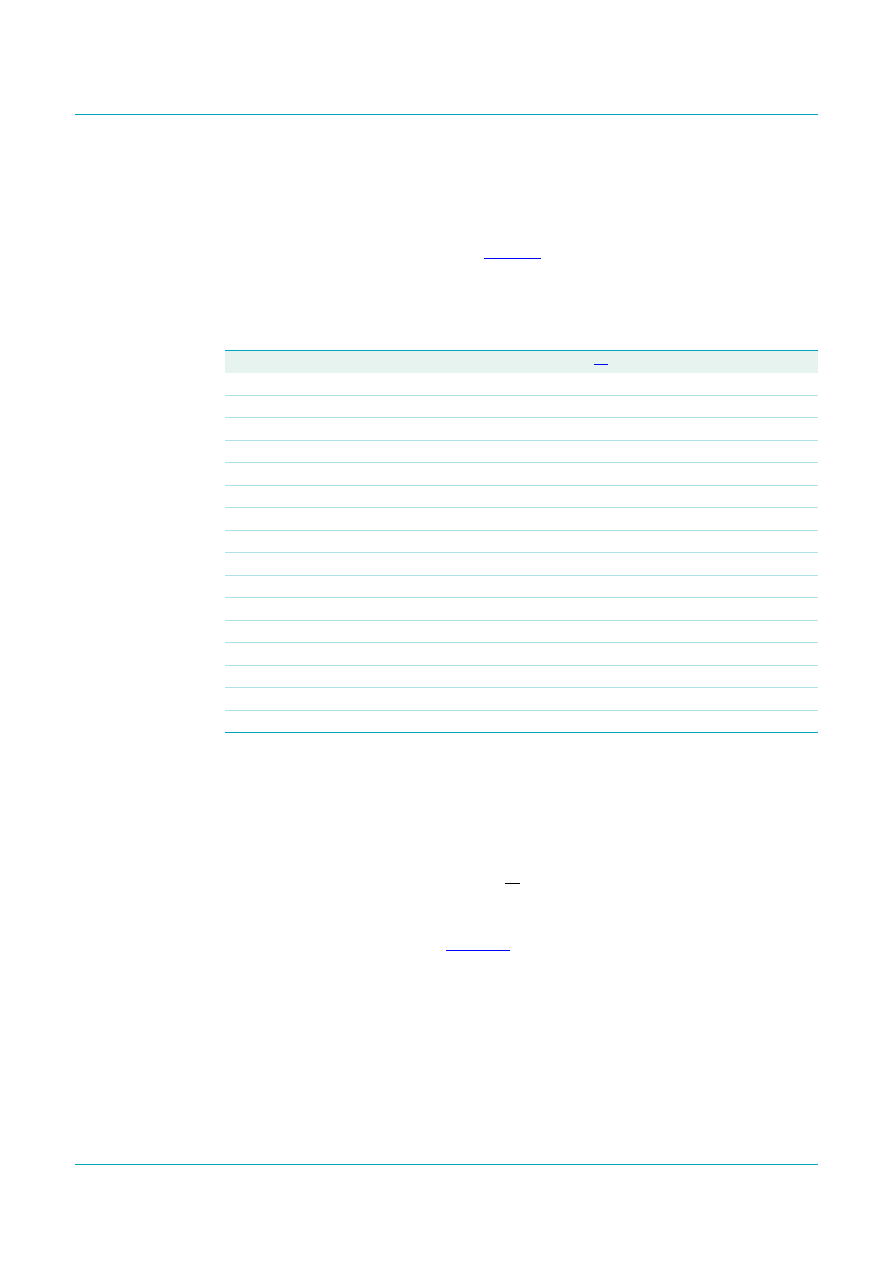

Fig 9.

I

2

C-bus data formats

002aab458

DATA

SLAVE ADDRESS

master write:

S

W

A

DATA

A

A

P

data transferred

(n bytes + acknowledge)

START condition

STOP condition

acknowledge

acknowledge

acknowledge

write

DATA

SLAVE ADDRESS

master read:

S

R

A

DATA

A

NA

P

data transferred

(n bytes + acknowledge)

START condition

STOP condition

acknowledge

acknowledge

not

acknowledge

read

DATA

SLAVE ADDRESS

combined

formats:

S

R/W

A

DATA

A

A

P

data transferred

(n bytes + acknowledge)

START condition

STOP condition

acknowledge

acknowledge

acknowledge

read or

write

SLAVE ADDRESS

Sr

R/W

A

repeated

START condition

acknowledge

read or

write

direction of transfer

may change at this point

data transferred

(n bytes + acknowledge)

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

11 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

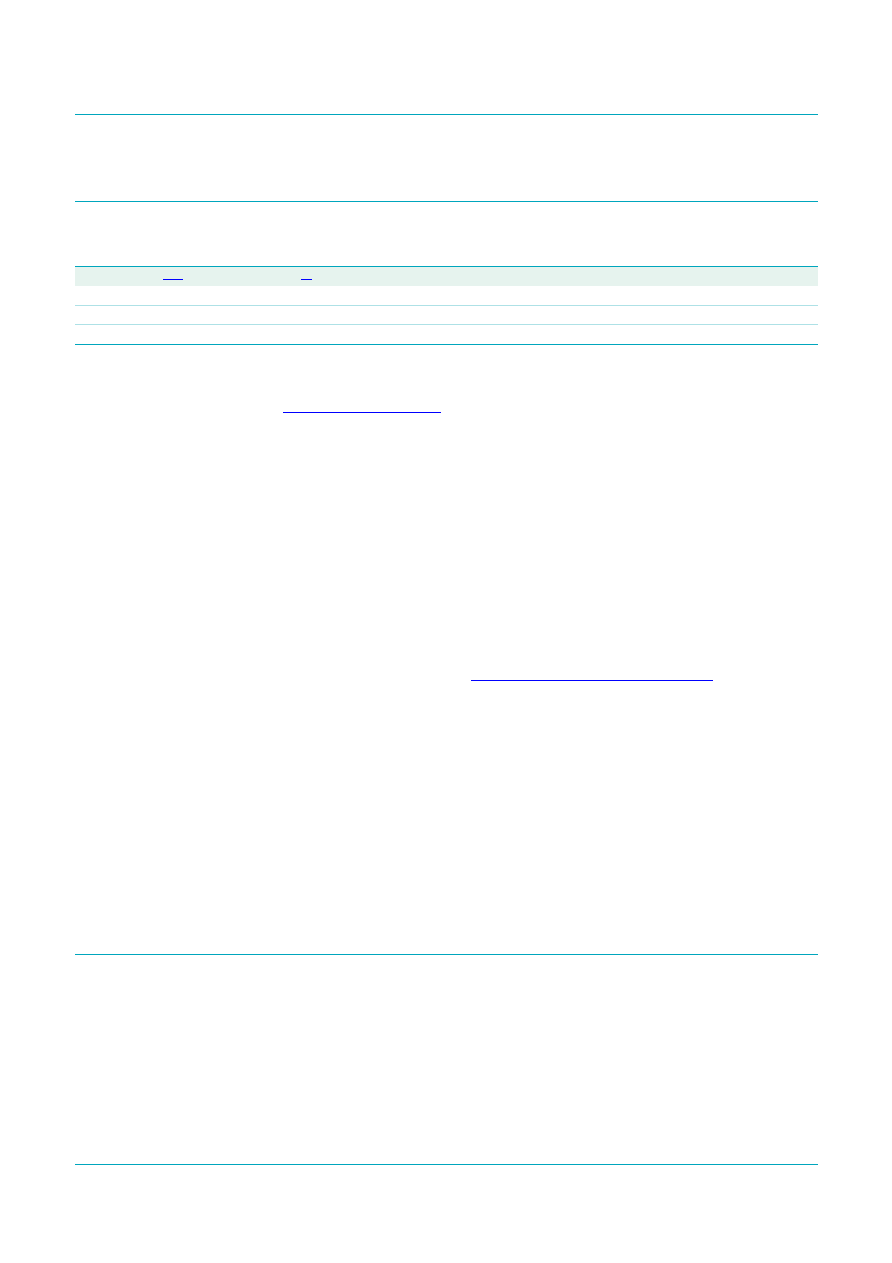

9.3 Addressing

Before any data is transmitted or received, the master must send the address of the

receiver via the SDA line. The first byte after the START condition carries the address of

the slave device and the read/write bit.

Table 11

shows how the PCA9502's address can

be selected by using A1 and A0 pins. For example, if these 2 pins are connected to V

DD

,

then the PCA9502's address is set to 0x90, and the master communicates with it through

this address.

[1]

X = logic 0 for write cycle; X = logic 1 for read cycle.

9.4 Use of sub-addresses

When a master communicates with the PCA9502 it must send a sub-address in the byte

following the slave address byte. This sub-address is the internal address of the word the

master wants to access for a single byte transfer, or the beginning of a sequence of

locations for a multi-byte transfer. A sub-address is an 8-bit byte. Unlike the device

address, it does not contain a direction (R/W) bit, and like any byte transferred on the bus

it must be followed by an acknowledge.

A register write cycle is shown in

Figure 10

. The START is followed by a slave address

byte with the direction bit set to `write', a sub-address byte, a number of data bytes, and a

STOP signal. The sub-address indicates which register the master wants to access. and

the data bytes which follow will be written one after the other to the sub-address location.

Table 11.

PCA9502 address map

A1

A0

PCA9502 I

2

C-bus addresses (hex)

[1]

V

DD

V

DD

0x90 (1001 000X)

V

DD

V

SS

0x92 (1001 001X)

V

DD

SCL

0x94 (1001 010X)

V

DD

SDA

0x96 (1001 011X)

V

SS

V

DD

0x98 (1001 100X)

V

SS

V

SS

0x9A (1001 101X)

V

SS

SCL

0x9C (1001 110X)

V

SS

SDA

0x9E (1001 111X)

SCL

V

DD

0xA0 (1010 000X)

SCL

V

SS

0xA2 (1010 001X)

SCL

SCL

0xA4 (1010 010X)

SCL

SDA

0xA6 (1010 011X)

SDA

V

DD

0xA8 (1010 100X)

SDA

V

SS

0xAA (1010 101X)

SDA

SCL

0xAC (1010 110X)

SDA

SDA

0xAE (1010 111X)

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

12 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

The register read cycle (see

Figure 11

) commences in a similar manner, with the master

sending a slave address with the direction bit set to `write' with a following sub-address.

Then, in order to reverse the direction of the transfer, the master issues a repeated START

followed again by the device address, but this time with the direction bit set to `read'. The

data bytes starting at the internal sub-address will be clocked out of the device, each

followed by a master-generated acknowledge. The last byte of the read cycle will be

followed by a negative acknowledge, signalling the end of transfer. The cycle is terminated

by a STOP signal.

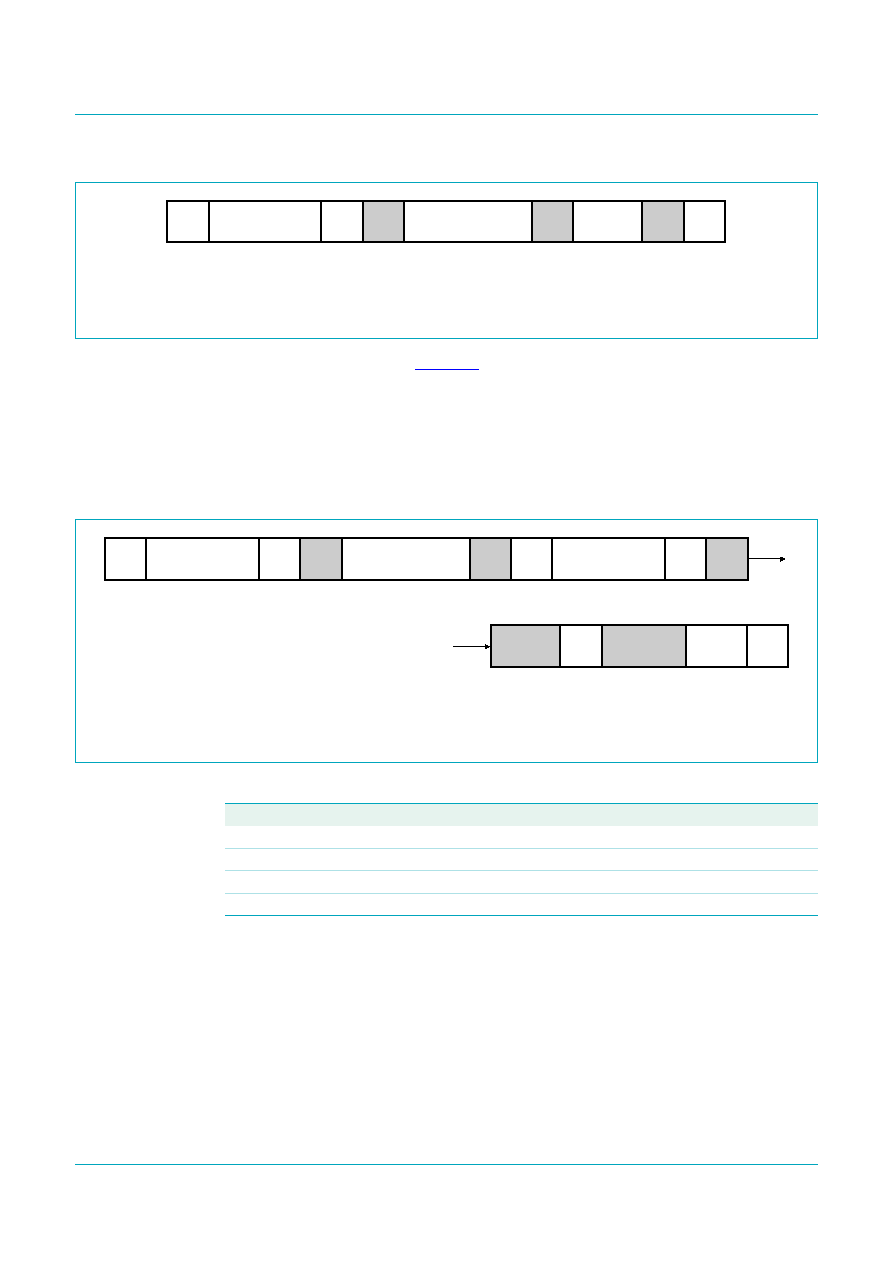

White block: host to PCA9502

Grey block: PCA9502 to host

Fig 10. Master writes to slave

S

SLAVE ADDRESS

002aab047

W

A

REGISTER ADDRESS

A

nDATA

A

P

White block: host to PCA9502

Grey block: PCA9502 to host

Fig 11. Master read from Slave

S

SLAVE ADDRESS

002aab048

W

A

REGISTER ADDRESS

A

NA

P

S

SLAVE ADDRESS

R

A

nDATA

A

LAST DATA

Table 12.

Register address byte (I

2

C-bus)

Bit

Name

Function

7

-

not used

6:3

A[3:0]

internal register select

2:1

-

not used, set to 0

0

-

not used

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

13 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

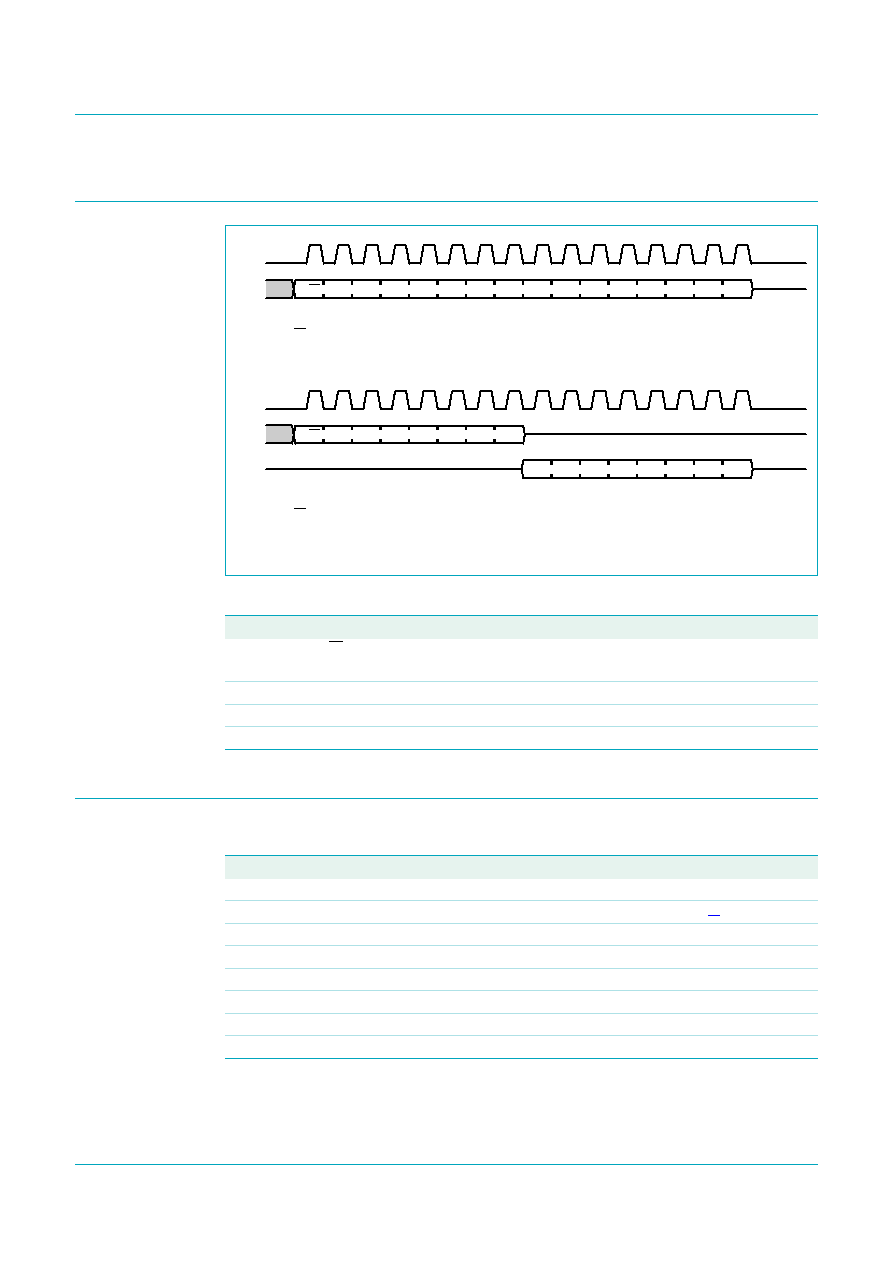

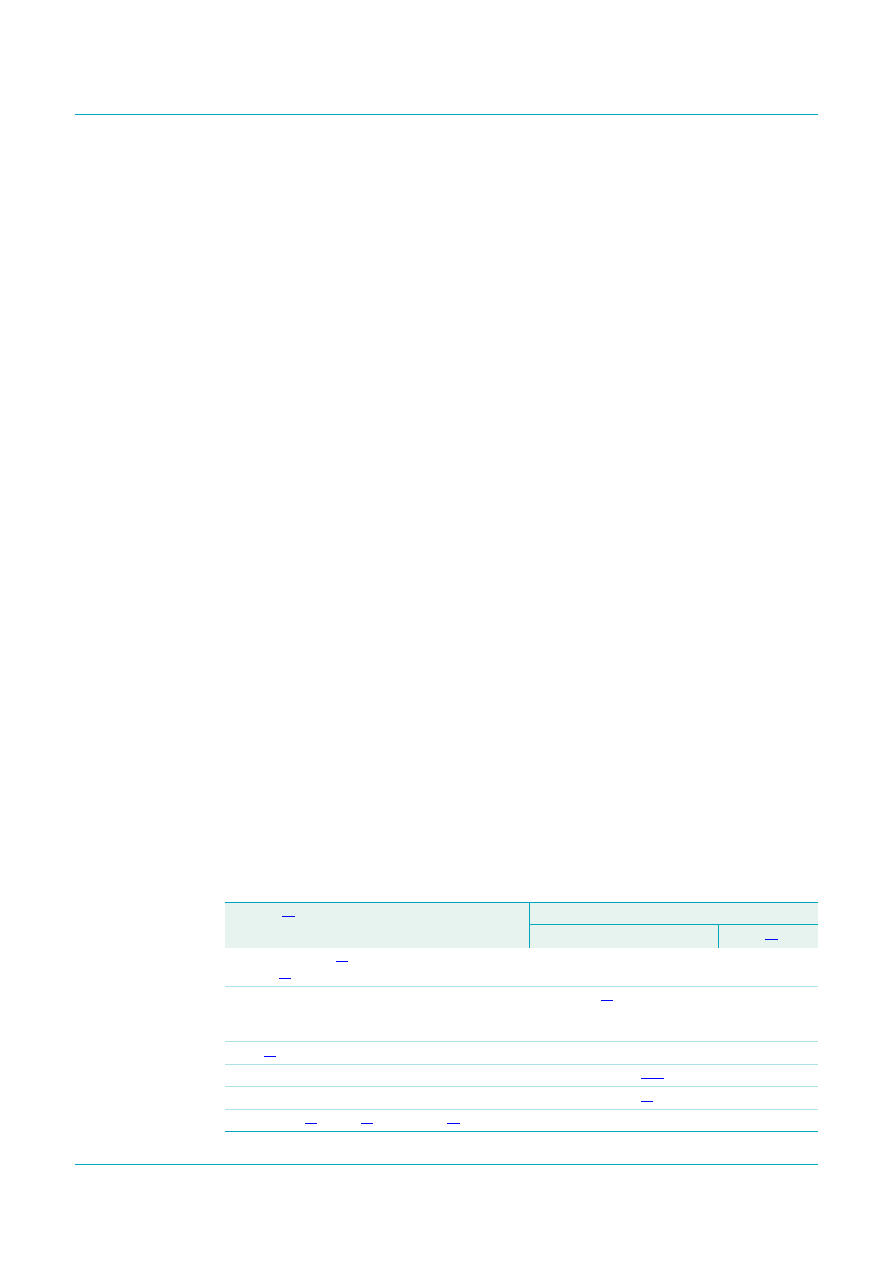

10. SPI operation

11. Limiting values

[1]

5.5 V steady state voltage tolerance on inputs and outputs is valid only when the supply voltage is present.

4.6 V steady state voltage tolerance on inputs and outputs when no supply voltage is present.

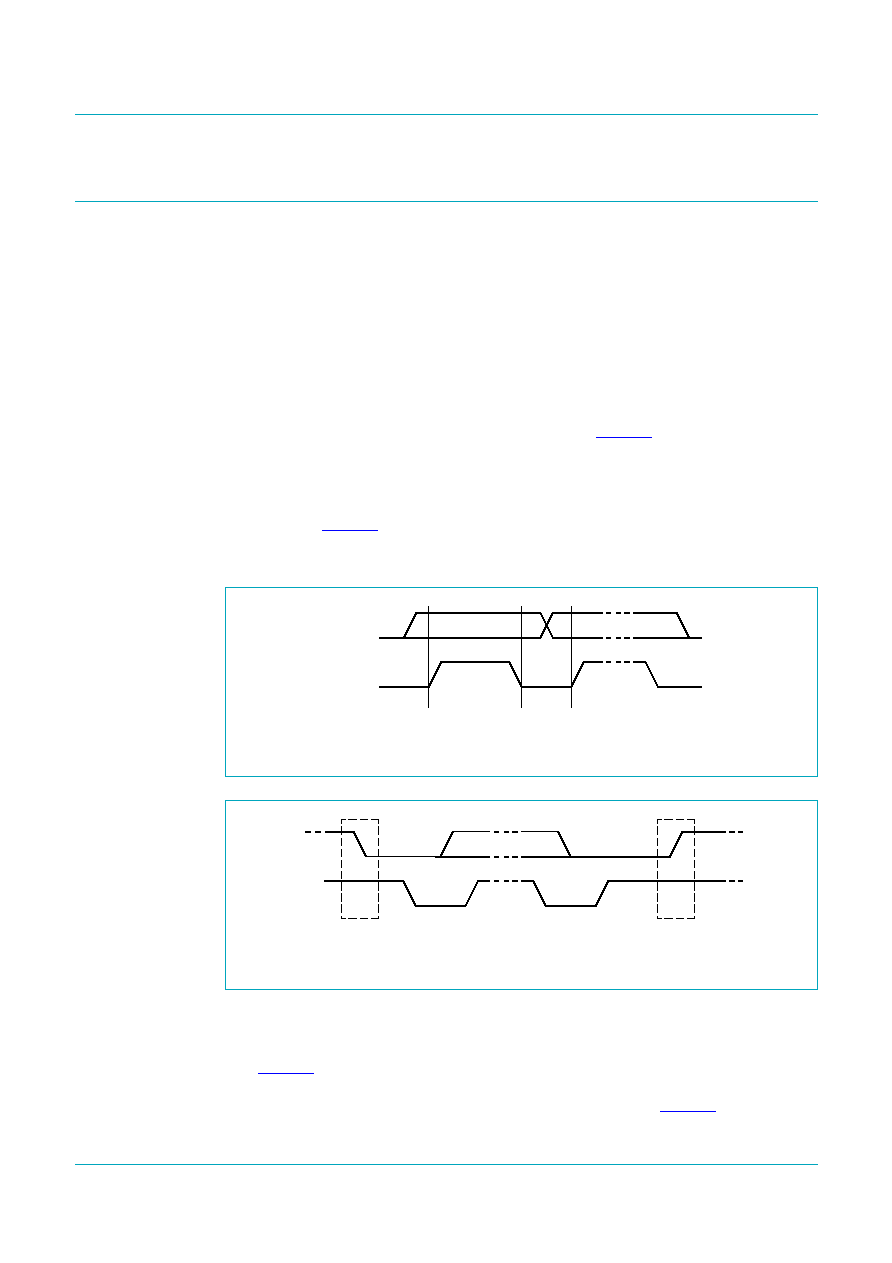

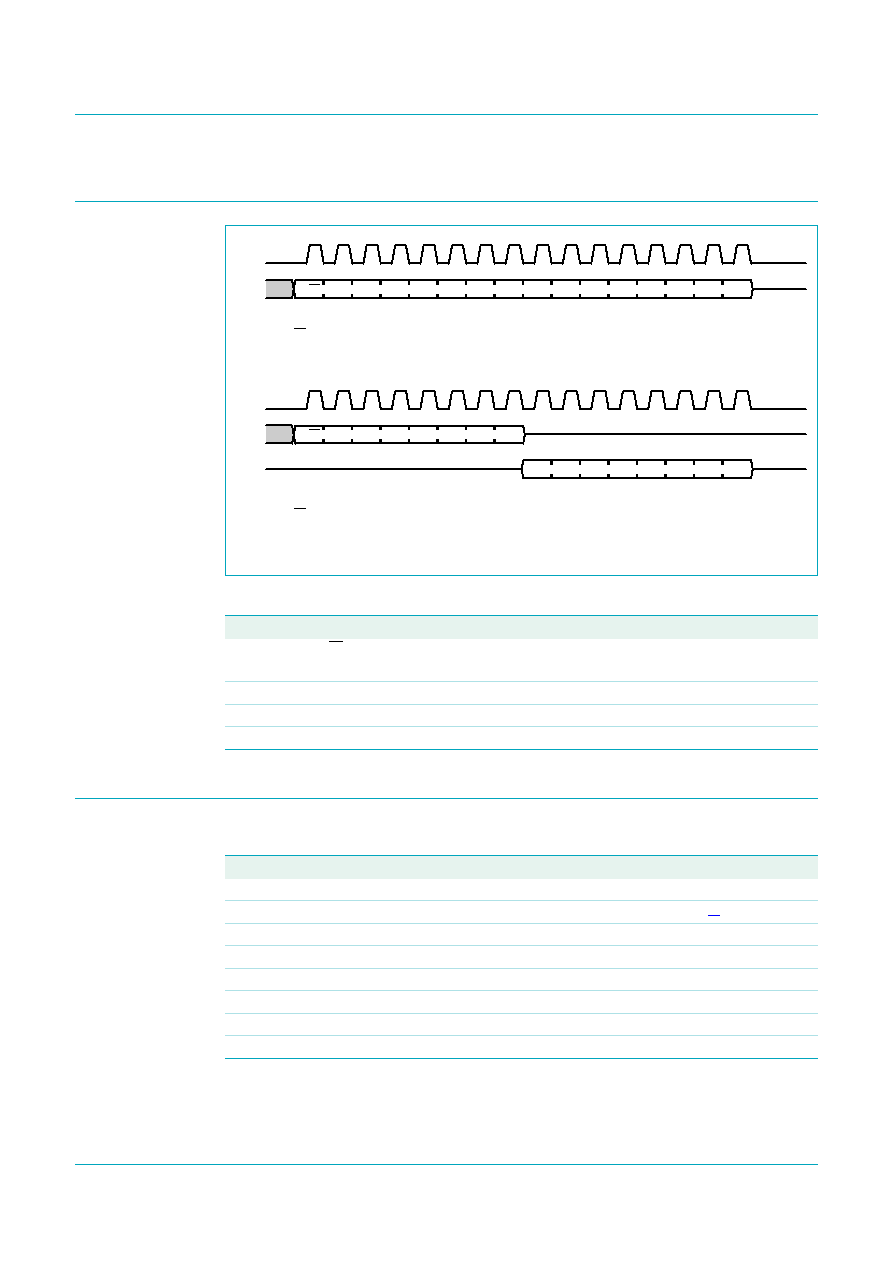

R/W = 0; A[3:0] = register address

a. Register write

R/W = 1; A[3:0] = register address

b. Register read

Fig 12. SPI operation

Table 13.

Register address byte (SPI)

Bit

Name

Function

7

R/W

1: read from PCA9502

0: write to PCA9502

6:3

A[3:0]

internal register select

2:1

-

not used, set to 0

0

-

not used

SI

A1

A2

A3

R/W

SCLK

0

A0

X

0

D6

D7

D4

D5

D2

D3

D0

D1

002aab925

SI

A1

A2

A3

R/W

SCLK

0

A0

X

0

SO

D6

D7

D4

D5

D2

D3

D0

D1

002aab926

Table 14.

Limiting values

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol

Parameter

Conditions

Min

Max

Unit

V

DD

supply voltage

-

0.3

+4.6

V

V

I

input voltage

any input

-

0.3

+5.5

[1]

V

I

I

input current

any input

-

10

+10

mA

I

O

output current

any output

-

10

+10

mA

P

tot

total power dissipation

-

300

mW

P/out

power dissipation per output

-

50

mW

T

amb

ambient temperature

-

40

+85

°

C

T

stg

storage temperature

-

65

+150

°

C

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

14 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

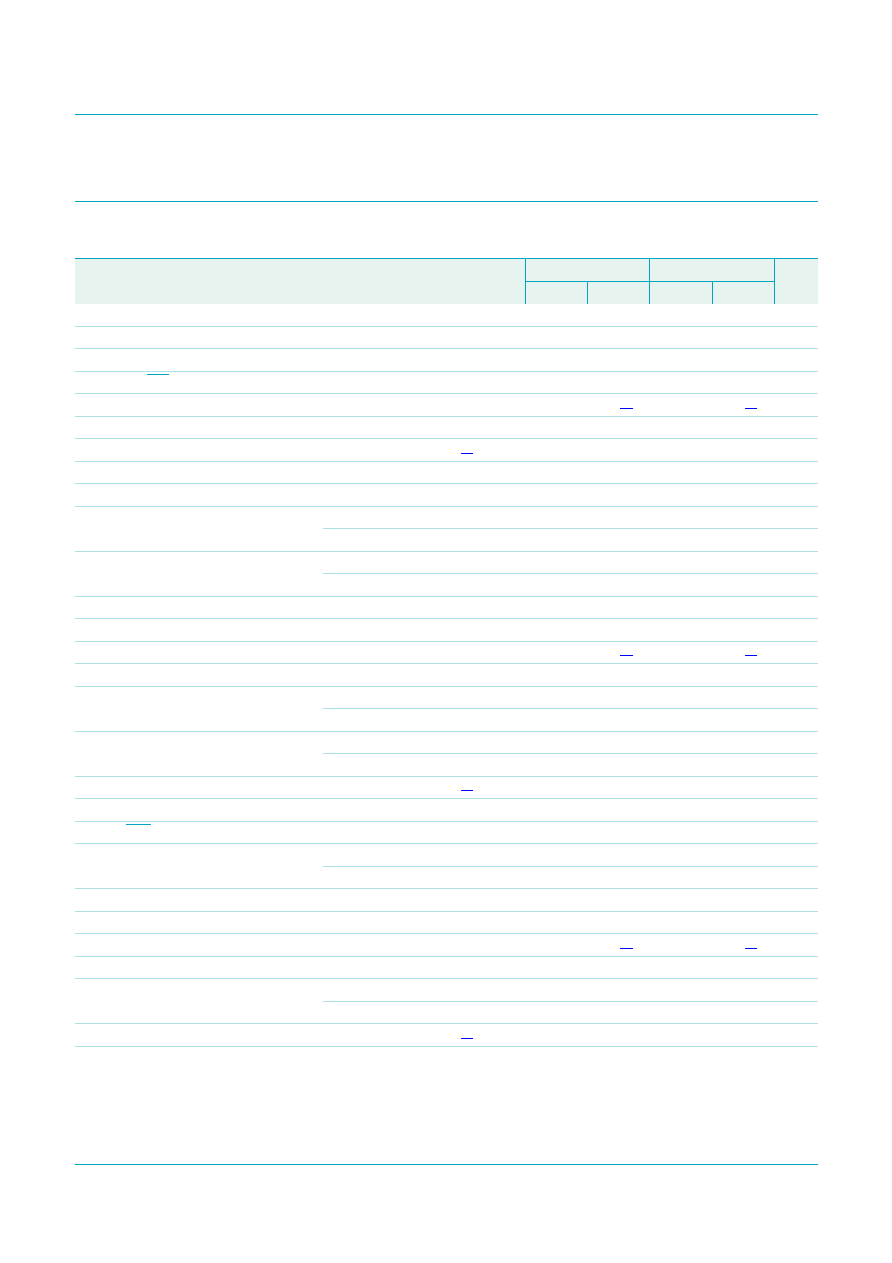

12. Static characteristics

Table 15.

Static characteristics

V

DD

= (2.5 V

±

0.2 V) or (3.3 V

±

0.3 V); T

amb

=

-

40

°

C to +85

°

C; unless otherwise specified.

Symbol

Parameter

Conditions

V

DD

= 2.5 V

V

DD

= 3.3 V

Unit

Min

Max

Min

Max

Supplies

V

DD

supply voltage

2.3

2.7

3.0

3.6

V

I

DD

supply current

operating; no load

-

6.0

-

6.0

mA

Inputs I2C/SPI

V

IH

HIGH-level input voltage

1.6

5.5

[1]

2.0

5.5

[1]

V

V

IL

LOW-level input voltage

-

0.6

-

0.8

V

I

L

leakage current

input; V

I

= 0 V or 5.5 V

[1]

-

1

-

1

µ

A

C

i

input capacitance

-

3

-

3

pF

Output SO

V

OH

HIGH-level output voltage

I

OH

=

-

400

µ

A

1.85

-

-

-

V

I

OH

=

-

4 mA

-

-

2.4

-

V

V

OL

LOW-level output voltage

I

OL

= 1.6 mA

-

0.4

-

-

V

I

OL

= 4 mA

-

-

-

0.4

V

C

o

output capacitance

-

4

-

4

pF

Inputs/outputs GPIO0 to GPIO7

V

IH

HIGH-level input voltage

1.6

5.5

[1]

2.0

5.5

[1]

V

V

IL

LOW-level input voltage

-

0.6

-

0.8

V

V

OH

HIGH-level output voltage

I

OH

=

-

400

µ

A

1.85

-

-

-

V

I

OH

=

-

4 mA

-

-

2.4

-

V

V

OL

LOW-level output voltage

I

OL

= 1.6 mA

-

0.4

-

-

V

I

OL

= 4 mA

-

-

-

0.4

V

I

L

leakage current

input; V

I

= 0 V or 5.5 V

[1]

-

1

-

1

µ

A

C

o

output capacitance

-

4

-

4

pF

Output IRQ

V

OL

LOW-level output voltage

I

OL

= 1.6 mA

-

0.4

-

-

V

I

OL

= 4 mA

-

-

-

0.4

V

C

o

output capacitance

-

4

-

4

pF

I

2

C-bus input/output SDA

V

IH

HIGH-level input voltage

1.6

5.5

[1]

2.0

5.5

[1]

V

V

IL

LOW-level input voltage

-

0.6

-

0.8

V

V

OL

LOW-level output voltage

I

OL

= 1.6 mA

-

0.4

-

-

V

I

OL

= 4 mA

-

-

-

0.4

V

I

L

leakage current

input; V

I

= 0 V or 5.5 V

[1]

-

10

-

10

µ

A

C

o

output capacitance

-

7

-

7

pF

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

15 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

[1]

5.5 V steady state voltage tolerance on inputs and outputs is valid only when the supply voltage is present. 3.8 V steady state voltage

tolerance on inputs and outputs when no supply voltage is present.

13. Dynamic characteristics

[1]

A detailed description of the I

2

C-bus specification, with applications, is given in brochure

"The I

2

C-bus and how to use it". This brochure

may be ordered using the code 9398 393 40011.

[2]

Minimum SCL clock frequency is limited by the bus time-out feature, which resets the serial bus interface if SDA is held LOW for a

minimum of 25 ms.

I

2

C-bus inputs SCL, CS/A0, SI/A1

V

IH

HIGH-level input voltage

1.6

5.5

[1]

2.0

5.5

[1]

V

V

IL

LOW-level input voltage

-

0.6

-

0.8

V

I

L

leakage current

input; V

I

= 0 V or 5.5 V

[1]

-

10

-

10

µ

A

C

i

input capacitance

-

7

-

7

pF

Table 15.

Static characteristics

...continued

V

DD

= (2.5 V

±

0.2 V) or (3.3 V

±

0.3 V); T

amb

=

-

40

°

C to +85

°

C; unless otherwise specified.

Symbol

Parameter

Conditions

V

DD

= 2.5 V

V

DD

= 3.3 V

Unit

Min

Max

Min

Max

Table 16.

I

2

C-bus timing specifications

All the timing limits are valid within the operating supply voltage, ambient temperature range and output load;

V

DD

= (2.5 V

±

0.2 V) or (3.3 V

±

0.3 V); T

amb

=

-

40

°

C to +85

°

C; refer to V

IL

and V

IH

with an input voltage of V

SS

to V

DD

.

All output load = 25 pF, except SDA output load = 400 pF.

[1]

Symbol Parameter

Conditions

Standard-mode

I

2

C-bus

Fast-mode

I

2

C-bus

Unit

Min

Max

Min

Max

f

SCL

SCL clock frequency

[2]

0

100

0

400

kHz

t

BUF

bus free time between a STOP and

START condition

4.7

-

1.3

-

µ

s

t

HD;STA

hold time (repeated) START condition

4.0

-

0.6

-

µ

s

t

SU;STA

set-up time for a repeated START

condition

4.7

-

0.6

-

µ

s

t

SU;STO

set-up time for STOP condition

4.7

-

0.6

-

µ

s

t

HD;DAT

data hold time

0

-

0

-

ns

t

VD;ACK

data valid acknowledge time

-

0.6

-

0.6

µ

s

t

VD;DAT

data valid time

SCL LOW to data out valid

-

0.6

-

0.6

ns

t

SU;DAT

data set-up time

250

-

150

-

ns

t

LOW

LOW period of the SCL clock

4.7

-

1.3

-

µ

s

t

HIGH

HIGH period of the SCL clock

4.0

-

0.6

-

µ

s

t

f

fall time of both SDA and SCL signals

-

300

-

300

ns

t

r

rise time of both SDA and SCL signals

-

1000

-

300

ns

t

SP

pulse width of spikes that must be

suppressed by the input filter

-

50

-

50

ns

t

d1

I

2

C-bus GPIO output valid time

0.5

-

0.5

-

µ

s

t

d4

I2C input pin interrupt valid time

0.2

-

0.2

-

µ

s

t

d5

I2C input pin interrupt clear time

0.2

-

0.2

-

µ

s

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

16 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

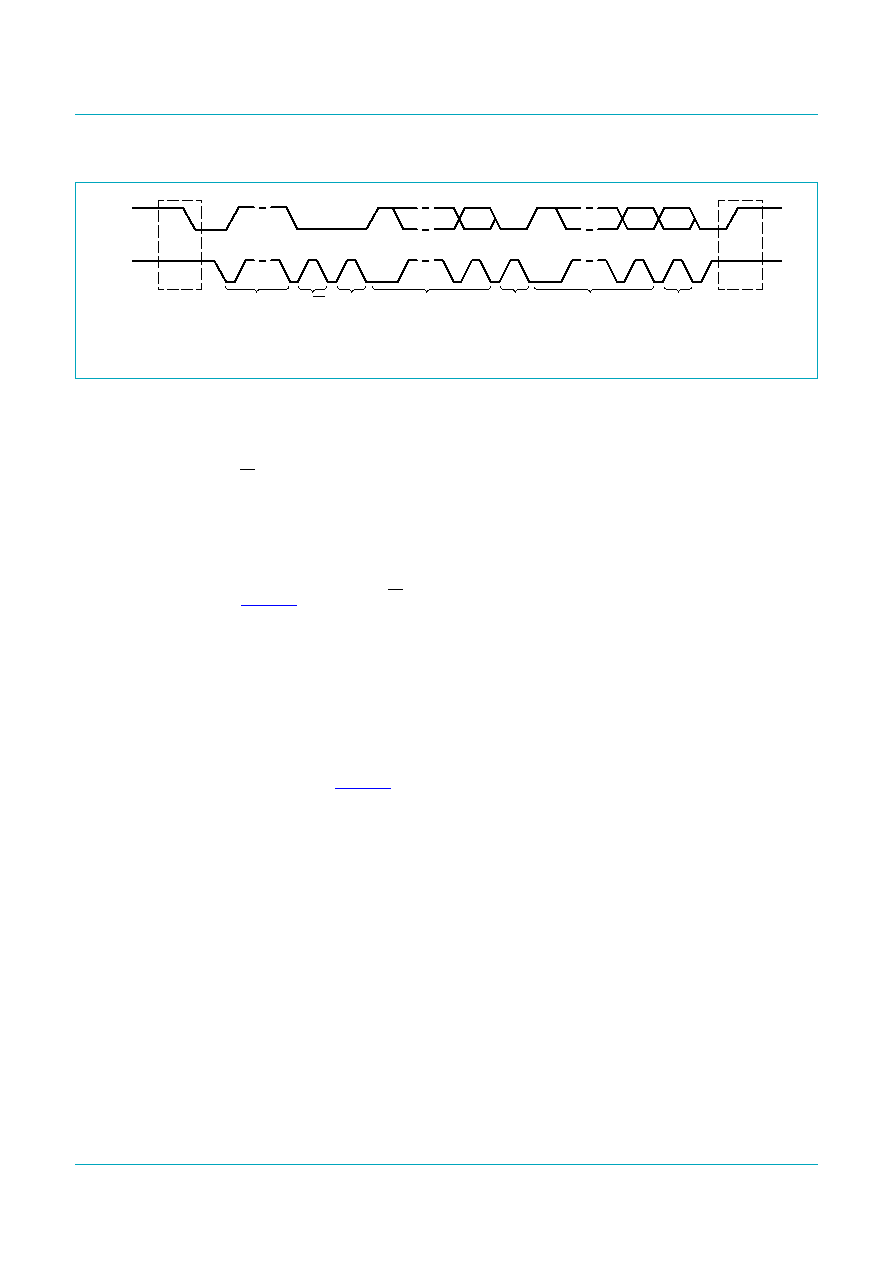

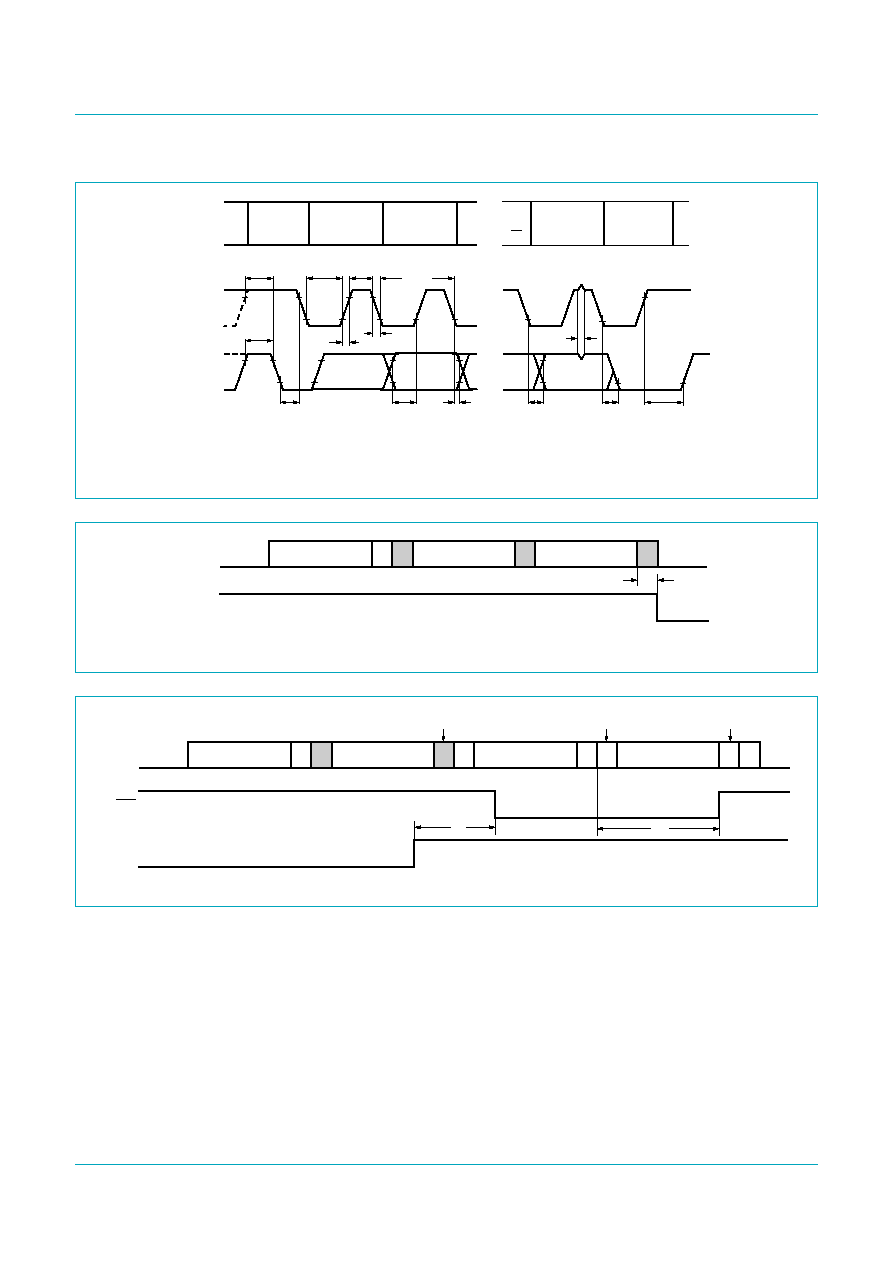

Rise and fall times refer to V

IL

and V

IH

.

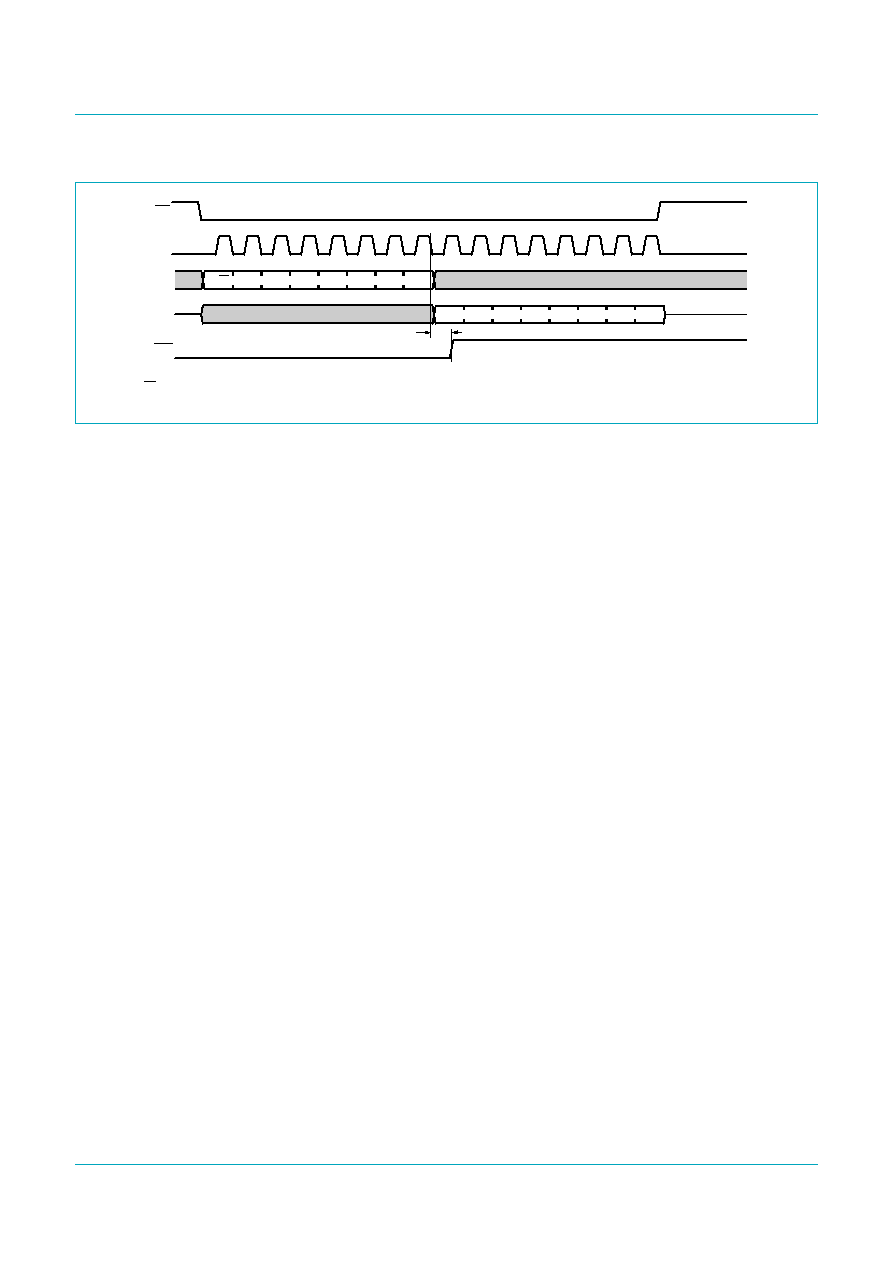

Fig 13. I

2

C-bus timing diagram

SCL

SDA

t

HD;STA

t

SU;DAT

t

HD;DAT

t

f

t

BUF

t

SU;STA

t

LOW

t

HIGH

t

VD;ACK

002aab489

t

SU;STO

protocol

START

condition

(S)

bit 7

MSB

(A7)

bit 6

(A6)

bit 0

LSB

(R/W)

acknowledge

(A)

STOP

condition

(P)

1

/f

SCL

t

r

t

VD;DAT

t

SP

Fig 14. Write to output

002aab255

A

W

SDA

A

GPIOn

DATA

A

IOSTATE REG.

SLAVE ADDRESS

A

t

d1

Fig 15. GPIO pin interrupt

002aab877

A

W

SDA

A

R

IRQ

t

d4

S

A

DATA

A

ACK from master

SLAVE ADDRESS

IOSTATE REG.

SLAVE ADDRESS

A

t

d5

GPIOn

P

ACK from slave

ACK from slave

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

17 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

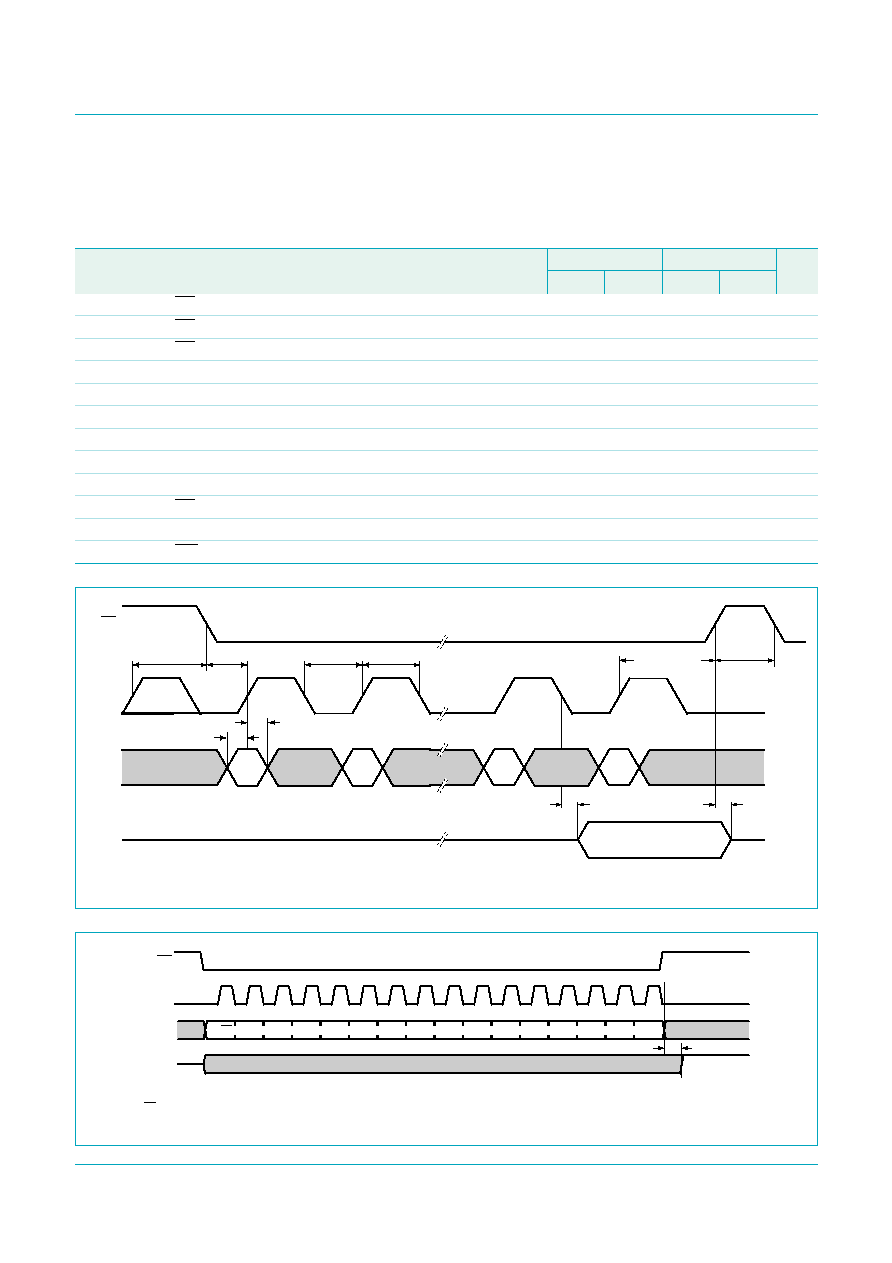

Table 17.

SPI-bus timing specifications

All the timing limits are valid within the operating supply voltage, ambient temperature range and output load;

V

DD

= (2.5 V

±

0.2 V) or (3.3 V

±

0.3 V); T

amb

=

-

40

°

C to +85

°

C; and refer to V

IL

and V

IH

with an input voltage of V

SS

to V

DD

.

All output load = 25 pF, unless otherwise specified.

Symbol

Parameter

Conditions

V

DD

= 2.5 V

V

DD

= 3.3 V

Unit

Min

Max

Min

Max

t

d(CS_NH-SOZ)

CS HIGH to SO 3-state delay time

C

L

= 100 pF

-

100

-

100

ns

t

su(CS_N-SCLK)

CS to SCLK setup time

100

-

100

-

ns

t

h(CS_N-SCLK)

CS to SCLK hold time

20

-

20

-

ns

t

d(SCLK-SO)

SCLK fall to SO valid delay time

C

L

= 100 pF

-

25

-

20

ns

t

su(SI-SCLK)

SI to SCLK setup time

10

-

20

-

ns

t

h(SI-SCLK)

SI to SCLK hold time

10

-

10

-

ns

T

SCLK

SCLK period

t

SCLKL

+ t

SCLKL

83

-

67

-

ns

t

SCLKH

SCLK HIGH time

30

-

25

-

ns

t

SCLKL

SCLK LOW time

30

-

25

-

ns

t

w(CS_NH)

CS HIGH pulse width

200

-

200

-

ns

t

d9

SPI output data valid time

200

-

200

-

ns

t

d13

SPI interrupt clear time

200

-

200

-

ns

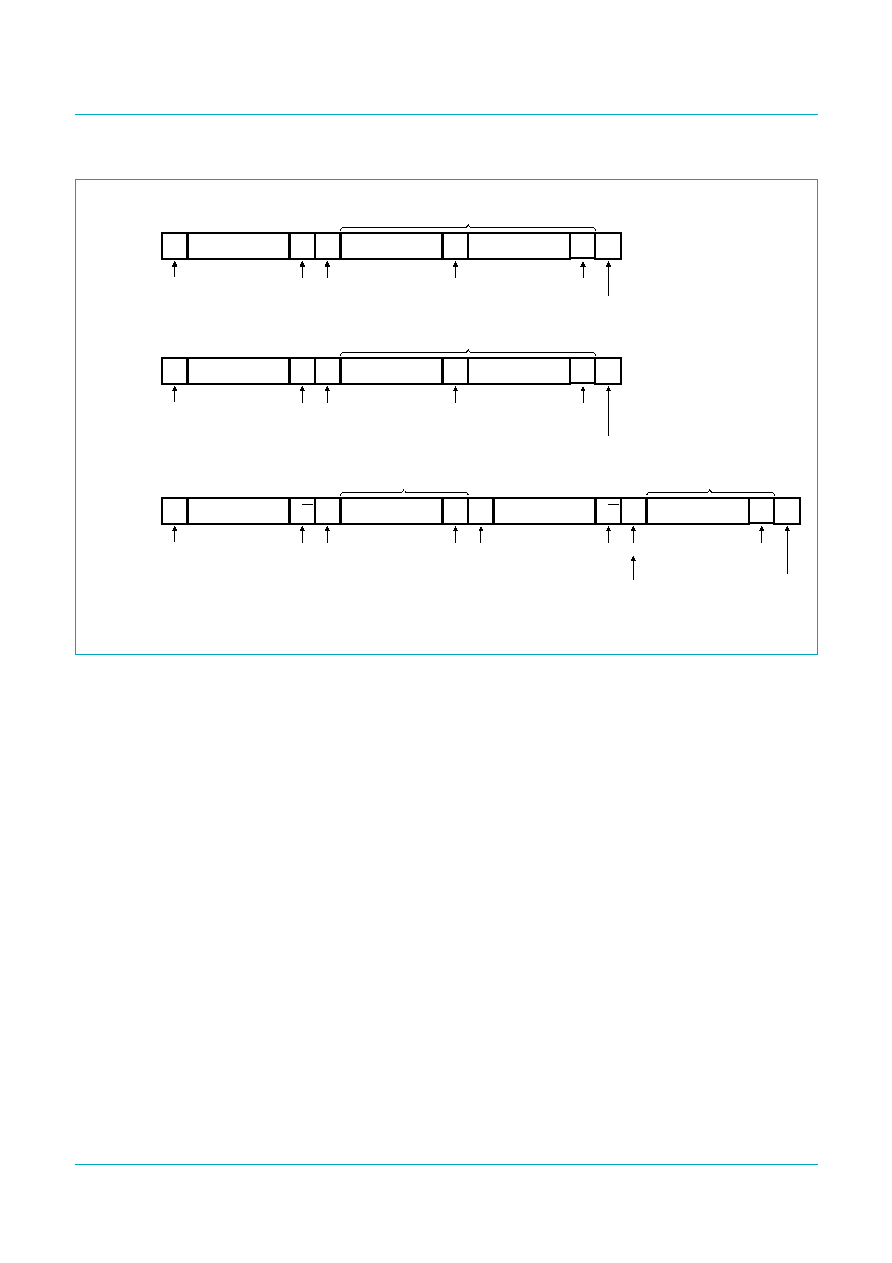

Fig 16. Detailed SPI-bus timing

t

h(CS_N-SCLK)

t

su(CS_N-SCLK)

t

SCLKL

t

SCLKH

t

h(CS_N-SCLK)

t

d(SCLK-SO)

t

d(CS_N-SOZ)

t

su(SI-SCLK)

t

h(SI-SCLK)

SO

SI

SCLK

CS

002aac429

t

w(CS_NH)

R/W = 0; A[3:0] = IOState (0x0B)

Fig 17. SPI write IOState to GPIO switch

SI

A1

A2

A3

R/W

SCLK

0

A0

X

0

002aab878

GPIOn

D6

D7

D4

D5

D2

D3

D0

D1

CS

t

d9

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

18 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

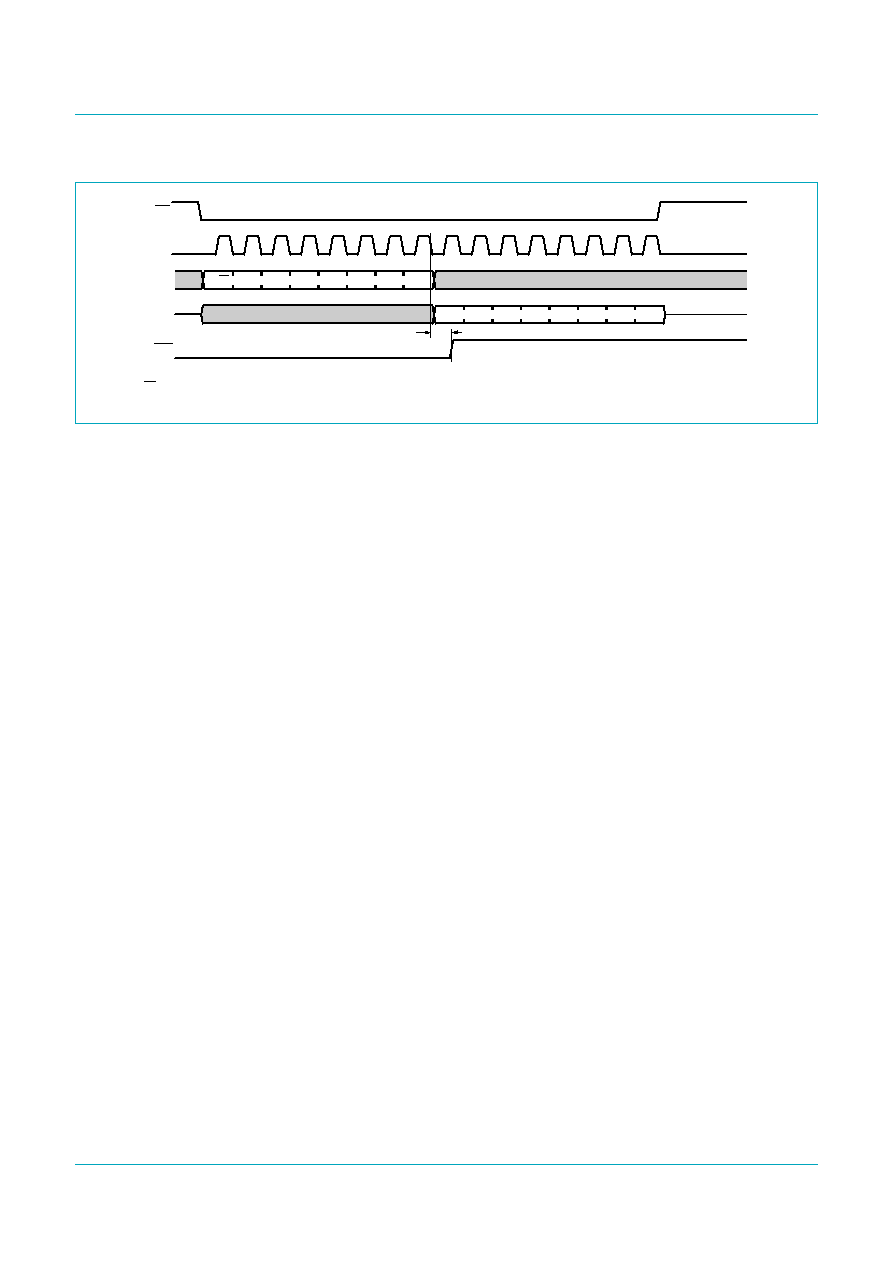

R/W = 1; A[3:0] = IOState (0x0B)

Fig 18. Read IOState to clear GPIO INT

SI

A1

A2

A3

R/W

SCLK

0

A0

X

0

002aab879

SO

CS

t

d13

IRQ

D6

D7

D4

D5

D2

D3

D0

D1

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

19 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

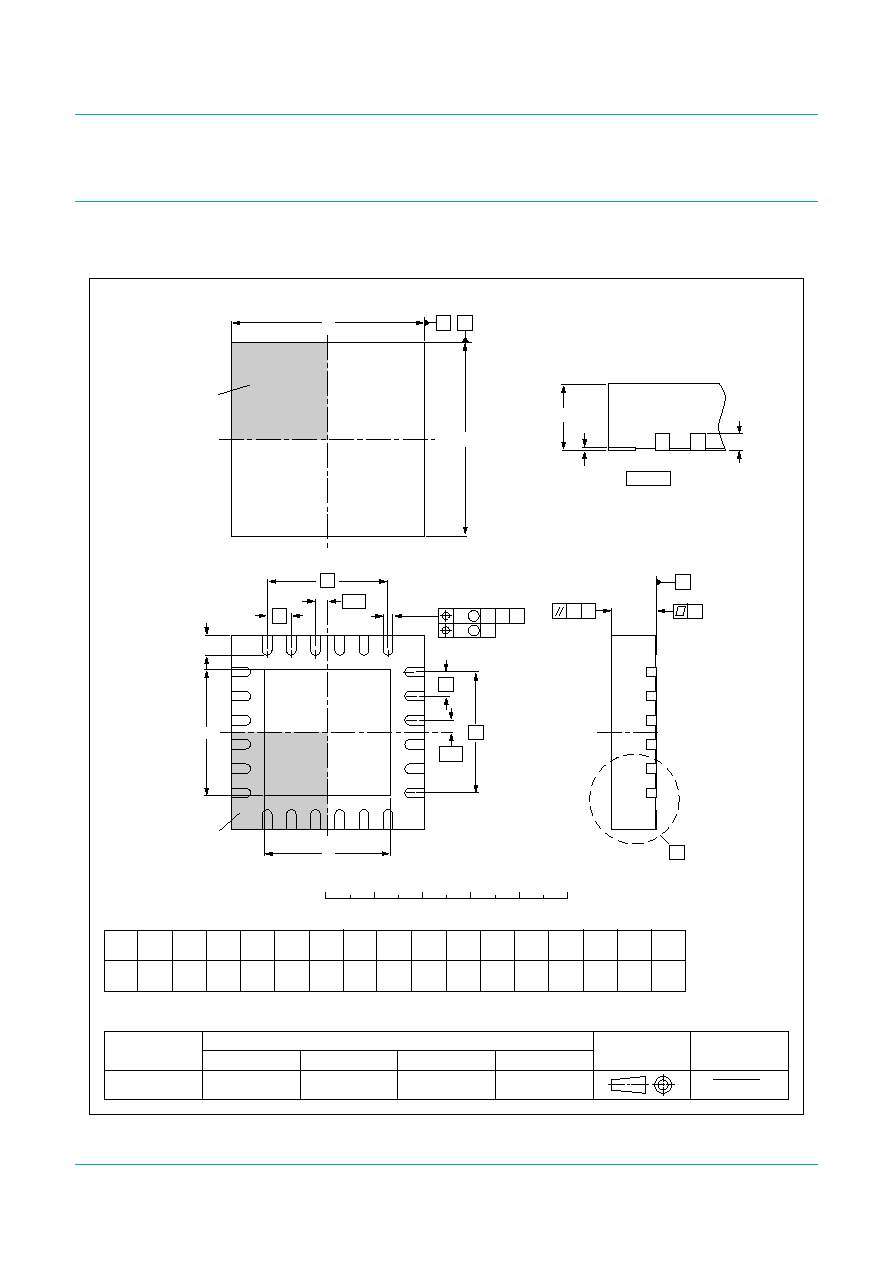

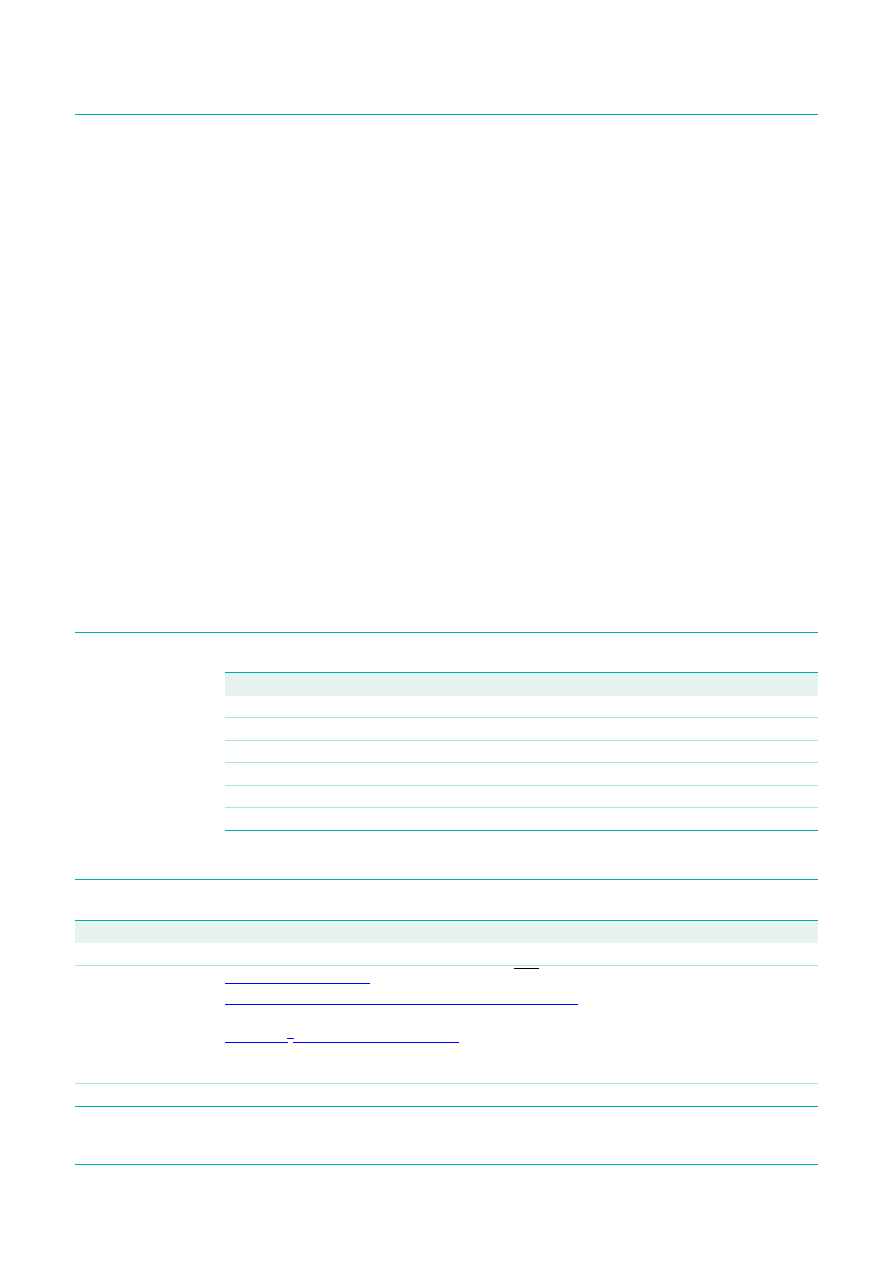

14. Package outline

Fig 19. Package outline SOT616-3 (HVQFN24)

0.5

1

0.2

A1

Eh

b

UNIT

y

e

REFERENCES

OUTLINE

VERSION

EUROPEAN

PROJECTION

ISSUE DATE

IEC

JEDEC

JEITA

mm

4.1

3.9

Dh

2.75

2.45

y1

4.1

3.9

2.75

2.45

e1

2.5

e2

2.5

0.30

0.18

c

0.05

0.00

0.05

0.1

DIMENSIONS (mm are the original dimensions)

SOT616-3

MO-220

04-11-19

05-03-10

- - -

- - -

0.5

0.3

L

0.1

v

0.05

w

0

2.5

5 mm

scale

SOT616-3

HVQFN24: plastic thermal enhanced very thin quad flat package; no leads;

24 terminals; body 4 x 4 x 0.85 mm

A

(1)

max.

A

A1

c

detail X

y

y1 C

e

L

Eh

Dh

e

e1

b

7

12

24

19

18

13

6

1

X

D

E

C

B

A

e2

terminal 1

index area

terminal 1

index area

A

C

C

B

v

M

w

M

1/2

e

1/2

e

E

(1)

Note

1. Plastic or metal protrusions of 0.075 mm maximum per side are not included.

D

(1)

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

20 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

15. Handling information

Inputs and outputs are protected against electrostatic discharge in normal handling.

However, to be completely safe you must take normal precautions appropriate to handling

integrated circuits.

16. Soldering

16.1 Introduction to soldering surface mount packages

There is no soldering method that is ideal for all surface mount IC packages. Wave

soldering can still be used for certain surface mount ICs, but it is not suitable for fine pitch

SMDs. In these situations reflow soldering is recommended.

16.2 Reflow soldering

Reflow soldering requires solder paste (a suspension of fine solder particles, flux and

binding agent) to be applied to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement. Driven by legislation and

environmental forces the worldwide use of lead-free solder pastes is increasing.

Several methods exist for reflowing; for example, convection or convection/infrared

heating in a conveyor type oven. Throughput times (preheating, soldering and cooling)

vary between 100 seconds and 200 seconds depending on heating method.

Typical reflow temperatures range from 215

°

C to 260

°

C depending on solder paste

material. The peak top-surface temperature of the packages should be kept below:

Moisture sensitivity precautions, as indicated on packing, must be respected at all times.

16.3 Wave soldering

Conventional single wave soldering is not recommended for surface mount devices

(SMDs) or printed-circuit boards with a high component density, as solder bridging and

non-wetting can present major problems.

Table 18.

SnPb eutectic process - package peak reflow temperatures (from

J-STD-020C

July 2004)

Package thickness

Volume mm

3

< 350

Volume mm

3

350

< 2.5 mm

240

°

C + 0/

-

5

°

C

225

°

C + 0/

-

5

°

C

2.5 mm

225

°

C + 0/

-

5

°

C

225

°

C + 0/

-

5

°

C

Table 19.

Pb-free process - package peak reflow temperatures (from

J-STD-020C July

2004)

Package thickness

Volume mm

3

< 350

Volume mm

3

350 to

2000

Volume mm

3

> 2000

< 1.6 mm

260

°

C + 0

°

C

260

°

C + 0

°

C

260

°

C + 0

°

C

1.6 mm to 2.5 mm

260

°

C + 0

°

C

250

°

C + 0

°

C

245

°

C + 0

°

C

2.5 mm

250

°

C + 0

°

C

245

°

C + 0

°

C

245

°

C + 0

°

C

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

21 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

To overcome these problems the double-wave soldering method was specifically

developed.

If wave soldering is used the following conditions must be observed for optimal results:

·

Use a double-wave soldering method comprising a turbulent wave with high upward

pressure followed by a smooth laminar wave.

·

For packages with leads on two sides and a pitch (e):

larger than or equal to 1.27 mm, the footprint longitudinal axis is preferred to be

parallel to the transport direction of the printed-circuit board;

smaller than 1.27 mm, the footprint longitudinal axis must be parallel to the

transport direction of the printed-circuit board.

The footprint must incorporate solder thieves at the downstream end.

·

For packages with leads on four sides, the footprint must be placed at a 45

°

angle to

the transport direction of the printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must be fixed with a droplet of

adhesive. The adhesive can be applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the adhesive is cured.

Typical dwell time of the leads in the wave ranges from 3 seconds to 4 seconds at 250

°

C

or 265

°

C, depending on solder material applied, SnPb or Pb-free respectively.

A mildly-activated flux will eliminate the need for removal of corrosive residues in most

applications.

16.4 Manual soldering

Fix the component by first soldering two diagonally-opposite end leads. Use a low voltage

(24 V or less) soldering iron applied to the flat part of the lead. Contact time must be

limited to 10 seconds at up to 300

°

C.

When using a dedicated tool, all other leads can be soldered in one operation within

2 seconds to 5 seconds between 270

°

C and 320

°

C.

16.5 Package related soldering information

Table 20.

Suitability of surface mount IC packages for wave and reflow soldering methods

Package

[1]

Soldering method

Wave

Reflow

[2]

BGA, HTSSON..T

[3]

, LBGA, LFBGA, SQFP,

SSOP..T

[3]

, TFBGA, VFBGA, XSON

not suitable

suitable

DHVQFN, HBCC, HBGA, HLQFP, HSO, HSOP,

HSQFP, HSSON, HTQFP, HTSSOP, HVQFN,

HVSON, SMS

not suitable

[4]

suitable

PLCC

[5]

, SO, SOJ

suitable

suitable

LQFP, QFP, TQFP

not recommended

[5][6]

suitable

SSOP, TSSOP, VSO, VSSOP

not recommended

[7]

suitable

CWQCCN..L

[8]

, PMFP

[9]

, WQCCN..L

[8]

not suitable

not suitable

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

22 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

[1]

For more detailed information on the BGA packages refer to the

(LF)BGA Application Note (AN01026);

order a copy from your Philips Semiconductors sales office.

[2]

All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the

maximum temperature (with respect to time) and body size of the package, there is a risk that internal or

external package cracks may occur due to vaporization of the moisture in them (the so called popcorn

effect). For details, refer to the Drypack information in the

Data Handbook IC26; Integrated Circuit

Packages; Section: Packing Methods.

[3]

These transparent plastic packages are extremely sensitive to reflow soldering conditions and must on no

account be processed through more than one soldering cycle or subjected to infrared reflow soldering with

peak temperature exceeding 217

°

C

±

10

°

C measured in the atmosphere of the reflow oven. The package

body peak temperature must be kept as low as possible.

[4]

These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the

solder cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink

on the top side, the solder might be deposited on the heatsink surface.

[5]

If wave soldering is considered, then the package must be placed at a 45

°

angle to the solder wave

direction. The package footprint must incorporate solder thieves downstream and at the side corners.

[6]

Wave soldering is suitable for LQFP, QFP and TQFP packages with a pitch (e) larger than 0.8 mm; it is

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

[7]

Wave soldering is suitable for SSOP, TSSOP, VSO and VSSOP packages with a pitch (e) equal to or larger

than 0.65 mm; it is definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

[8]

Image sensor packages in principle should not be soldered. They are mounted in sockets or delivered

pre-mounted on flex foil. However, the image sensor package can be mounted by the client on a flex foil by

using a hot bar soldering process. The appropriate soldering profile can be provided on request.

[9]

Hot bar soldering or manual soldering is suitable for PMFP packages.

17. Abbreviations

18. Revision history

Table 21.

Abbreviations

Acronym

Description

GPIO

General Purpose Input/Output

I

2

C-bus

Inter Integrated Circuit bus

I/O

Input/Output

LCD

Liquid Crystal Display

POR

Power-On Reset

SPI

Serial Peripheral Interface

Table 22.

Revision history

Document ID

Release date

Data sheet status

Change notice

Supersedes

PCA9502_2

20060803

Product data sheet

-

PCA9502_1

Modifications:

·

Table 2 "Pin description"

: updated description of IRQ (pin 12)

·

Table 10 "IOControl register (address 0x0E) bit description"

: added example in description of bit 0,

IOLatch

·

Table 16 "I

2

C-bus timing specifications"

: removed symbol/parameter t

d15

(SCL delay time after

reset) and Table note 3.

·

deleted (old) Figure 13, "SCL delay after reset"

PCA9502_1

20060707

Product data sheet

-

-

PCA9502_2

© Koninklijke Philips Electronics N.V. 2006. All rights reserved.

Product data sheet

Rev. 02 -- 3 August 2006

23 of 24

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

19. Legal information

19.1

Data sheet status

[1]

Please consult the most recently issued document before initiating or completing a design.

[2]

The term `short data sheet' is explained in section "Definitions".

[3]

The product status of device(s) described in this document may have changed since this document was published and may differ in case of multiple devices. The latest product status

information is available on the Internet at URL

http://www.semiconductors.philips.com.

19.2

Definitions

Draft -- The document is a draft version only. The content is still under

internal review and subject to formal approval, which may result in

modifications or additions. Philips Semiconductors does not give any

representations or warranties as to the accuracy or completeness of

information included herein and shall have no liability for the consequences of

use of such information.

Short data sheet -- A short data sheet is an extract from a full data sheet

with the same product type number(s) and title. A short data sheet is intended

for quick reference only and should not be relied upon to contain detailed and

full information. For detailed and full information see the relevant full data

sheet, which is available on request via the local Philips Semiconductors

sales office. In case of any inconsistency or conflict with the short data sheet,

the full data sheet shall prevail.

19.3

Disclaimers

General -- Information in this document is believed to be accurate and

reliable. However, Philips Semiconductors does not give any representations

or warranties, expressed or implied, as to the accuracy or completeness of

such information and shall have no liability for the consequences of use of

such information.

Right to make changes -- Philips Semiconductors reserves the right to

make changes to information published in this document, including without

limitation specifications and product descriptions, at any time and without

notice. This document supersedes and replaces all information supplied prior

to the publication hereof.

Suitability for use -- Philips Semiconductors products are not designed,

authorized or warranted to be suitable for use in medical, military, aircraft,

space or life support equipment, nor in applications where failure or

malfunction of a Philips Semiconductors product can reasonably be expected

to result in personal injury, death or severe property or environmental

damage. Philips Semiconductors accepts no liability for inclusion and/or use

of Philips Semiconductors products in such equipment or applications and

therefore such inclusion and/or use is at the customer's own risk.

Applications -- Applications that are described herein for any of these

products are for illustrative purposes only. Philips Semiconductors makes no

representation or warranty that such applications will be suitable for the

specified use without further testing or modification.

Limiting values -- Stress above one or more limiting values (as defined in

the Absolute Maximum Ratings System of IEC 60134) may cause permanent

damage to the device. Limiting values are stress ratings only and operation of

the device at these or any other conditions above those given in the

Characteristics sections of this document is not implied. Exposure to limiting

values for extended periods may affect device reliability.

Terms and conditions of sale -- Philips Semiconductors products are sold

subject to the general terms and conditions of commercial sale, as published

at

http://www.semiconductors.philips.com/profile/terms

, including those

pertaining to warranty, intellectual property rights infringement and limitation

of liability, unless explicitly otherwise agreed to in writing by Philips

Semiconductors. In case of any inconsistency or conflict between information

in this document and such terms and conditions, the latter will prevail.

No offer to sell or license -- Nothing in this document may be interpreted

or construed as an offer to sell products that is open for acceptance or the

grant, conveyance or implication of any license under any copyrights, patents

or other industrial or intellectual property rights.

19.4

Trademarks

Notice: All referenced brands, product names, service names and trademarks

are the property of their respective owners.

I

2

C-bus -- logo is a trademark of Koninklijke Philips Electronics N.V.

20. Contact information

For additional information, please visit: http://www.semiconductors.philips.com

For sales office addresses, send an email to: sales.addresses@www.semiconductors.philips.com

Document status

[1][2]

Product status

[3]

Definition

Objective [short] data sheet

Development

This document contains data from the objective specification for product development.

Preliminary [short] data sheet

Qualification

This document contains data from the preliminary specification.

Product [short] data sheet

Production

This document contains the product specification.

Philips Semiconductors

PCA9502

8-bit I/O expander with I

2

C-bus/SPI interface

© Koninklijke Philips Electronics N.V. 2006.

All rights reserved.

For more information, please visit: http://www.semiconductors.philips.com.

For sales office addresses, email to: sales.addresses@www.semiconductors.philips.com.

Date of release: 3 August 2006

Document identifier: PCA9502_2

Please be aware that important notices concerning this document and the product(s)

described herein, have been included in section `Legal information'.

21. Contents

1

General description . . . . . . . . . . . . . . . . . . . . . . 1

2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1

General features . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2

I

2

C-bus features . . . . . . . . . . . . . . . . . . . . . . . . 1

2.3

SPI features . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4

Ordering information . . . . . . . . . . . . . . . . . . . . . 2

5

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6

Pinning information . . . . . . . . . . . . . . . . . . . . . . 3

6.1

Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.2

Pin description . . . . . . . . . . . . . . . . . . . . . . . . . 3

7

Functional description . . . . . . . . . . . . . . . . . . . 4

7.1

Hardware reset, Power-On Reset (POR)

and software reset . . . . . . . . . . . . . . . . . . . . . . 4

7.2

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8

Register descriptions . . . . . . . . . . . . . . . . . . . . 5

8.1

Programmable I/O pins Direction register

(IODir) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8.2

Programmable I/O pins State register

(IOState) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8.3

I/O Interrupt Enable register (IOIntEna) . . . . . . 6

8.4

I/O Control register (IOControl). . . . . . . . . . . . . 6

9

I

2

C-bus operation . . . . . . . . . . . . . . . . . . . . . . . . 7

9.1

Data transfers . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9.2

Addressing and transfer formats. . . . . . . . . . . . 8

9.3

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9.4

Use of sub-addresses. . . . . . . . . . . . . . . . . . . 11

10

SPI operation . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11

Limiting values. . . . . . . . . . . . . . . . . . . . . . . . . 13

12

Static characteristics. . . . . . . . . . . . . . . . . . . . 14

13

Dynamic characteristics . . . . . . . . . . . . . . . . . 15

14

Package outline . . . . . . . . . . . . . . . . . . . . . . . . 19

15

Handling information. . . . . . . . . . . . . . . . . . . . 20

16

Soldering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16.1

Introduction to soldering surface mount

packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

16.2

Reflow soldering . . . . . . . . . . . . . . . . . . . . . . . 20

16.3

Wave soldering . . . . . . . . . . . . . . . . . . . . . . . . 20

16.4

Manual soldering . . . . . . . . . . . . . . . . . . . . . . 21

16.5

Package related soldering information . . . . . . 21

17

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . 22

18

Revision history . . . . . . . . . . . . . . . . . . . . . . . . 22

19

Legal information. . . . . . . . . . . . . . . . . . . . . . . 23

19.1

Data sheet status . . . . . . . . . . . . . . . . . . . . . . 23

19.2

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

19.3

Disclaimers. . . . . . . . . . . . . . . . . . . . . . . . . . . 23

19.4

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . 23

20

Contact information . . . . . . . . . . . . . . . . . . . . 23

21

Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24