©

Semiconductor Components Industries, LLC, 2000

November, 2000 Rev.3

1

Publication Order Number:

MTB60N06HD/D

MTB60N06HD

Preferred Device

Power MOSFET

60 Amps, 60 Volts

NChannel D2PAK

This Power MOSFET is designed to withstand high energy in the

avalanche and commutation modes. The energy efficient design also

offers a draintosource diode with a fast recovery time. Designed for

low voltage, high speed switching applications in power supplies,

converters and PWM motor controls, these devices are particularly

well suited for bridge circuits where diode speed and commutating

safe operating areas are critical and offer additional safety margin

against unexpected voltage transients.

·

Avalanche Energy Specified

·

SourcetoDrain Diode Recovery Time Comparable to a

Discrete Fast Recovery Diode

·

Diode is Characterized for Use in Bridge Circuits

·

IDSS and VDS(on) Specified at Elevated Temperature

·

Short Heatsink Tab Manufactured Not Sheared

·

Specially Designed Leadframe for Maximum Power Dissipation

MAXIMUM RATINGS

(TC = 25

°

C unless otherwise noted)

Rating

Symbol

Value

Unit

DrainSource Voltage

VDSS

60

Vdc

DrainGate Voltage (RGS = 1.0 M

)

VDGR

60

Vdc

GateSource Voltage

Continuous

NonRepetitive (tp

10 ms)

VGS

VGSM

±

20

±

30

Vdc

Vpk

Drain Current Continuous

Drain Current

Continuous @ 100

°

C

Drain Current

Single Pulse (tp

10

µ

s)

ID

ID

IDM

60

42.3

180

Adc

Apk

Total Power Dissipation

Derate above 25

°

C

Total Power Dissipation @ TA = 25

°

C

(Note 1.)

PD

125

1.0

2.5

Watts

W/

°

C

Watts

Operating and Storage Temperature

Range

TJ, Tstg

55 to

150

°

C

Single Pulse DraintoSource Avalanche

Energy Starting TJ = 25

°

C

(VDD = 25 Vdc, VGS = 10 Vdc, Peak

IL = 60 Apk, L = 0.3 mH, RG = 25

)

EAS

540

mJ

Thermal Resistance

Junction to Case

Junction to Ambient

Junction to Ambient, when mounted

with the minimum recommended pad size

R

JC

R

JA

R

JA

1.0

62.5

50

°

C/W

Maximum Lead Temperature for Soldering

Purposes, 1/8

from case for 10

seconds

TL

260

°

C

1. When mounted with the minimum recommended pad size.

MARKING DIAGRAM

& PIN ASSIGNMENT

T60N06HD

YWW

1

Gate

4

Drain

2

Drain

3

Source

60 AMPERES

60 VOLTS

RDS(on) = 14 m

Device

Package

Shipping

ORDERING INFORMATION

MTB60N06HD

D2PAK

50 Units/Rail

D2PAK

CASE 418B

STYLE 2

1

2

3

4

http://onsemi.com

NChannel

D

S

G

T60N06HD

= Device Code

Y

= Year

WW

= Work Week

MTB60N06HDT4

D2PAK

800/Tape & Reel

Preferred devices are recommended choices for future use

and best overall value.

MTB60N06HD

http://onsemi.com

2

ELECTRICAL CHARACTERISTICS

(TJ = 25

°

C unless otherwise noted)

Characteristic

Symbol

Min

Typ

Max

Unit

OFF CHARACTERISTICS

DraintoSource Breakdown Voltage

(Cpk

2.0) (Note 4.)

(VGS = 0 Vdc, ID = 250

µ

Adc)

Temperature Coefficient (Positive)

V(BR)DSS

60

71

Vdc

mV/

°

C

Zero Gate Voltage Drain Current

(VDS = 60 Vdc, VGS = 0 Vdc)

(VDS = 60 Vdc, VGS = 0 Vdc, TJ = 125

°

C)

IDSS

10

100

µ

Adc

GateBody Leakage Current

(VGS =

±

20 Vdc, VDS = 0 Vdc)

IGSS

100

nAdc

ON CHARACTERISTICS (Note 2.)

Gate Threshold Voltage

(Cpk

3.0) (Note 4.)

(VDS = VGS, ID = 250

µ

Adc)

Threshold Temperature Coefficient (Negative)

VGS(th)

2.0

3.0

7.0

4.0

Vdc

mV/

°

C

Static DrainSource OnResistance

(Cpk

3.0) (Note 4.)

(VGS = 10 Vdc, ID = 30 Adc)

RDS(on)

0.011

0.014

Ohm

DrainSource OnVoltage (VGS = 10 Vdc)

(ID = 60 Adc)

(ID = 30 Adc, TJ =125

°

C)

VDS(on)

1.0

0.9

Vdc

Forward Transconductance

(VDS = 4.0 Vdc, ID = 30 Adc)

gFS

15

20

mhos

DYNAMIC CHARACTERISTICS

Input Capacitance

(V

25 Vd

V

0 Vd

Ciss

1950

2800

pF

Output Capacitance

(VDS = 25 Vdc, VGS = 0 Vdc,

f = 1.0 MHz)

Coss

660

920

Transfer Capacitance

f = 1.0 MHz)

Crss

147

300

SWITCHING CHARACTERISTICS (Note 3.)

TurnOn Delay Time

td(on)

14

26

ns

Rise Time

(VDD= 30 Vdc, ID = 60 Adc,

VGS = 10 Vdc

tr

197

394

TurnOff Delay Time

VGS = 10 Vdc,

RG = 9.1

)

td(off)

50

102

Fall Time

RG 9.1

)

tf

124

246

Gate Charge

(S

Fi

8)

QT

51

71

nC

(See Figure 8)

(VDS = 48 Vdc, ID = 60 Adc,

Q1

12

(VDS 48 Vdc, ID 60 Adc,

VGS = 10 Vdc)

Q2

24

Q3

21

SOURCEDRAIN DIODE CHARACTERISTICS

Forward OnVoltage

(IS = 60 Adc, VGS = 0 Vdc)

(IS = 60 Adc, VGS = 0 Vdc,

TJ = 125

°

C)

VSD

0.99

0.89

1.0

Vdc

Reverse Recovery Time

(S

Fi

15)

trr

60

ns

(See Figure 15)

(IS = 60 Adc, VGS = 0 Vdc,

ta

36

(IS 60 Adc, VGS 0 Vdc,

dIS/dt = 100 A/

µ

s)

tb

24

Reverse Recovery Stored Charge

QRR

0.143

µ

C

INTERNAL PACKAGE INDUCTANCE

Internal Drain Inductance

(Measured from the drain lead 0.25

from package to center of die)

LD

4.5

nH

Internal Source Inductance

(Measured from the source lead 0.25

from package to source bond pad)

LS

7.5

nH

2. Pulse Test: Pulse Width

300

µ

s, Duty Cycle

2%.

3. Switching characteristics are independent of operating junction temperature.

4. Reflects typical values.

Cpk =

Max limit Typ

3 x SIGMA

MTB60N06HD

http://onsemi.com

3

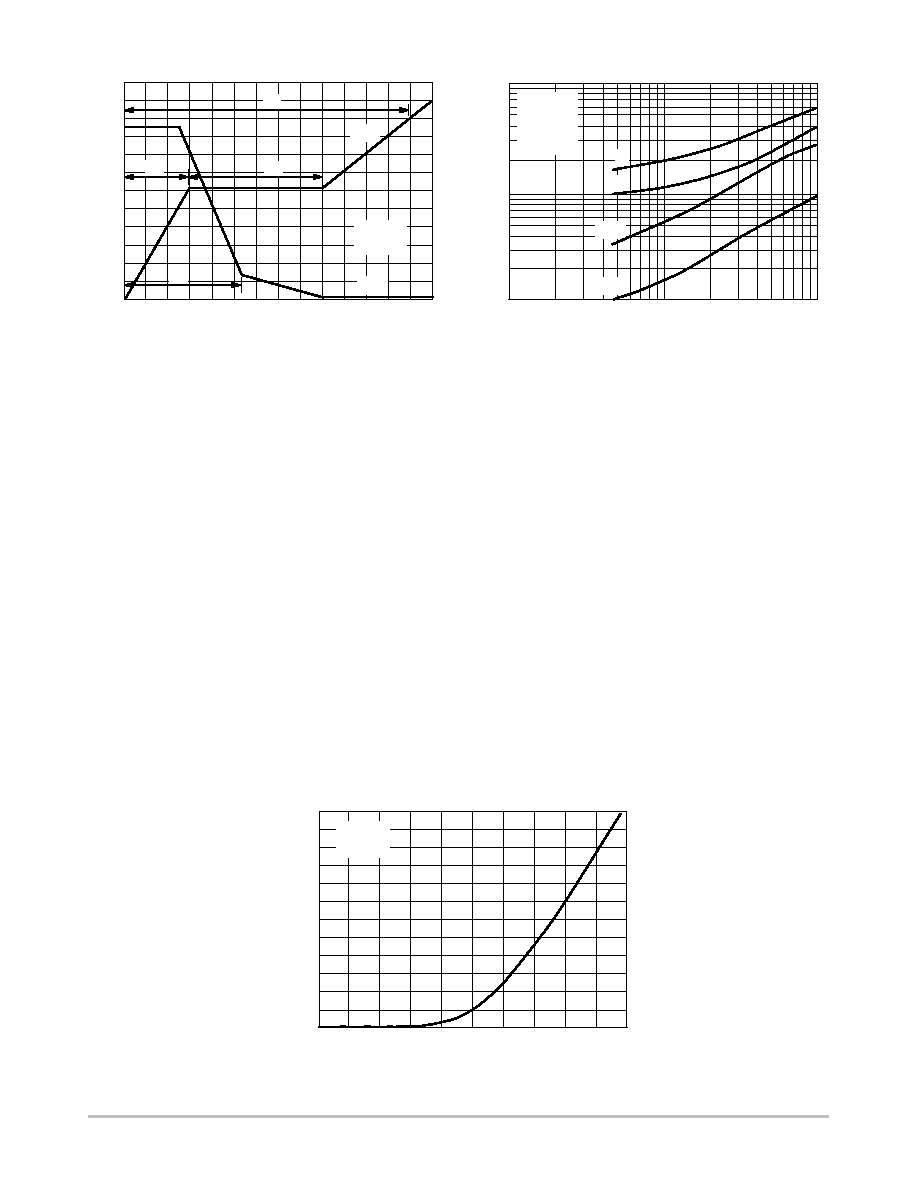

TYPICAL ELECTRICAL CHARACTERISTICS

R DS(on)

, DRAIN-T

O-SOURCE RESIST

ANCE

(NORMALIZED)

R DS(on)

, DRAIN-T

O-SOURCE RESIST

ANCE (OHMS)

R DS(on)

, DRAIN-T

O-SOURCE RESIST

ANCE (OHMS)

ID, DRAIN CURRENT (AMPS)

TJ, JUNCTION TEMPERATURE (

°

C)

VDS, DRAIN-TO-SOURCE VOLTAGE (VOLTS)

I DSS

, LEAKAGE (nA)

ID, DRAIN CURRENT (AMPS)

I D

, DRAIN CURRENT

(AMPS)

VDS, DRAIN-TO-SOURCE VOLTAGE (VOLTS)

VGS, GATE-TO-SOURCE VOLTAGE (VOLTS)

I D

, DRAIN CURRENT

(AMPS)

0

20

40

80

120

100

60

0

1.0

2.0

3.0

4.0

5.0

0

20

40

80

120

Figure 1. OnRegion Characteristics

2.0

2.8

3.6

4.4

6.0

7.6

Figure 2. Transfer Characteristics

0

20

40

60

80

120

0.006

0.008

0.012

0.016

0.020

0.0100

0.0108

0.0116

0.0124

0.0132

Figure 3. OnResistance versus Drain Current

and Temperature

Figure 4. OnResistance versus Drain Current

and Gate Voltage

- 50

0.6

0.8

1.0

1.4

1.8

0

10

20

40

50

60

1

10

100

1000

Figure 5. OnResistance Variation with

Temperature

Figure 6. DraintoSource Leakage

Current versus Voltage

- 25

0

25

50

75

100

125

150

100

60

0.5

1.5

2.5

3.5

4.5

6.8

0.018

0.014

0.010

100

0

20

40

60

80

120

100

0.0128

0.0120

0.0112

0.0104

1.2

1.6

30

VGS = 10 V

9 V

8 V

100

°

C

25

°

C

TJ = - 55

°

C

TJ = 25

°

C

15 V

VGS = 10 V

VGS = 10 V

- 55

°

C

VGS = 0 V

TJ = 125

°

C

100

°

C

25

°

C

5 V

6 V

TJ = 25

°

C

7 V

10

30

50

70

90

110

10

30

50

70

90

110

VDS

10 V

5.2

VGS = 10 V

ID = 30 A

TJ = 100

°

C

25

°

C

MTB60N06HD

http://onsemi.com

4

POWER MOSFET SWITCHING

Switching behavior is most easily modeled and predicted

by recognizing that the power MOSFET is charge

controlled. The lengths of various switching intervals (

t)

are determined by how fast the FET input capacitance can

be charged by current from the generator.

The published capacitance data is difficult to use for

calculating rise and fall because draingate capacitance

varies greatly with applied voltage. Accordingly, gate

charge data is used. In most cases, a satisfactory estimate of

average input current (IG(AV)) can be made from a

rudimentary analysis of the drive circuit so that

t = Q/IG(AV)

During the rise and fall time interval when switching a

resistive load, VGS remains virtually constant at a level

known as the plateau voltage, VSGP. Therefore, rise and fall

times may be approximated by the following:

tr = Q2 x RG/(VGG VGSP)

tf = Q2 x RG/VGSP

where

VGG = the gate drive voltage, which varies from zero to VGG

RG = the gate drive resistance

and Q2 and VGSP are read from the gate charge curve.

During the turnon and turnoff delay times, gate current is

not constant. The simplest calculation uses appropriate

values from the capacitance curves in a standard equation for

voltage change in an RC network. The equations are:

td(on) = RG Ciss In [VGG/(VGG VGSP)]

td(off) = RG Ciss In (VGG/VGSP)

The capacitance (Ciss) is read from the capacitance curve at

a voltage corresponding to the offstate condition when

calculating td(on) and is read at a voltage corresponding to the

onstate when calculating td(off).

At high switching speeds, parasitic circuit elements

complicate the analysis. The inductance of the MOSFET

source lead, inside the package and in the circuit wiring

which is common to both the drain and gate current paths,

produces a voltage at the source which reduces the gate drive

current. The voltage is determined by Ldi/dt, but since di/dt

is a function of drain current, the mathematical solution is

complex. The MOSFET output capacitance also

complicates the mathematics. And finally, MOSFETs have

finite internal gate resistance which effectively adds to the

resistance of the driving source, but the internal resistance

is difficult to measure and, consequently, is not specified.

The resistive switching time variation versus gate

resistance (Figure 9) shows how typical switching

performance is affected by the parasitic circuit elements. If

the parasitics were not present, the slope of the curves would

maintain a value of unity regardless of the switching speed.

The circuit used to obtain the data is constructed to minimize

common inductance in the drain and gate circuit loops and

is believed readily achievable with board mounted

components. Most power electronic loads are inductive; the

data in the figure is taken with a resistive load, which

approximates an optimally snubbed inductive load. Power

MOSFETs may be safely operated into an inductive load;

however, snubbing reduces switching losses.

GATE-TO-SOURCE OR DRAIN-TO-SOURCE VOLTAGE (VOLTS)

C, CAP

ACIT

ANCE (pF)

0

1000

2000

3000

5000

Figure 7. Capacitance Variation

4000

10

0

10

15

20

25

VGS

VDS

5

5

VDS = 0 V

Ciss

Crss

VGS = 0 V

TJ = 25

°

C

Ciss

Coss

Crss

MTB60N06HD

http://onsemi.com

5

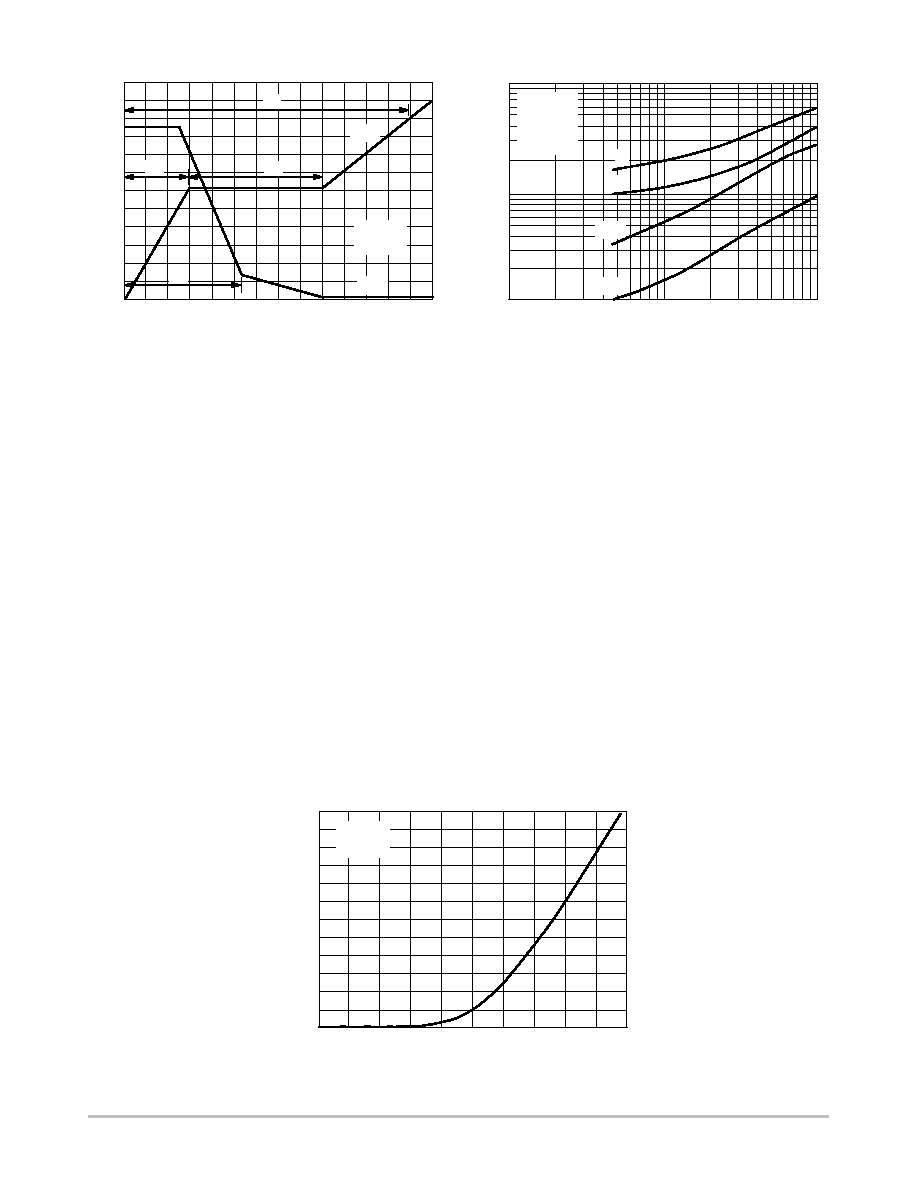

QT, TOTAL GATE CHARGE (nC)

RG, GATE RESISTANCE (Ohms)

t, TIME

(ns)

V DS

, DRAIN-T

O-SOURCE VOL

T

AGE (VOL

TS)

V GS

, GA

TE-T

O-SOURCE VOL

T

AGE (VOL

TS)

Figure 8. GateToSource and DrainToSource

Voltage versus Total Charge

1

10

100

10

100

1000

VDD = 30 V

ID = 60 A

VGS = 10 V

TJ = 25

°

C

tr

tf

td(on)

td(off)

Figure 9. Resistive Switching Time

Variation versus Gate Resistance

0

8

24

40

48

56

16

32

10

6

2

0

8

4

12

60

50

40

30

10

20

0

QT

Q2

VGS

ID = 60 A

TJ = 25

°

C

VDS

Q3

Q1

DRAINTOSOURCE DIODE CHARACTERISTICS

The switching characteristics of a MOSFET body diode

are very important in systems using it as a freewheeling or

commutating diode. Of particular interest are the reverse

recovery characteristics which play a major role in

determining switching losses, radiated noise, EMI and RFI.

System switching losses are largely due to the nature of

the body diode itself. The body diode is a minority carrier

device, therefore it has a finite reverse recovery time, trr, due

to the storage of minority carrier charge, QRR, as shown in

the typical reverse recovery wave form of Figure 12. It is this

stored charge that, when cleared from the diode, passes

through a potential and defines an energy loss. Obviously,

repeatedly forcing the diode through reverse recovery

further increases switching losses. Therefore, one would

like a diode with short trr and low QRR specifications to

minimize these losses.

The abruptness of diode reverse recovery effects the

amount of radiated noise, voltage spikes, and current

ringing. The mechanisms at work are finite irremovable

circuit parasitic inductances and capacitances acted upon by

high di/dts. The diode's negative di/dt during ta is directly

controlled by the device clearing the stored charge.

However, the positive di/dt during tb is an uncontrollable

diode characteristic and is usually the culprit that induces

current ringing. Therefore, when comparing diodes, the

ratio of tb/ta serves as a good indicator of recovery

abruptness and thus gives a comparative estimate of

probable noise generated. A ratio of 1 is considered ideal and

values less than 0.5 are considered snappy.

Compared to ON Semiconductor standard cell density

low voltage MOSFETs, high cell density MOSFET diodes

are faster (shorter trr), have less stored charge and a softer

reverse recovery characteristic. The softness advantage of

the high cell density diode means they can be forced through

reverse recovery at a higher di/dt than a standard cell

MOSFET diode without increasing the current ringing or the

noise generated. In addition, power dissipation incurred

from switching the diode will be less due to the shorter

recovery time and lower switching losses.

I S

, SOURCE CURRENT

(AMPS)

VSD, SOURCE-TO-DRAIN VOLTAGE (VOLTS)

Figure 10. Diode Forward Voltage versus Current

0

10

30

50

60

40

20

0.5

0.6

0.7

0.8

0.9

1.0

VGS = 0 V

TJ = 25

°

C