©

Semiconductor Components Industries, LLC, 1999

February, 2000 Rev. 1

1

Publication Order Number:

MCR68/D

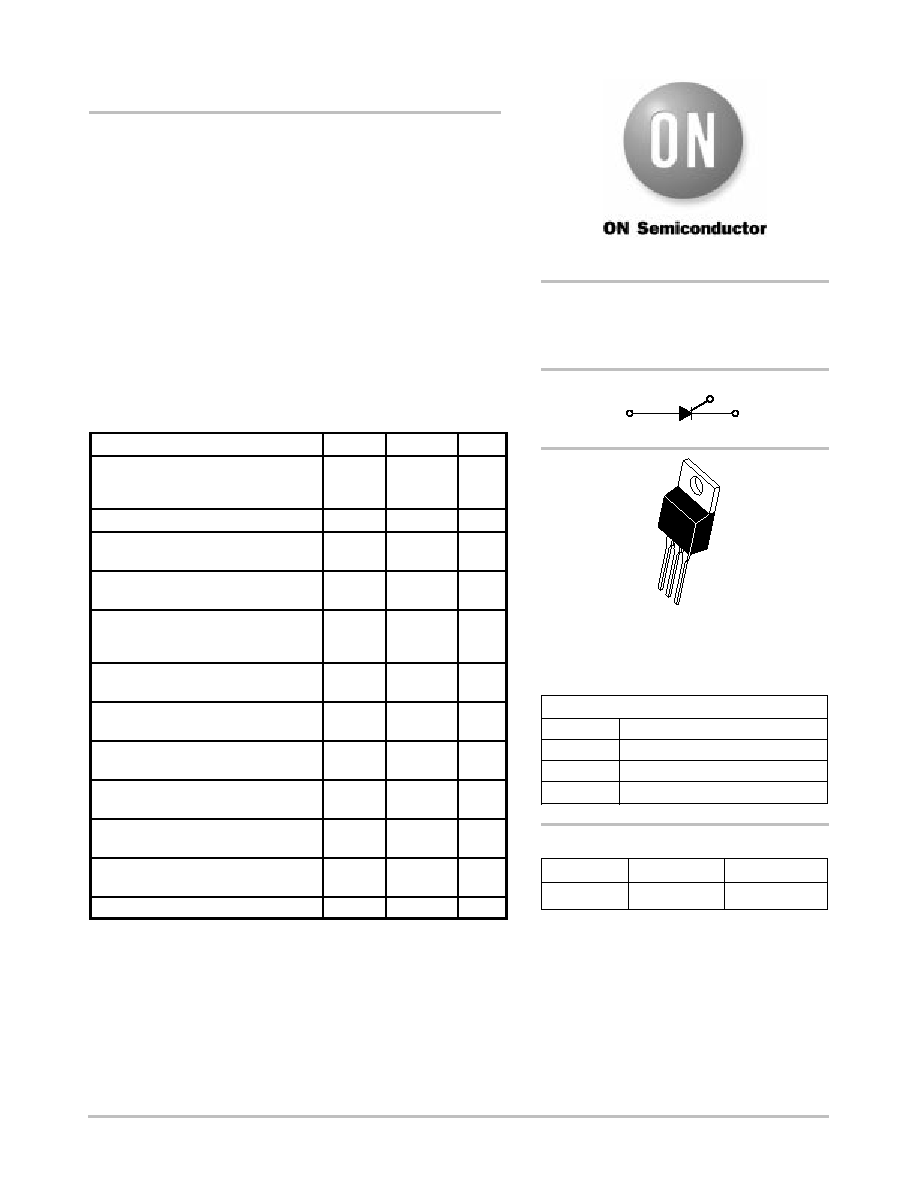

MCR68-2

Silicon Controlled Rectifiers

Reverse Blocking Thyristors

Designed for overvoltage protection in crowbar circuits.

·

Glass-Passivated Junctions for Greater Parameter Stability and

Reliability

·

Center-Gate Geometry for Uniform Current Spreading Enabling

High Discharge Current

·

Small Rugged, Thermowatt Package Constructed for Low Thermal

Resistance and Maximum Power Dissipation and Durability

·

High Capacitor Discharge Current, 300 Amps

·

Device Marking: Logo, Device Type, e.g., MCR682, Date Code

MAXIMUM RATINGS

(TJ = 25

°

C unless otherwise noted)

Rating

Symbol

Value

Unit

Peak Repetitive OffState Voltage(1)

(TJ =

*

40 to +125

°

C, Gate Open)

MCR682

VDRM,

VRRM

50

Volts

Peak Discharge Current(2)

ITM

300

Amps

On-State RMS Current

(180

°

Conduction Angles; TC = 85

°

C)

IT(RMS)

12

Amps

Average On-State Current

(180

°

Conduction Angles; TC = 85

°

C)

IT(AV)

8.0

Amps

Peak Non-Repetitive Surge Current

(1/2 Cycle, Sine Wave, 60 Hz,

TJ = 125

°

C)

ITSM

100

Amps

Circuit Fusing Considerations

(t = 8.3 ms)

I2t

40

A2s

Forward Peak Gate Current

(t

1.0

µ

s, TC = 85

°

C)

IGM

2.0

Amps

Forward Peak Gate Power

(t

1.0

µ

s, TC = 85

°

C)

PGM

20

Watts

Forward Average Gate Power

(t = 8.3 ms, TC = 85

°

C)

PG(AV)

0.5

Watt

Operating Junction Temperature Range

TJ

40 to

+125

°

C

Storage Temperature Range

Tstg

40 to

+150

°

C

Mounting Torque

--

8.0

in. lb.

(1) VDRM and VRRM for all types can be applied on a continuous basis. Ratings

apply for zero or negative gate voltage; however, positive gate voltage shall

not be applied concurrent with negative potential on the anode. Blocking

voltages shall not be tested with a constant current source such that the

voltage ratings of the devices are exceeded.

(2) Ratings apply for tw = 1 ms. See Figure 1 for ITM capability for various

duration of an exponentially decaying current waveform, tw is defined as

5 time constants of an exponentially decaying current pulse.

SCRs

12 AMPERES RMS

50 VOLTS

Device

Package

Shipping

ORDERING INFORMATION

MCR682

TO220AB

500/Box

http://onsemi.com

K

G

A

TO220AB

CASE 221A

STYLE 3

1

2

3

4

PIN ASSIGNMENT

1

2

3

Anode

Gate

Cathode

4

Anode

MCR682

http://onsemi.com

2

THERMAL CHARACTERISTICS

Characteristic

Symbol

Max

Unit

Thermal Resistance, Junction to Case

R

JC

2.0

°

C/W

Thermal Resistance, Junction to Ambient

R

JA

60

°

C/W

Maximum Lead Temperature for Soldering Purposes 1/8

from Case for 10 Seconds

TL

260

°

C

ELECTRICAL CHARACTERISTICS

(TC = 25

°

C unless otherwise noted.)

Characteristic

Symbol

Min

Typ

Max

Unit

OFF CHARACTERISTICS

Peak Repetitive Forward or Reverse Blocking Current

(VAK = Rated VDRM or VRRM, Gate Open)

TJ = 25

°

C

TJ = 125

°

C

IDRM, IRRM

--

--

--

--

10

2.0

µ

A

mA

ON CHARACTERISTICS

Peak Forward On-State Voltage

(ITM = 24 A)(1)

(ITM = 300 A, tw = 1 ms)(2)

VTM

--

--

--

6.0

2.2

--

Volts

Gate Trigger Current (Continuous dc)

(VD = 12 V, RL = 100

)

IGT

2.0

7.0

30

mA

Gate Trigger Voltage (Continuous dc)

(VD = 12 V, RL = 100

)

VGT

--

0.65

1.5

Volts

Gate NonTrigger Voltage

(VD = 12 Vdc, RL = 100

, TJ = 125

°

C)

VGD

0.2

0.40

--

Volts

Holding Current

(VD = 12 V, Initiating Current = 200 mA, Gate Open)

IH

3.0

15

50

mA

Latching Current

(VD = 12 Vdc, IG = 150 mA)

IL

--

--

60

mA

Gate Controlled Turn-On Time(3)

(VD = Rated VDRM, IG = 150 mA)

(ITM = 24 A Peak)

tgt

--

1.0

--

µ

s

DYNAMIC CHARACTERISTICS

Critical Rate-of-Rise of Off-State Voltage

(VD = Rated VDRM, Gate Open, Exponential Waveform, TJ = 125

°

C)

dv/dt

10

--

--

V/

µ

s

Critical Rate-of-Rise of On-State Current

IG = 150 mA

TJ = 125

°

C

di/dt

--

--

75

A/

µ

s

(1) Pulse duration

p

300

µ

s, duty cycle

p

2%.

(2) Ratings apply for tw = 1 ms. See Figure 1 for ITM capability for various durations of an exponentially decaying current waveform. tw is defined

as 5 time constants of an exponentially decaying current pulse.

(3) The gate controlled turn-on time in a crowbar circuit will be influenced by the circuit inductance.

MCR682

http://onsemi.com

3

+ Current

+ Voltage

VTM

IDRM at VDRM

IH

Symbol

Parameter

VDRM

Peak Repetitive Off State Forward Voltage

IDRM

Peak Forward Blocking Current

VRRM

Peak Repetitive Off State Reverse Voltage

IRRM

Peak Reverse Blocking Current

VTM

Peak On State Voltage

IH

Holding Current

Voltage Current Characteristic of SCR

Anode +

on state

Reverse Blocking Region

(off state)

Reverse Avalanche Region

Anode

Forward Blocking Region

IRRM at VRRM

(off state)

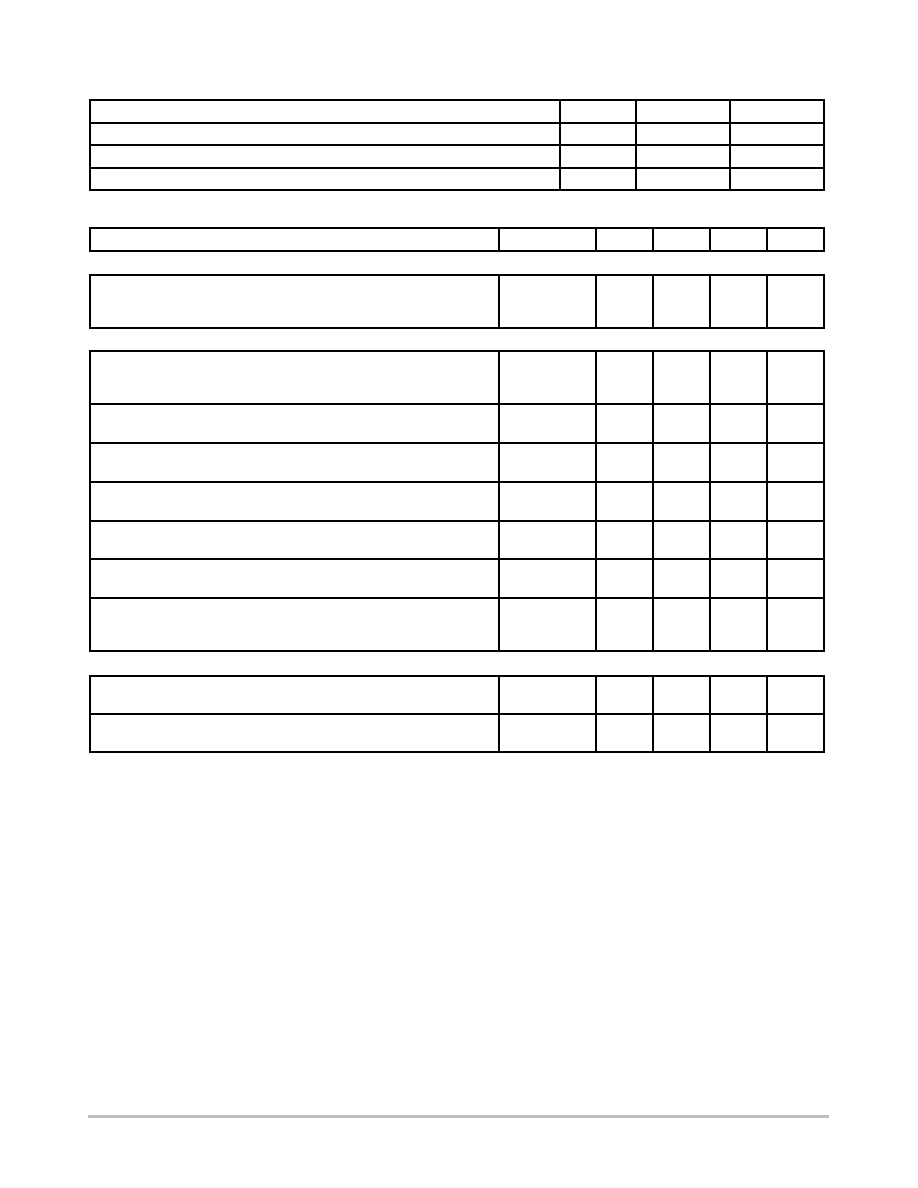

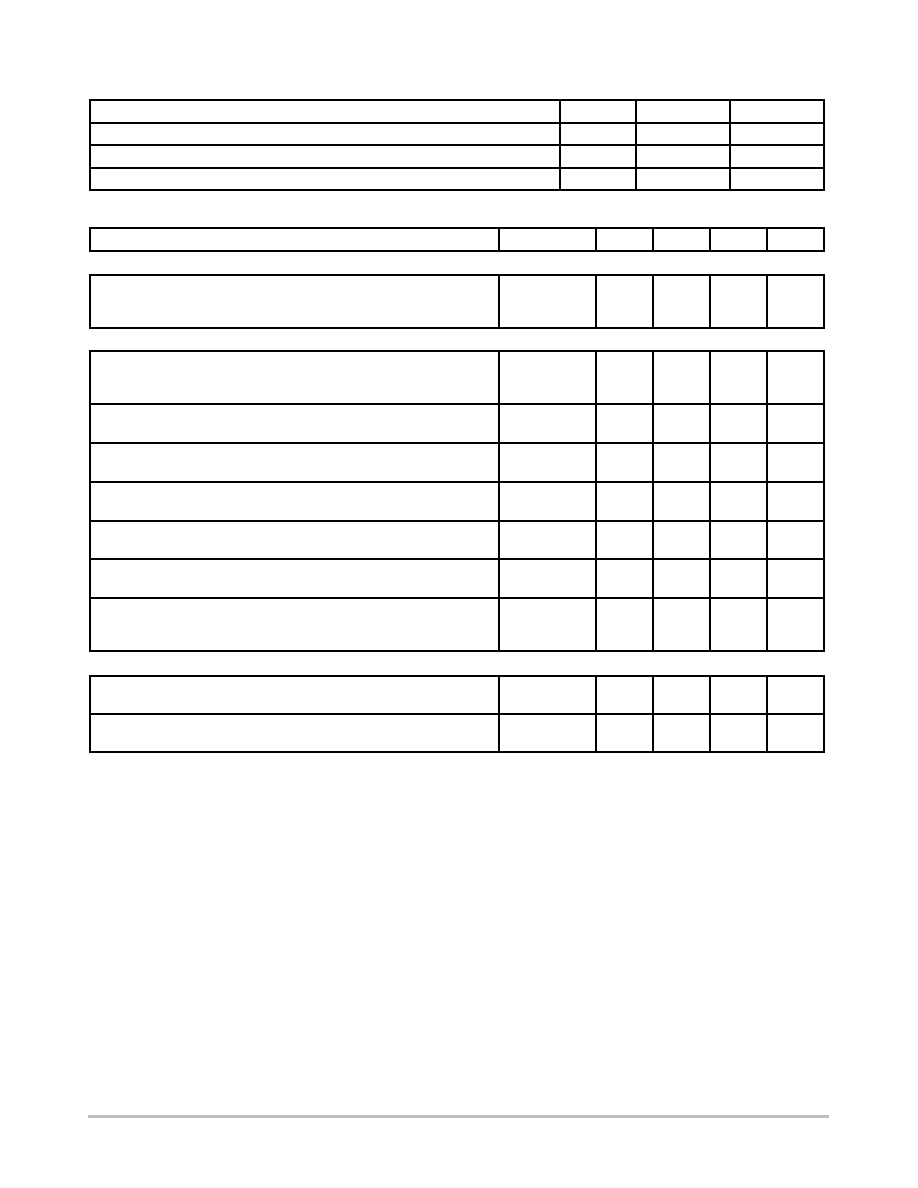

I , PEAK DISCHARGE CURRENT

(AMPS)

TM

NORMALIZED PEAK CURRENT

300

20

50

100

200

20

1000

0.5

50

tw, PULSE CURRENT DURATION (ms)

2.0

1.0

tw

tw = 5 time constants

ITM

10

5.0

0.8

25

0

0.2

0.4

0.6

1.0

50

75

100

125

TC, CASE TEMPERATURE (

°

C)

Figure 1. Peak Capacitor Discharge Current

Figure 2. Peak Capacitor Discharge Current

Derating

T

, MAXIMUM C

CASE

TEMPERA

TURE ( C)

°

75

80

85

90

95

100

105

110

115

120

125

5.0

2.0

1.0

8.0

10

IT(AV), AVERAGE ON-STATE CURRENT (AMPS)

dc

Half Wave

Figure 3. Current Derating

P

,

A

VERAGE

POWER

DISSIP

A

TION

(W

A

TTS)

(A

V) 2.0

4.0

8.0

10

14

18

20

Half Wave

dc

5.0

2.0

1.0

8.0

10

4.0

IT(AV), AVERAGE ON-STATE CURRENT (AMPS)

TJ = 125

°

C

Figure 4. Maximum Power Dissipation

MCR682

http://onsemi.com

4

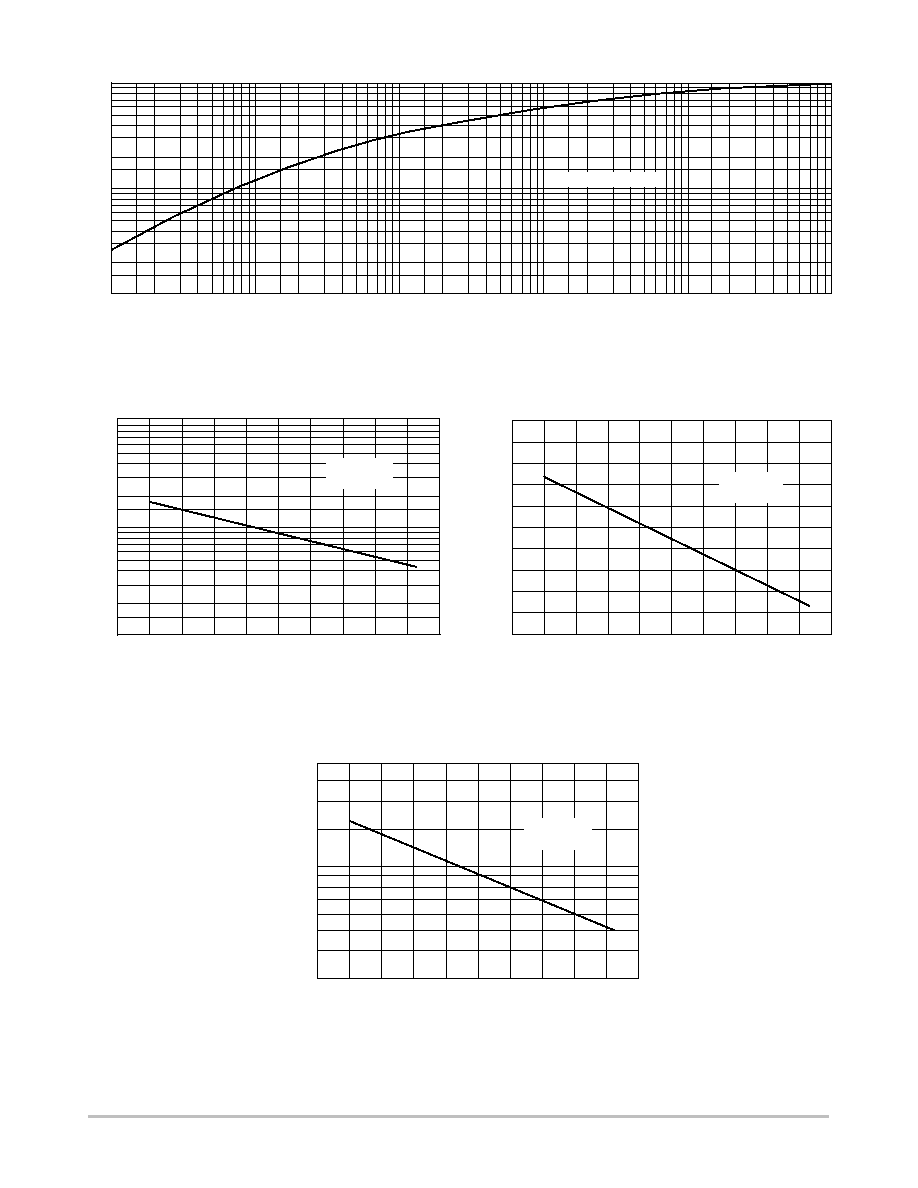

2 k

10 k

5 k

3 k

10

t, TIME (ms)

1 k

500

300

200

100

50

30

0.2

20

1

0.7

0.5

0.1

0.2

0.02

5

2

3

1

0.5

0.3

0.1

0.3

0.07

0.05

0.03

0.01

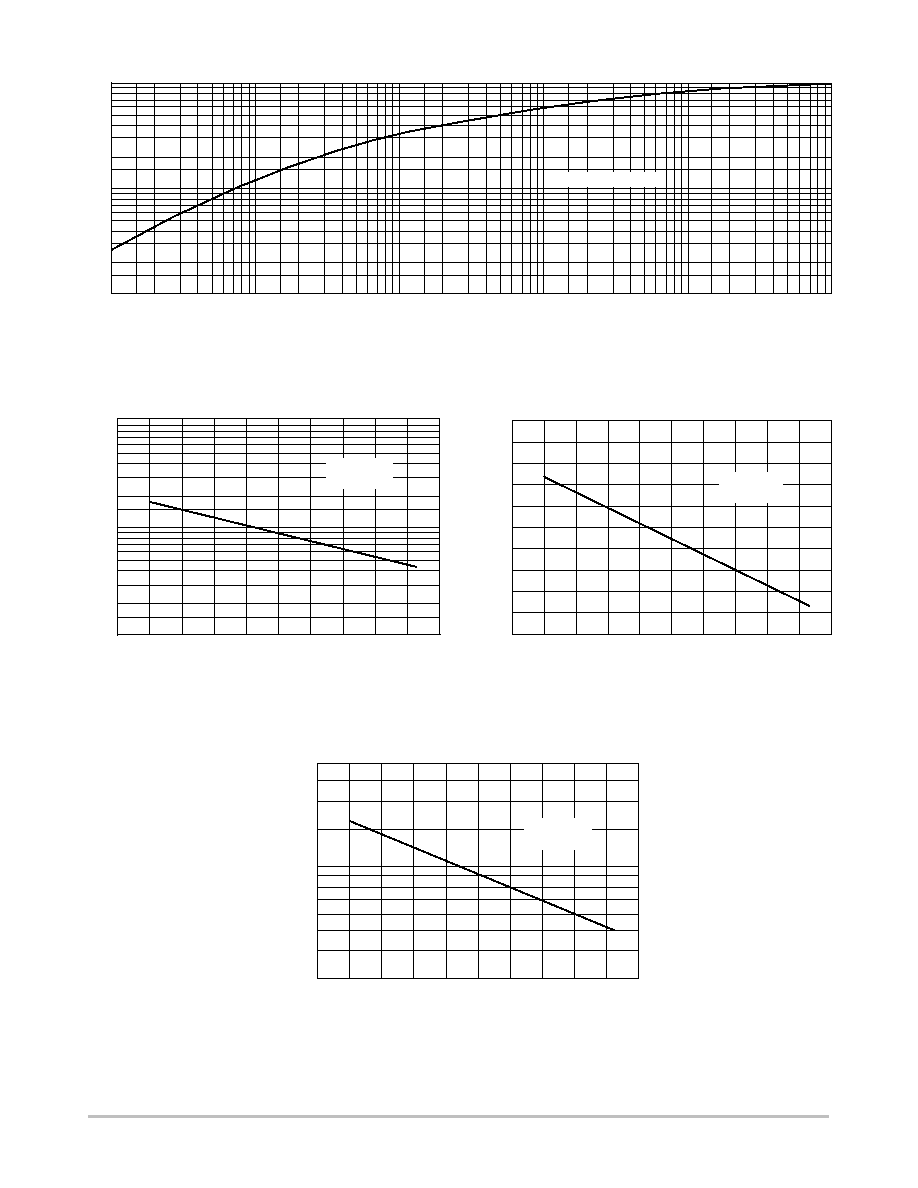

Z

JC(t) = R

JC

·

r(t)

r(t), TRANSIENT

THERMAL

RESIST

ANCE

(NORMALIZED)

Figure 5. Thermal Response

NORMALIZED GA

TE

TRIGGER

CURRENT

NORMALIZED GA

TE

TRIGGER

VOL

T

AGE

NORMALIZED HOLD CURRENT

40

10

0.2

0.3

140

120

100

80

60

40

20

0

20

0.5

1.2

1.0

0.8

40

60

1.4

TJ, JUNCTION TEMPERATURE (

°

C)

40

0

20

60

0.5

3.0

5.0

140

80

100

120

2.0

1.0

20

60

TJ, JUNCTION TEMPERATURE (

°

C)

VD = 12 Volts

RL = 100

VD = 12 Volts

RL = 100

0.3

0.5

0.8

1.0

140

120

40

100

3.0

2.0

20

60

80

0

40

TJ, JUNCTION TEMPERATURE (

°

C)

20

60

VD = 12 Volts

ITM = 100 mA

Figure 6. Gate Trigger Current

Figure 7. Gate Trigger Voltage

Figure 8. Holding Current

MCR682

http://onsemi.com

5

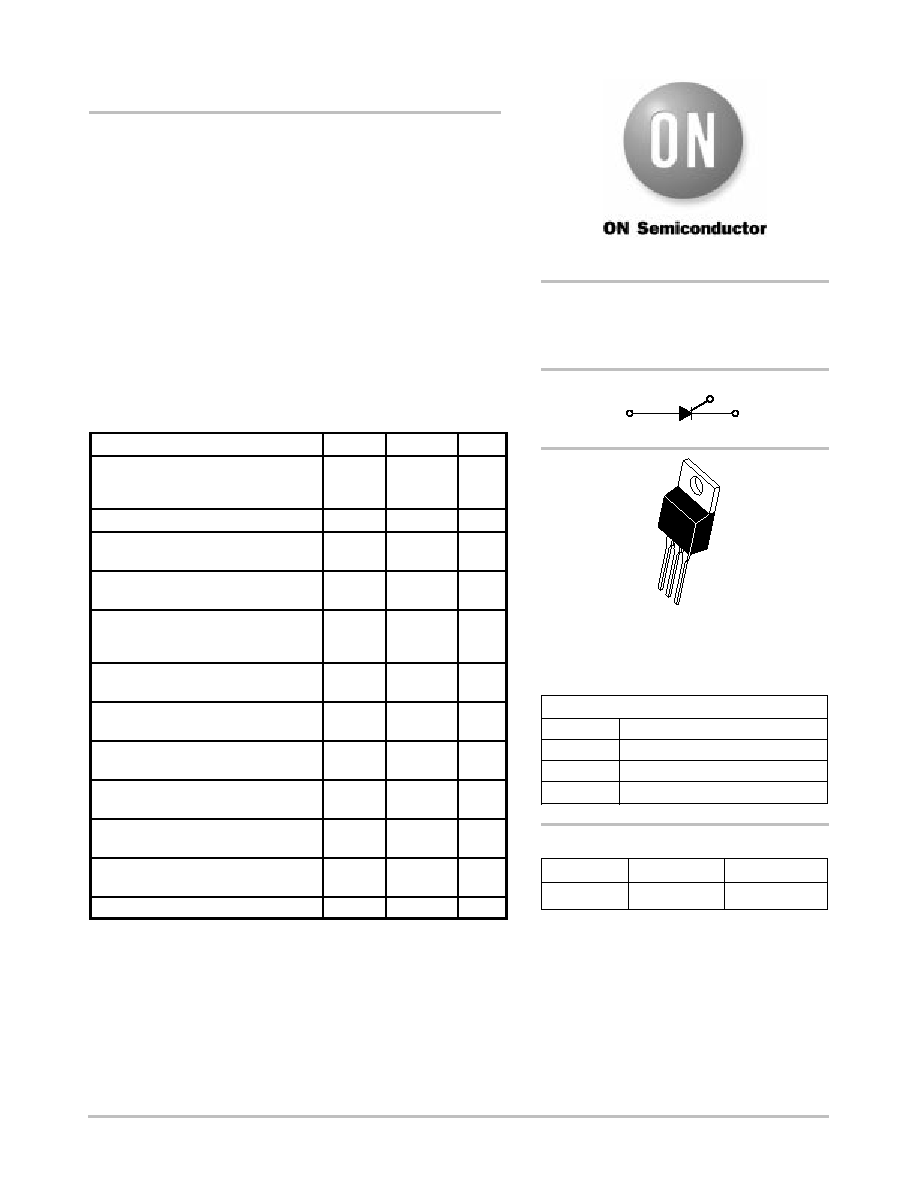

PACKAGE DIMENSIONS

TO220AB

CASE 221A07

ISSUE Z

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION Z DEFINES A ZONE WHERE ALL

BODY AND LEAD IRREGULARITIES ARE

ALLOWED.

DIM

MIN

MAX

MIN

MAX

MILLIMETERS

INCHES

A

0.570

0.620

14.48

15.75

B

0.380

0.405

9.66

10.28

C

0.160

0.190

4.07

4.82

D

0.025

0.035

0.64

0.88

F

0.142

0.147

3.61

3.73

G

0.095

0.105

2.42

2.66

H

0.110

0.155

2.80

3.93

J

0.014

0.022

0.36

0.55

K

0.500

0.562

12.70

14.27

L

0.045

0.060

1.15

1.52

N

0.190

0.210

4.83

5.33

Q

0.100

0.120

2.54

3.04

R

0.080

0.110

2.04

2.79

S

0.045

0.055

1.15

1.39

T

0.235

0.255

5.97

6.47

U

0.000

0.050

0.00

1.27

V

0.045

1.15

Z

0.080

2.04

A

K

L

V

G

D

N

Z

H

Q

F

B

1

2

3

4

T

SEATING

PLANE

S

R

J

U

T

C

STYLE 3:

PIN 1. CATHODE

2. ANODE

3. GATE

4. ANODE