©

Semiconductor Components Industries, LLC, 2003

May, 2003 - Rev. 3

1

Publication Order Number:

MBRB4030/D

MBRB4030

Preferred Device

SWITCHMODE

TM

Power Rectifier

Using the Schottky Barrier principle with a proprietary barrier

metal. These state-of-the-art devices have the following features:

·

Guardring for Stress Protection

·

Maximum Die Size

·

150

°

C Operating Junction Temperature

·

Short Heat Sink Tab Manufactured - Not Sheared

Mechanical Characteristics

·

Case: Epoxy, Molded, Epoxy Meets UL94, VO

·

Weight: 1.7 Grams (approximately)

·

Finish: All External Surfaces Corrosion Resistant and Terminal

Leads Readily Solderable

·

Shipped 50 Units per Plastic Tube

·

Available in 24 mm Tape and Reel, 800 Units per 13

Reel by Adding

a "T4" Suffix to the Part Number

·

Marking: B4030

·

Device Meets MSL1 Requirements

·

ESD Ratings:

Machine Model, C (>400 V)

Human Body Model, 3B (>8000 V)

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

V

RRM

V

RWM

V

R

30

V

Average Rectified Forward Current

(At Rated V

R

) T

C

= +115

°

C (Note 1.)

I

F(AV)

40

A

Peak Repetitive Forward Current

(At Rated V

R

, Square Wave,

20 kHz) T

C

= +112

°

C

I

FRM

80

A

Non-Repetitive Peak Surge Current

(Surge Applied at Rated Load

Conditions Halfwave, Single

Phase, 60 Hz)

I

FSM

300

A

Peak Repetitive Reverse Surge

Current (2.0

m

s, 1.0 kHz)

I

RRM

2.0

A

Storage Temperature Range

T

stg

-65 to

+150

°

C

Operating Junction

Temperature Range

T

J

-65 to

+150

°

C

Voltage Rate of Change

(Rated V

R

)

dv/dt

10,000

V/

m

s

Reverse Energy

(Unclamped Inductive Surge)

(T

C

= 25

°

C, L = 3.0 mH)

W

600

mJ

1. Rating applies when pins 1 and 3 are connected.

Device

Package

Shipping

ORDERING INFORMATION

MBRB4030

D

2

PAK

D

2

PAK

CASE 418B

STYLE 3

50/Rail

3

4

1

SCHOTTKY BARRIER

RECTIFIER

40 AMPERES

30 VOLTS

Preferred devices are recommended choices for future use

and best overall value.

3

1

4

MBRB4030T4

D

2

PAK

800/Tape & Reel

MARKING DIAGRAM

B4030

B4030 = Device Code

http://onsemi.com

MBRB4030

http://onsemi.com

2

THERMAL CHARACTERISTICS

Characteristic

Symbol

Value

Unit

Thermal Resistance - Junction to Case

R

JC

1.0

°

C/W

Thermal Resistance - Junction to Ambient

(Note 3.)

R

JA

50

°

C/W

ELECTRICAL CHARACTERISTICS

Maximum Instantaneous Forward Voltage (Notes 2. and 4.), per Device

(I

F

= 20 A, T

C

= + 25

°

C)

(I

F

= 20 A, T

C

= +150

°

C)

(I

F

= 40 A, T

C

= + 25

°

C)

(I

F

= 40 A, T

C

= +150

°

C)

V

F

0.46

0.34

0.55

0.45

V

Maximum Instantaneous Reverse Current (Note 4.), per Device

(Rated DC Voltage, T

C

= + 25

°

C)

(Rated DC Voltage, T

C

= +125

°

C)

I

R

0.35

150

mA

2. Rating applies when pins 1 and 3 are connected.

3. Rating applies when surface mounted on the miniumum pad size recommended.

4. Pulse Test: Pulse Width = 300

µ

s, Duty Cycle

2.0%

MBRB4030

http://onsemi.com

3

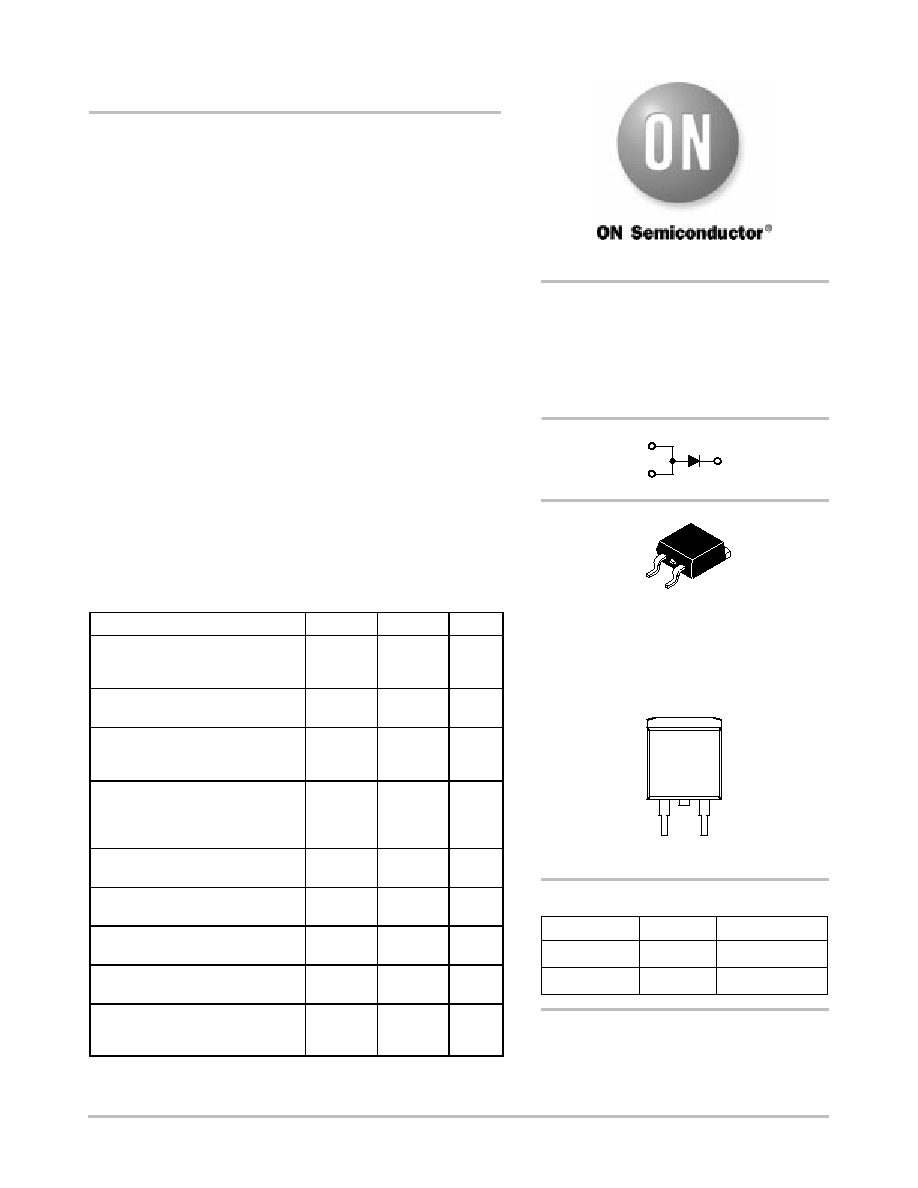

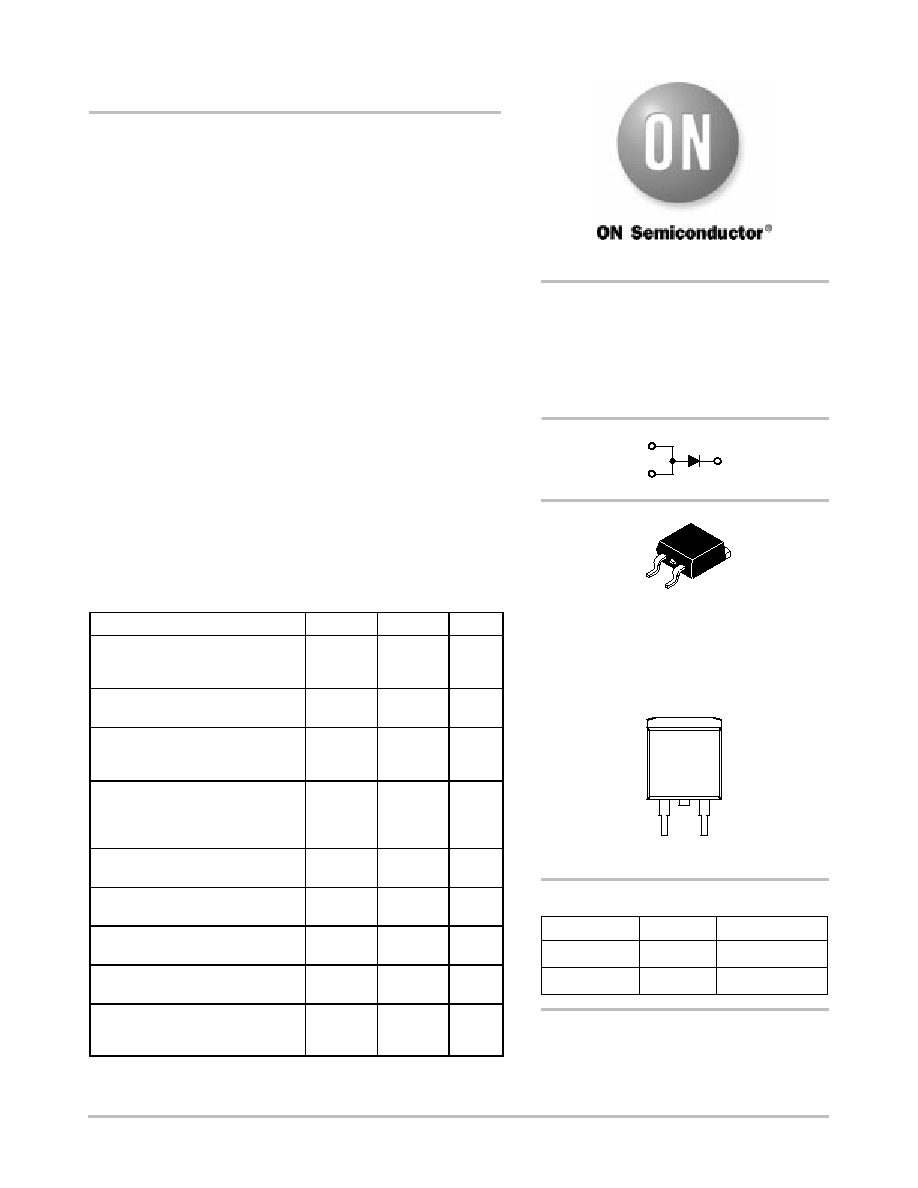

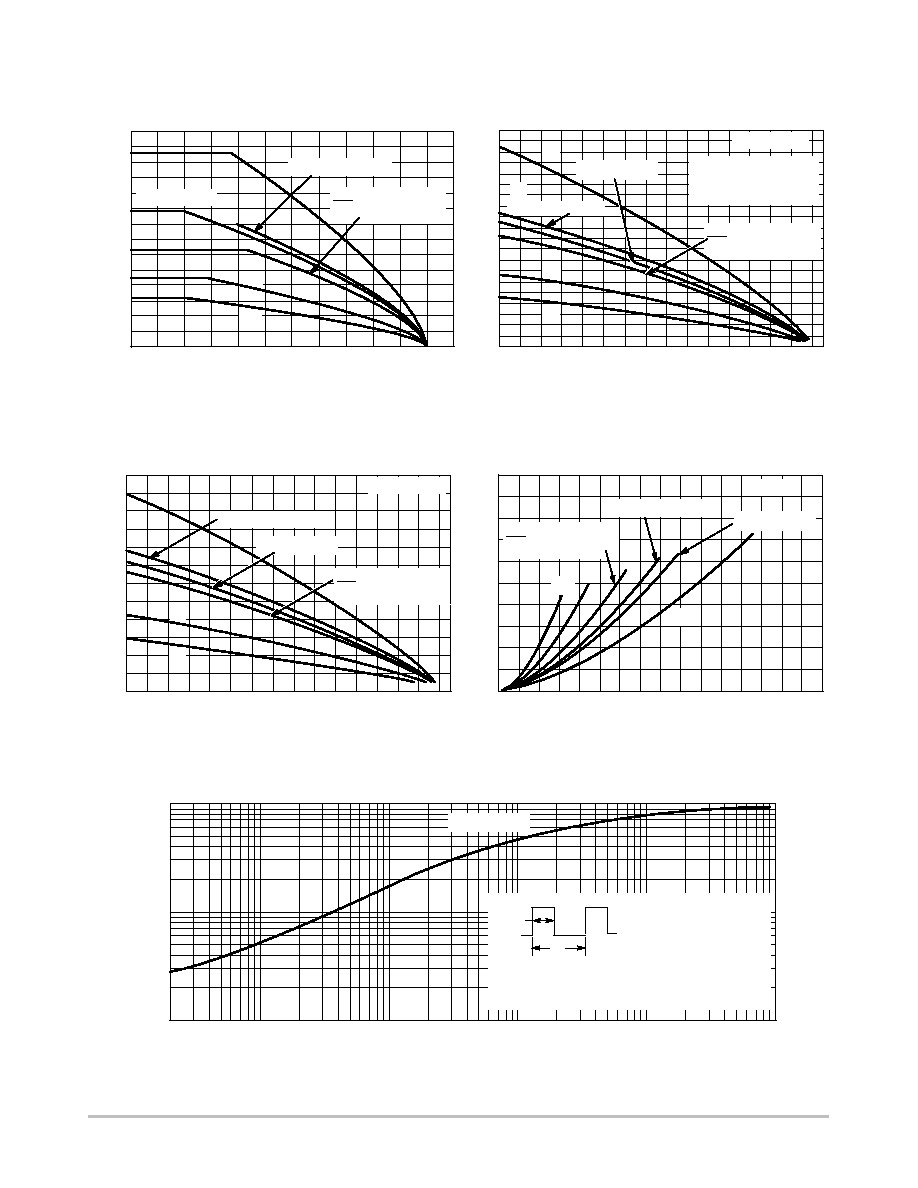

ELECTRICAL CHARACTERISTICS

V

R

, REVERSE VOLTAGE (V)

V

R

, REVERSE VOLTAGE (V)

I R

, REVERSE CURRENT

(A)

I F

, INST

ANT

ANEOUS FOR

W

ARD CURRENT

(mA)

(PIN 1 SHOR

TED

T

O

PIN 3)

Figure 1. Maximum Forward Voltage

V

F

, INSTANTANEOUS VOLTAGE (V)

100

10

1.0

0.1

0.8

0.6

0.4

0.2

0

Figure 2. Typical Forward Voltage

V

F

, INSTANTANEOUS VOLTAGE (V)

100

10

1.0

0.1

0.7

0.6

0.4

0.1

0

Figure 3. Maximum Reverse Current

V

R

, REVERSE VOLTAGE (V)

1.0

0.1

0.01

10

-3

10

-4

10

-5

30

25

15

10

0

Figure 4. Typical Reverse Current

1.0

0.1

0.01

10

-3

10

-4

10

-5

30

25

10

0

I R

, REVERSE CURRENT

(A)

0.7

0.5

0.3

0.1

0.5

0.3

0.2

20

5

20

15

5

Figure 5. Maximum and Typical Capacitance

10

4

1000

10

C, CAP

ACIT

ANCE (pF)

1

TYPICAL

25

°

C

T

J

= 150

°

C

100

°

C

T

J

= 25

°

C

25

°

C

T

J

= 150

°

C

100

°

C

25

°

C

T

J

= 150

°

C

100

°

C

25

°

C

T

J

= 150

°

C

100

°

C

I F

, INST

ANT

ANEOUS FOR

W

ARD CURRENT

(mA)

(PIN 1 SHOR

TED

T

O

PIN 3)

MAXIMUM

MBRB4030

http://onsemi.com

4

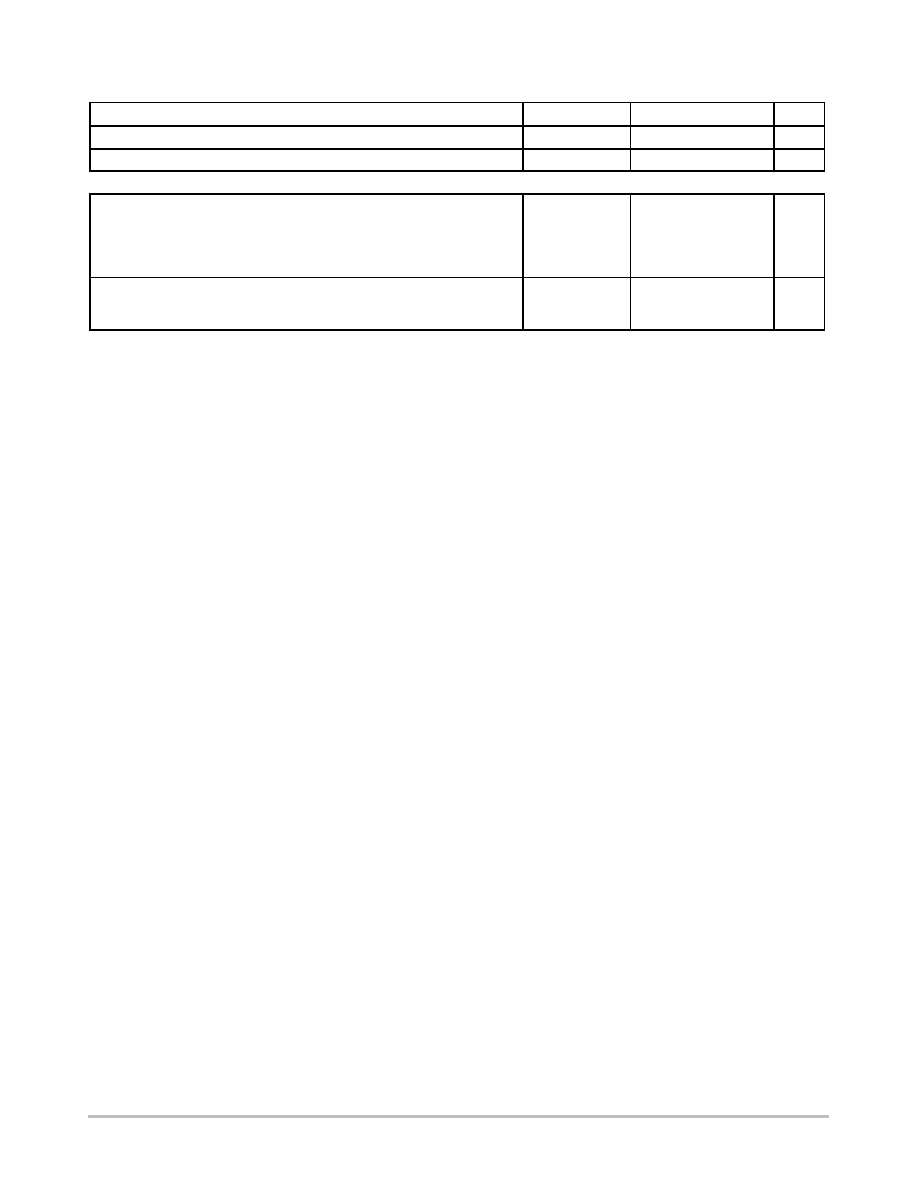

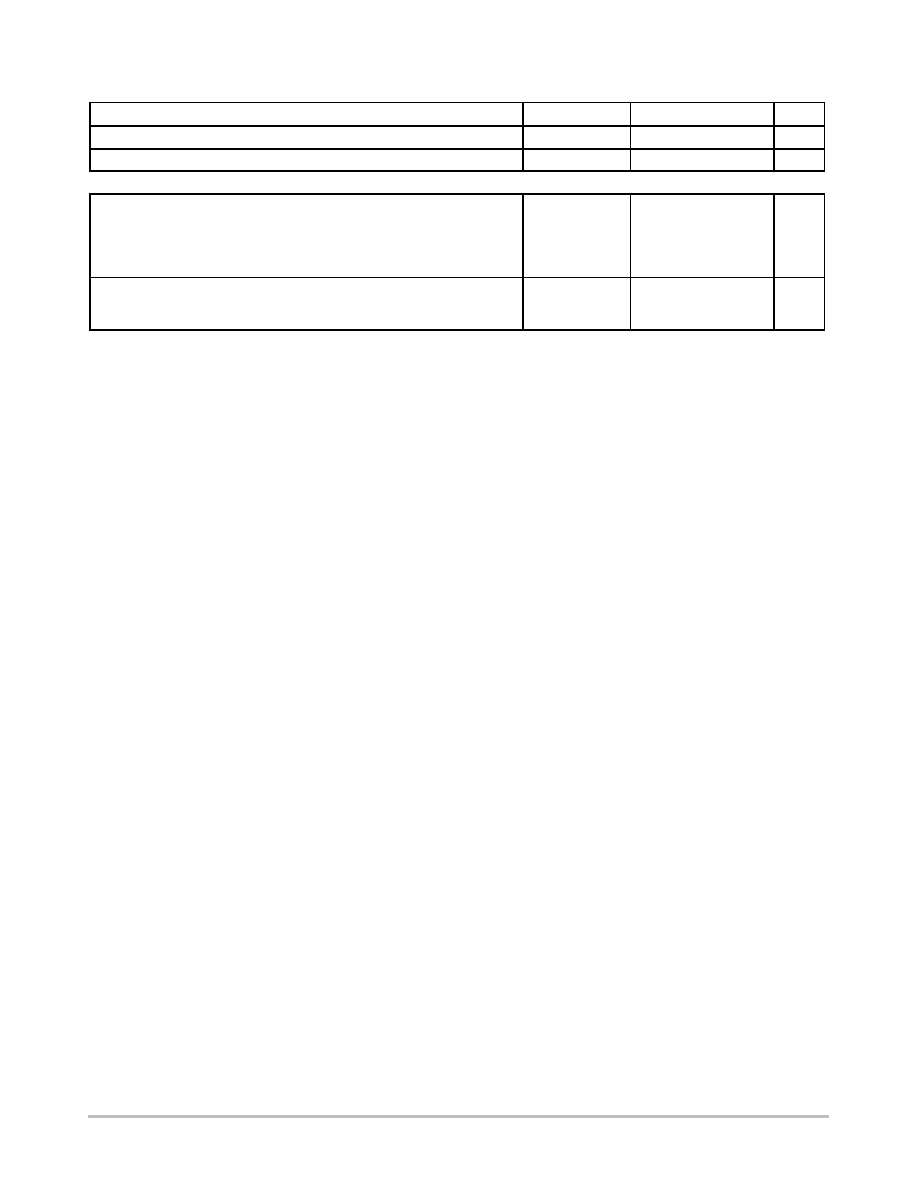

ELECTRICAL CHARACTERISTICS

I

F(AV)

, AVERAGE FORWARD CURRENT (A)

50

40

30

20

10

0

70

50

30

P F(A

V)

,

A

VERAGE FOR

W

ARD POWER DISSIP

A

TION (W

A

TTS)

60

40

80

DC

10

(PIN 1 SHOR

TED

T

O

PIN 3)

T

A

, AMBIENT TEMPERATURE (

°

C)

I F(A

V)

,

A

VERAGE FOR

W

ARD CURRENT

(A)

(PIN 1 SHOR

TED

T

O

PIN 3)

T

A

, AMBIENT TEMPERATURE (

°

C)

20

15

10

5

0

50

I F(A

V)

,

A

VERAGE FOR

W

ARD CURRENT

(A)

100

DC

10

20

SQUARE WAVE

(PIN 1 SHOR

TED

T

O

PIN 3)

150

12

10

8

6

2

0

150

100

0

50

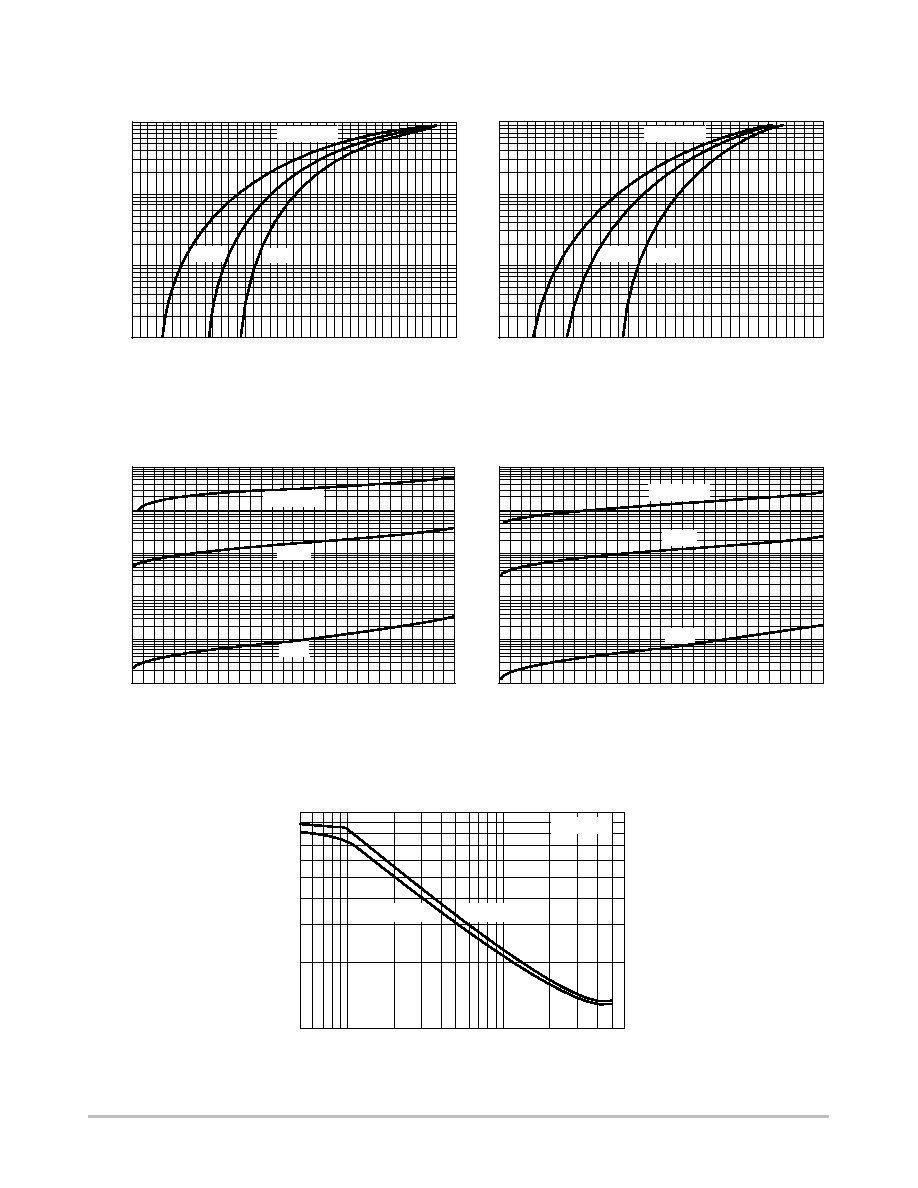

t, TIME (ms)

1.0

0.1

0.01

100

0.1

R(t), EFFECTIVE

TRANSIENT

THERMAL

10

1.0

1000

SINGLE PULSE

RESIST

ANCE (NORMALIZED)

SURFACE MOUNTED ON

MINIMUM RECOMMENDED

PAD SIZE

R

JA

= 25

°

C/W

4

SQUARE WAVE

20

0

10

I

PK

I

AV

= 5.0 (CAPACITIVE

LOAD)

I

PK

I

AV

= 5.0 (CAPACITIVE

LOAD)

(RESISTIVE LOAD)

I

PK

I

AV

= 5.0 (CAPACITIVE

LOAD)

20

T

J

= 150

°

C

10

20

DC

(RESISTIVE LOAD)

R

JA

= 50

°

C/W

(RESISTIVE LOAD)

SQUARE WAVE

T

C

, CASE TEMPERATURE (

°

C)

70

50

40

30

20

10

0

140

120

100

I F(A

V)

,

A

VERAGE FOR

W

ARD CURRENT

(A)

130

110

150

10

20

SQUARE WAVE

(PIN 1 SHOR

TED

T

O

PIN 3)

60

DC

I

PK

I

AV

= 5.0

(RESISTIVE LOAD)

(CAPACITIVE

LOAD)

P

pk

P

pk

t

p

t

1

TIME

DUTY CYCLE, D = t

p

/t

1

PEAK POWER, P

pk

, is peak of an

equivalent square power pulse.

T

JL

= P

pk

·

R

JL

[D + (1 - D)

·

r(t

1

+ t

p

) + r(t

p

) - r(t

1

)]

where

T

JL

= the increase in junction temperature above the lead temperature

r(t) = normalized value of transient thermal resistance at time, t, for example,

r(t) =

r(t

1

+ t

p

) = normalized value of transient thermal resistance at time, t

1

+ t

p

.

Figure 6. Current Derating, Infinite Heatsink

Figure 7. Current Derating

Figure 8. Current Derating, Free Air

Figure 9. Forward Power Dissipation

Figure 10. Thermal Response

MBRB4030

http://onsemi.com

5

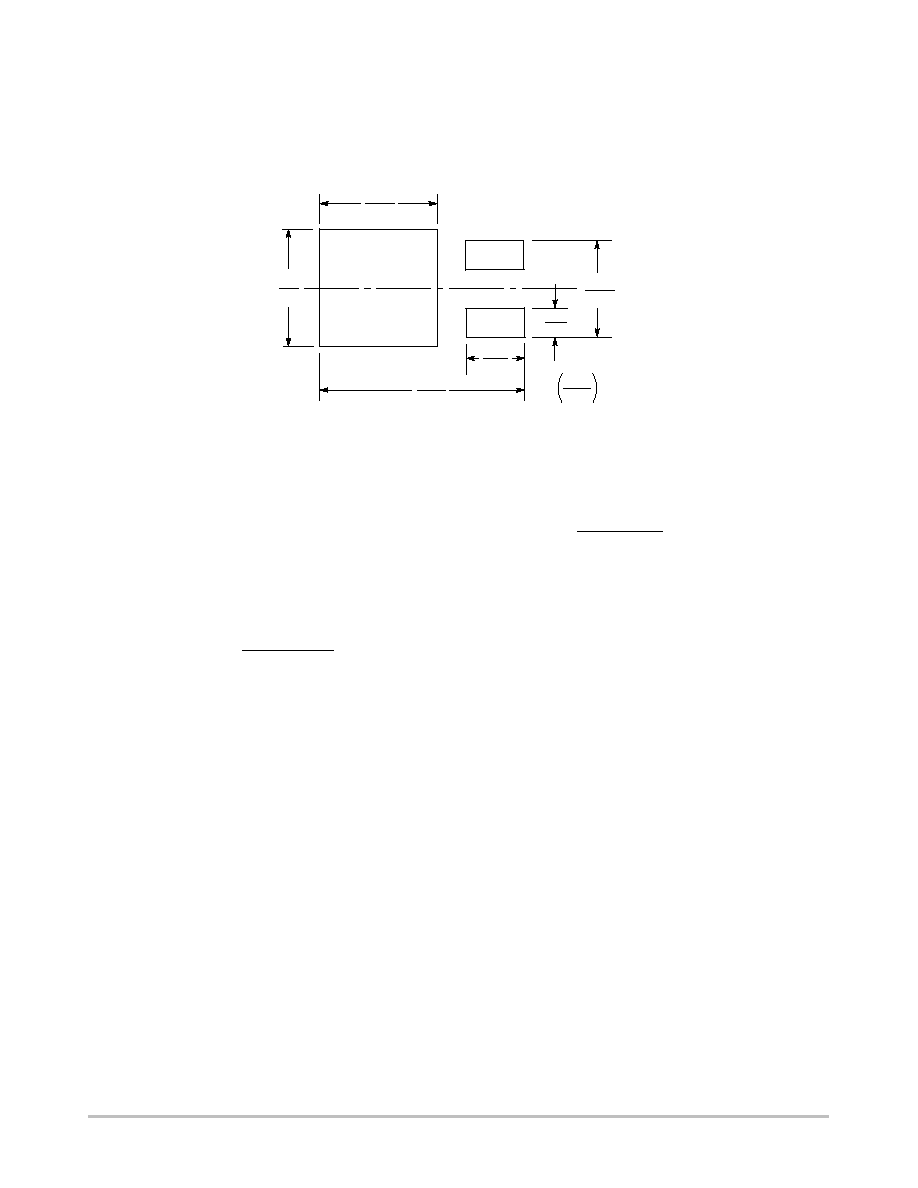

INFORMATION FOR USING THE D

2

PAK SURFACE MOUNT PACKAGE

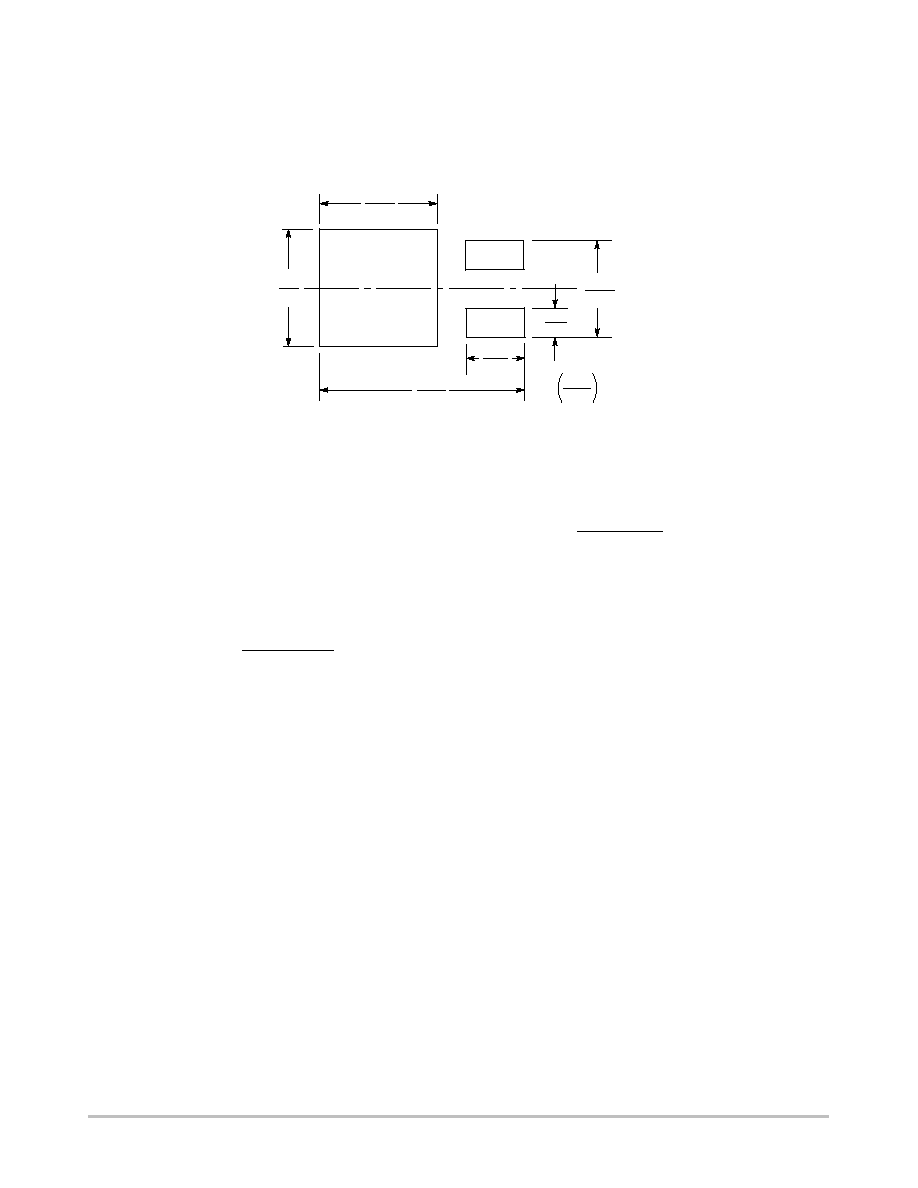

MINIMUM RECOMMENDED FOOTPRINTS FOR SURFACE MOUNTED APPLICATIONS

Surface mount board layout is a critical portion of the

total design. The footprint for the semiconductor packages

must be the correct size to insure proper solder connection

interface between the board and the package. With the

correct pad geometry, the packages will self align when

subjected to a solder reflow process.

mm

inches

0.33

8.38

0.04

1.016

0.67

17.02

0.42

10.66

0.12

3.05

0.24

6.096

D

2

PAK POWER DISSIPATION

The power dissipation of the D

2

PAK is a function of the

drain pad size. This can vary from the minimum pad size

for soldering to a pad size given for maximum power

dissipation. Power dissipation for a surface mount device is

determined by T

J(max)

, the maximum rated junction

temperature of the die, R

JA

, the thermal resistance from

the device junction to ambient; and the operating

temperature, T

A

. Using the values provided on the data

sheet for the D

2

PAK package, P

D

can be calculated as

follows:

P

D

=

T

J(max)

- T

A

R

JA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values

into the equation for an ambient temperature T

A

of 25

°

C,

one can calculate the power dissipation of the device which

in this case is 2.5 watts.

P

D

= 150

°

C - 25

°

C = 2.5 watts

50

°

C/W

The 50

°

C/W for the D

2

PAK package assumes the

recommended drain pad area of 158K mil

2

on FR-4 glass

epoxy printed circuit board to achieve a power dissipation

of 2.5 watts using the footprint shown. Another alternative

is to use a ceramic substrate or an aluminum core board

such as Thermal Clad

TM

. By using an aluminum core board

material such as Thermal Clad, the power dissipation can

be doubled using the same footprint.

GENERAL SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within

a short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

·

Always preheat the device.

·

The delta temperature between the preheat and

soldering should be 100

°

C or less.*

·

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering

method, the difference shall be a maximum of 10

°

C.

·

The soldering temperature and time shall not exceed

260

°

C for more than 5 seconds.

·

When shifting from preheating to soldering, the

maximum temperature gradient shall be 5

°

C or less.

·

After soldering has been completed, the device should

be allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and

result in latent failure due to mechanical stress.

·

Mechanical stress or shock should not be applied

during cooling

* * Soldering a device without preheating can cause

excessive thermal shock and stress which can result in

damage to the device.

* * Due to shadowing and the inability to set the wave

height to incorporate other surface mount components, the

D

2

PAK is not recommended for wave soldering.