OKI Semiconductor

FEDW9041BB-02

Issue Date: May 20. 2002

MBF9041BB

SAW Antenna Duplexer (700 to 1000 MHz)

1/11

GENERAL DESCRIPTION

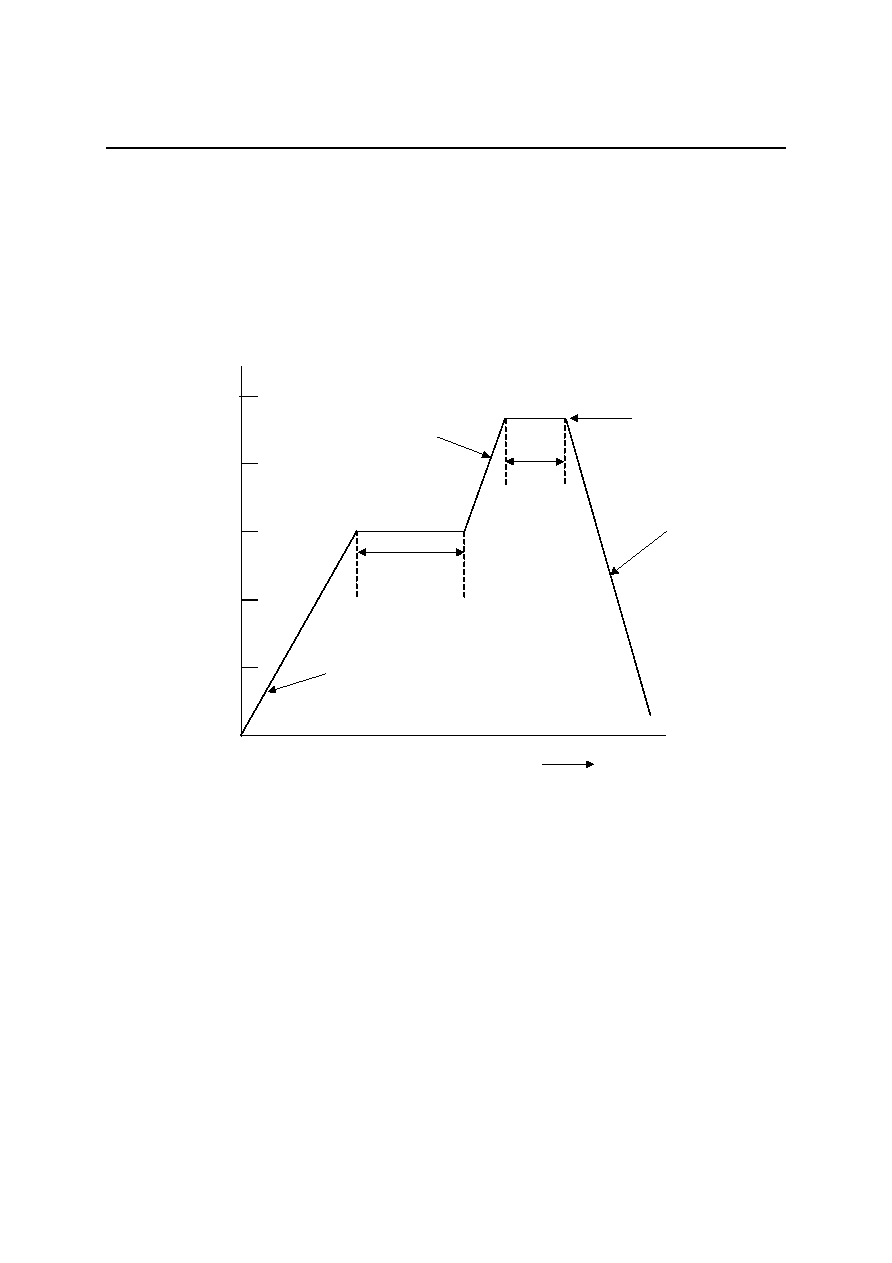

The MBF9041BB is the SAW antenna duplexer for the frequency range of 700 to 1000 MHz.

This SAW Duplexer integrates RF filters at Tx and Rx side, and matching circuit into PKG. This helps to save the

space and weight greatly in the target application such as mobile telephone.

This SAW Duplexer has very low insertion loss by using high quality package.

Due to high harmonics characteristics, total number of components at RF circuit can be minimized.

Thanks to high isolation performance, high sensitivity can be expected. Low insertion loss at Tx saves the power

consumption of mobile telephone which prolong the battery life.

FEATURES

·

Complying Standard AMPS, IS-95, IS-136

·

Thin package: less than 1.5 mm in height

·

PKG I/O Impedance: 50

PRODUCT DESCRIPTION

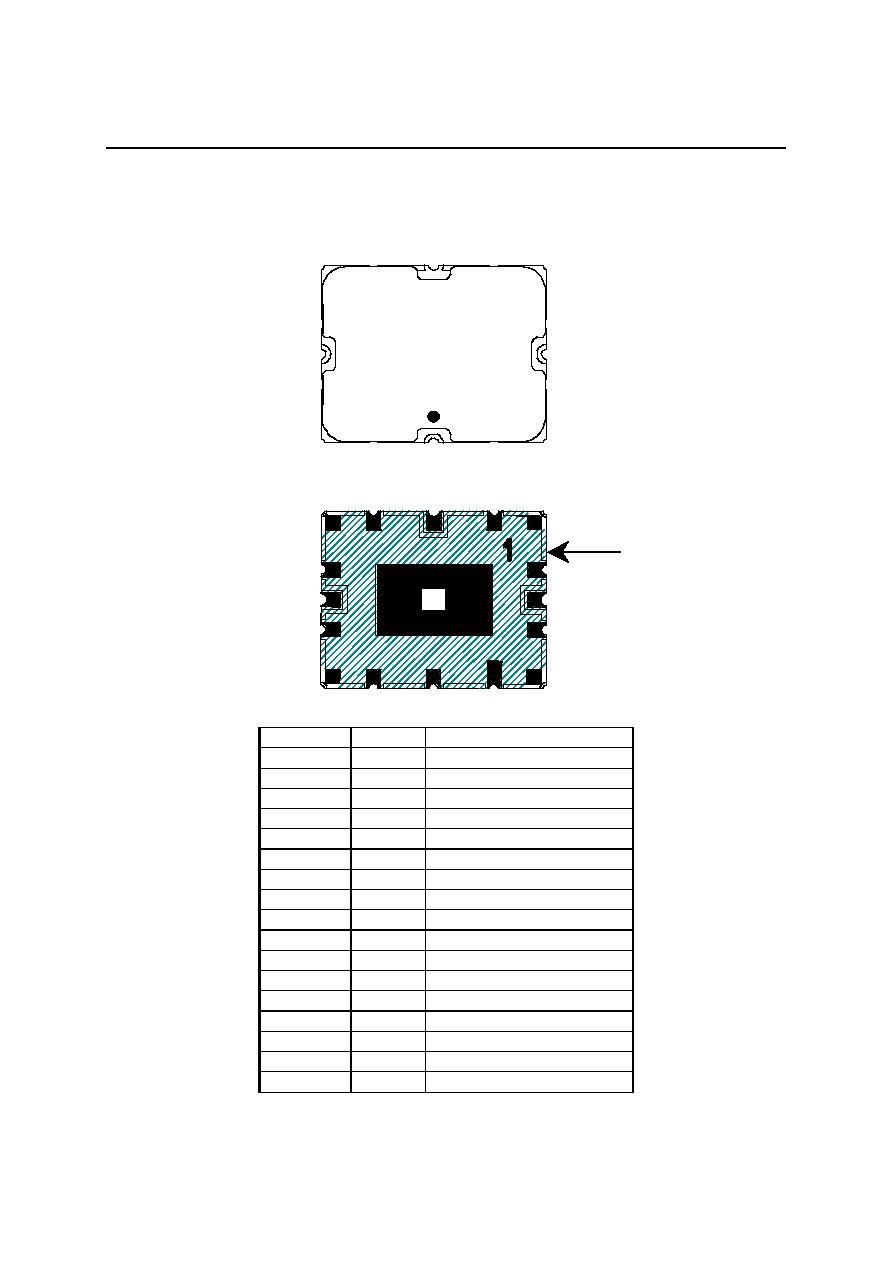

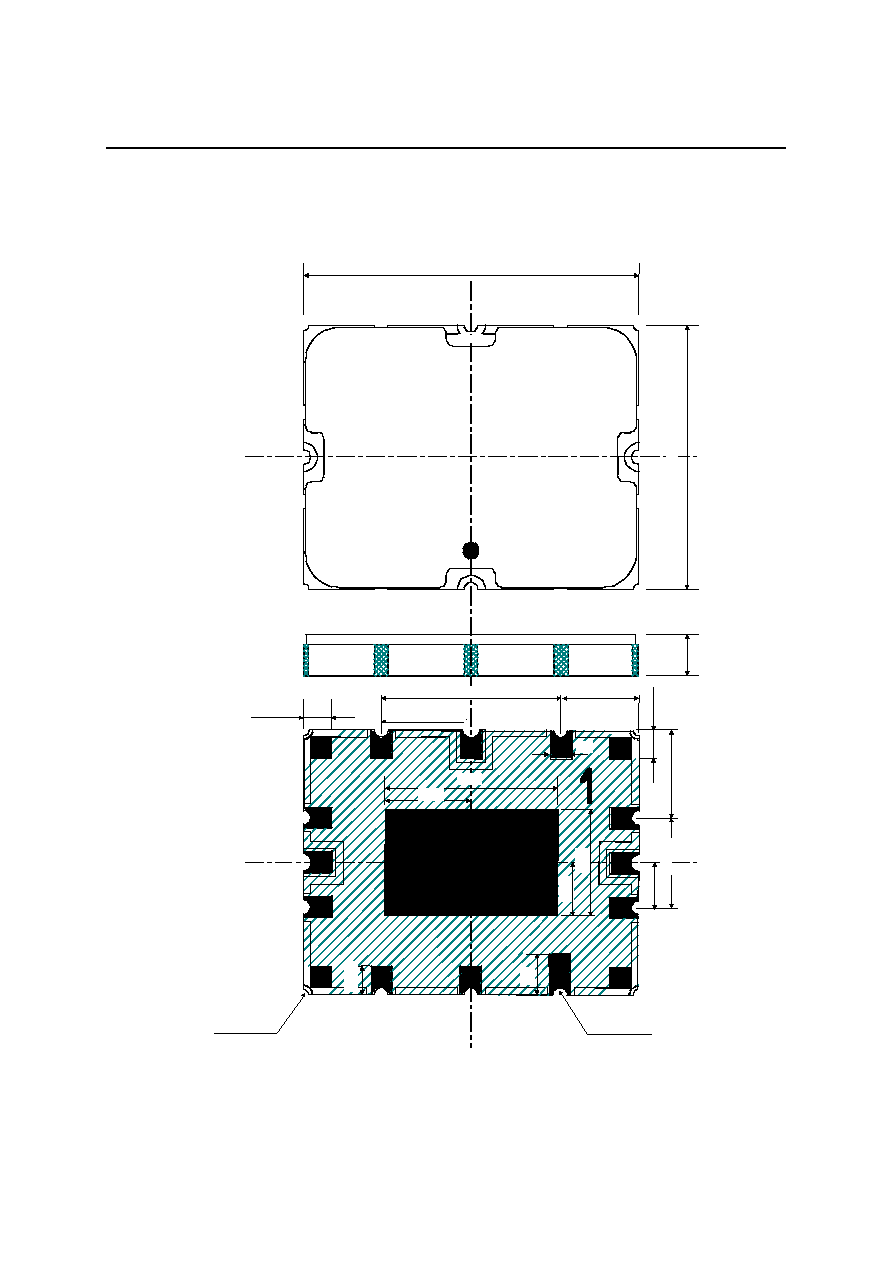

Package Type

MBF9041BB

OKI

041BB

YZZZ

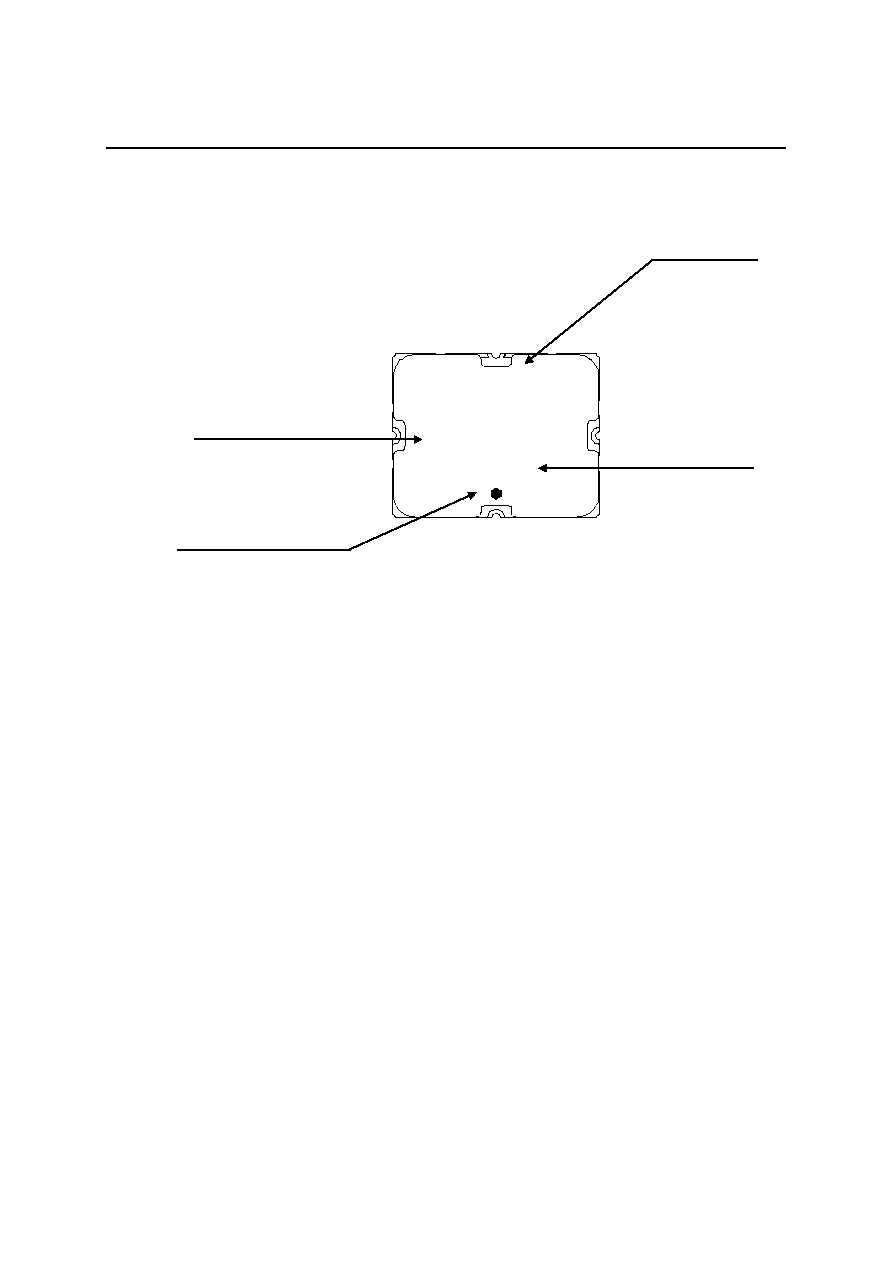

ANT

Rx

Tx

FEDW9041BB-02

OKI Semiconductor

MBF9041BB

9/11

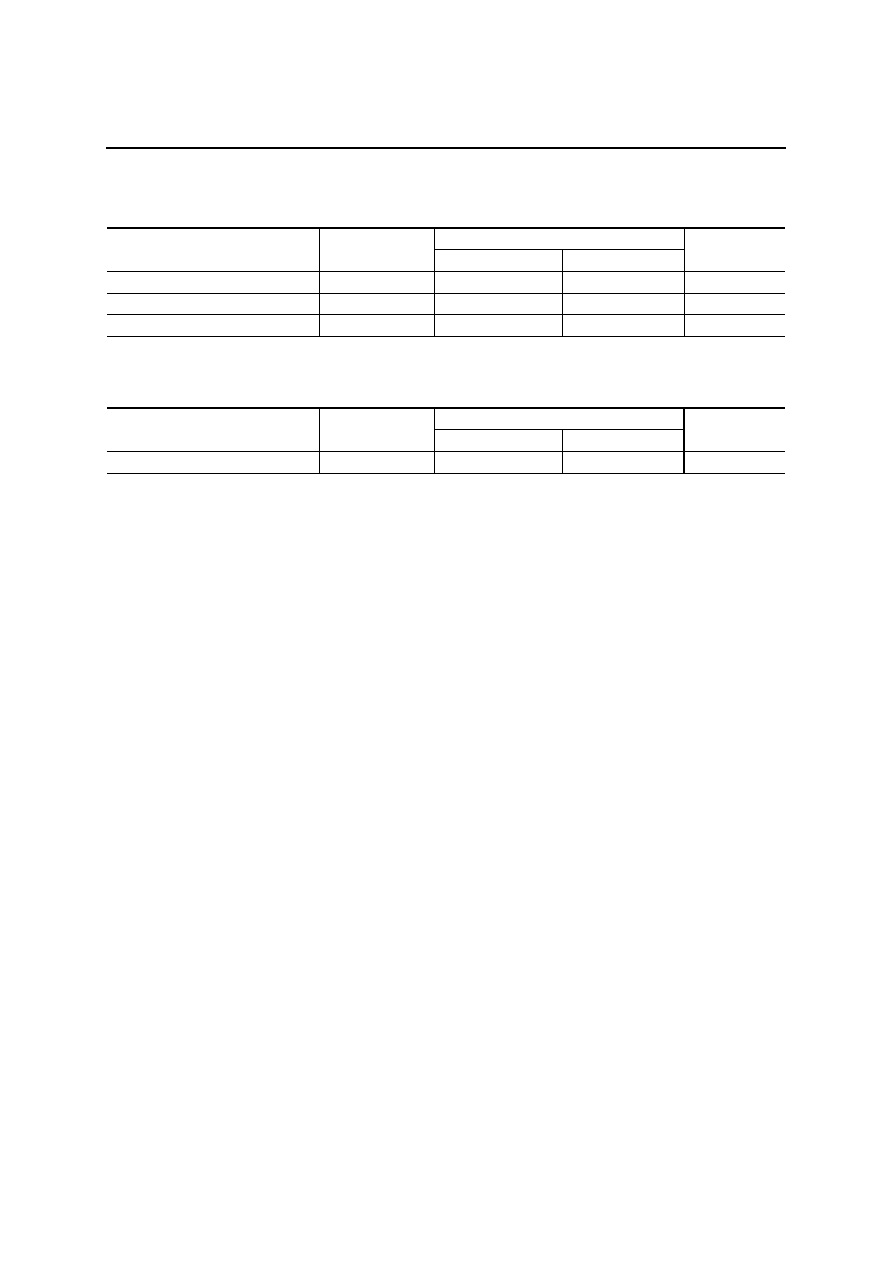

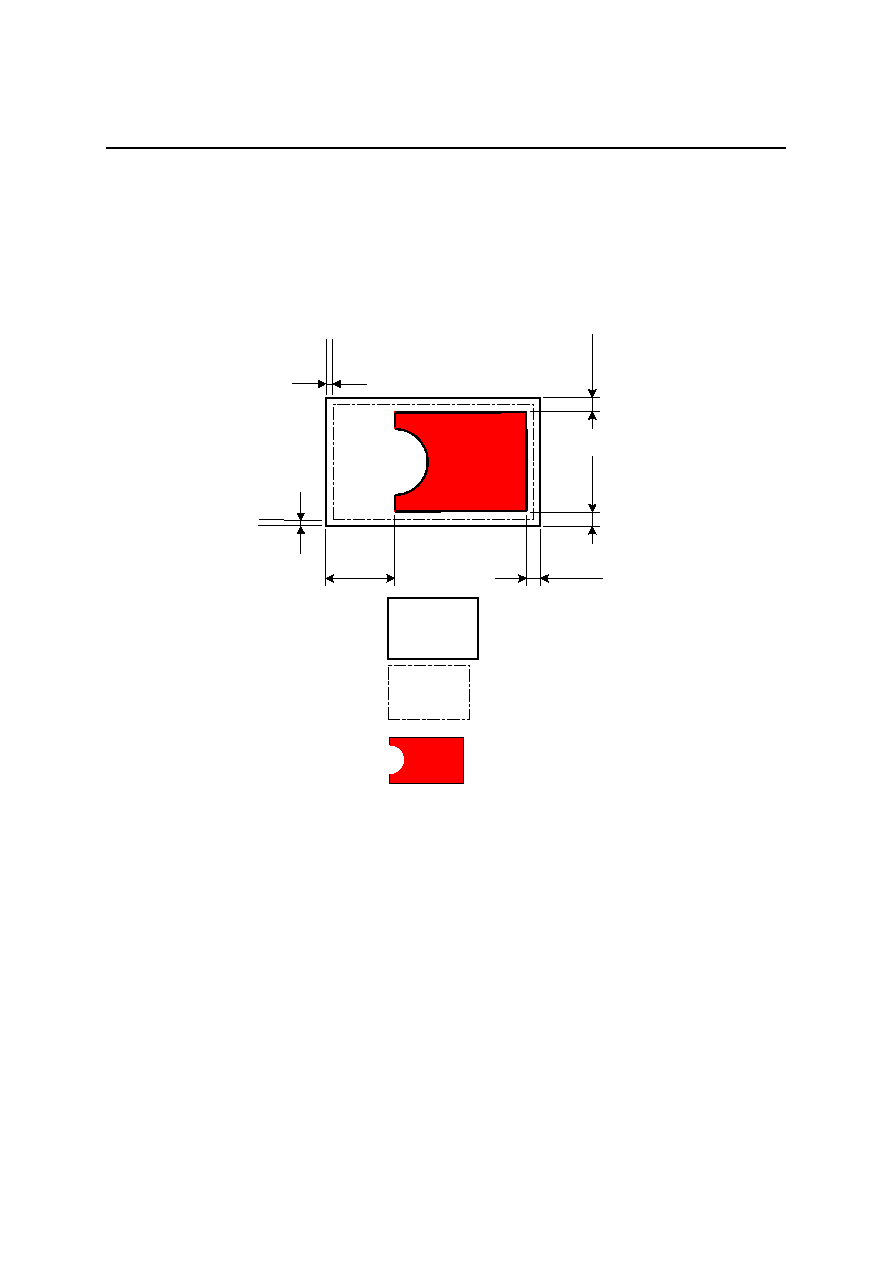

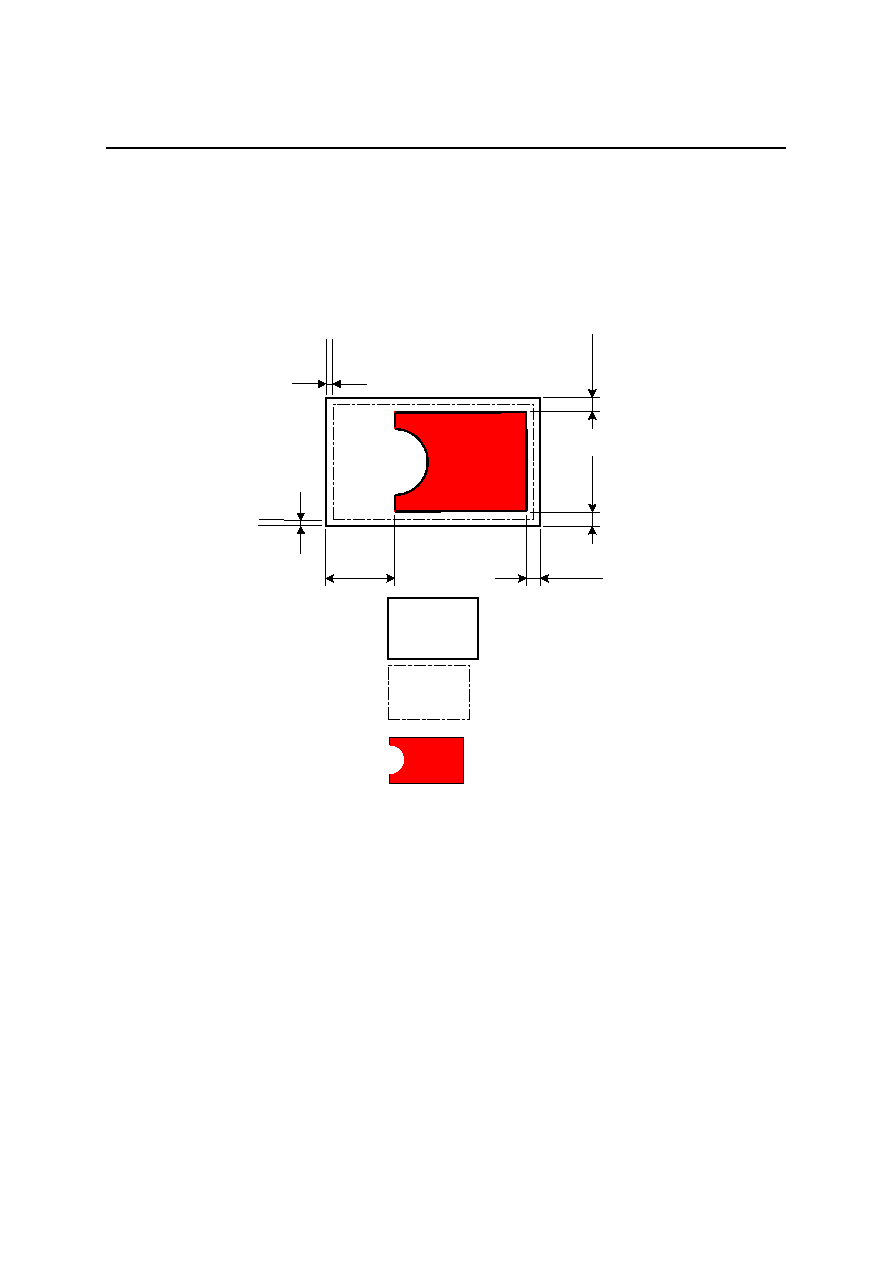

RECOMMENDATION FOR SOLDER PAD PATTERN

The solder pad pattern should be designed by customers because it depends on the electrical

performance of the customers' system. Following is an example of solder pad pattern which is used in

OKI's package evaluation board. Please be noted that this is for reference purpose only.

0.1 mm

0.1 mm

0.5 mm

PCB pad pattern

Metal mask pattern

0.1 mm

25

µ

m

25

µ

m

Pad of Device

Please pay attention to the following items to maintain electrical performance.

(1) Metal mask pattern for cream solder should be 25

µ

m smaller on each side. Metal mask is 0.15 mm in

thickness.

(2) As the impedance of Tx, Rx, ANT is designed for 50

, please consider this for the design of mother board.

(3) The performance of these devices is assured when GND pad (Pin 17) is connected. GND pad (Pin 17) should

be soldered in the same way as above.

FEDW9041BB-02

OKI Semiconductor

MBF9041BB

11/11

NOTICE

1. The information contained herein can change without notice owing to product and/or technical improvements.

Before using the product, please make sure that the information being referred to is up-to-date.

2. The outline of action and examples for application circuits described herein have been chosen as an

explanation for the standard action and performance of the product. When planning to use the product, please

ensure that the external conditions are reflected in the actual circuit, assembly, and program designs.

3. When designing your product, please use our product below the specified maximum ratings and within the

specified operating ranges including, but not limited to, operating voltage, power dissipation, and operating

temperature.

4. Oki assumes no responsibility or liability whatsoever for any failure or unusual or unexpected operation

resulting from misuse, neglect, improper installation, repair, alteration or accident, improper handling, or

unusual physical or electrical stress including, but not limited to, exposure to parameters beyond the specified

maximum ratings or operation outside the specified operating range.

5. Neither indemnity against nor license of a third party's industrial and intellectual property right, etc. is

granted by us in connection with the use of the product and/or the information and drawings contained herein.

No responsibility is assumed by us for any infringement of a third party's right which may result from the use

thereof.

6. The products listed in this document are intended for use in general electronics equipment for commercial

applications (e.g., office automation, communication equipment, measurement equipment, consumer

electronics, etc.). These products are not authorized for use in any system or application that requires special

or enhanced quality and reliability characteristics nor in any system or application where the failure of such

system or application may result in the loss or damage of property, or death or injury to humans.

Such applications include, but are not limited to, traffic and automotive equipment, safety devices, aerospace

equipment, nuclear power control, medical equipment, and life-support systems.

7. Certain products in this document may need government approval before they can be exported to particular

countries. The purchaser assumes the responsibility of determining the legality of export of these products

and will take appropriate and necessary steps at their own expense for these.

8.

No part of the contents contained herein may be reprinted or reproduced without our prior permission.

Copyright 2002 Oki Electric Industry Co., Ltd.