NJL5902R

- 1 -

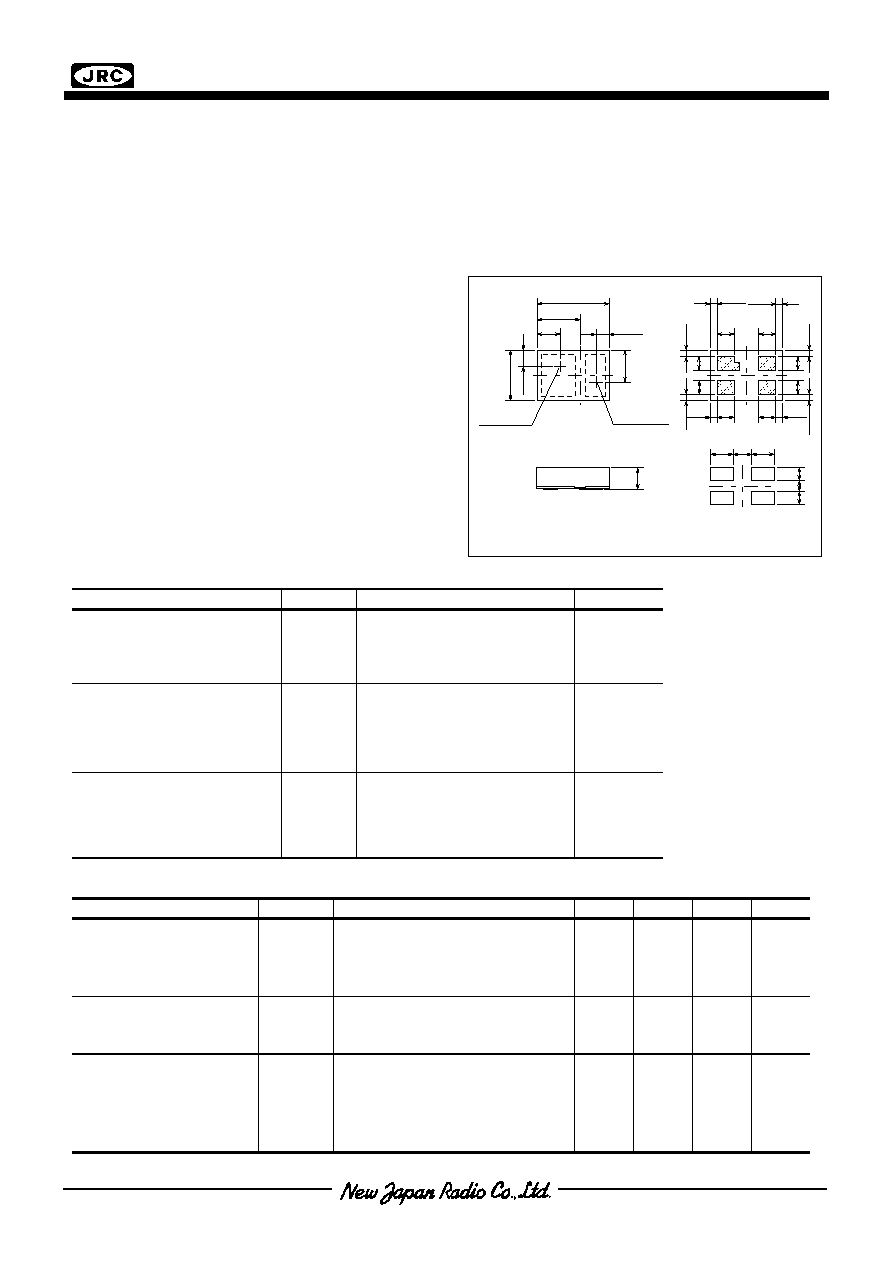

(0.85)

1.54

(0.5)

2.6

(0.6

2)

1.9

0.65

0.20 0.20

0.65

0.5

0.

5

0.25

0.2

5

0.65

0.5

0.5

0.2

5

0.25

0.2

5

0.65

(

1

.

16)

PT CENTER

LED CENTER

0.85

0.7 0.85

0.5

0.4

0.5

0.25

0.8

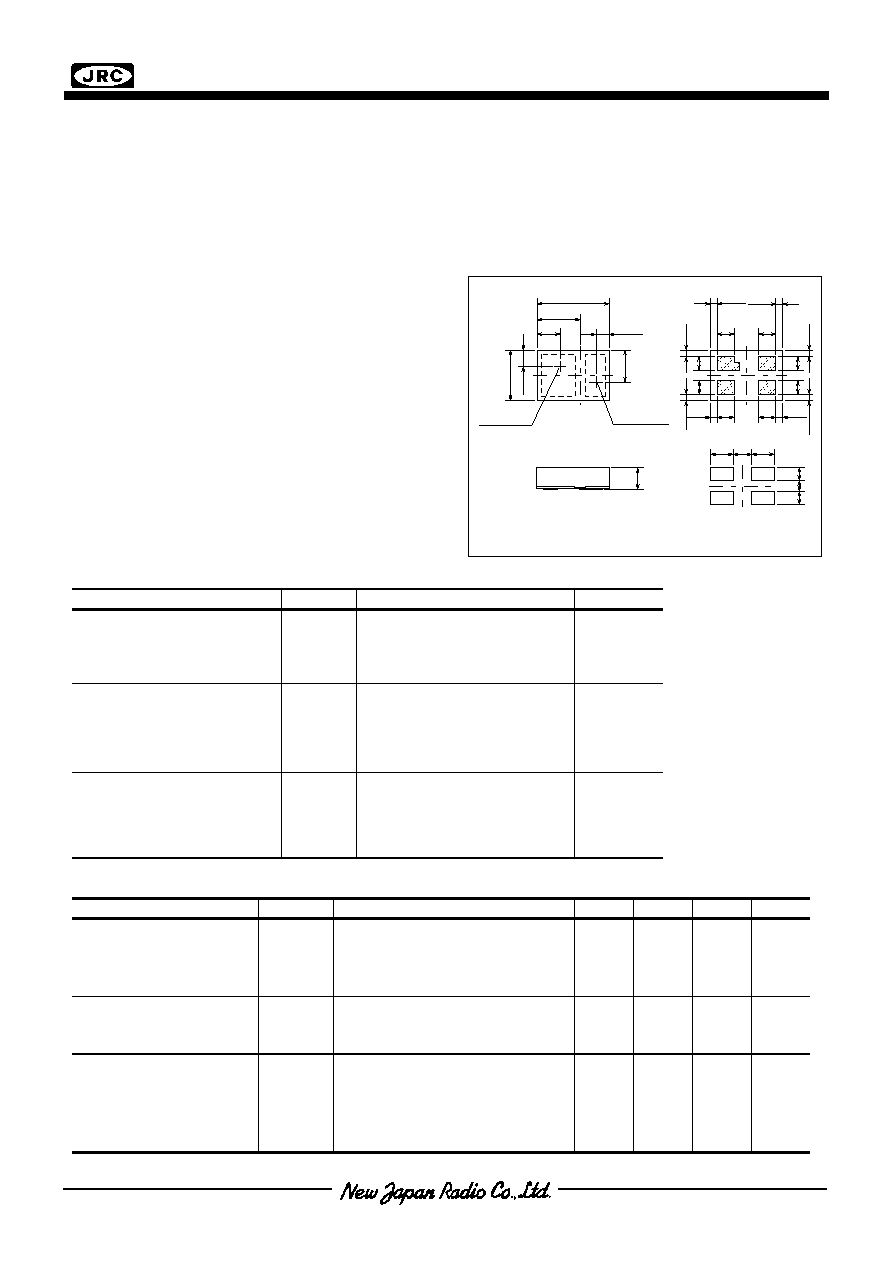

COBP PHOTO REFLECTOR

GENERAL DESCRIPTION

The NJL5902R is the compact surface mount type photo reflector in which Lead (Pb)-free reflow soldering permitted (260

°

C,

2times). The NJL5902R reduced to the operating dark current of 1/6 compared with our conventional products/NJL5901R, and

has realized the high S/N ratio in the combination of the high output LED and a high sensitivity Si photo-transistor.

FEATURES

OUTLINE (typ.)

Unit : mm

·

Pb free solder re-flowing permitted: 260

°

C, 2times

·

Miniature, thin, surface mount: 1.9mm

×

2.6mm

×

0.8mm

·

Operating dark current: 0.3

µ

A max.

·

Built-in visible light cut-off filter

·

High output, high S/N ratio

APPLICATIONS

·

Detecting the location of optical pickup head for CD/DVD

·

Detecting the location of lens for DSC and Cellular phone's

camera module

·

Detecting the rotation of various motors

·

Paper edge detection and mechanism timing detection of

facsimile, copy machine etc.

ABSOLUTE MAXIMUM RATINGS

(Ta=25

°

C)

PARAMETER SYMBOL

RATINGS

UNIT

Emitter

Forward Current (Continuous)

Reverse Voltage (Continuous)

Power Dissipation

I

F

V

R

P

D

30

6

45

mA

V

mW

Detector

Collector-Emitter Voltage

Emitter-Collector Voltage

Collector Current

Collector Power Dissipation

V

CEO

V

ECO

I

C

P

C

16

6

10

25

V

V

mA

mW

Coupled

Total Power Dissipation

Operating Temperature

Storage Temperature

Reflow Soldering Temperature

P

tot

T

opr

T

stg

T

sol

60

-20

to

+85

-40

to

+85

260

mW

°

C

°

C

°

C

ELECTRO-OPTICAL CHARACTERISTICS

(Ta=25

°

C)

PARAMETER SYMBOL TEST

CONDITION

MIN

TYP

MAX

UNIT

Emitter

Forward Voltage

Reverse Current

Capacitance

V

F

I

R

C

t

I

F

=4mA

V

R

=6V

V

R

=0V,f=1MHz

--

--

--

--

--

25

1.4

10

--

V

µ

A

pF

Detector

Dark Current

Collector-Emitter Voltage

I

CEO

V

CEO

V

CE

=10V

I

C

=100

µ

A

--

16

--

--

0.2

--

µ

A

V

Coupled

Output Current

Operating Dark Current *1

Rise Time

Fall Time

I

O

I

CEOD

t

r

t

f

I

F

=4mA,V

CE

=2V,d=0.7mm

I

F

=4mA,V

CE

=2V

I

O

=100

µ

A,V

CE

=2V,RL=1K

,d=0.7mm

I

O

=100

µ

A,V

CE

=2V,RL=1K

,d=0.7mm

90

--

--

--

--

--

30

30

250

0.3

--

--

µ

A

µ

A

µ

s

µ

s

*1 Icoed may increase according to the periphery situation of the surface mounted product.

A:anode

K:cathode

C:collector

E:emitter

PCB pattern

NJL5902R

- 2 -

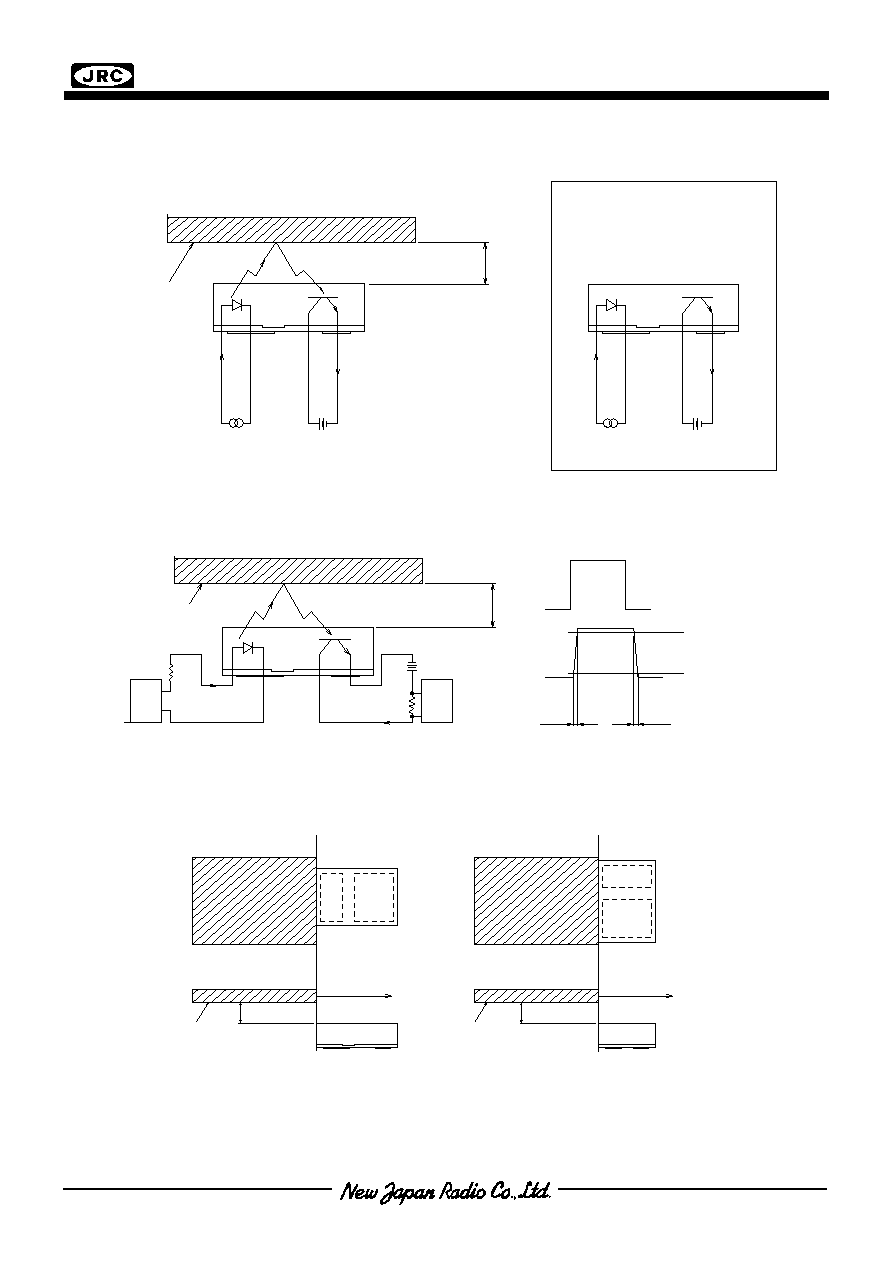

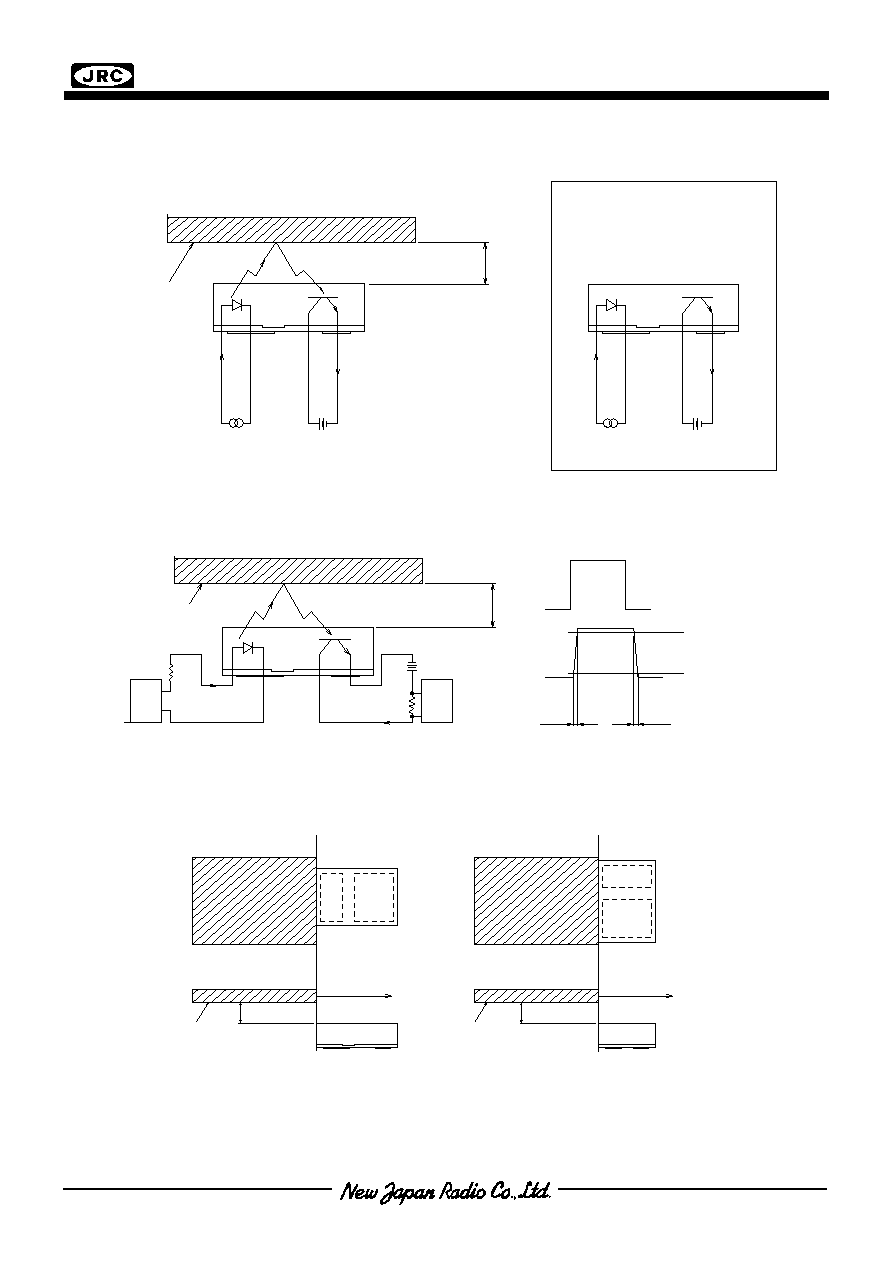

OUTPUT CURRENT TEST CONDITION

DARK CURRENT TEST CONDITION

The infrared signal from LED is reflected at the aluminum surface.

RESPONSE TIME TEST CONDITION

EDGE RESPONSE TEST CONDITION

0.7mm

Aluminum

Evapolation

Surface

I

F

I

CEOD

V

CE

I

F

I

CEOD

V

CE

0.7mm

I

F

Io

V+

R

L

R

D

P.G

OSC

Input

Output

tr

tf

10%

90%

Aluminum

Evapolation

Surface

l=0mm

0.7mm

0.7mm

l=0mm

Aluminum

Evaporation

Surface

Aluminum

Evaporation

Surface

Direction X

Direction Y

Light Sealed Dark Box

NJL5902R

- 3 -

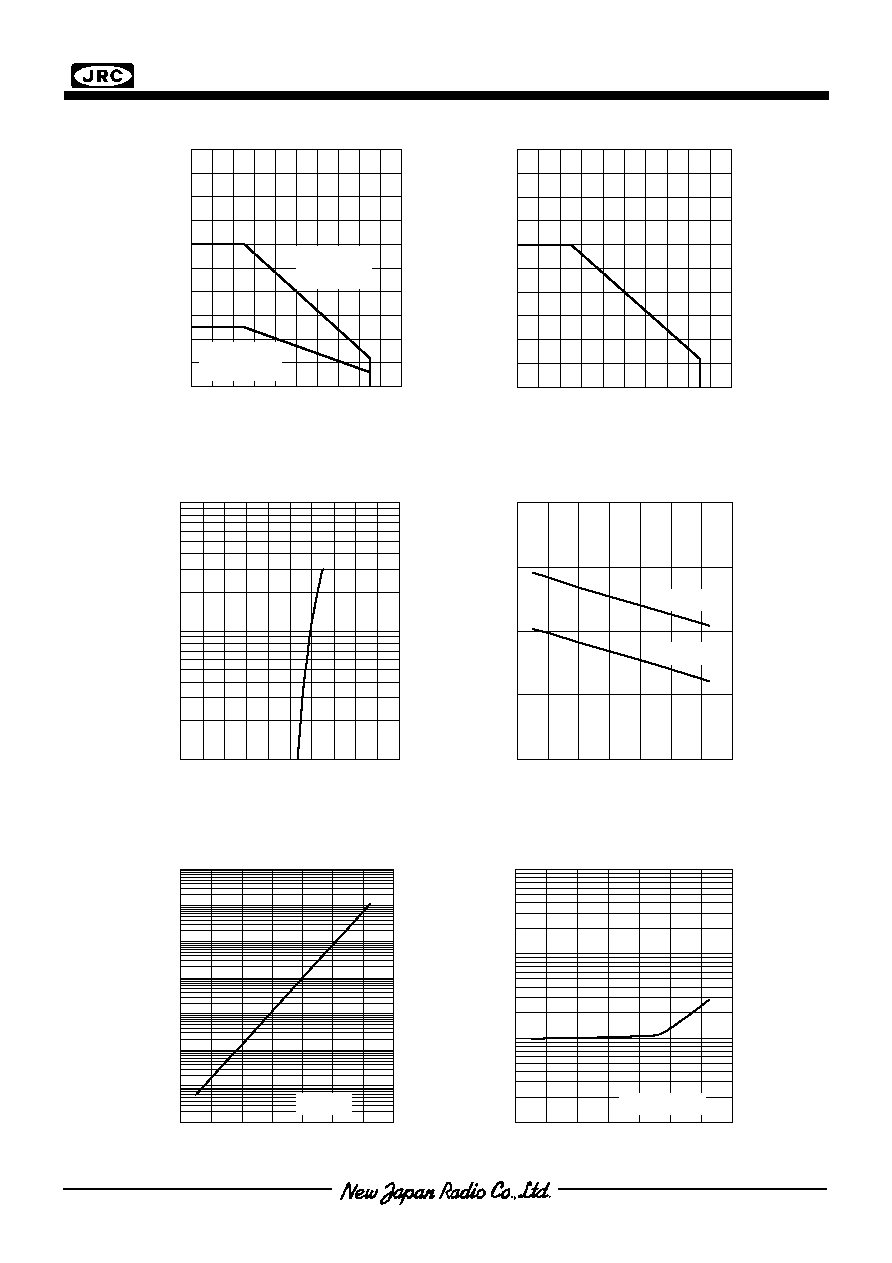

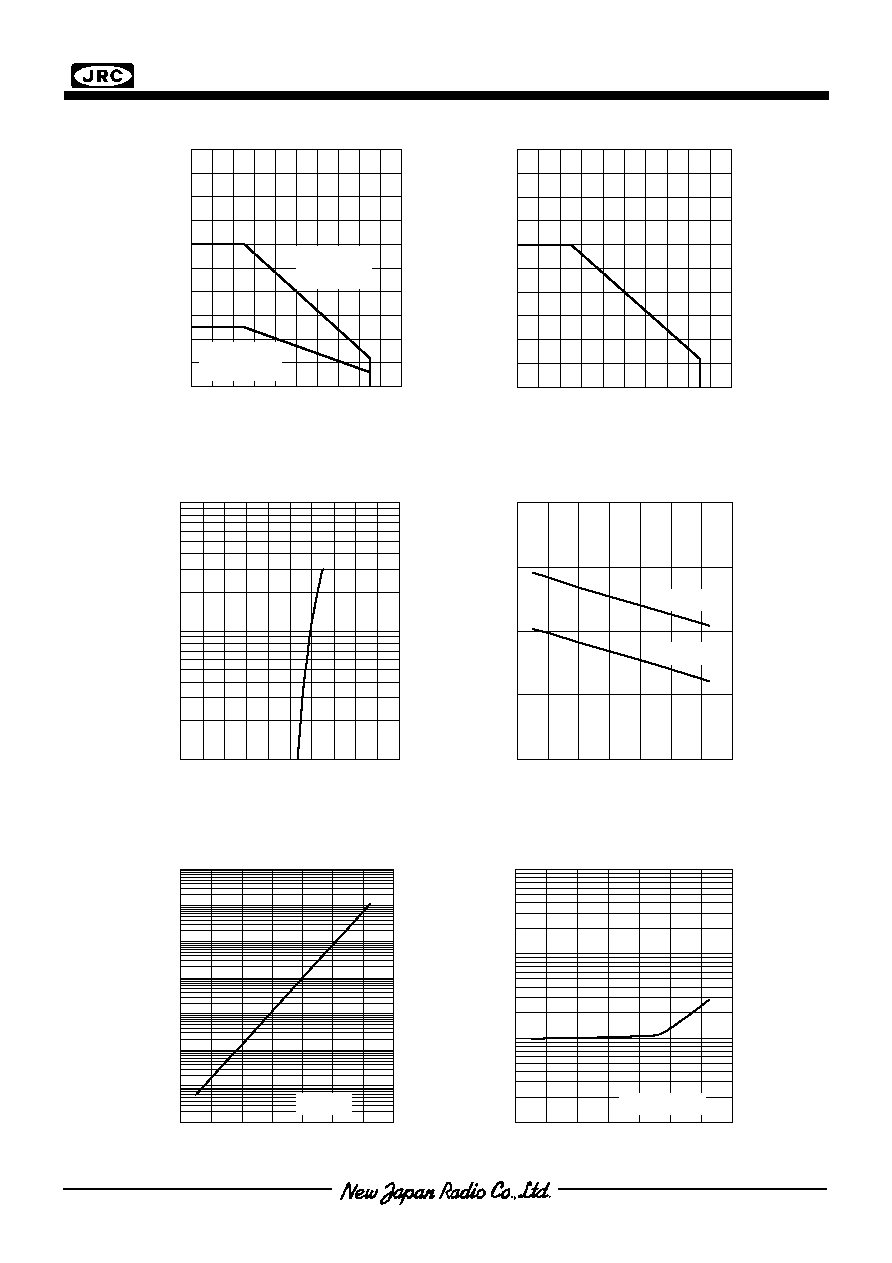

Forward Voltage vs. Forward Current

1

10

100

0

1

2

Forward Voltage VF(V)

F

o

rw

ar

d C

u

r

r

e

n

t

I

F

(m

A

)

Forward Voltage vs. Temperature

0.8

1

1.2

1.4

1.6

-40

-20

0

20

40

60

80

100

Ambient Temperature Ta(

°

C)

F

o

r

w

a

r

d

V

o

l

t

age

V

F

(

V

)

Dark Current vs. Temperature

0.001

0.01

0.1

1

10

100

1000

10000

-40

-20

0

20

40

60

80

100

Ambient Temperature Ta(°C)

D

a

rk

Cu

rre

nt

I

c

e

o

(

n

A

)

Operating Dark Current vs. Temperature

0.01

0.1

1

10

-40

-20

0

20

40

60

80

100

Ambient Temperature Ta(°C)

O

per

at

i

n

g D

a

rk

C

u

r

r

ent

I

c

eod

(µ

A

)

Power Dissipation vs. Temperature

0

10

20

30

40

50

60

70

80

90

100

0

20

40

60

80

100

Ambient Temperature Ta(

°

C)

Power Dissipat

ion P(mW)

Forward Current vs. Temperature

0

5

10

15

20

25

30

35

40

45

50

0

20

40

60

80

100

Ambient Temperature Ta(°C)

Forward Current

I

F

(mA)

Total Power

Dissipation

Collector Power

Dissipation

TYPICAL CHARACTERISTICS

IF=4mA

IF=30mA

Vce=10V

IF=4mA,Vce=2V

NJL5902R

- 4 -

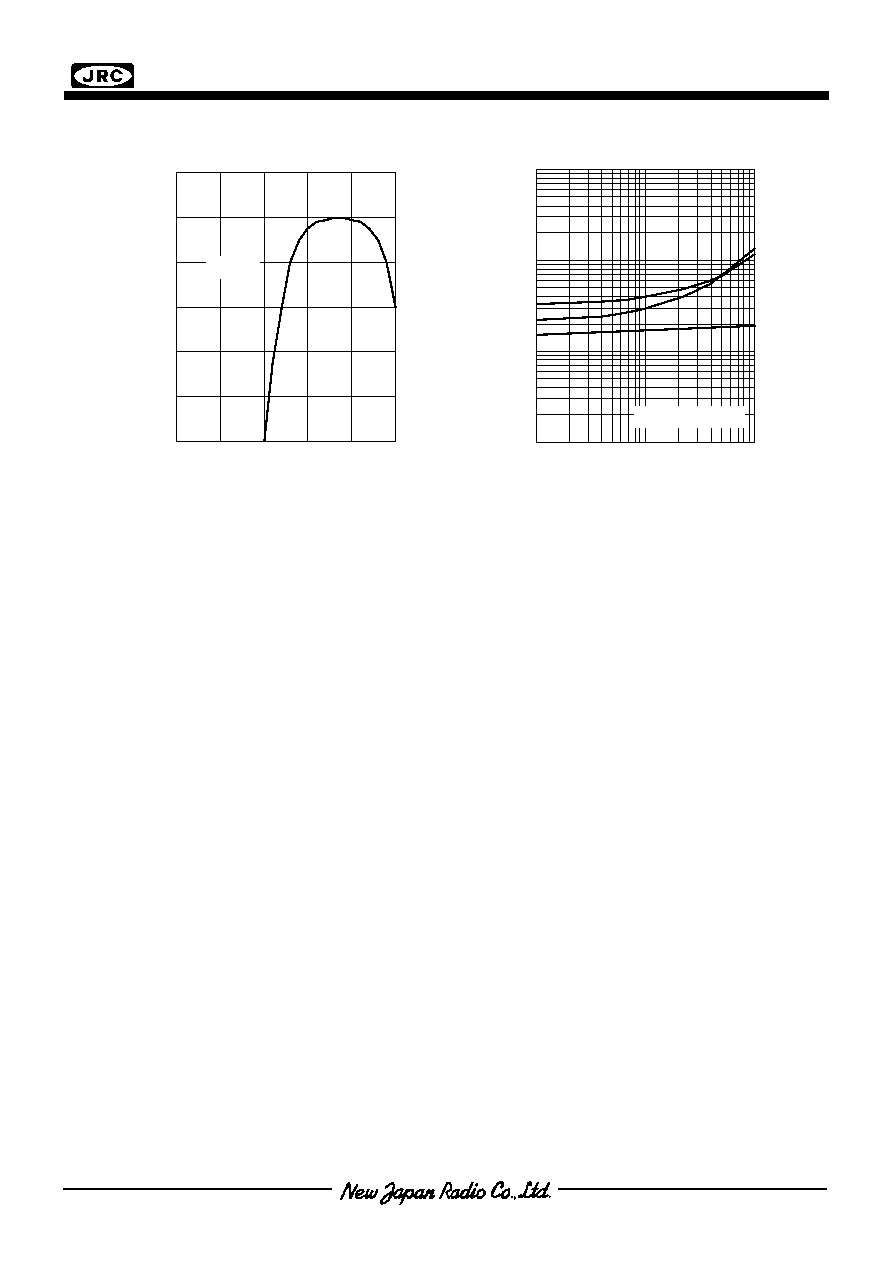

Output Current vs. Distance (Ta=25°C)

0

20

40

60

80

100

120

0

1

2

3

4

5

Reflector Distance d(mm)

R

e

l

a

t

i

v

e

O

u

t

put

C

u

r

r

ent

I

o

/

I

o(

m

a

x

.

)

(

%

)

Output Current vs. Edge Distance(Ta=25°C)

0

20

40

60

80

100

120

0

0.4

0.8

1.2

1.6

2

2.4

Edge Distance l(mm)

R

e

l

a

t

i

v

e

O

u

t

put

C

u

r

r

ent

I

o

/

I

o(

m

a

x

.

)

(

%

)

Output Current vs. Forward Current

(Ta=25

°

C)

0

50

100

150

200

250

300

350

400

450

500

0

2

4

6

8

10

Forward Current IF(mA)

O

u

tp

u

t

C

u

r

r

e

n

t

Io

(

µ

A

)

Output Current vs. Temperature

0

20

40

60

80

100

120

-40

-20

0

20

40

60

80

100

Ambient Temperature Ta(

°

C)

R

e

l

a

ti

ve

O

u

tp

u

t

C

u

r

r

e

n

t

Io

/I

o

(

2

5

°

C

)

(

%

)

Output Characteristics (Ta=25°C)

0

50

100

150

200

250

300

350

400

450

500

0

1

2

3

4

5

Collector-Emitter Voltage Vce(V)

O

u

tp

u

t

C

u

r

r

e

n

t

Io

(

µ

A

)

Vce Saturation (Ta=25°C)

0

0.1

0.2

0.3

0.4

0.5

0.1

1

10

Forward Current IF(mA)

C

o

l

l

e

c

t

o

r

-

Em

i

t

t

e

r

V

o

l

t

a

g

e

Vc

e

(

V)

IF=4mA,Vce=2V

IF=4mA,Vce=2V

IF=4mA,Vce=2V,d=0.7mm

Direction X

Direction Y

IVce=2V,d=0.7m

IF=4mA

IF=2mA

IF=6mA

IF=8mA

IF=10mA

Io=200

µ

A

Io=150

µ

A

Io=100

µ

A

Io=50

µ

A

NJL5902R

- 5 -

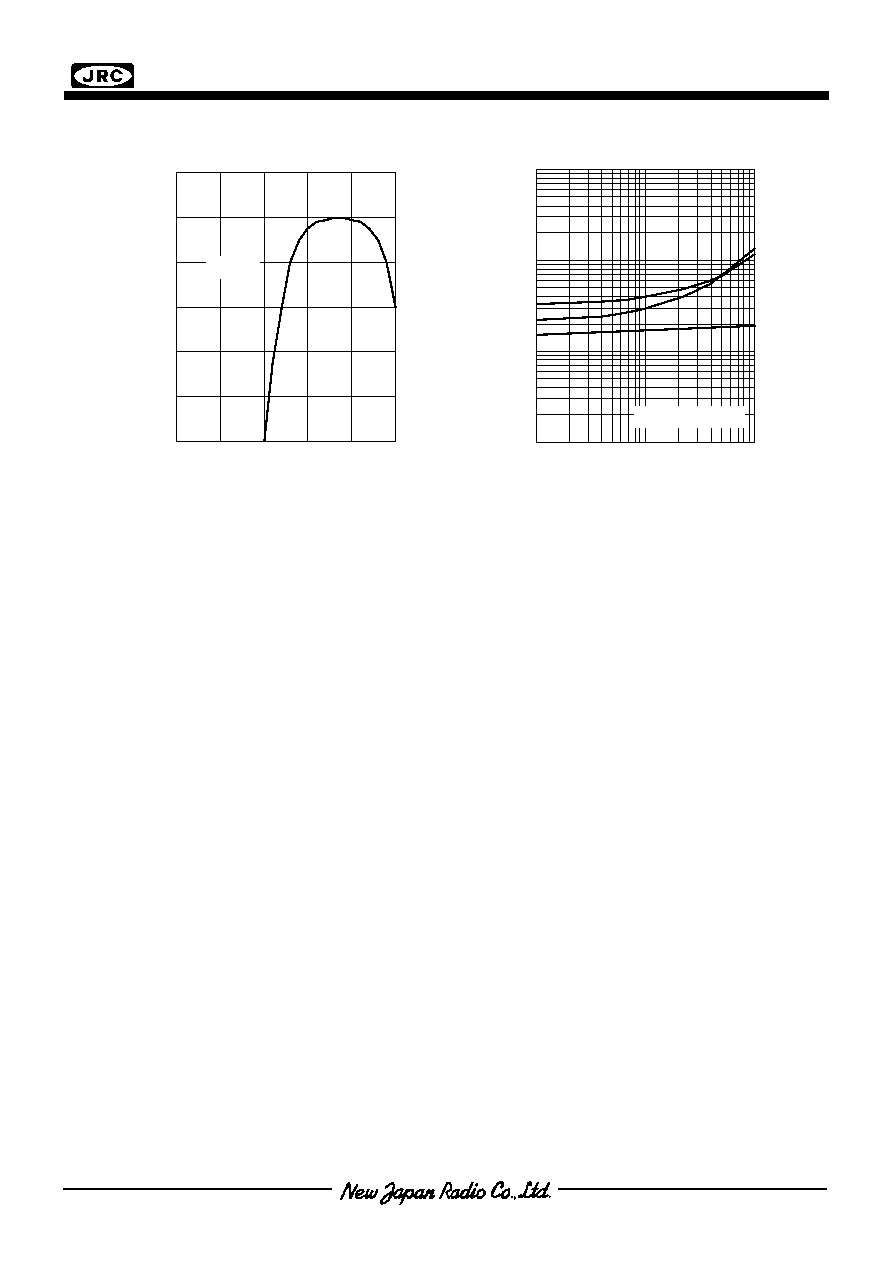

Spectral Response (Ta=25

°

C)

0

20

40

60

80

100

120

500

600

700

800

900

1000

Wavelength

(nm)

R

e

l

a

t

i

v

e

R

e

s

p

ons

e (

%

)

Switching Time vs. Load Resistance

(Ta=25

°

C)

1

10

100

1000

0.1

1

10

Load Resistance RL(k

)

S

w

it

c

h

in

g

T

i

m

e

t

(

µ

s

)

Vce=2V

td

tf

tr

Vce=2V,Io=100

µ

A

NJL5902R

- 6 -

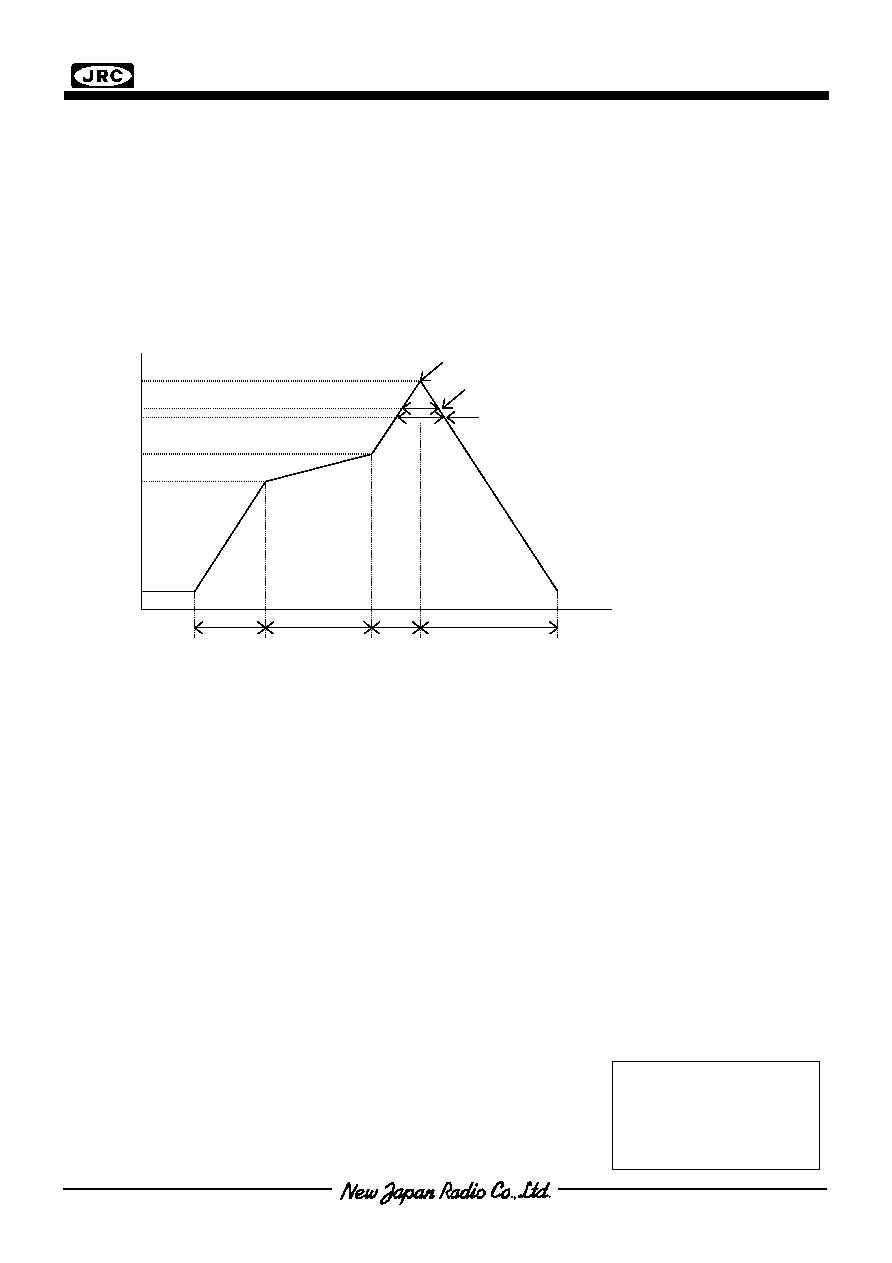

PRECAUTION FOR HANDLING

1. Soldering to actual circuit board

Soldering condition

The surface temperature of plastic package is lower than 260

°

C.

Soldering Method

1) Reflow Method

Soldering to be done within twice under the recommended condition mentioned below

2) Reflow Method (In case of infrared heating)

The temperature profile is same as the above

Avoid direct irradiation to the plastic package because it may absorb the Infrared Radiation and its surface

temperature will be higher than the lead.

3) The other method

Avoid rapid heating up like dipping the devices directly into the melting solder or vapor phase method (VPS).

Solder the device in short time as soon as possible.

If the device is heated and kept in high temperature for longer time, its reliability would be affected.

2. Cleaning

Avoid washing the device after soldering by reflow method.

3. Attention in handling

1) Treat not to touch the lens surface.

2) Avoid dust and any other foreign materials on the lens surface such as paint, bonding material, etc.

4. Storage

Mount the device as soon as possible after opening the envelope. In order to prevent from degradation by the moisture at

the reflow process, the device is contained in damp proof packaging.

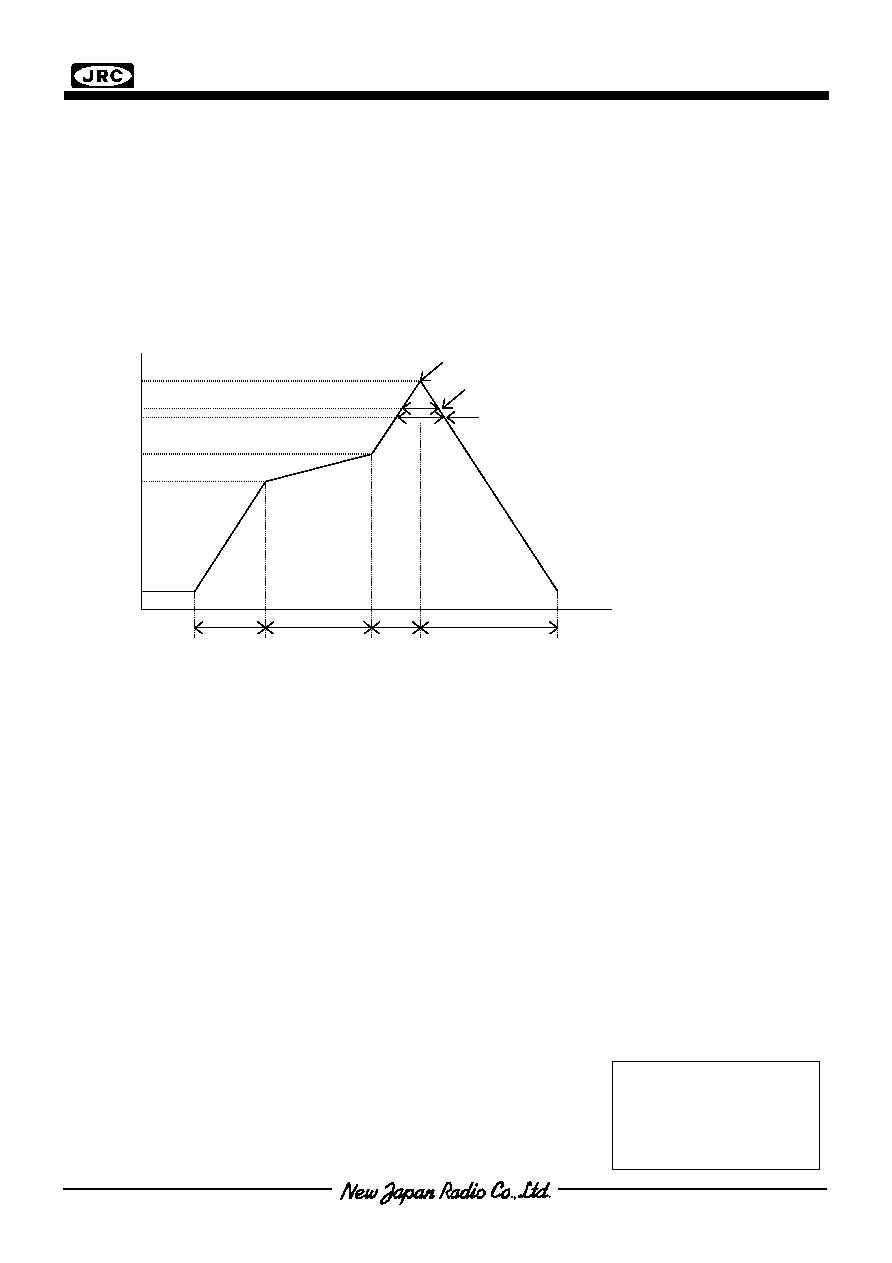

a b

c g

e

150

°

C

260

°

C

Room

Temp.

f

180

°

C

230

°

C

220

°

C

d

a : Temperature ramping rate : 1 to 4

°

C/s

b : Pre-heating temperature

time

: 150 to 180

°

C

: 60 to 120s

c : Temperature ramping rate : 1 to 4

°

C /s

d : 220

°

C or higher time

: Shorter than 60s

e : 230

°

C or higher time

: Shorter than 40s

f : Peak temperature

: Lower than 260

°

C

g : Temperature ramping rate : 1 to 6

°

C /s

The temperature of the surface of mold package

[CAUTION]

The specifications on this databook are only

given for information , without any guarantee

as regards either mistakes or omissions. The

application circuits in this databook are

described only to show representative usages

of the product and not intended for the

guarantee or permission of any right including

the industrial rights.