MOTOROLA

SEMICONDUCTOR

TECHNICAL DATA

Motorola TVS/Zener Device Data

7-1

500 mW Leadless (SOD-123) Data Sheet

Designer's

TM

Data Sheet

Surface Mount Silicon Zener Diodes

Plastic SOD 123 Package

Three complete series of Zener Diodes are offered in the convenient, surface mount

plastic SOD-123 package. These devices provide a convenient alternative to the leadless

34 package style.

·

500 mW Rating on FR-4 or FR-5 Board

·

Package Designed for Optimal Automated Board Assembly

·

Corrosion Resistant Finish, Easily Solderable

·

ESD Rating of Class 3 (exceeding 16 kV) per the Human Body Model

·

Small Package Size for High Density Applications

·

Available in 8 mm Tape and Reel

Add "T1" to the device number to order the 7 inch / 3000 unit reel.

Add "T3" to the device number to order the 13 inch / 10,000 unit reel.

·

Wafer Fab Location: Phoenix, Arizona

Assembly/Test Location: Seremban, Malaysia

MMSZ2V4T1 thru MMSZ75T1

·

Specified Similar to European BZV55C Series

·

Wide Voltage Range -- 2.4 to 75 Volts

DEVICE RATING

(TA = 25

°

C unless otherwise noted)

Rating

Symbol

Value

Unit

Power Dissipation on FR-4 or FR-5 Board [1]

Derate above TL = 75

°

C

PD

--

500

6.7

mW

mW/

°

C

Thermal Resistance Junction to Lead [2]

Thermal Resistance Junction to Ambient [2]

R

JL

R

JA

150

340

°

C/W

Junction Temperature Range

TJ

55 to +150

°

C

Storage Temperature Range

Tstg

55 to +150

°

C

Lead Solder Temperature Maximum (10 sec. duration)

--

260

°

C

[1] FR-4 or FR-5 = 3.5 x 1.5 inches, using the Motorola minimum recommended footprint as shown in Figure 11.

[2] Thermal Resistance measurement obtained via Infrared Scan Method

Designer's Data for "Worst Case'' Conditions -- The Designer's Data Sheet permits the design of most circuits entirely from the information presented. Limit curves -- representing

boundaries on device characteristics -- are given to facilitate "worst case'' design.

Designer's is a trademark of Motorola, Inc.

Thermal Clad is a trademark of the Bergquist Company.

Preferred devices are Motorola recommended choices for future use and best overall value.

MMSZ2V4T1

SERIES

PLASTIC SURFACE

MOUNT

ZENER DIODES

500 MILLIWATTS

1.8 91 VOLTS

CASE 425, STYLE 1

PLASTIC

1: CATHODE

2: ANODE

1

2

MMSZ2V4T1 Series

Motorola TVS/Zener Device Data

7-2

500 mW Leadless (SOD-123) Data Sheet

ELECTRICAL CHARACTERISTICS

(TA = 25

°

C unless otherwise noted), (VF = 0.9 V Max. @ IF = 10 mA for all types)

T

M

ki

Zener Voltage

VZ1 (Volts)

@ IZT1 = 5 mA

[1][2]

Max Zener

Impedance

ZZT1

@ IZT1 = 5 mA

Max

Reverse

Leakage

Current

Zener Voltage

VZ2 (Volts)

@ IZT2 = 1 mA

[1]

Max Zener

Impedance

ZZT2

@ IZT1 = 1 mA

Type

Number

Marking

Nom

Min

Max

@ IZT1 = 5 mA

[3]

IR @ VR

µ

A Volts

Min

Max

@ IZT1 = 1 mA

[3]

MMSZ2V4T1

T1

2.4

2.28

2.52

100

50

1

1.7

2.1

600

MMSZ2V7T1

T2

2.7

2.57

2.84

100

20

1

1.9

2.4

600

MMSZ3V0T1

T3

3.0

2.85

3.15

95

10

1

2.1

2.7

600

MMSZ3V3T1

T4

3.3

3.14

3.47

95

5

1

2.3

2.9

600

MMSZ3V6T1

T5

3.6

3.42

3.78

90

5

1

2.7

3.3

600

MMSZ3V9T1

U1

3.9

3.71

4.10

90

3

1

2.9

3.5

600

MMSZ4V3T1

U2

4.3

4.09

4.52

90

3

1

3.3

4.0

600

MMSZ4V7T1

U3

4.7

4.47

4.94

80

3

2

3.7

4.7

500

MMSZ5V1T1

U4

5.1

4.85

5.36

60

2

2

4.2

5.3

480

MMSZ5V6T1

U5

5.6

5.32

5.88

40

1

2

4.8

6.0

400

MMSZ6V2T1

V1

6.2

5.89

6.51

10

3

4

5.6

6.6

150

MMSZ6V8T1

V2

6.8

6.46

7.14

15

2

4

6.3

7.2

80

MMSZ7V5T1

V3

7.5

7.13

7.88

15

1

5

6.9

7.9

80

MMSZ8V2T1

V4

8.2

7.79

8.61

15

0.7

5

7.6

8.7

80

MMSZ9V1T1

V5

9.1

8.65

9.56

15

0.5

6

8.4

9.6

100

MMSZ10T1

A1

10

9.50

10.50

20

0.2

7

9.3

10.6

150

MMSZ11T1

A2

11

10.45

11.55

20

0.1

8

10.2

11.6

150

MMSZ12T1

A3

12

11.40

12.60

25

0.1

8

11.2

12.7

150

MMSZ13T1

A4

13

12.35

13.65

30

0.1

8

12.3

14.0

170

MMSZ15T1

A5

15

14.25

15.75

30

0.05

10.5

13.7

15.5

200

MMSZ16T1

X1

16

15.20

16.80

40

0.05

11.2

15.2

17.0

200

MMSZ18T1

X2

18

17.10

18.90

45

0.05

12.6

16.7

19.0

225

MMSZ20T1

X3

20

19.00

21.00

55

0.05

14

18.7

21.1

225

MMSZ22T1

X4

22

20.80

23.10

55

0.05

15.4

20.7

23.2

250

MMSZ24T1

X5

24

22.80

25.20

70

0.05

16.8

22.7

25.5

250

MMSZ27T1

Y1

27

25.65

28.35

80

0.05

18.9

25

28.9

300

MMSZ30T1

Y2

30

28.50

31.50

80

0.05

21

27.8

32

300

MMSZ33T1

Y3

33

31.35

34.65

80

0.05

23.1

30.8

35

325

MMSZ36T1

Y4

36

34.20

37.80

90

0.05

25.2

33.8

38

350

MMSZ39T1

Y5

39

37.05

40.95

130

0.05

27.3

36.7

41

350

MMSZ43T1

Z1

43

40.85

45.15

150

0.05

30.1

39.7

46

375

MMSZ47T1

Z2

47

44.65

49.35

170

0.05

32.9

43.7

50

375

MMSZ51T1

Z3

51

48.45

53.55

180

0.05

35.7

47.6

54

400

MMSZ56T1

Z4

56

53.20

58.80

200

0.05

39.2

51.5

60

425

MMSZ62T1

Z5

62

58.90

65.10

215

0.05

43.4

57.4

66

450

MMSZ68T1

Z6

68

64.60

71.40

240

0.05

47.6

63.4

72

475

MMSZ75T1

Z7

75

71.25

78.75

255

0.05

52.5

69.4

79

500

[1] Zener voltage is measured with the zener current applied for PW = 1.0 ms.

[2] All part numbers shown indicate a V

Z tolerance of

±

5%.

[3] Z

ZT1 and ZZT2 are measured by dividing the AC voltage drop across the device by the AC current applied. The specified limits are for IZ(AC) = 0.1 IZ(DC),

[3]

with the AC frequency = 1 kHz.

[4] The zener impedance, Z

ZT2, for the 27 through 75 volt types is tested at 0.5 mA rather than the test current of 0.1 mA used for VZ2.

MMSZ2V4T1 Series

Motorola TVS/Zener Device Data

7-3

500 mW Leadless (SOD-123) Data Sheet

TYPICAL CHARACTERISTICS

VZ

, TEMPERA

TURE COEFFICIENT

(mV/

C)

°

VZ, NOMINAL ZENER VOLTAGE (V)

3

2

1

0

1

2

3

4

5

6

7

8

12

11

10

9

8

7

6

5

4

3

2

Figure 1. Temperature Coefficients

(Temperature Range 55

°

C to +150

°

C)

TYPICAL TC VALUES

FOR MMSZ5221BT1 SERIES

VZ @ IZT

VZ

, TEMPERA

TURE COEFFICIENT

(mV/

C)

°

100

10

1

10

100

VZ, NOMINAL ZENER VOLTAGE (V)

Figure 2. Temperature Coefficients

(Temperature Range 55

°

C to +150

°

C)

VZ @ IZT

P

D

, POWER DISSIP

A

TION (W

A

TTS)

1.2

1.0

0.8

0.6

0.4

0.2

0

150

125

100

75

50

25

0

T, TEMPERATURE (

°

C)

Figure 3. Steady State Power Derating

PD versus TA

PD versus TL

P

pk

, PEAK SURGE POWER (W

A

TTS)

0.1

PW, PULSE WIDTH (ms)

Figure 4. Maximum Nonrepetitive Surge Power

1

10

100

1000

1000

100

10

1

RECTANGULAR

WAVEFORM, TA = 25

°

C

100

VZ, NOMINAL ZENER VOLTAGE

Figure 5. Effect of Zener Voltage on

Zener Impedance

10

1

Z

ZT

, DYNAMIC IMPEDANCE (

)

1000

100

10

1

TJ = 25

°

C

IZ(AC) = 0.1 IZ(DC)

f = 1 kHz

IZ = 1 mA

5 mA

20 mA

VF, FORWARD VOLTAGE (V)

Figure 6. Typical Forward Voltage

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

I F

, FOR

W

ARD

CURRENT

(mA)

1000

100

10

1

75 V (MMSZ5267BT1)

91 V (MMSZ5270BT1)

150

°

C

75

°

C 25

°

C

0

°

C

TYPICAL TC VALUES

FOR MMSZ5221BT1 SERIES

MMSZ2V4T1 Series

Motorola TVS/Zener Device Data

7-4

500 mW Leadless (SOD-123) Data Sheet

TYPICAL CHARACTERISTICS

C, CAP

ACIT

ANCE

(pF)

100

VZ, NOMINAL ZENER VOLTAGE (V)

Figure 7. Typical Capacitance

1000

100

10

1

10

1

BIAS AT

50% OF VZ NOM

TA = 25

°

C

0 V BIAS

1 V BIAS

12

VZ, ZENER VOLTAGE (V)

Figure 9. Zener Voltage versus Zener Current

(VZ Up to 12 V)

100

10

1

0.1

0.01

10

8

6

4

2

0

TA = 25

°

C

I Z

, ZENER CURRENT

(mA)

VZ, ZENER VOLTAGE (V)

Figure 10. Zener Voltage versus Zener Current

(12 V to 91 V)

100

10

1

0.1

0.01

10

30

50

70

90

TA = 25

°

C

I R

, LEAKAGE CURRENT

(

A

)

µ

90

VZ, NOMINAL ZENER VOLTAGE (V)

Figure 8. Typical Leakage Current

1000

100

10

1

0.1

0.01

0.001

0.0001

0.00001

80

70

60

50

40

30

20

10

0

+150

°

C

+ 25

°

C

55

°

C

I Z

, ZENER CURRENT

(mA)

MMSZ2V4T1 Series

Motorola TVS/Zener Device Data

7-5

500 mW Leadless (SOD-123) Data Sheet

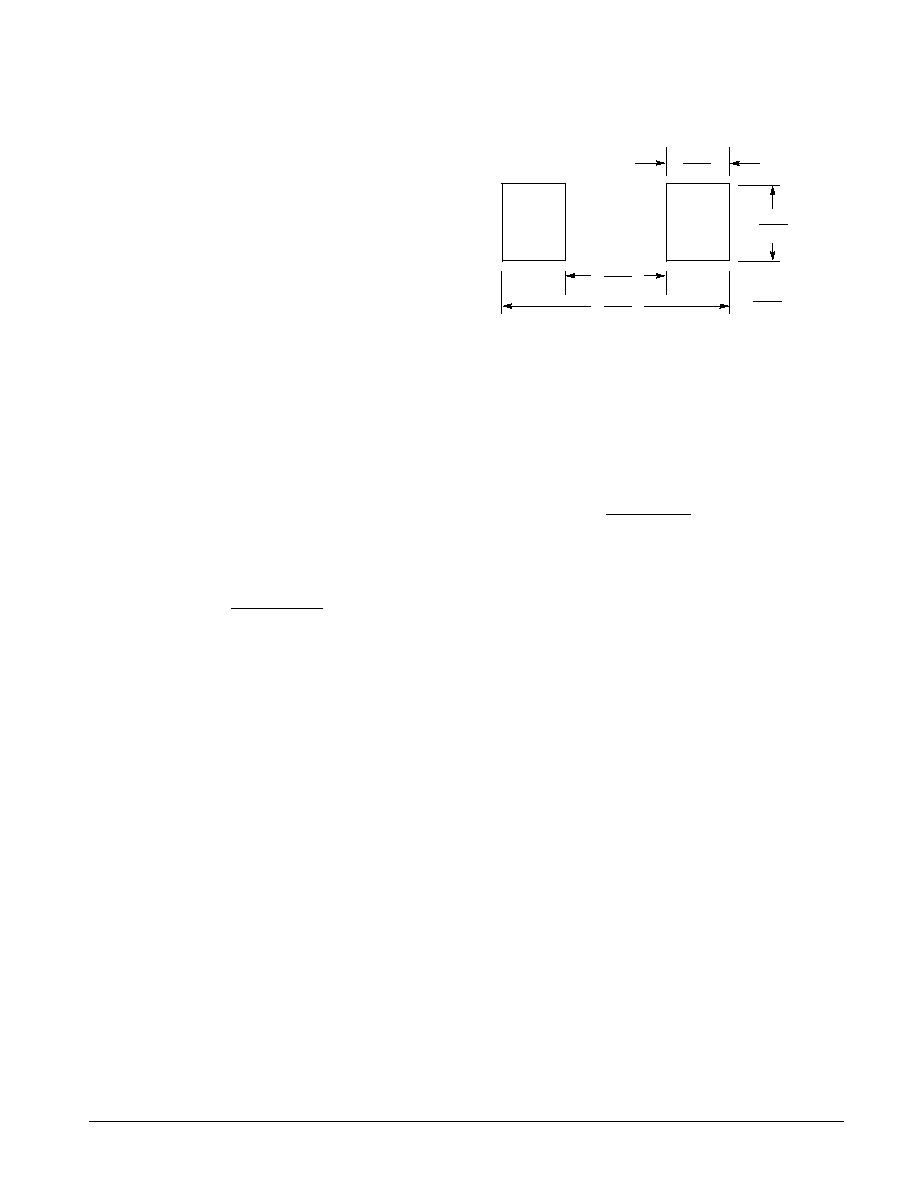

INFORMATION FOR USING THE SOD-123 SURFACE MOUNT PACKAGE

MINIMUM RECOMMENDED FOOTPRINTS FOR

SURFACE MOUNT APPLICATIONS

Surface mount board layout is a critical portion of the total

design. The footprint for the semiconductor packages must be

the correct size to ensure proper solder connection interface

between the board and the package.

The minimum recommended footprint for the SOD-123 is

shown at the right.

The SOD-123 package can be used on existing surface

mount boards which have been designed for the leadless 34

package style. The footprint compatibility makes conversion

from leadless 34 to SOD-123 straightforward.

ÉÉÉÉ

ÉÉÉÉ

ÉÉÉÉ

ÉÉÉÉ

ÉÉÉÉ

mm

inches

0.91

0.036

1.22

0.048

2.36

0.093

4.19

0.165

Figure 11. Minimum Recommended Footprint

SOD-123 POWER DISSIPATION

The power dissipation of the SOD-123 is a function of the

pad size. This can vary from the minimum pad size for

soldering to a pad size given for maximum power dissipation.

Power dissipation for a surface mount device is determined by

TJ(max), the maximum rated junction temperature of the die,

R

JA, the thermal resistance from the device junction to

ambient; and the operating temperature, TA. Using the values

provided on the data sheet for the SOD-123 package, PD can

be calculated as follows:

PD =

TJ(max) TA

R

JA

The values for the equation are found in the maximum

ratings table on the data sheet. Substituting these values into

the equation for an ambient temperature TA of 25

°

C, one can

calculate the power dissipation of the device which in this case

is 0.37 watts.

PD =

150

°

C 25

°

C

340

°

C/W

= 0.37 watts

The 340

°

C/W for the SOD-123 package assumes using

recommended footprint shown on FR-4 glass epoxy printed

circuit board. Another alternative is to use a ceramic substrate

or an aluminum core board such as Thermal Clad

TM

. By using

an aluminum core board material such as Thermal Clad, the

power dissipation can be doubled using the same footprint.

GENERAL SOLDERING PRECAUTIONS

The melting temperature of solder is higher than the rated

temperature of the device. When the entire device is heated

to a high temperature, failure to complete soldering within a

short time could result in device failure. Therefore, the

following items should always be observed in order to

minimize the thermal stress to which the devices are

subjected.

·

Always preheat the device.

·

The delta temperature between the preheat and soldering

should be 100

°

C or less.*

·

When preheating and soldering, the temperature of the

leads and the case must not exceed the maximum

temperature ratings as shown on the data sheet. When

using infrared heating with the reflow soldering method,

the difference shall be a maximum of 10

°

C.

·

The soldering temperature and time shall not exceed

260

°

C for more than 10 seconds.

·

When shifting from preheating to soldering, the maximum

temperature gradient shall be 5

°

C or less.

·

After soldering has been completed, the device should be

allowed to cool naturally for at least three minutes.

Gradual cooling should be used as the use of forced

cooling will increase the temperature gradient and result

in latent failure due to mechanical stress.

·

Mechanical stress or shock should not be applied during

cooling

* Soldering a device without preheating can cause excessive

thermal shock and stress which can result in damage to the

device.