_________________________________________________________________Maxim Integrated Products

1

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim's website at www.maxim-ic.com.

MAX3657 Evaluation Kit

________________ General Description

The MAX3657 evaluation kit is a fully assembled chip-on-

board electrical demonstration kit that provides easy

evaluation of the MAX3657 155Mbps +3.3V trans-

impedance amplifier.

Note that the MAX3657 Evaluation Kit provides an

electrical interface to the IC that is similar, but not exactly

the same as a photodiode.

____________________________ Features

Easy +3.3V Electrical Evaluation of the MAX3657

Fully Assembled and Tested

EV Kit Designed for 50

Interfaces

______________ Ordering Information

PART TEMP. RANGE IC PACKAGE

MAX3657EVKIT -40°C to +85°C Dice

______________Component Suppliers

SUPPLIER

PHONE

FAX

AVX

843-444-2863

843-626-3123

Coilcraft

847-639-6400

847-639-1469

Digi-Key

218-681-6674

218-681-3380

EF Johnson

402-474-4800

402-474-4858

Murata

415-964-6321

415-964-8165

Note: Please indicate that you are using the MAX3657

when ordering from these suppliers.

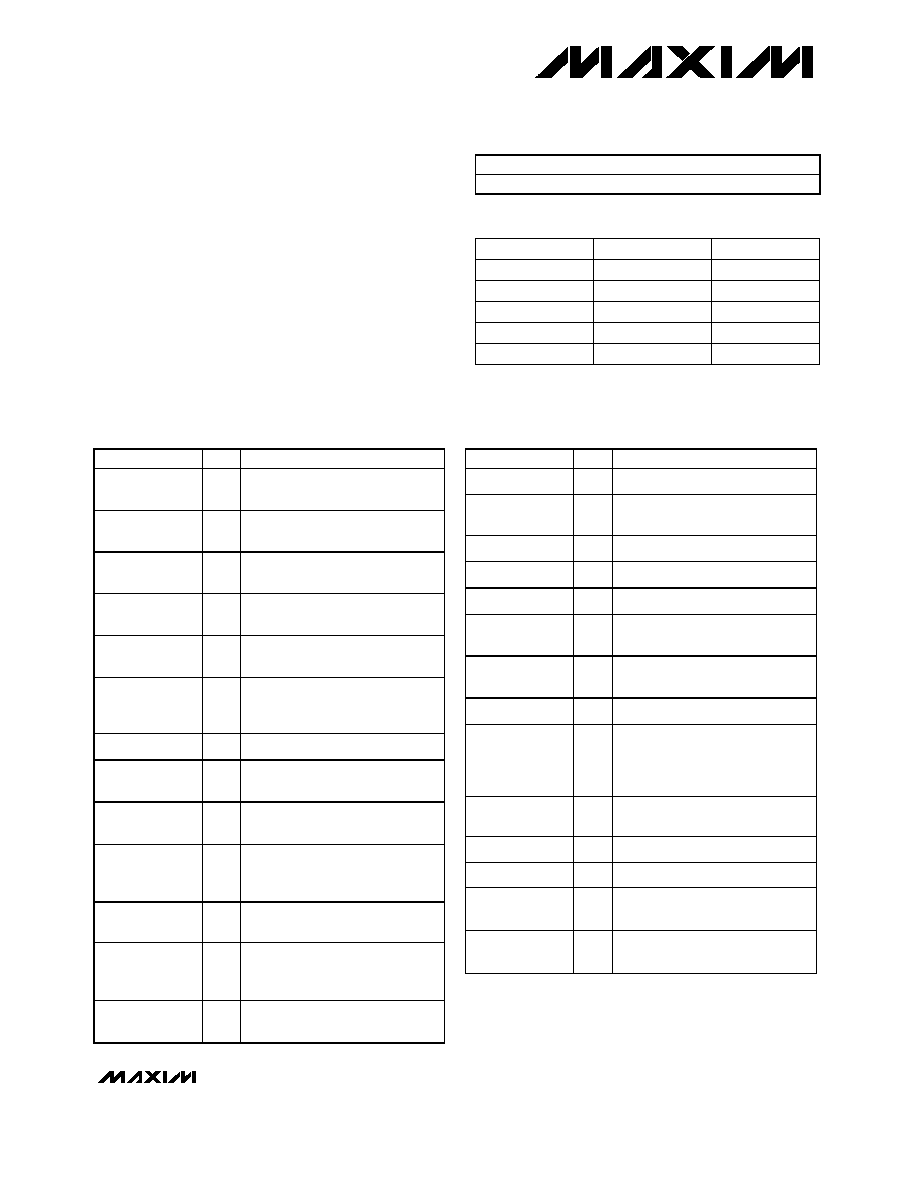

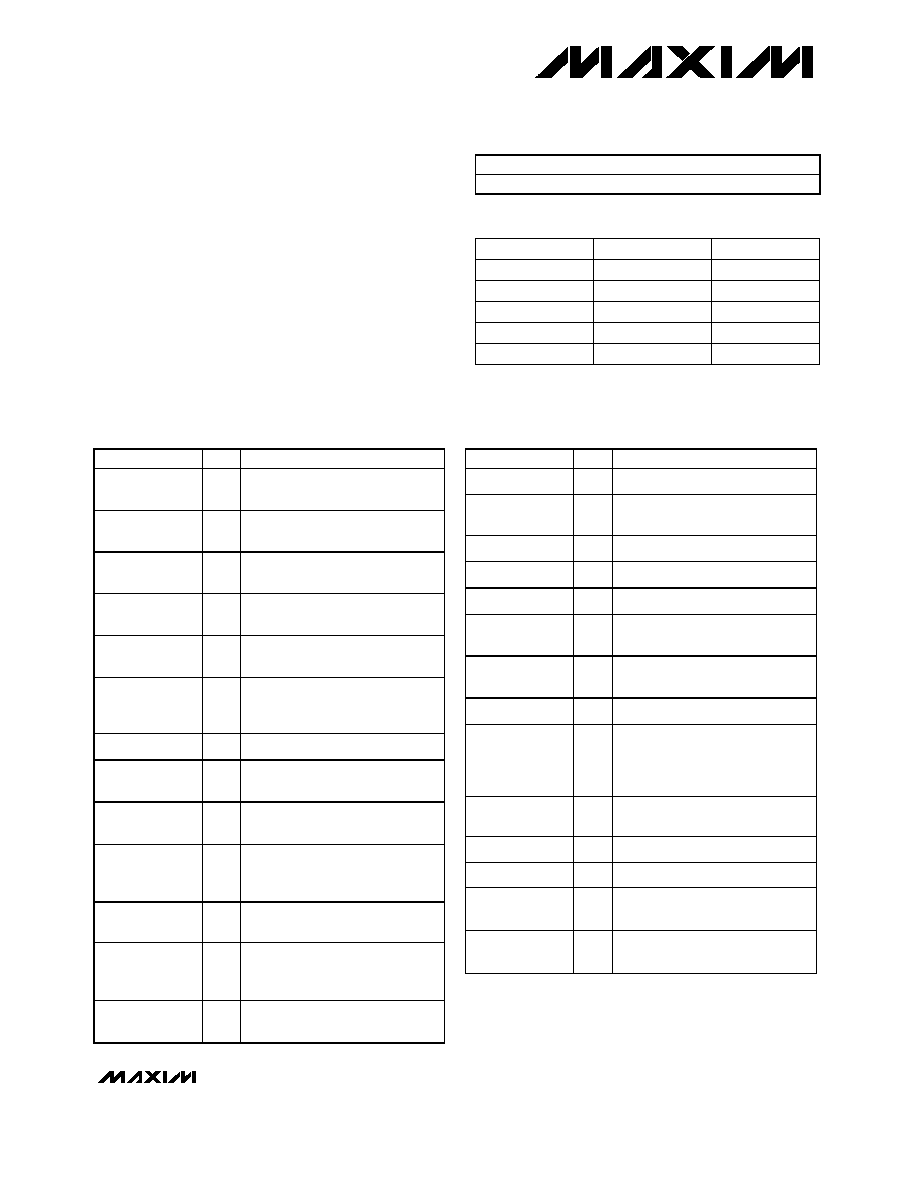

____________________ Component List

DESIGNATION QTY

DESCRIPTION

C2 C23

2

0.01

µF ± 5% Ceramic Capacitor

(0201) - Do not Install

C3

1

10

µF ±10% tantalum capacitor

Do Not Install

C4

1

0.9pF

± .075pF Ceramic

Capacitor (0402)

C5 C100

2

0.01

µF

± 10% Ceramic

Capacitor (0402)

C6, C7, C24,

C27

4

1

µF ± 5% Ceramic Capacitor

(0402) Do Not Install

C8, C9, C13,

C14, C96, C98,

C118, C119

8

1

µF ± 5% Ceramic Capacitor

(0402)

C17, C99

2

10

µF ±10% tantalum capacitor

C97

1

0.4pF

± 0.05pF Ceramic

Capacitor (0402)

J3 J4 J5, J22

J26 J27

6

SMA connectors

(edge-mount, round)

J19, J23, J24,

J25

4

SMA connectors

(edge-mount, round) Do not

Install

JU3, JU4, JU5,

JU6

4

2-pin headers (0.1in centers)

L1

1

56nH inductors (0805)

Coilcraft CS-560XKBC Do Not

Install

L2 L30

2

56nH inductors (0805)

Coilcraft CS-560XKBC

DESIGNATION QTY

DESCRIPTION

R2, R98

2

49.9

±1% resistor (0402)

R3, R4 R120,

R121

4

100

±1% resistor (0402)

R5 R100

2

10k

±1% resistor (0402)

R6

1

1k

±1% resistor (0402)

R7, R38

2

499

±1% resistor (0402)

R28-R29 R33-

R34

4

100

±1% resistor (0402) Do

Not Install

R31

1

1k

±1% resistor (0402) Do Not

Install

R99 R102 R103 3

4.99k

±1% resistor (0402)

TP2, TP4, TP5,

TP6 TP8, TP9,

TP10 TP13-

TP14, TP19

10

TESTPOINT DIGI-KEY 5000K-

ND

TP1, TP18,

TP11, TP12

4

TESTPOINT DIGI-KEY 5000K-

ND Do Not Install

U1

1

MAX3657 ETC 12 QFN

U2

1

MAX3657 DIE

U3

1

User Supplied 4 PIN TO CAN

U4

1

User Supplied 5 PIN TO CAN

19-2898; Rev 0, 5/03

MAX3657 Evaluation Kit

2

________________________________________________________________________________________

Evaluate: MAX3657

_________________________ Quick Start

Test Equipment Required

Test Equipment Required

Test Equipment Required

Test Equipment Required

·

+3.3V power supply with 100mA current capability

·

Signal-source, 155Mbps minimum capability

·

Oscilloscope with at least 100MHz performance

Procedure

Procedure

Procedure

Procedure

This procedure will set up the 12 Pin QFN section of the

evaluation board for 155Mbps operation.

1) Connect a signal source to J26 (IN). Set the signal

amplitude to 250mV

P-P

(Corresponding to 250

µA

P-P

current into the TIA). Set the data rate to 155Mbps.

2) Apply

150

µA to the DC_IN test point (TP10) using a

constant current source to emulate the DC

component of the input signal. A voltage source

connected from TP10 to GND may be used if a

constant current source is not available.

3) Connect OUT+ (J22) and OUT- (J27) to the 50

inputs of a high-speed oscilloscope.

4) Remove the shunt from JU6 to enable the DC

cancellation loop.

5) Install the shunt on JU5.to enable the average

current monitor.

6) Connect a 3.3V supply to the supply terminal (TP 13)

and to the GND terminal.

7) The differential signal at the oscilloscope should be

approximately 150mV

P-P

.

_______________ Detailed Description

The MAX3657 accepts a DC-coupled input from a high-

speed photodiode, for optical modulation amplitudes

ranging from -38dBm to 0dBm. The MAX3657 evaluation

board facilitates characterization of the MAX3657 TIA

with or without a photodiode. The MAX3657 comes from

the factory with the die attached and 12 pin QFN sections

completely assembled. The user must assemble the TO

header sections, if used.

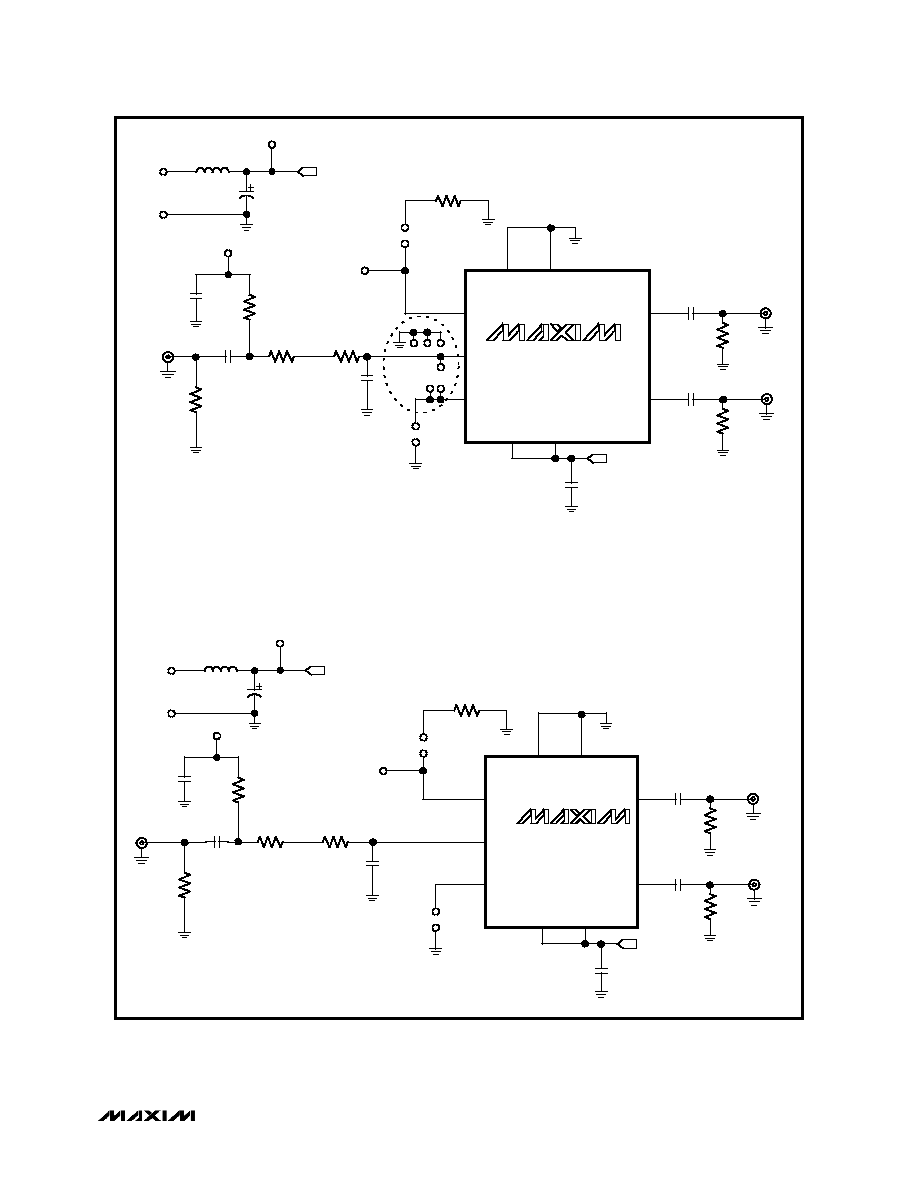

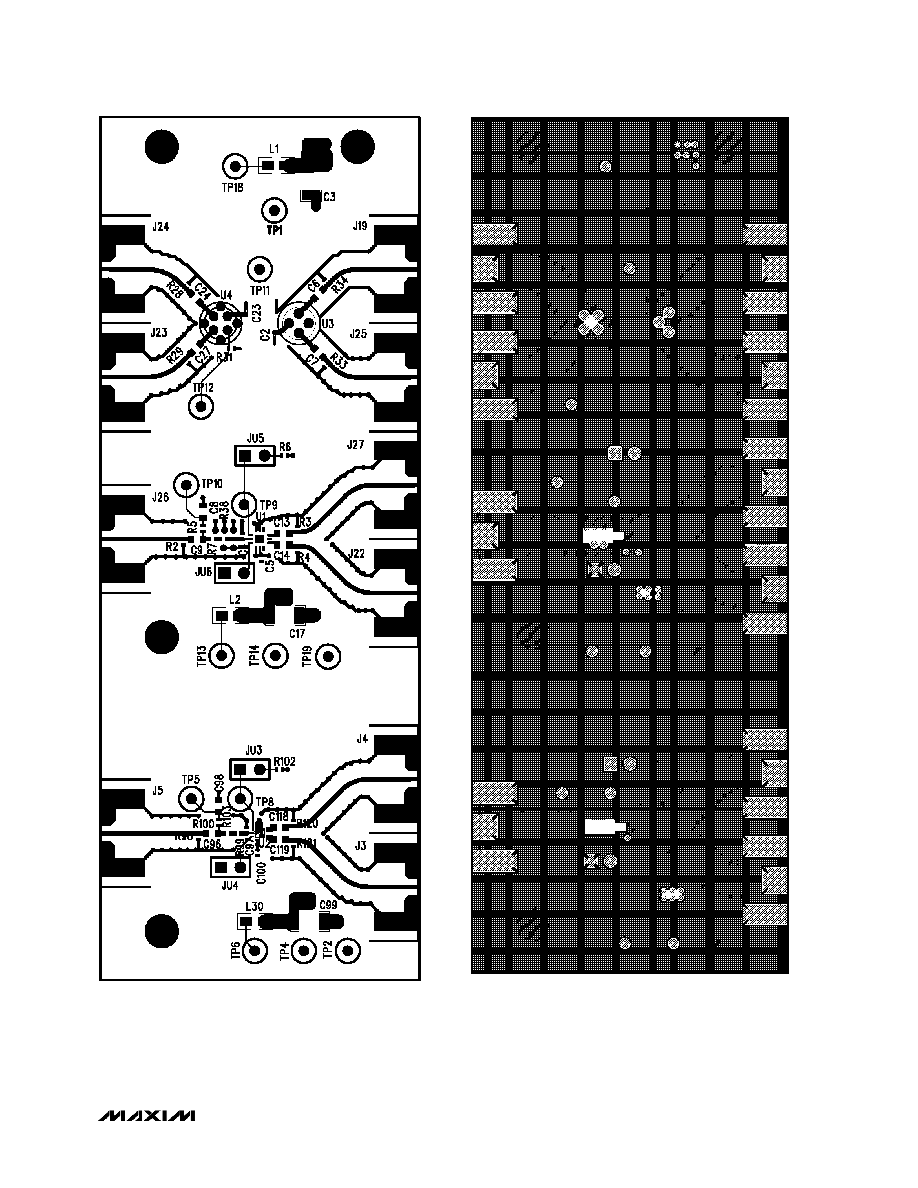

Die Attached Section

Die Attached Section

Die Attached Section

Die Attached Section

The die-attached section provides a simple circuit for

emulating a photodiode current input. The connector at

IN (J1) is terminated with 50

to ground. Signal voltage

applied to the evaluation kit's input is AC coupled to a

resistance in series with the MAX3657's input, creating

an input signal current. Photodiode DC current can be

emulated by injecting DC current into the DC_IN_ pin.

12 Pin QFN Section

12 Pin QFN Section

12 Pin QFN Section

12 Pin QFN Section

The 12 pin QFN section provides photodiode emulation

using similar circuitry as the die-bonded section. An

optional TO assembled photodiode interface is also

provided. To use a TO mounted photo diode, remove

R38, R7, and C4. Figure 2 shows a typical mounting

scheme for a photo diode in a TO header.

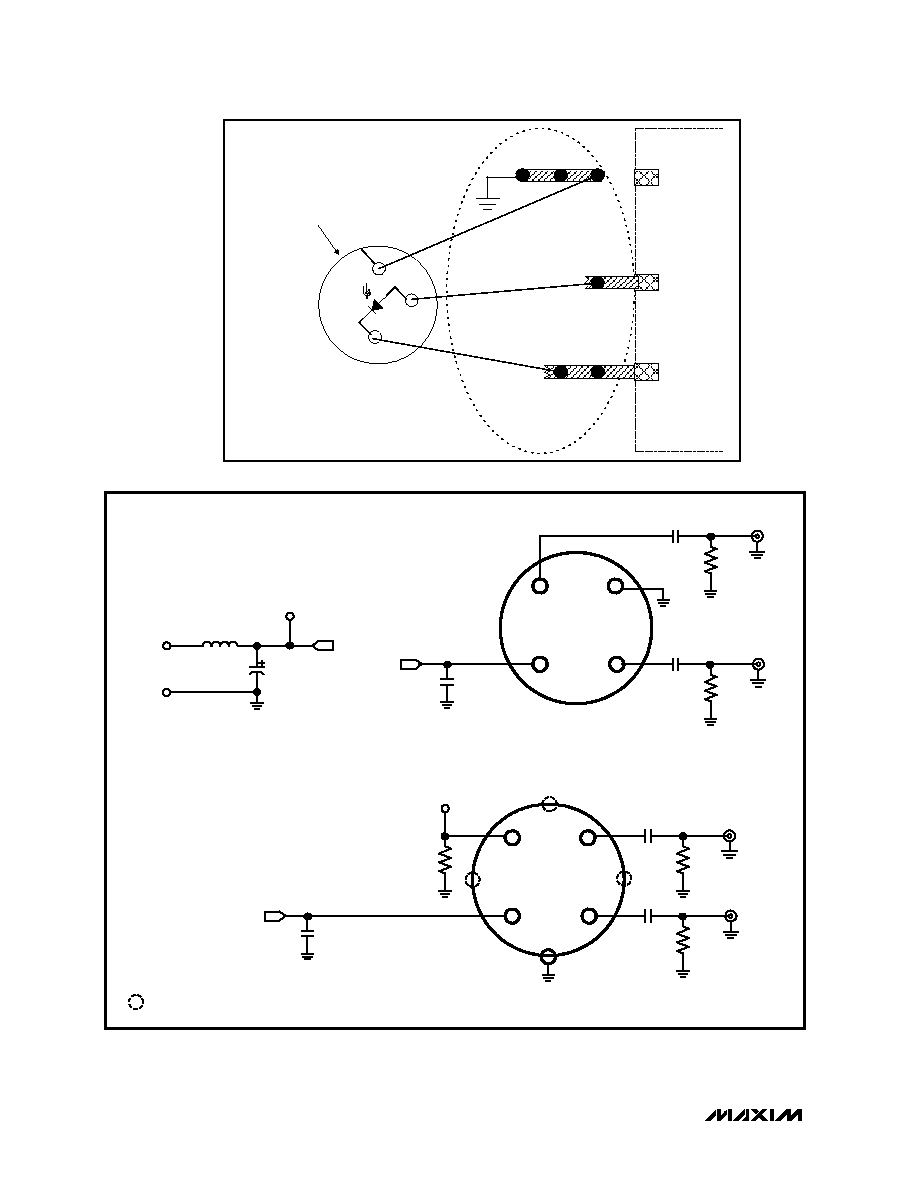

4 and 5 Pin TO Header Layout

4 and 5 Pin TO Header Layout

4 and 5 Pin TO Header Layout

4 and 5 Pin TO Header Layout

The TO header assembly layout provides a user-

assembled interface for evaluation of 4 and 5 pin TO

headers. (See the MAX3657 datasheet for a suggested

TO header layout.)

Test Equipment Interface

Test Equipment Interface

Test Equipment Interface

Test Equipment Interface

The MAX3657 outputs are back terminated with 100

ohms. To facilitate interface with 50

equipment, the

MAX3657 EV Kit places external 100

termination

resistors in parallel with each output so that the EV Kit

will match a 50

environment.

Note that the output load has a direct effect on the overall

gain and output signal swing. Because of the external

100

resistors, the overall gain is reduced by 50%. If

matching a 50

environment is not critical, higher gain

can be achieved by increasing the load resistance.

Photodiode Emulation

Photodiode Emulation

Photodiode Emulation

Photodiode Emulation

Use the following procedure to emulate the high-speed

current signal generated by a photodiode:

Select the desired optical power (PAVE in dBm) and

extinction ratio (re).

Calculate the average current (IAVE in Amps) as follows:

=

1000

10

I

)

10

/

P

(

AVG

AVE

where

is photodiode responsivity in A/W

Calculate the AC signal current (I

INPUT

in Amps

P-P

) as

follows, and adjust the signal generator to obtain it:

)

1

re

(

)

1

re

(

I

2

I

AVE

INPUT

+

-

=

For example, to emulate a signal with an average power

of -25dBm and an extinction ratio of 8.

-25dBm optical power will produce 2.7

µA of average

input current (assume a photodiode responsivity of

0.85A/W). Install a current meter between an external

DC source and the DC_IN test point. Adjust the source to

provide 2.7

µA.

The signal amplitude is 2I

AVE

(r

e

-1)/(r

e

+1) = 4.2

µA. To

generate this current through the two 4.99k

series input

resistors and the 800

internal resistance, set the signal

source to produce an output level of 45mV

P-P

.

Noise measurements

Noise measurements

Noise measurements

Noise measurements

Remove the input resistors and shunt capacitor before

attempting noise measurements. Be very careful when

working around the exposed bond wires of the die

bonded section. With the input resistors and shunt

capacitor removed, the total capacitance at the IN pin is

approximately 0.25pF for the die-attached section and

about 0.5pF for the QFN section.