General Description

The MAX1450 evaluation kit (EV kit) demonstrates sili-

con piezoresistive sensor calibration and temperature

compensation using the MAX1450. The kit includes an

assembled and tested PC board with a Lucas

NovaSensor

®

pressure sensor calibrated at room tem-

perature. It also supports several popular pressure-sen-

sor packages. The board uses multiturn potentiometers

and configuration switches to calibrate and tempera-

ture-compensate a sensor to 1% accuracy.

Features

o

Proven PC Board Layout

o

Convenient Test Points Provided On-Board

o

Includes Calibrated (at room temperature)

Lucas NovaSensor Pressure Sensor

o

Fully Assembled and Tested

o

Supports Many Popular Sensor Packages

Quick Start

Use the quick-start procedure to evaluate initial factory

calibration accuracy or to modify the calibration set-

tings. Before recalibrating the MAX1450, you should

test the precalibrated EV board. Supply power to the

PC board and measure the output voltage as a function

of pressure and temperature. As shipped from the fac-

tory, the EV kit has been calibrated at room tempera-

ture but not compensated over temperature.

Required Equipment

· Precision regulated power supply capable of providing

+5.000V

· Multimeter with at least five significant digits

· 015psi gauge pneumatic pressure controller/calibrator

Initial Setup

The four-pin sensor connector (P2) can be used to

probe the four sensor nodes: sensor excitation (IN+),

sensor ground (IN-), sensor positive output (OUT+), and

sensor negative output (OUT-). This connector may also

serve as a means of wiring to an alternate sensor.

Connector P2 allows the user to supply power to the

board, and to measure output voltage and sensor exci-

tation voltage.

Room Temperature Bench Test

The board's output is ratiometric to the supply; there-

fore, supply voltage must be set accurately to minimize

measurement error.

Evaluates: MAX1450

MAX1450 Evaluation Kit

________________________________________________________________ Maxim Integrated Products

1

19-1611; Rev 0; 1/00

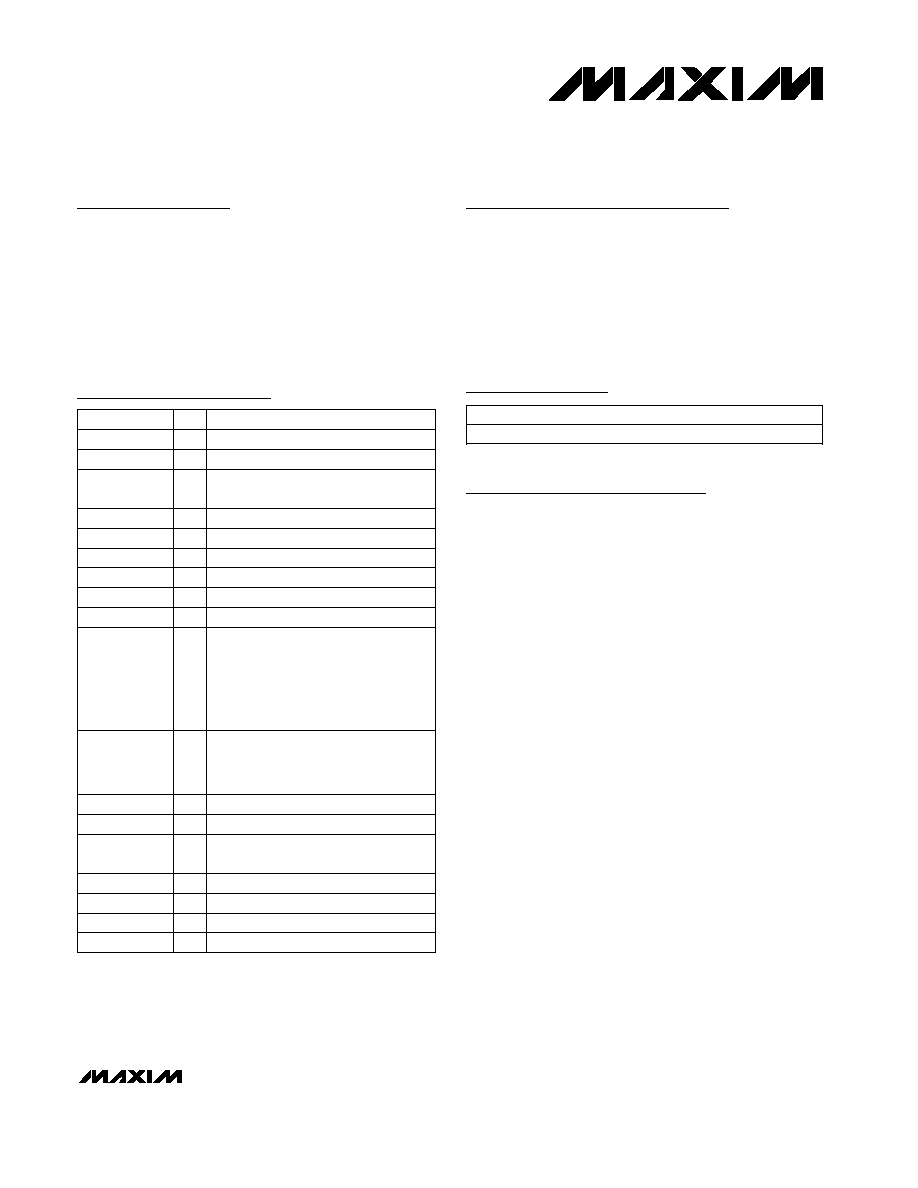

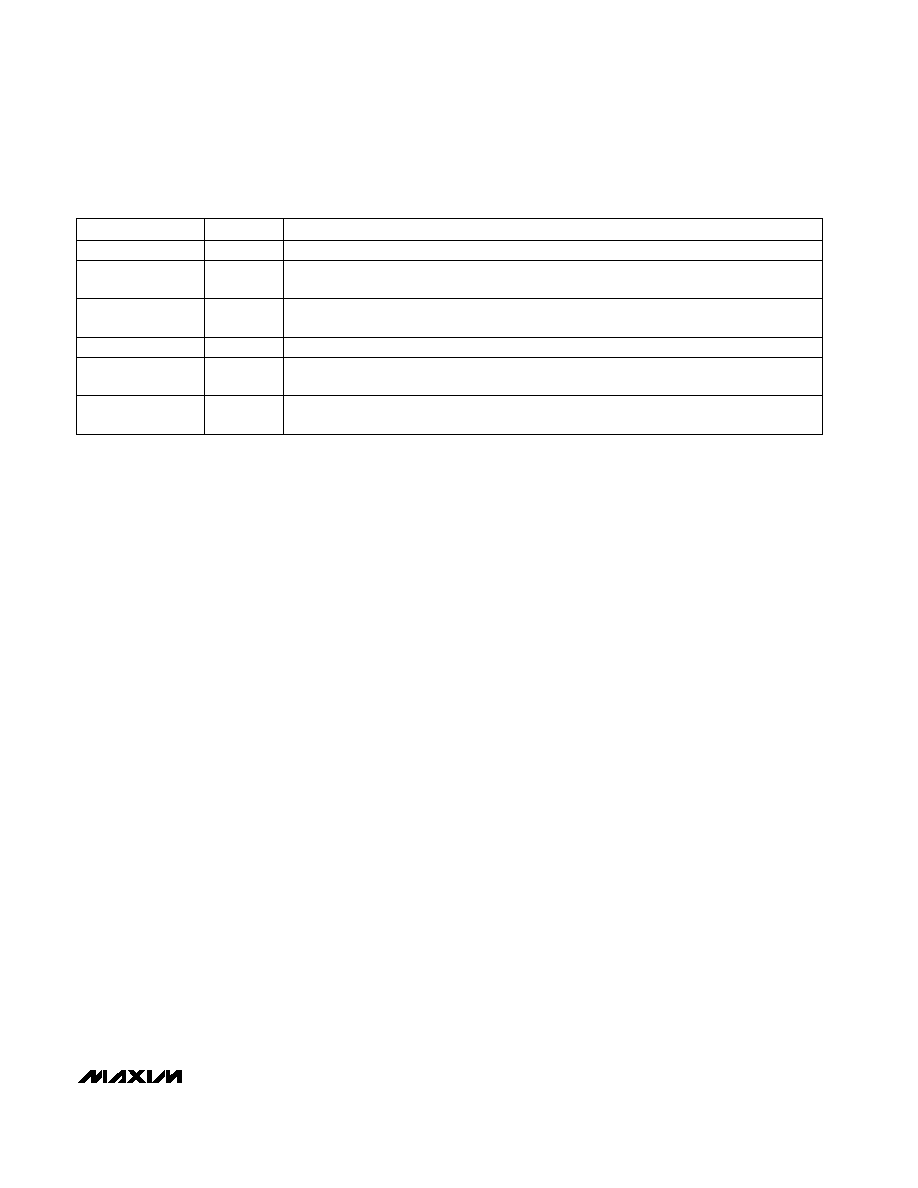

Component List

PART

MAX1450EVKIT

-40°C to +125°C

TEMP. RANGE

IC PACKAGE

20 SSOP

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

Ordering Information

Five-position SPST dip switch

1

SW1

Open

0

R6, R8R11

1M

±5% resistors (1206)

5

R1R5

DESIGNATION

10-pin headers

2

P3, P4

4-pin headers

2

P1, P2

6.2V, 500mW, surface-mount zener

diode

1

D1

0.01µF ceramic capacitor

1

C4

0.1µF ceramic capacitors

3

C1, C2, C3

DESCRIPTION

QTY

MAX1450 EV kit data sheet

1

None

PC board

1

None

Maxim MAX1450CAP (20-pin SSOP)

1

U1

Sensor site 2

Sensym SDX and ISO series,

IC sensors LP series, or

Lucas NovaSensor NPI series

0

S2

Sensor site 1

Lucas NovaSensor NPH-8-100GH

(TO-8, 100kPa gauge)

Other possible sensors:

Sentir AP-301 (modified TO-5) or

IC sensors models 10/20/30/40 (TO-8)

1

S1

MAX1450 data sheet

1

None

Open

0

JU1, JU2

50k

trim potentiometers

3

VR1, VR2, VR3

500k

trim potentiometer

(supplied but not mounted)

1

VR4

100k

trim potentiometer

1

VR5

NovaSensor is a registered trademark of Lucas Varity.

Evaluates: MAX1450

MAX1450 Evaluation Kit

2

_______________________________________________________________________________________

Connect the negative power-supply terminal to the ana-

log connector pin labeled VSS. Connect the positive

power-supply terminal to the analog connector pin

labeled VDD. Connect the DVM to the analog connector

pin labeled VOUT; the ground return should be connect-

ed to the VSS pin.

IMPORTANT:

To avoid problems with ground loops and

noise, connect all equipment to the same AC circuit and

use one common earth ground

. If the power supply

has a programmable current limit, set it to about 10mA.

Adjust the supply voltage to +5.000V, measuring the

voltage at test point VDD with respect to test point VSS.

There should be no connection to the sensor pressure

port. Since the sensor supplied is a gauge type, the out-

put voltage at connector P2 should read approximately

0.5V.

Room Temperature Pressure Test

Carefully remove the plastic sensor protector (if sup-

plied) and connect a silicone pressure tube to the sen-

sor pressure port. Grasp the sensor, not the PC board,

while fitting the tube in place. Perform any required

pressure controller initialization/calibration procedures,

then vent the system. At 0psig, the output voltage

should read between 0.49V and 0.51V. Perform a few

pressure cycles (015psi with supplied sensor) to mini-

mize hysteresis effects. Apply full-scale pressure and

confirm that the output reads between 4.49V and 4.51V.

Test at intermediate pressures to measure for pressure

linearity errors.

Detailed Description

of Hardware

The MAX1450 EV kit performs analog calibration and

temperature compensation of a silicon piezoresistive

sensor. The board is shipped fully assembled and tested,

with a calibrated Lucas Novasensor. Three sensor con-

nection sites are provided: S1, S2, and P1. The board

operates with a 5V nominal supply voltage. Since its

output is ratiometric (proportional) to the supply voltage,

it is critical to maintain a precise supply voltage during

test. The nominal calibrated output voltage range will

be 0.5V (at minimum pressure) to 4.5V (at maximum

pressure). Other output voltage ranges are also possible,

within the common-mode output range of the MAX1450.

Replacing the Sensor

The MAX1450 may be used to calibrate and tempera-

ture-compensate a wide variety of pressure sensor

types; however, some sensors may require additional

external circuitry. This EV kit is designed for bulk micro-

machined silicon piezoresistive pressure sensors. See

Table 1. Connector P1 will accept any generic sensor

configured as a four-wire closed Wheatstone bridge. It

is most useful with sensors that require off-board mount-

ing, such as those that have large threaded pressure

ports. This connector may also be used as a sensor

test point. Sensor sites S1 and S2 provide several over-

lapping footprints for popular metal, plastic, and ceramic

sensors, which use a slip tube as a pressure port. See

the Component List for models that are accepted at

these sites. Only one sensor may be installed at a time.

Sensor sites S1 and S2 are not provided for accommo-

dating differential pressure-sensing applications that

require two pressure sensors.

Power Requirements

The MAX1450 EV kit operates with a nominal supply

voltage of +5V and requires about 5mA of supply cur-

rent, including the sensor. The supply may vary

between +4.5V and +5.5V, and a 6.2V zener diode has

been added across the power-supply lines (VDD and

VSS) to protect the MAX1450. Connector P2 is provided

for connecting power, as well as for measuring the out-

put voltage and sensor excitation voltage.

Calibration and Temperature-

Compensation Procedure

The MAX1450 EV kit can correct four common types of

sensor errors: offset, full-span output (FSO), offset temp-

co, and FSO tempco. The user may choose which para-

meters to correct depending on the sensor behavior,

operating temperature range, and desired accuracy.

Sensor calibration corrects the offset and FSO errors at

a single temperature. Temperature compensation,

which is optional, minimizes offset and FSO error drifts

with changes in temperature, and will require an envi-

ronmental chamber. To correct offset and FSO errors

over a range of temperatures, use the offset tempco

(VR1, OFTC) and FSO tempco (VR4, FSOTC) poten-

tiometers.

Since the PC board is not conformal coated, the envi-

ronmental chamber must not allow condensation to take

place. If condensation occurs, bake the PC board at

+125°C (with no power applied) for a minimum of one

hour. The circuit may behave erratically if moisture con-

denses on the PC board due to weak ionic paths affect-

ing high-impedance nodes on the board. The electron-

ics should be conformal coated in any application

where moisture condensation may occur.

Put the board in an environmental chamber and test the

board over any temperatures between -40°C and

+125°C. First perform one or two full excursions of tem-

perature and pressure to minimize hysteresis errors.

Most of the error after compensation is due to sensor

drift and nonrepeatable behavior. To understand the

source of these errors, monitor the low-level sensor out-

put using the P1 sensor connector to separate sensor

errors from MAX1450 errors. To avoid attenuating the

sensor output signal, take this measurement using a

multimeter with an input impedance >10M

.

Required Equipment

· Precision regulated power supply capable of providing

+5.000V

· Multimeter with at least five significant digits

· 015psi gauge pneumatic pressure controller/cali-

brator

· Dry air or nitrogen

· Noncondensing environmental chamber capable of

handling -40°C to +125°C

Initial Setup

Trim potentiometer VR4 (FSOTC) is required only when

compensating over temperature. Installing VR4 may

perturb previous calibration setpoints. Begin with the

switches and potentiometers as shown in Table 2.

Connect the sensor to a pressure source and test for

leaks. Connect the EV kit to a +5V power source. Since

output voltage is ratiometric to the power supply, an

accurate power-supply setting is required. If the power

supply has a programmable current limit, set it to about

10mA. Current consumption should not exceed 5mA.

Calibration Procedure

This procedure describes how to calibrate at a single

temperature. The following example is designed to cali-

brate a sensor with a nominal output voltage of 0.5V at

P

MIN

and an output voltage of 4.5V at P

MAX

; thus, the

ideal FSO will be 4V.

Choosing PGA Gain Setting

1) Set the temperature to T1 and allow sufficient soak

time.

2) Confirm that the supply voltage is correct.

3) Set the pressure to P

MIN

.

4) Adjust VR3 (FSO trim) until V

BDRIVE

(Vbdr, BDRV) is

approximately 2.0V.

5) Measure the differential sensor output (INP - INM).

6) Set the pressure to P

MAX

; remeasure (INP - INM).

7) Calculate the sensor FSO.

8) Divide the ideal FSO (4V) by the sensor FSO to cal-

culate the ideal PGA gain required.

9) Choose the PGA gain setting that is closest to the

calculated ideal gain.

10) Program the PGA gain chosen using the three pro-

gramming switches (SW1-1, SW1-2, SW1-3).

Example:

1) Set the temperature to T1 and allow it to soak.

2) Confirm the supply voltage.

3) Set the pressure to P

MIN

.

4) Adjust VR3 until V

BDRIVE

= 2.42V.

5) Measure (INP - INM) at P

MIN

to be -0.011V.

6) Measure (INP - INM) at P

MAX

to be 0.056V.

7) Calculate sensor FSO to be 0.067V.

8) Calculate the ideal gain to be 4 / 0.067 = 59.7V/V.

9) Determine the closest available gain setting to

be 65 (PGA value is 1).

10) Set the PGA to 001 (binary), close SW1-1 (LSB),

open SW1-2, and open SW1-3.

Evaluates: MAX1450

MAX1450 Evaluation Kit

_______________________________________________________________________________________

3

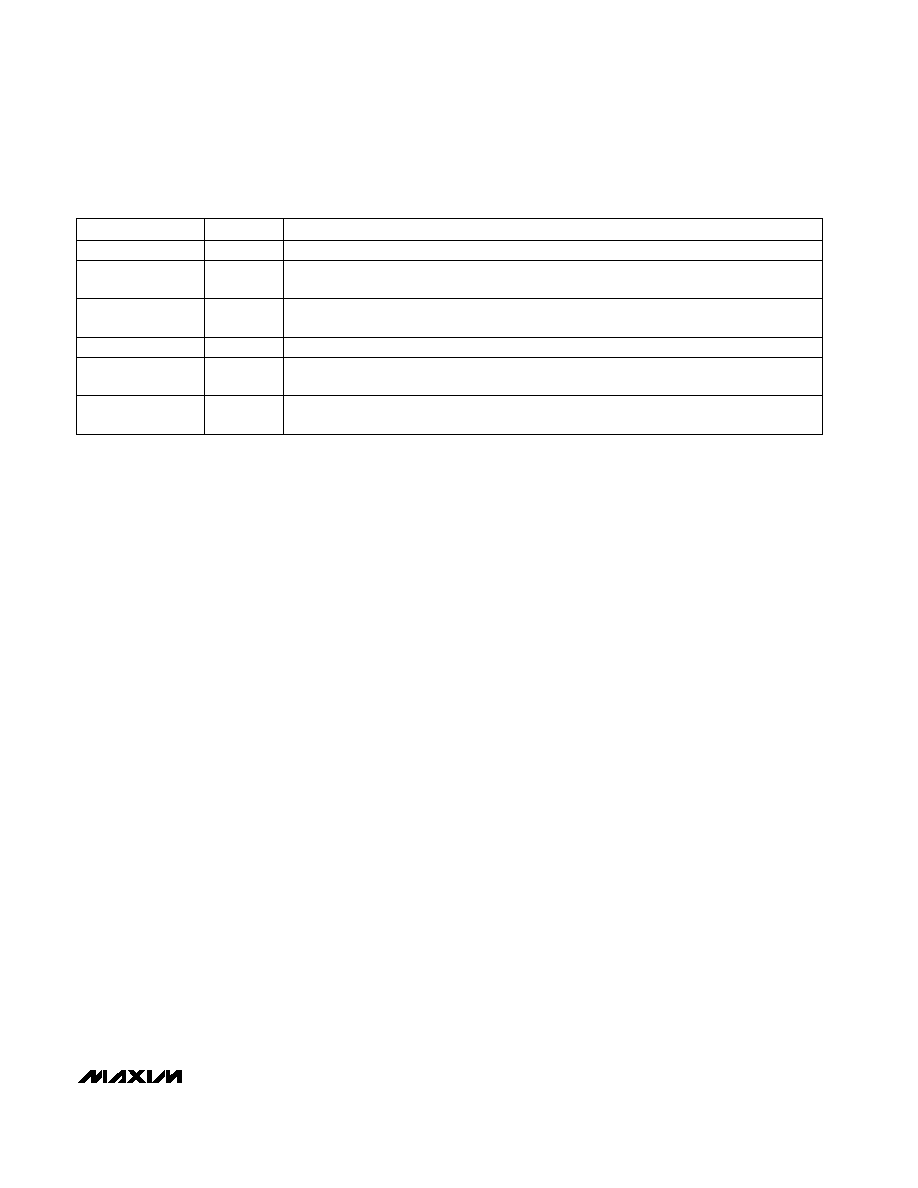

Table 1. Sensor Requirements for EV Kit

PARAMETER

VALUE

DESCRIPTION

Bridge Resistance

5k

(typ)

Sensor input impedance at +25°C

Resistance Tempco

TCR >

|

TCS

|

The sensor input impedance tempco must exceed the absolute value of the sensor pressure-

sensitivity tempco.

Pressure Sensitivity

~10 to 30

mV/V/FSO

Differential output FSO, per volt of sensor excitation

Sensitivity Tempco

TCS < 0

The sensitivity tempco must be negative.

Sensor Offset

|

V

OFFSET

|

< 100mV

The sensor offset voltage (absolute value) at minimum gain must be less than about 100mV.

At higher gains, the offset must be proportionately smaller.

Offset Tempco

|OTC| <

|

TCS

|

The absolute value of the sensor offset tempco must be less than the absolute value of its sensitivity

tempco, when both are expressed in terms of the sensor's FSO.

Evaluates: MAX1450

Determining and Setting the Ideal

Sensor Excitation Voltage at T1

1) Set the pressure to P

MIN

.

2) Measure the output voltage (V

OUT

) at P

MIN

.

3) If V

OUT

> 0.5V, open SW1-4 (SOF); if V

OUT

< 0.5V,

close SW1-4.

4) Adjust VR2 (OFST trim) until V

OUT

is 0.5V.

5) Set the pressure to P

MAX

, and measure V

OUT

at

P

MAX

.

6) Calculate the uncorrected FSO as follows: V

OUT

at

P

MAX

- V

OUT

at P

MIN

.

7) Calculate the FSO error as follows: uncorrected

FSO / ideal FSO.

8) Set the pressure to P

MIN

, and measure V

BDRIVE

(uncorrected V

BDRIVE

).

9) Determine the ideal V

BDRIVE

as follows: uncorrected

V

BDRIVE

/ FSO error.

10) Using VR3 (FSO trim), set V

ISRC

(pin 17) to ideal

V

BDRIVE

.

11) Using VR5 (R

ISRC

trim), set V

BDRIVE

to ideal

V

BDRIVE

.

Example:

1) Set the pressure to P

MIN

.

2) Measure V

OUT

at P

MIN

to be 0.987V.

3) Open SW1-4 (the voltage at OFFSET, pin 9, is

subtracted from the output).

4) Adjust VR2 until V

OUT

at P

MIN

= 0.503V.

5) Set the pressure to P

MAX

, then measure V

OUT

at P

MAX

to be 4.742V.

6) Calculate the uncorrected FSO as follows: 4.742

- 0.503 = 4.239V.

7) Calculate the FSO error as follows: 4.239 / 4 =

1.0597 (approximately 6% too high).

8) Measure V

BDRIVE

as 2.42V (uncorrected

V

BDRIVE

).

9) Calculate ideal V

BDRIVE

as follows: 2.42 /

1.0597 = 2.284V.

10) Adjust VR3 until V

ISRC

= 2.284V.

11) Adjust VR5 until V

BDRIVE

= 2.284V.

Setting Offset Voltage at T1

1) Set VR2 fully CCW (V

OFFSET

, pin 9 = 0).

2) Set the pressure to P

MIN

.

3) Measure the output voltage V

OUT

at P

MIN

.

4) If V

OUT

> 0.5V, open SW1-4; if V

OUT

< 0.5V, close

SW1-4.

5) Adjust VR2 until V

OUT

is 0.5V.

Example:

1) Set VR2 fully CCW.

2) Set the pressure to P

MIN

.

3) Measure V

OUT

P

MIN

to be 0.387V.

4) Close SW1-4 (the voltage at OFFSET, pin 9, is

added to the output).

5) Adjust VR2 until V

OUT

at P

MIN

= 0.496V.

MAX1450 Evaluation Kit

4

_______________________________________________________________________________________

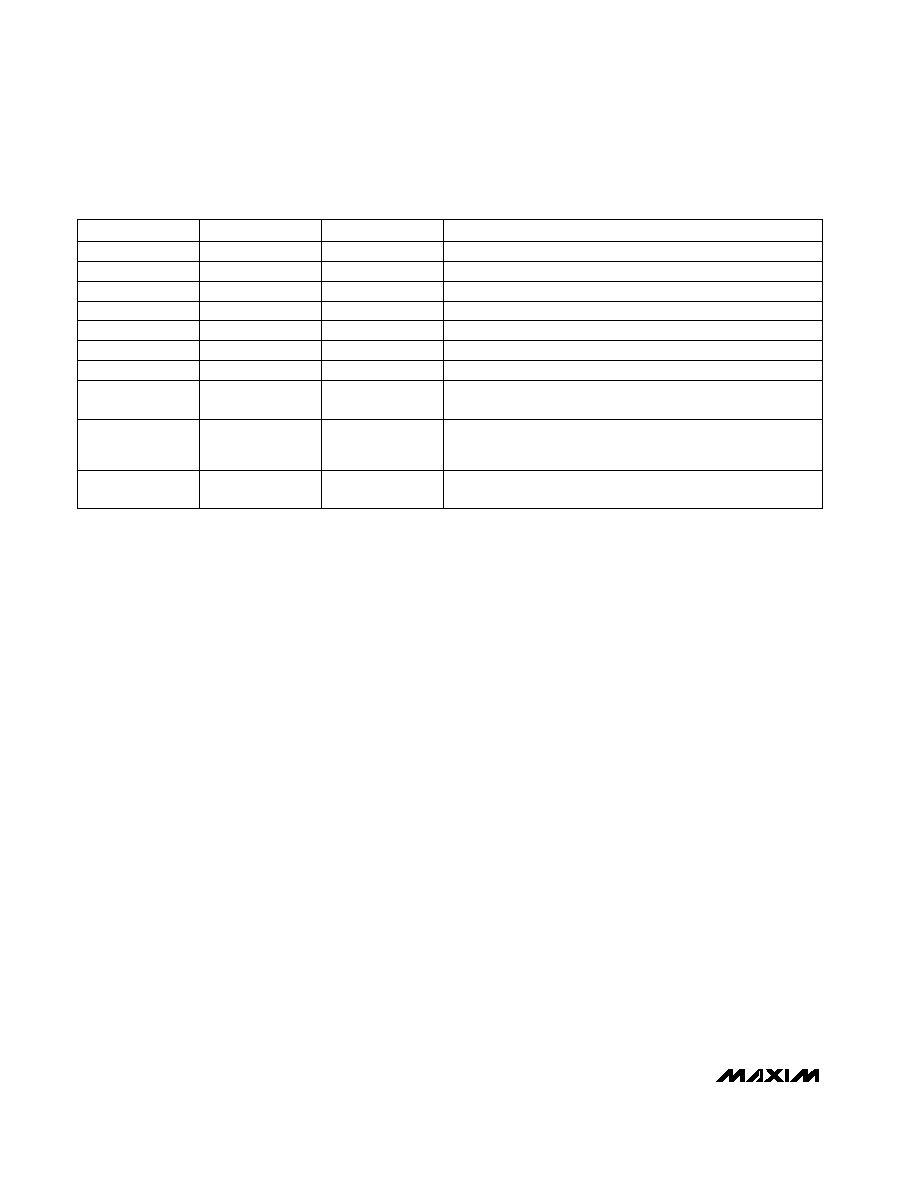

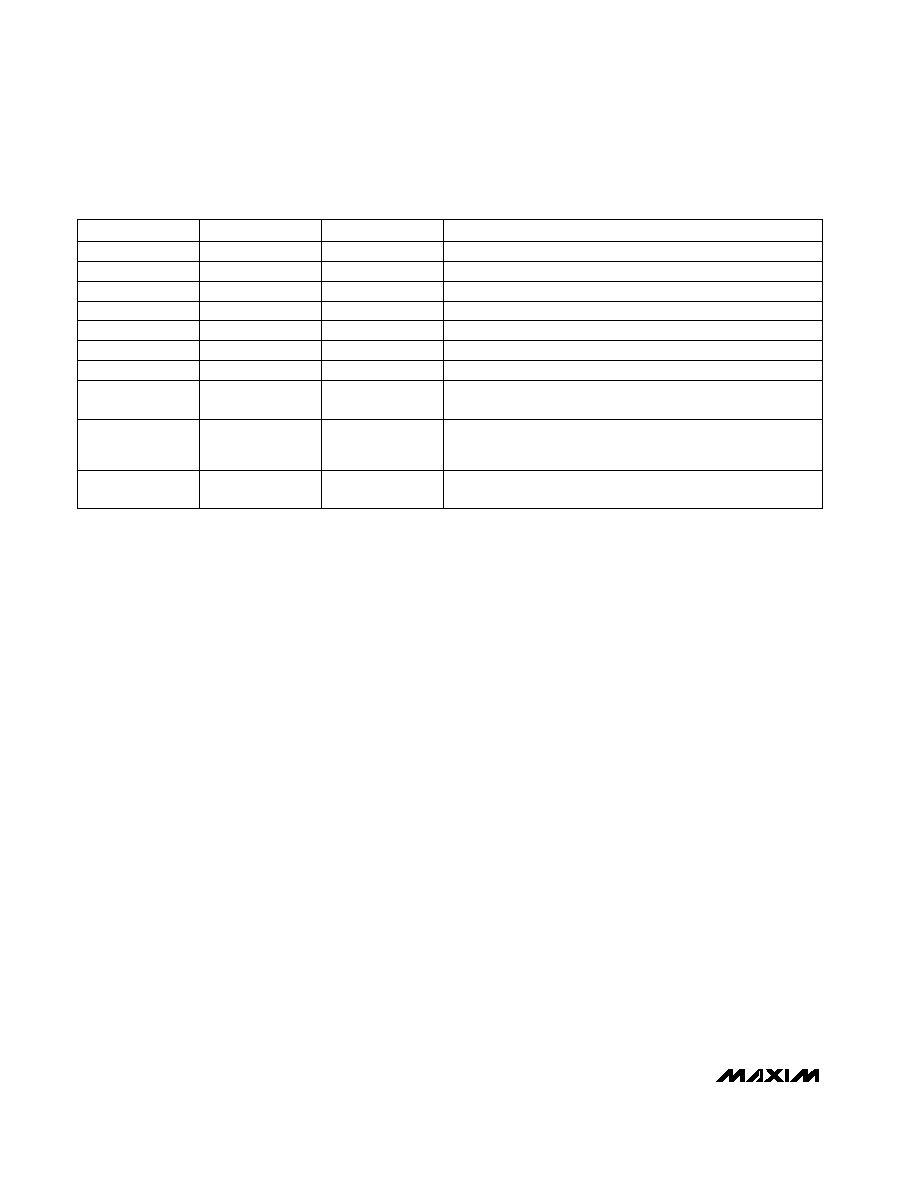

PARAMETER

FUNCTION

INITIAL SETTING

SW1-1

PGA LSB

Off (open)

SW1-2

PGA NSB

Off (open)

SW1-3

PGA MSB

Off (open)

SW1-4

Offset Sign

On (closed)

SW1-5

Offset TC Sign

On (closed)

VR1

Offset TC Adjust

Fully CCW

DESCRIPTION

Minimum gain

Minimum gain

Minimum gain

Sign bit is set to positive.

Sign bit is set to positive.

No offset TC correction is performed. V

OFFSET

, pin 9 = 0.

VR2

Offset Adjust

Fully CCW

VR3

FSO Adjust

Approximately

midscale

VR4

FSO TC Adjust

Do not install VR4

unless compensating

over temperature.

VR5

R

ISRC

Adjust

Approximately

midscale

No offset correction is added. V

OFFTC

, pin 8 = 0.

Sets initial V

ISRC

to ~2.5V.

No FSO TC adjustment

Sets initial R

ISRC

to ~ 50k

.

Table 2. Initial Settings

Offset and FSO calibration (at T1) is now complete.

Remeasure the EV kit's output voltage (V

OUT

) at both

P

MIN

and P

MAX

. If required, make small readjustments

to FSO and to offset using their respective adjusting

potentiometers. If large errors are observed (~ 0.5% or

greater), recalibrate from step 1.

Temperature-Compensation Procedure

Accuracy may be improved by measuring offset and

FSO errors at a second temperature T2 (T2 > T1). The

FSOTC and OFFTC potentiometers will be used to com-

pensate for the drift in offset and FSO.

Compensating FSO TC Error at T2

1) Increase the temperature to T2 and allow sufficient

soak time.

2) Confirm that the supply voltage is correct.

3) Set the pressure to P

MIN

.

4) Measure

V

BDRIVE

(uncorrected V

BDRIVE

at T2).

5) Compare this uncorrected V

BDRIVE

with the ideal

V

BDRIVE

at T1 (see Determining and Setting the

Ideal Sensor Excitation Voltage at T1). If the uncor-

rected V

BDRIVE

is less than or equal to the ideal

V

BDRIVE

at T1, the sensor cannot be compensated

and you should abort the procedure. If it is greater

than the ideal V

BDRIVE

, the sensor can be compen-

sated and you may proceed.

6) Measure

V

OUT

at P

MIN

.

7) Set the pressure to P

MAX

, and measure V

OUT

at

P

MAX

.

8) Calculate the uncorrected FSO as follows: V

OUT

at

P

MAX

- V

OUT

at P

MIN

.

9) Calculate the FSO error as follows: uncorrected

FSO / ideal FSO.

10) Set the pressure to P

MIN

, and remeasure V

BDRIVE

(uncorrected V

BDRIVE

).

11) Determine the ideal V

BDRIVE

as follows: uncorrected

V

BDRIVE

/ FSO error.

12) Using VR4 (FSO TC trim), set V

BDRIVE

to ideal

V

BDRIVE

.

Example:

1) Increase the temperature to T2 and allow suffi-

cient soak time.

2) Confirm that the supply voltage is correct.

3) Set the pressure to P

MIN

.

4) Measure the uncorrected V

BDRIVE

at T2 as

2.961V.

5) Since it is greater than 2.284V, we can proceed.

6) Measure

V

OUT

at P

MIN

to be 0.6V.

7) Set the pressure to P

MAX

, and measure V

OUT

at

P

MAX

to be 4.72V.

8) Calculate the uncorrected FSO as follows: 4.72

- 0.6 = 4.12V.

9) Calculate FSO error as follows: 4.12 / 4 = 1.03

(approximately 3% too high).

10) Set the pressure to P

MIN

, and remeasure

V

BDRIVE

(uncorrected V

BDRIVE

).

11) Determine the ideal V

BDRIVE

as follows: 2.961 /

1.03 = 2.875V.

12) Adjust VR4 (FSO TC trim) until V

BDRIVE

=

2.875V.

Compensating Offset TC Error at T2

1) Set the pressure to P

MIN

.

2) Measure

V

OUT

at P

MIN

.

3) Calculate the offset TC error as follows: V

OUT

at

P

MIN

- 0.5.

4) Calculate the delta V

BDRIVE

as follows: ideal

V

BDRIVE

at T2 - ideal V

BDRIVE

at T1.

5) Calculate the offset TC correction factor as follows:

offset TC error / (1.15

·

delta V

BDRIVE

).

6) If offset TC error is positive, set SW1-5 to open

(negative offset TC correction); if it is negative,

close SW1-5.

7) Calculate V

OFFTC

as follows: offset TC correction

factor

·

V

BDRIVE

at T2.

8) Measure the voltage at OFFTC (pin 8), and adjust

VR1 to the value V

OFFTC

.

Example:

1) Set the pressure to P

MIN

.

2) Measure

V

OUT

at P

MIN

to be 0.75V.

3) Calculate the offset TC error as follows: 0.75 -

0.5 = +0.25V.

4) Calculate delta V

BDRIVE

as follows: 2.875 -

2.284 = +0.591V.

5) Calculate offset TC correction factor as follows:

0.25 / (1.15

·

0.591) = 0.368 (+36.7% of

V

BDRIVE

).

6) Since offset TC correction factor is positive,

open SW1-5.

7) Calculate

V

OFFTC

as 0.368

·

2.875 = 1.058V.

8) Adjust VR1 until V

OFFTC

= 1.058V.

Evaluates: MAX1450

MAX1450 Evaluation Kit

_______________________________________________________________________________________

5