General Description

The MAX1403 evaluation system (EV system) is a com-

plete, multichannel data-acquisition system consisting of

a MAX1403 evaluation kit (EV kit) and a Maxim 68HC11

microcontroller (µC) module. The MAX1403 is a low-

power, multichannel, serial-output analog-to-digital con-

verter (ADC). Windows 95/98TM-compatible software pro-

vides a handy user interface to exercise the MAX1403's

features. Source code in C++ and 68HC11 assembly lan-

guage is provided for the low-level portion of the software.

Order the EV system for comprehensive evaluation of

the MAX1403 using a personal computer. Order only

the EV kit if the 68HC11 µC module has already been

purchased with a previous Maxim EV system or for cus-

tom use in other µC-based systems.

The MAX1403 EV kit and EV system can also be used

to evaluate the MAX1401. Simply order a free sample of

the MAX1401CAI along with the MAX1403EVKIT.

MAX1403 Stand-Alone EV Kit

The MAX1403 EV kit provides a proven PC board layout

to facilitate evaluation of the MAX1403 with user-provid-

ed software and hardware. It must be interfaced to

appropriate timing signals for proper operation. Refer to

the MAX1403 data sheet for timing requirements. See

Table 2 for jumper functions.

MAX1403 EV System

The MAX1403 EV system operates from a user-sup-

plied +5V to +12V DC power supply.

Features

o

Easy to Configure

o

Collects Up to 8192 Samples at Full Speed

o

Complete Evaluation System

o

Proven PC Board Layout

o

Fully Assembled and Tested

Evaluates: MAX1401/MAX1403

MAX1403 EV System

________________________________________________________________

Maxim Integrated Products

1

19-1490; Rev 0; 5/99

MAX1403 EV System

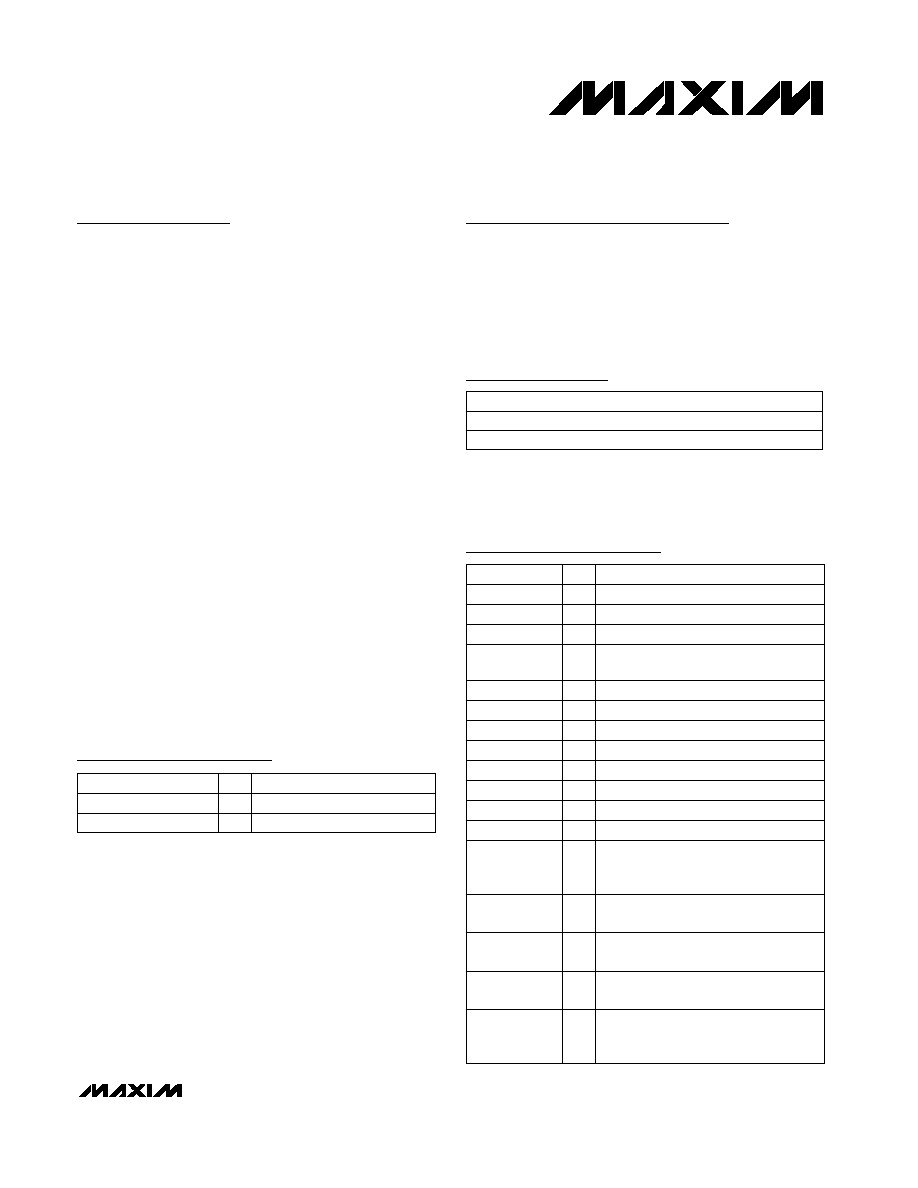

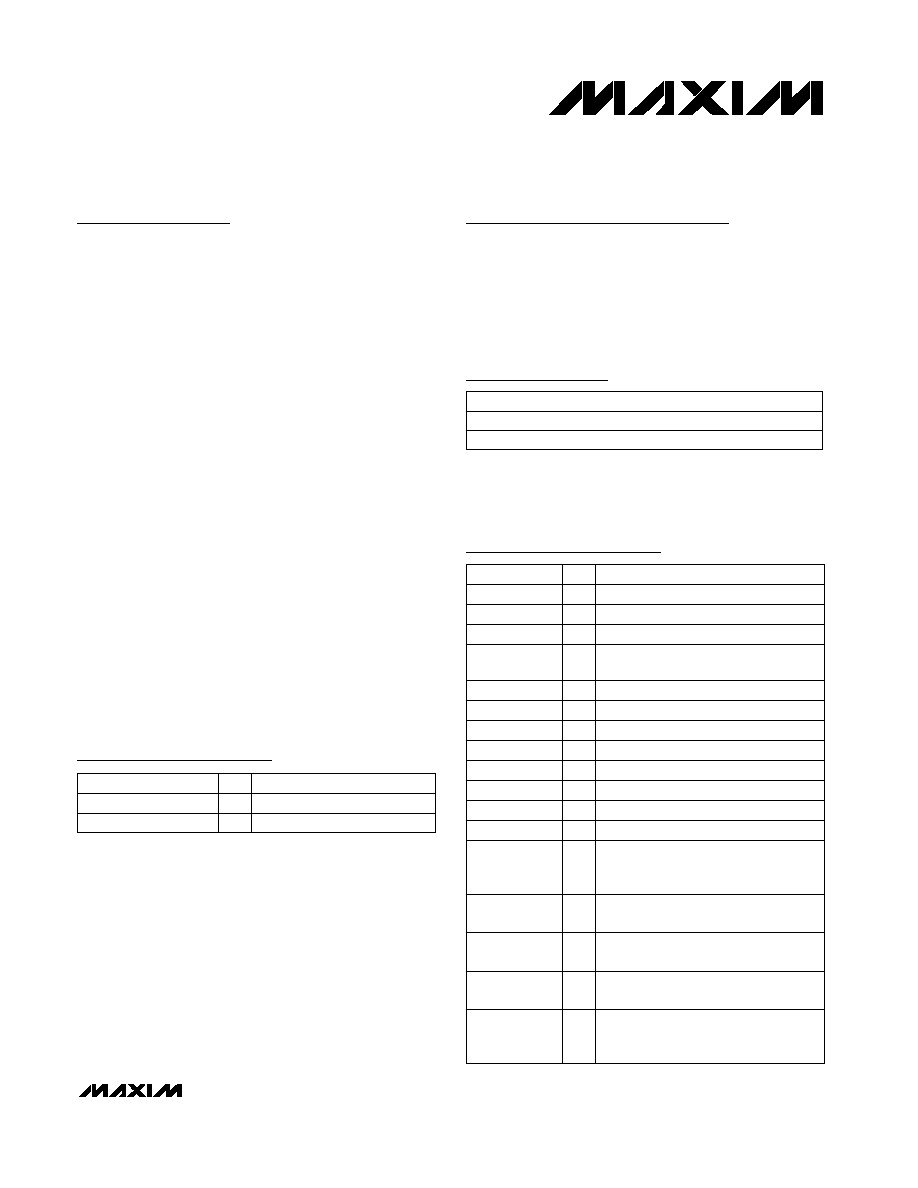

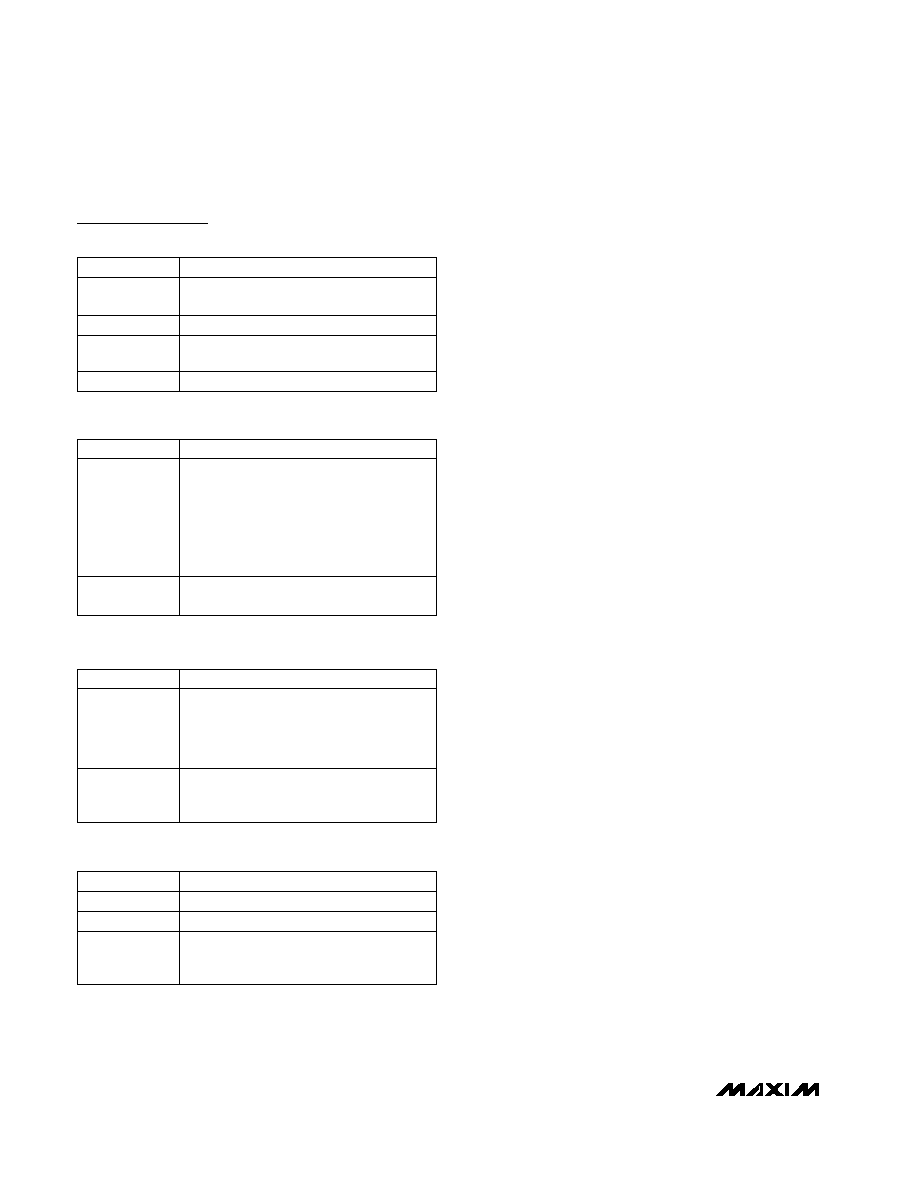

Component List

PART

MAX1403EVKIT

MAX1403EVL11

0°C to +70°C

0°C to +70°C

TEMP. RANGE

INTERFACE TYPE

User-Supplied

Windows Software

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

Ordering Information

Component Suppliers

MAX1403 EV Kit

Component List

Not installed

0

R10

Not installed

0

R9

10

, 5% resistors (1206)

2

R7, R8

100

, 5% resistors (1206)

6

R1R6

Not installed

0

JU1JU8

Female SMA connector

1

J2

DESIGNATION

2 x 20 right-angle socket

1

J1

2.2µF aluminum electrolytic radial-

leaded capacitor

1

C15

Not installed

0

C12, C13

0.1µF ceramic capacitors (1206)

3

C9, C10, C11

100pF ceramic capacitors (1206)

6

C3C8

DESCRIPTION

QTY

Windows 95/98 is a trademark of Microsoft Corp.

Note:

The MAX1403 software can be used only with the com-

plete evaluation system (MAX1403EVL11), which includes the

68L11DMODULE together with the MAX1403EVKIT.

PART

68HC11 µC Module

1

68L11DMODULE

MAX1403 Evaluation Kit

1

MAX1403EVKIT

DESCRIPTION

QTY

Maxim MAX1403CAI

1

U1

Maxim MAX6520EUR

(SOT23 voltage reference, 1.2V,

20ppm/°C max)

1

U2

2.4576MHz ceramic resonator

Murata CST2.45MGW040

1

Y1

3" x 4" PC board

MAX1403 evaluation kit

1

None

3 1/2" software disk

MAX1403 evaluation kit

1

None

Maxim 68HC11 module monitor, ROM

Version 1.1 (Version 1.0 ROM will not

work with this EV kit.)

1

None

Evaluates: MAX1401/MAX1403

MAX1403 EV System

2

_______________________________________________________________________________________

_________________________Quick Start

Recommended Equipment

Obtain the following equipment before you begin:

· A DC power supply that generates +5VDC to +12VDC

at 30mA to 50mA

· An IBM PC-compatible computer running Windows

95/98

· A spare serial communications port, preferably a 9-

pin plug

· A serial cable to connect the computer's serial port

to the Maxim 68HC11 Module

1) Before you begin, make sure your 68HC11 module

has the Rev. 1.1 ROM. The software will not function

with the Rev. 1.0 ROM.

2) Carefully connect the boards by aligning the 40-pin

header of the MAX1403 EV kit with the 40-pin con-

nector of the 68HC11 module. Gently press them

together. The two boards should be flush against

one another.

3) Connect the DC power source to the µC module at

terminal block J2, located next to the ON/OFF

switch, along the top edge of the µC module.

Observe the polarity marked on the board.

4) Connect a cable from the computer's serial port to

the µC module. If using a 9-pin serial port, use a

straight-through, 9-pin female-to-male cable. If the

only available serial port uses a 25-pin connector, a

standard 25-pin to 9-pin adapter will be required.

The EV kit software checks the modem status lines

(CTS, DSR, DCD) to confirm that the correct port

has been selected.

5) Install the software on your computer by running the

INSTALL.EXE program from the floppy disk. The

program files are copied and icons are created for

them in the Windows 95/98 Start Menu. The EV kit

software evaluates both the MAX1403 and the

MAX1401.

6) Start the MAX1403 program by opening its icon in

the Start Menu.

7) The program will prompt you to connect the µC

module and turn its power on. Slide SW1 to the "ON"

position. Select the correct serial port, and click OK.

The program will automatically download the file

KIT1403.L11 to the module.

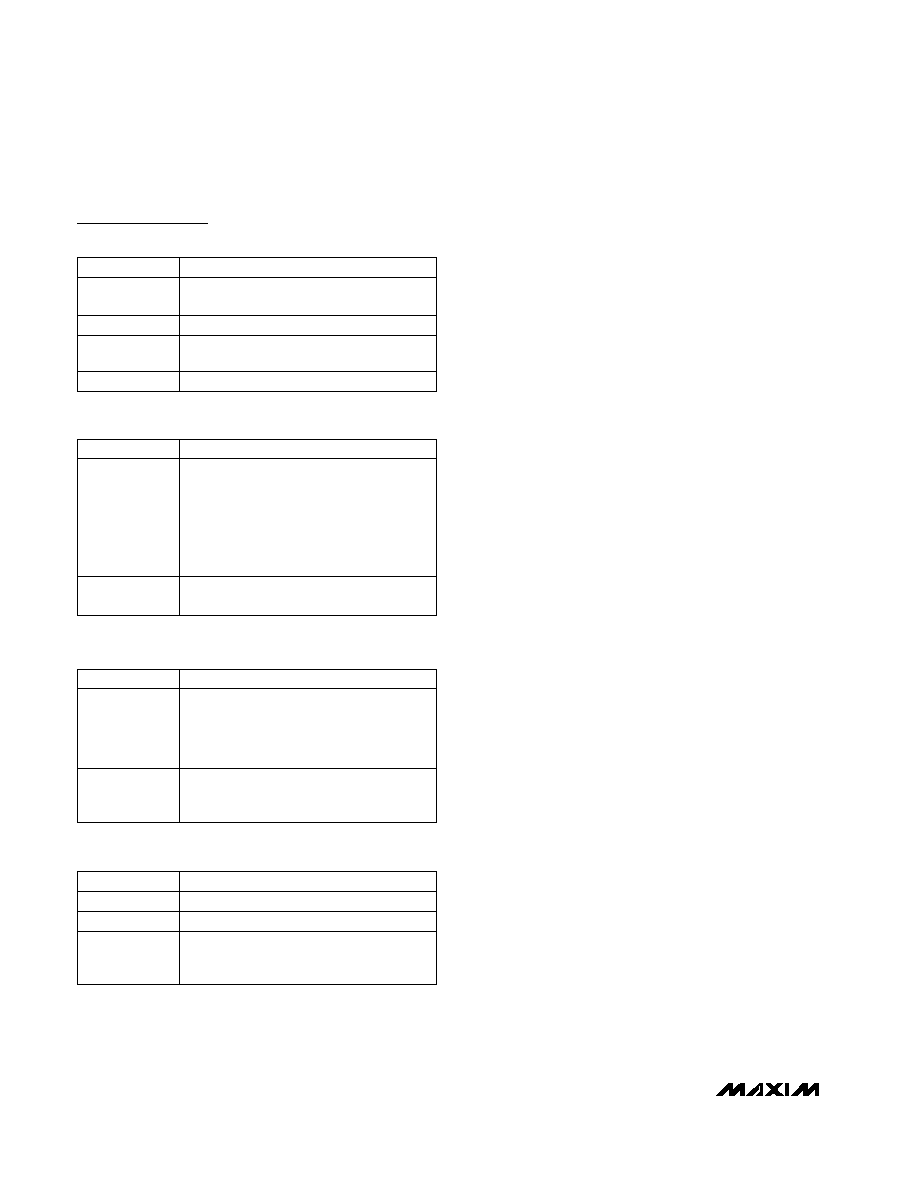

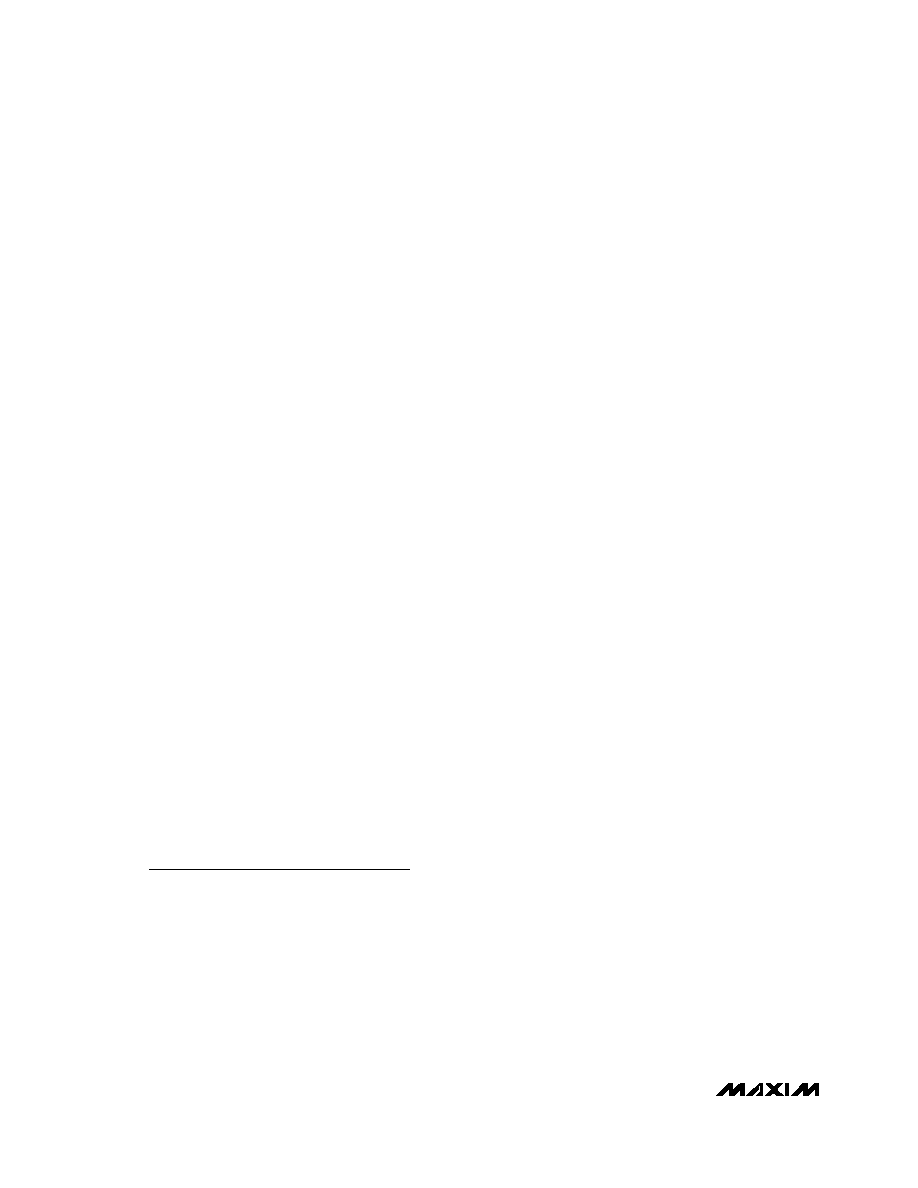

Example Source Code Files

68HC16 Source Code Files

Install/Uninstall Program Files

Header file for MAX1403.CPP, provided for

reference.

MAX1403.H

DESCRIPTION

FILE

Source code defining the program inter-

face with the Maxim 68HC11 Module ROM

(Rev. 1.1).

EVKIT.ASM

Main source code for the KIT1403.L11 pro-

gram, provided for reference. Maxim holds

the copyright but allows customers to

adapt the program for their own use without

charge.

KIT1403.ASM

Database for uninstall program.

UNINST.INI

Installs the EV kit files on your computer.

INSTALL.EXE

Removes the EV kit files from your comput-

er. This file is automatically copied to

C:\WINDOWS during installation.

UNMAXIM.EXE

MAX1403 EV Kit Files

Windows Application Program Files

Program settings file

MAX1403.INI

Software loaded into 68HC11 microcon-

troller

KIT1403.L11

Help file

MAX1403.HLP

Application program that runs under

Windows 95/98

MAX1403.EXE

DESCRIPTION

FILE

DESCRIPTION

FILE

DESCRIPTION

FILE

Source code module for driving the

MAX1403, provided for reference. Includes

definitions of the register names and low-

level access routines. Compiled with

Borland C++ 4.52. Maxim holds the copy-

right but allows customers to adapt the pro-

gram for their own use without charge.

MAX1403.CPP

8) When the software successfully establishes commu-

nication with the EV kit board, you will see a configu-

ration tool and some other windows. Verify that the

CLKIN and Reference Voltage settings are correct.

Close or minimize this dialog box.

9) Apply input signals to the inputs labeled AIN1AIN5,

at the bottom edge of the MAX1403 EV kit board.

AIN6 is analog common. Observe the readout on

the screen.

Upgrading the 68HC11 Module

The MAX1403 EV kit requires Rev. 1.1 of the Maxim

68HC11 Module ROM. Check the label on device U10

on the module; if it says "Rev. 1.0," the device must be

replaced.

The Rev. 1.1 ROM is a 28-pin DIP that comes with the

EV kit. If it was omitted, contact the factory for a

replacement.

To install the new ROM, use the following procedure.

Use antistatic handling precautions. To reduce the risk

of ESD damage, gather all required materials and per-

form the installation at one sitting.

1) Slide the ON/OFF switch to the OFF position.

2) Using a flat-blade screwdriver, gently pry U10, the

REV 1.0 ROM, out of its socket.

3) Remove the REV 1.1 ROM from its antistatic pack-

aging.

4) Align the REV 1.1 ROM in the U10 socket pins.

Observe correct polarity (the notch at the top of the

ROM). Verify that the pins are lined up with the

socket, and gently press the ROM into place.

Proceed to the regular

Quick Start instructions.

Detailed Description

_________________________of Software

The MAX1403 digitizes up to seven inputs. The various

program functions are grouped into windows that are

accessible from the Show menu on the main menu bar.

Main Display

The main display shows the calculated input voltage

and raw A/D output code for each active channel.

Although there are nine input channels, only certain

configurations are allowed.

Select any single channel or one of the scanning

sequences from the Inputs menu. AIN 1-6 designates

an analog input between the AIN1 pin and the AIN6 pin.

CALOFF designates the signal between the CALOFF+

and CALOFF- pins. CALGAIN designates the signal

between the CALGAIN+ and CALGAIN- pins.

The EV kit software assumes that CALOFF+ and

CALOFF- are grounded so that CALOFF measures 0V.

Similarly, the software assumes that CALGAIN+ is con-

nected to REFIN+ and CALGAIN- is connected to

REFIN- so that CALGAIN measures the reference volt-

age. These two points calibrate the code-to-voltage

translation function performed in the software.

The MAX1403 automatically triggers its measurements,

unless the FSYNC control bit is set. The EV kit software

communicates with the MAX1403 at intervals deter-

mined by the Update Every combo box. To halt this

automatic update, uncheck the Update Every checkbox

or change the Update Every to a value between 100ms

and 60,000ms.

Normally, the microcontroller collects new data as soon

as it becomes available by using the INT pin to trigger

an interrupt service routine. If the INT pin is not used as

an interrupt, then the MAX1403 must not be operated in

free-running mode. Check or uncheck the Use INT

Interrupt checkbox to configure the evaluation kit soft-

ware.

Configuration Tool

The Configuration Tool controls parameters that apply

to the entire EV kit. Like the other windows, the

Configuration Tool can be activated from the Show

menu of the main menu bar. The CLK control should

match the external ceramic resonator or crystal that

sets the master clock frequency. The VREF Reference

Voltage control tells the software what the reference

voltage is. This is used to convert the raw A/D output

codes into the corresponding input voltage to speed

user evaluation. The Data-Rate control determines how

often the MAX1403 performs a measurement. Some

data rates provide 16-bit, noise-free resolution when

used with the SINC

3

filter (discussed below). The Filter

Sync control can be used to inhibit the MAX1403 from

performing its self-timed measurements. The Buffer

Inputs checkbox enables the internal input buffers. The

Burnout Test Currents checkbox enables two small

(0.1µA) current sources to provide an input stimulus.

When used with a transducer, these current sources

can be used to verify that the transducer has not failed

open or short circuit.

At the bottom of the window are input voltage-range

selection buttons. These buttons configure all input

channels for the same input voltage range. Although

the MAX1403 can be operated with three different input

ranges at the same time, the EV kit software supports

only a single range for all channels.

Evaluates: MAX1401/MAX1403

MAX1403 EV System

_______________________________________________________________________________________

3

Evaluates: MAX1401/MAX1403

The digital filter on the MAX1403 can be configured for

SINC

3

or SINC

1

operation, which affects the filter cutoff

frequency. (SINC

1

means SIN(X) ÷ X, and SINC

3

means

(SIN(X) ÷ X)

3

.) The SINC

3

filter is required for 16-bit accu-

racy. The SINC

1

filter provides faster settling time with less

accuracy. Alternatively, the raw modulator output can be

driven out the DOUT pin; however, the EV kit software

cannot read data from the MAX1403 in this mode.

Calibration Tool

The MAX1403 EV kit software can average the mea-

surements from the calibration channels and use the

measured values to correct the voltage displays. The

calibration algorithm assumes that the CALOFF inputs

are externally connected together and that the CAL-

GAIN inputs are externally connected to the reference

voltage (VREF). View the calibration tool by selecting it

from the Show menu.

The software automatically disables calibration if either

of the calibration channels reports a code of 0 or

262143. This is to prevent erroneous calibration when

using a transfer function that does not include both 0V

and VREF.

When Use CALOFF and CALGAIN for Calibration is

checked, the software averages the raw A/D codes for

the CALOFF and CALGAIN channels. The average is

calculated as a weighted sum of the new data and the

old average value. The Slower/Faster slide bar controls

the weight of the new data vs. the weight of the old

average.

The EV kit software assumes that all three transfer func-

tion registers are set to the same value.

This calibration affects only the displayed voltage, not

the raw code numbers. The average CALOFF and

CALGAIN code values are used as the endpoints of a

linear interpolation, with CALOFF measuring 0V and

CALGAIN measuring VREF.

The linear interpolation formula is as follows:

Note:

When using the calibration tool with the

MAX1403 in buffered mode, CALOFF+ and CALOFF-

should be disconnected from GND and connected

instead to REFIN+ so that they remain within the speci-

fied input range.

Sampling Tool

To sample data at full speed, select Sample from the

main display menu, make your selections, and click on

the Begin Sampling button. Sampling rate is controlled

by the Configuration tool. Sample size is restricted to a

power of two. Sample Size controls the number of sam-

ples collected on each selected channel. After the

samples have been collected, the data is automatically

uploaded to the host and is graphed. Once displayed,

the data may be saved to a file.

While the Sampling tool is open, the other windows are

locked out. Close the Sampling tool by clicking the

Close icon in the upper corner.

Register Display Tool

This tool displays all of the internal registers of the

MAX1403. Modify any bit value by checking or

unchecking its box. (The START bit and the zero bits in

the Special Function register (SFR) cannot be modi-

fied). The Read All Registers button causes the soft-

ware to read all of the MAX1403's registers. (Not func-

tional when the MDOUT or FULLPD bit is set.) Refer to

Table 1 for a guide to register bit functions.

Communications Register (COMMS)

Setting the FSYNC control bit inhibits the MAX1403

from performing its self-timed measurements. If

FSYNC = 1 when it is time to perform a measurement,

the MAX1403 simply skips that measurement. Thus,

power-line frequency rejection is not affected by the

FSYNC bit.

Setting the STDBY bit places the part in low-power

standby mode. The serial interface and the CLK oscilla-

tor continue to operate. The part can be restored to

normal operation by clearing the STDBY bit.

Special Function Register (SFR)

Setting the MDOUT bit makes the raw modulator output

available on the DOUT pin; however, the EV kit software

cannot read data from the MAX1403 in this mode.

Setting the FULLPD bit in the SFR register places the

part in full power-down mode. The master oscillator

does not run. To restore normal operation, click on the

Reset menu item in the main display. This causes the

68HC11 software to pulse the MAX1403 RESET pin.

Transfer Function Registers (TF1, TF2, TF3)

The three transfer function registers (TF1, TF2, TF3) con-

trol how input voltage is mapped to code values. The

transfer function registers control a programmable-gain

amplifier (PGA) and an offset-correction DAC.

If U/B = 1, the transfer function maps unipolar voltages

between 0V and VREF. If U/B = 0, then the transfer

function maps bipolar voltages between -VREF and

+VREF. Next, the PGA increases the code-per-volt pro-

Voltage

VREF Code CALOFFcode

CALGAINcode CALOFFcode PGAgain

=

-

-

(

)

(

)

MAX1403 EV System

4

_______________________________________________________________________________________

cessing gain, reducing the full-scale voltage range by a

factor of 1, 2, 4, 8, 16, 32, 64, or 128. Finally, the offset-

correction DAC offsets the voltage range by up to ±7/6

of the full-scale voltage range.

Input pins AIN1 and AIN2 are controlled by TF1. Input

pins AIN3 and AIN4 are controlled by TF2. Input pin

AIN5 is controlled by TF3. Input pin AIN6 is the analog

common.

When SCAN = 1, the CALOFF and CALGAIN channels

are controlled by TF3. When SCAN = 0, the CALOFF

and CALGAIN channels are controlled by one of the

transfer function registers, as selected by the A1 and

A0 bits.

For simplicity, the EV kit software assumes that all three

transfer functions are configured alike.

Detailed Description

________________________of Hardware

U1, the MAX1403, is a multichannel, high-resolution

A/D converter (refer to the MAX1403 data sheet). U2,

the MAX6520, is a 1.2V reference (refer to the

MAX6520 data sheet). Y1 contains a ceramic resonator

and its load capacitors. R1R6, together with C3C8,

form anti-aliasing input filters. R8 and C11 filter the digi-

tal power supply. The analog supply comes through fil-

ter R7/C10.

Input Filtering

The EV kit has an RC filter on each input with a time

constant of approximately 0.01µs = 10ns (R = 100

,

C = 100pF). When scanning between channels, the RC

filter's settling time may increase the acquisition time

required for full accuracy.

Evaluating the MAX1401

The MAX1401 can be evaluated by shorting across

jumpers JU6 and JU7. The MAX1401 is exactly like the

MAX1403, except that the function of pins 5, 6, 7, and 8

is changed. Instead of the OUT1/OUT2 outputs and

DS0/DS1 inputs, these pins are used to provide access

to the analog signal between the multiplexer and the

A/D converter. Tables 2 and 3 list the jumper functions

and default settings. Refer to the MAX1401 data sheet

for detailed information.

Measuring Supply Current

Supply current can be estimated by measuring the volt-

age across a series resistor. On the EV kit board, the

MAX1403 draws all of its analog and digital power

through R8, which is 10

. In addition, all analog supply

current flows through R7, which is also 10

.

Troubleshooting

Problem:

unacceptable amounts of noise in the signal.

Collect a sample of 1024 measurements at a 60Hz data

rate. Observe whether the problem is caused by 60Hz

noise.

Any AC-powered equipment connected to the analog

signal ground can inject noise. Try replacing AC-pow-

ered DVMs with battery-powered DVMs.

Evaluates: MAX1401/MAX1403

MAX1403 EV System

_______________________________________________________________________________________

5