Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

page 1

IRPT205

Revised 5/97

PD 6.073C

TM

Integrated Power Stage for 3 hp Motor Drives

IRPT2051

PRELIMINARY

· 3 hp (2.2kW) motor drive

Industrial rating at 150% overload for 1 minute

· 380 - 480V AC, 50/60Hz

· Available as complete system or sub-system assemblies

Power Module

· 3-phase rectifier bridge

· 3-phase, short circuit rated, ultrafast IGBT inverter

· Brake IGBT and diode

· Low inductance (current sense) shunts in positive and

negative DC rail

· NTC temperature sensor

· Pin-to-base plate isolation 2500V rms

· Easy-to-mount two-screw package

· Case temp. range -25° deg C to 125 deg C operational

Driver-

Plus Board

· DC bus capacitor filter with NTC inrush current limiter

· IR2233 monolithic 3-phase HVIC driver

· Driver stage for brake transistor

· On-board +15V and +5V power supply

· MOV surge suppression at input

· DC bus voltage and current feedback

· Protection for short-circuit, earth/ground fault,

overtemperature and overvoltage

· Terminal blocks for 3-phase input/output and brake

connections

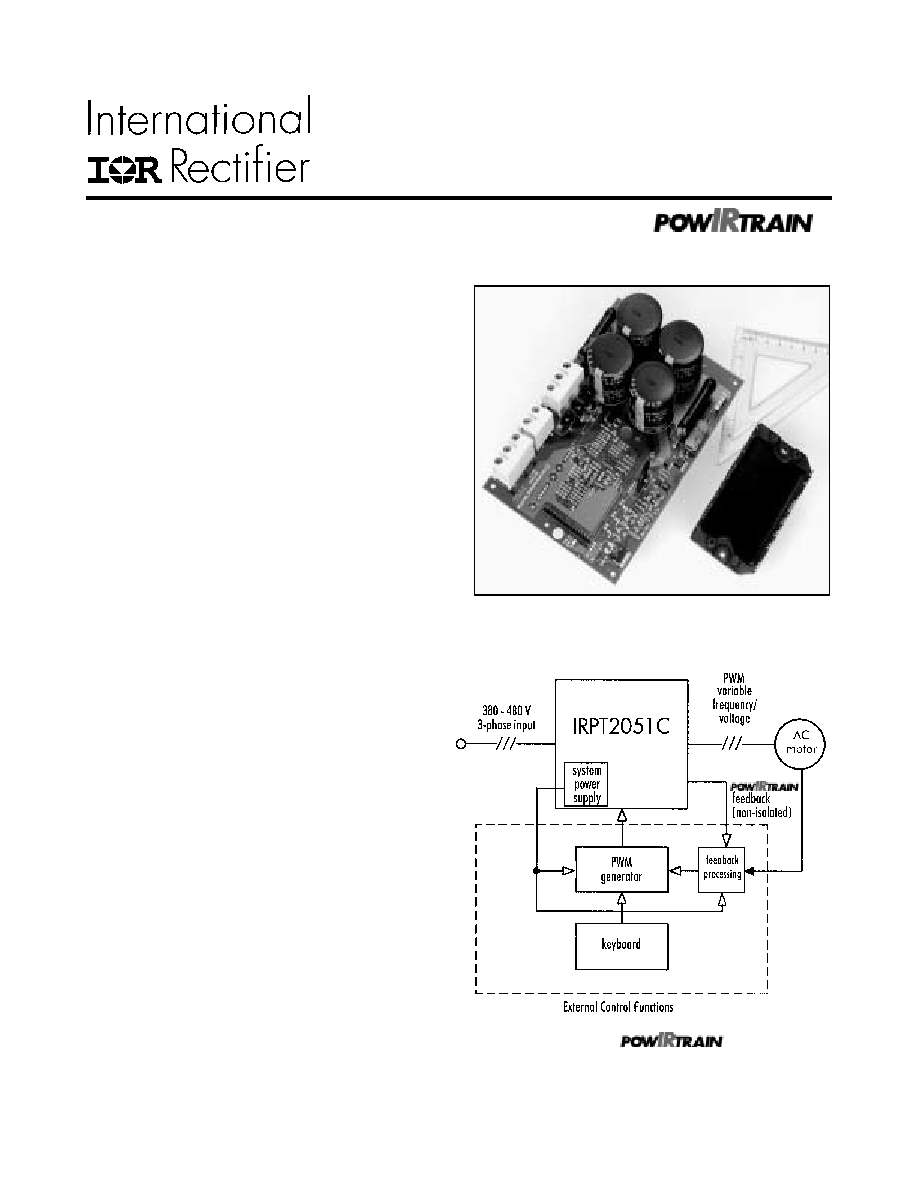

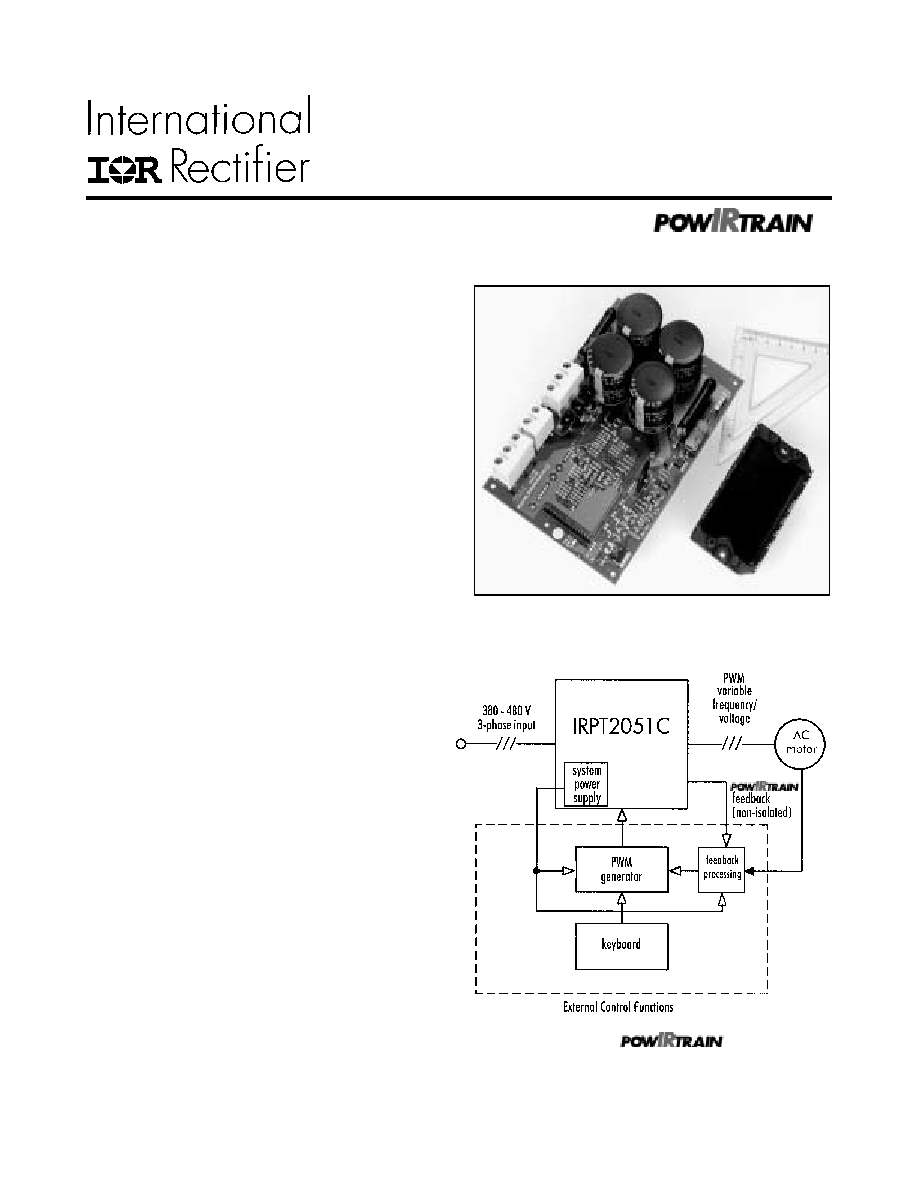

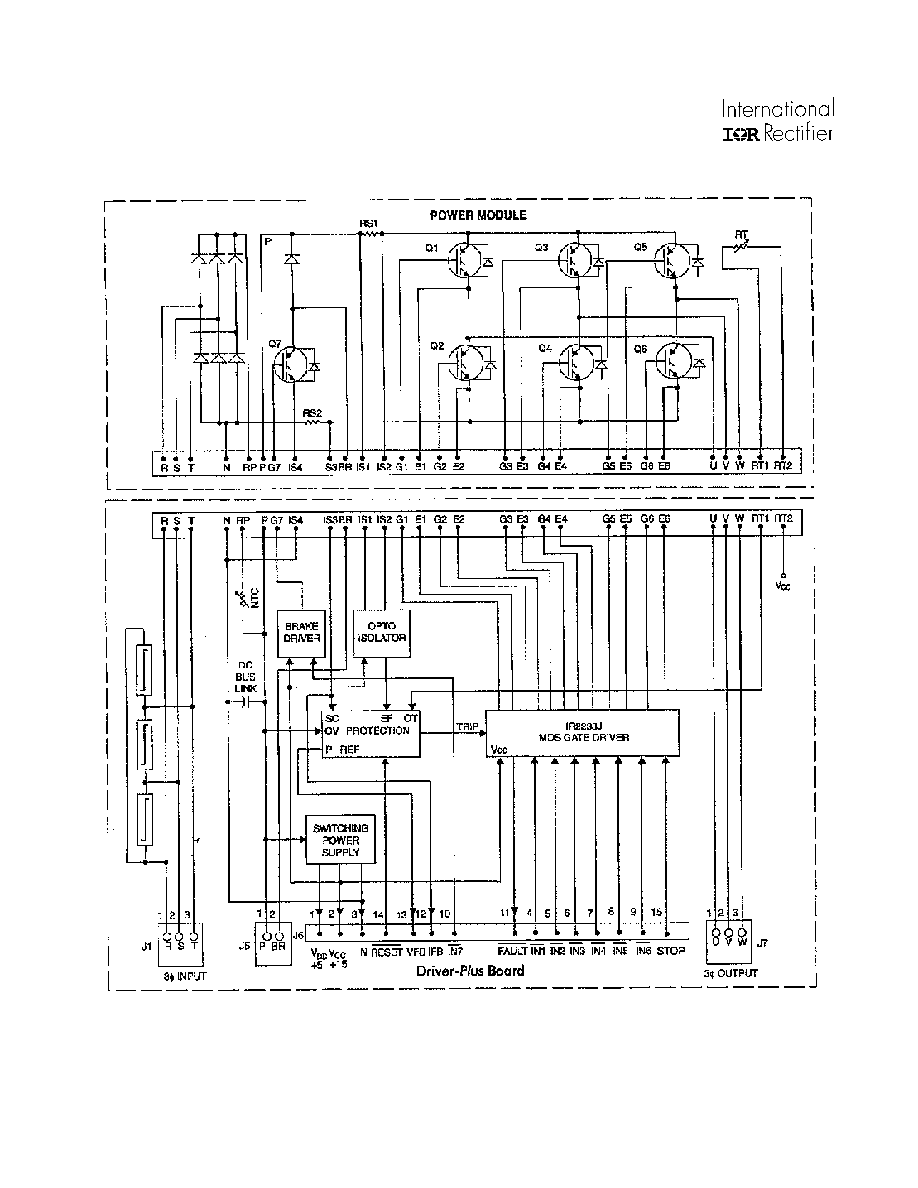

Figure 1. The IRPT2051C

within a motor

control system

page 2

IRPT2051

System Description

The IRPT2051C

provides the complete

power conversion function for a 3hp (2.2kW) variable-frequency,

variable-voltage, AC motor controller. The

combines a power assembly IRPT2051A with a Driver-Plus

Board IRPT2051D. Figure 1 shows the block diagram of the

within an AC motor control system.

The power module contains a 3-phase input bridge rectifier, 3-

phase IGBT and diode, 3-phase IGBT inverter, current sense

shunts, and a thermistor. It is designed for easy mounting to a

heat sink.

The Driver-Plus Board contains DC link capacitors, capacitor

soft charge function using NTC thermistor, surge suppression

MOVs, IGBT gate drivers, DC bus voltage and current feedback

signals, protection circuitry and local power supply. It is de-

signed to mate with a controller board through a single row

header. Terminal blocks are also provided on the Driver-Plus

Board for all end-user line input, motor output, and brake resis-

tor.

Output power is Pulse-Width Modulated (PWM), 3-phase,

variable-frequency, variable voltage controlled by an externally-

generated user-provided PWM controller for inverter IGBT

switching. The power supply offers the user non-isolated 5V and

15V to power the microcontroller.

The IRPT2051C offers several benefits to the drive manufac-

turer as listed below:

· It eliminates component selection, design layout, intercon-

nection, gate drive, local power supply, thermal sensing,

current sensing, and protection.

· Gate drive and protection circuits are designed to closely

match the operating characteristics of the power semicon-

ductors. This allows power losses to be minimized and

power rating to be maximized to a greater extent than is

possible by designing with individual components.

· It reduces the effort of calculating and evaluating power

semiconductor losses and junction temperature.

· It reduces the manufacturer's part inventory and simplifies

assembly.

[

specifications and ratings are given for

system input and output voltage and current, power losses

and heat sink requirements over a range of operating con-

ditions.

system ratings are verified by IR

in final testing.]

The IRPT2051A Power Module

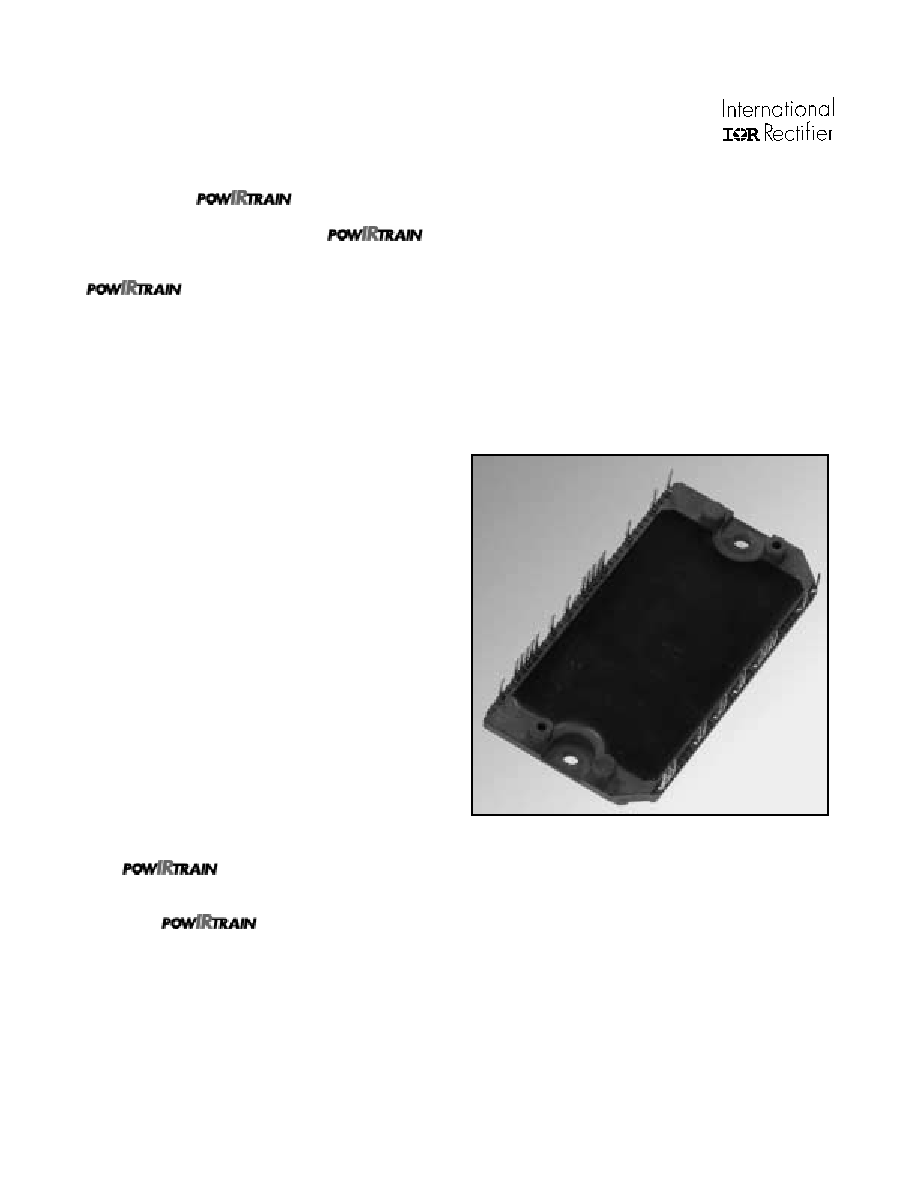

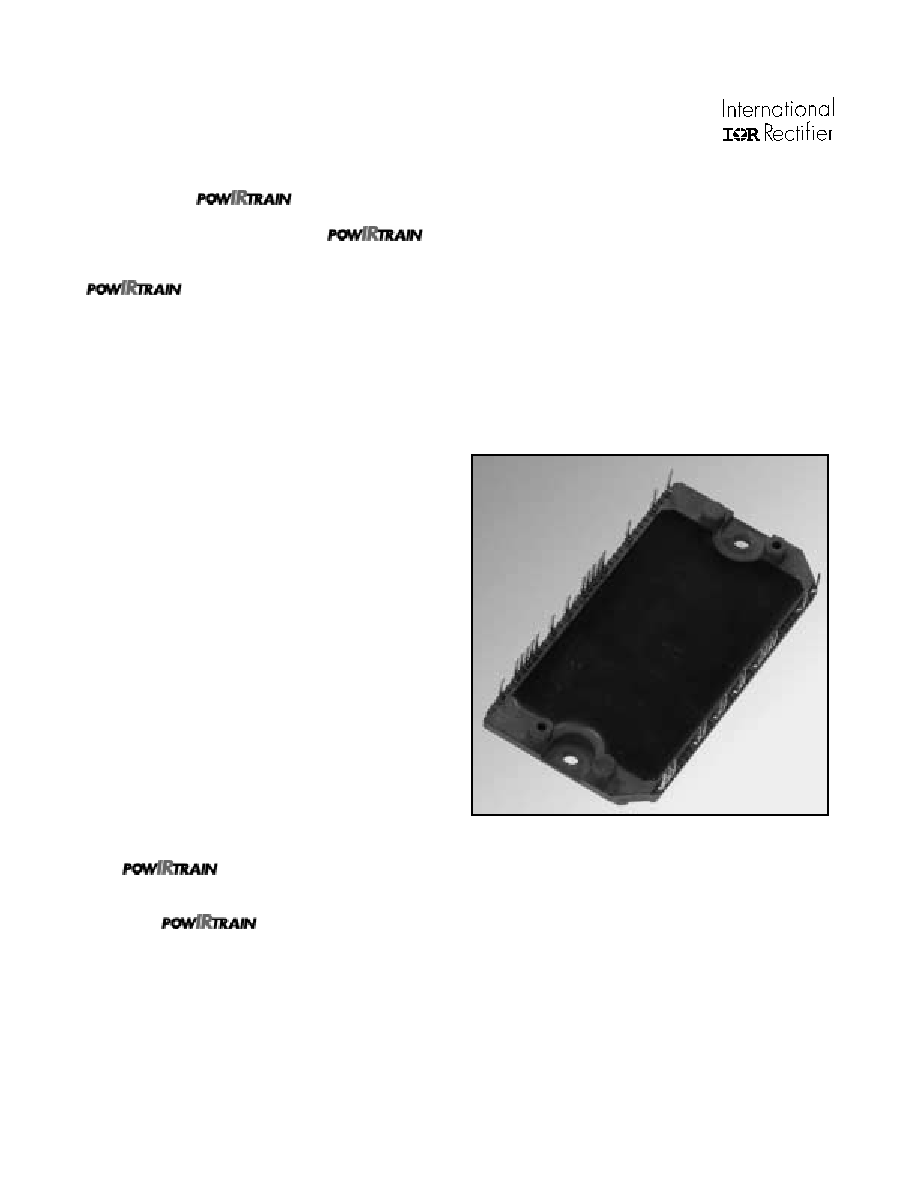

The IRPT2051A power module, shown in figure 2, is a chip

and wire epoxy-encapsulated module. It houses input rectifiers,

brake IGBT and freewheeling diode, output inverter, current

sense shunts and NTC thermistor. The 3-phase input bridge

rectifiers are rated at 1600V. The brake circuit uses 1200V

IGBT and free-wheeling diode. The inverter section employs

1200V, short circuit rates, ultrafast IGBTs and ultrafast free-

wheeling diodes. Current sensing is achieved through 25 m

low-inductance shunts provided in the positive and negative

DC bus rail. The NTC thermistor provides temperature sensing

capability. The lead spacing on the power modulemeets UL840

pollution level 3 requirements.

Figure 2. IRPT2051A Power Module

The power circuit and layout within the module are carefully

designed to minimize inductance in the power path, to reduce

noise during inverter operation and to improve the inverter effi-

ciency. The Driver-Plus Board required to run the inverter can

be soldered to the power module pins, thus minimizing assembly

and alignment. The power module is designed to be mounted to

a heat sink with two screw mount positions, in order to insure

good thermal contact between the module substrate and the heat

sink.

page 3

IRPT2051

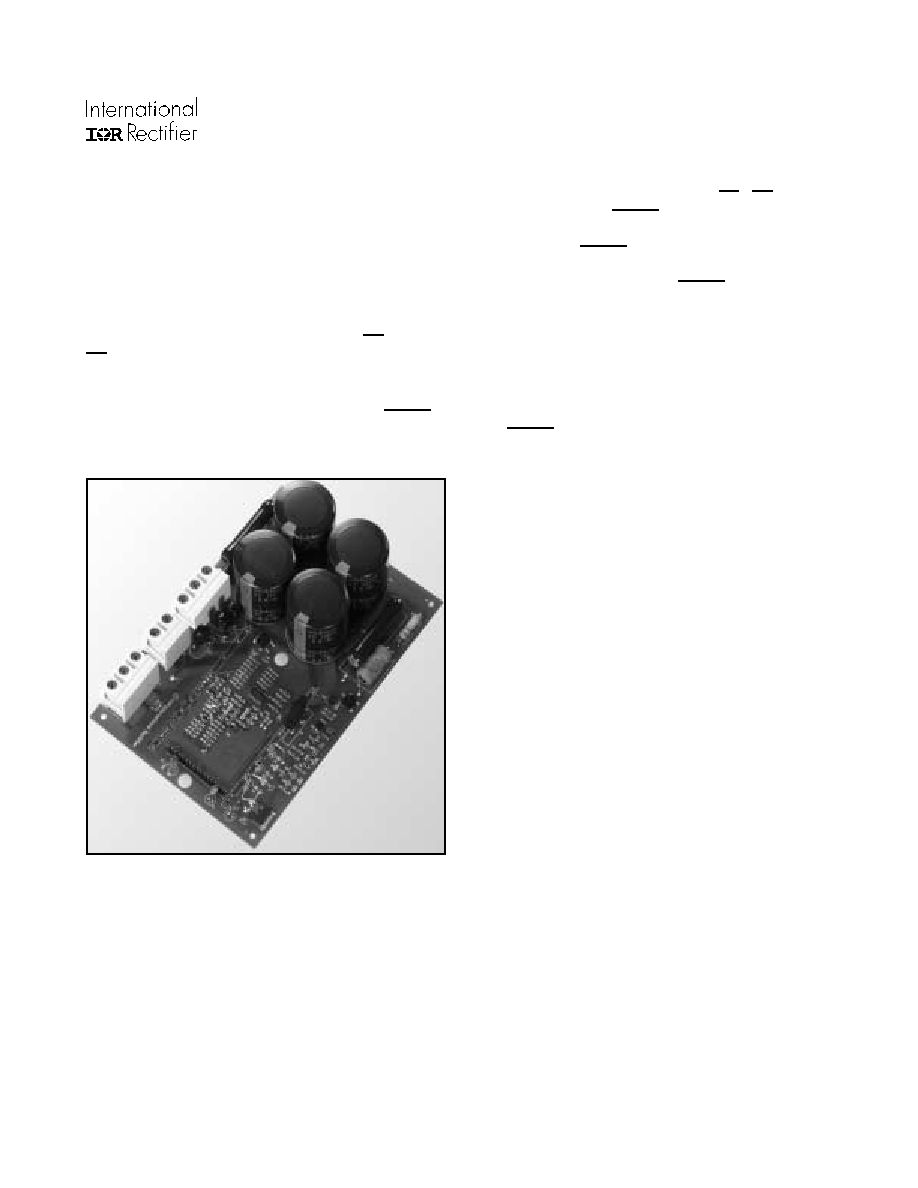

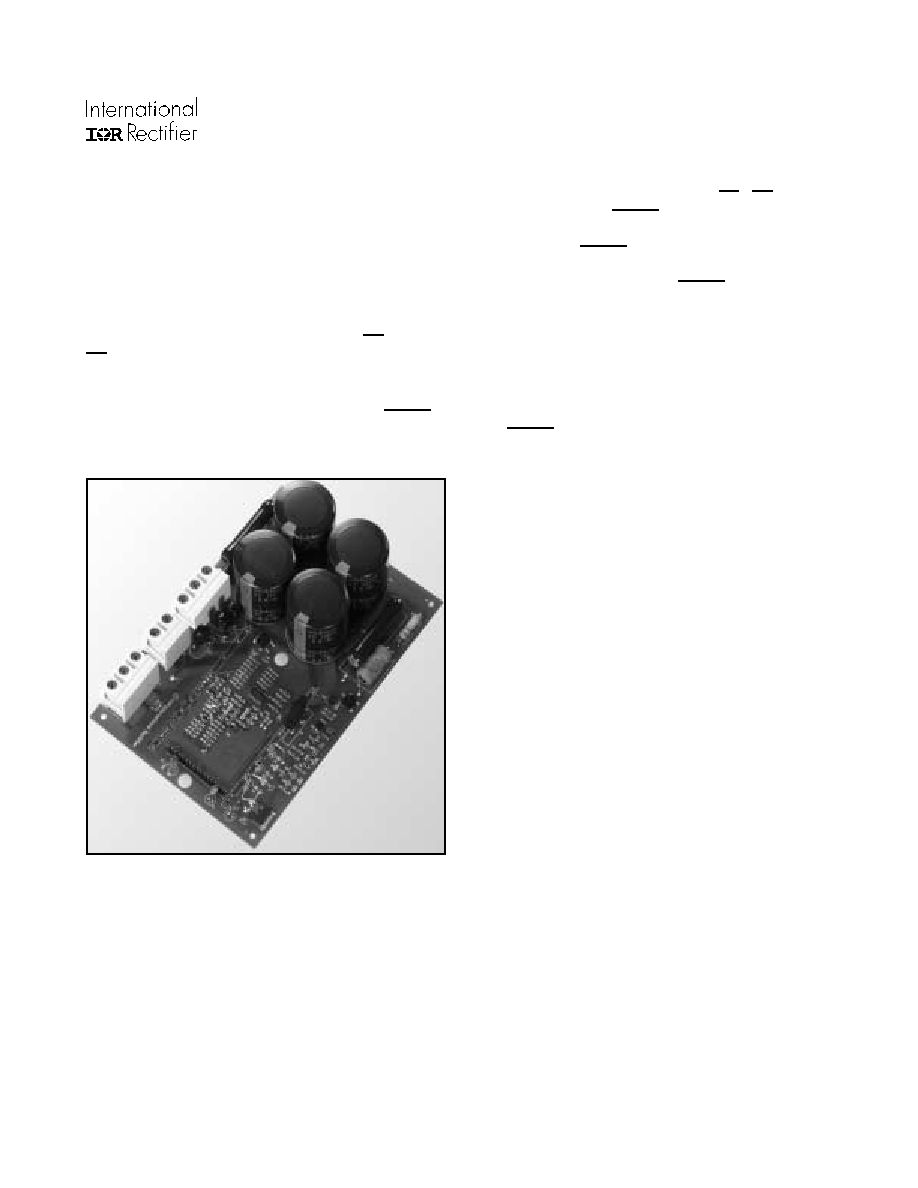

The IRPT2051D Driver-

Plus Board

The Driver-Plus Board, shown in figure 3, is the interface be-

tween the controller and the power stage. It contains the IGBT

gate drivers, protection circuitry, feedback, brake drive and local

power supply. The driver also interfaces to the AC input line. It

houses the DC link capacitors, NTC in-rush limiting thermistor,

and surge suppression MOVs.

The inverter gate drive circuits, implemented with an

IR2233 monolithic 3-phase HVIC driver, deliverrs gate drive to

the IGBTs corresponding to PWM control signals IN1 through

IN6. it introduces a 0.2 µsec dead time between upper and lower

gate signals for each phase. Any additional dead time necessary

tmust be included in the PWM signals. After a fault condition

all inverter gate drivers are disabled and latched. The FAULT

pin is also pulled low through an open drain which illuminates a

red LED. Gate drives must be enabled with an active low pulse

applied to the RESET pin while PWM inputs In1,...IN6 are held

high (off condition). The FAULT condition can also be set by

the controller through an active high signal on the STOP pin.

After power-up, the RESET pin must be pulled low before any

input signals are activated.

The protection circuitry will set a FAULT for short-circuit,

earth-fault, over-temperature, or over-voltage conditions as

specified. Current signals are sensed through shunts in positive

and negative DC bus rails. Earth faults are sensed using the

high-side shunt and the signal is fed through an opto-isolator to

the protection circuitry. Over-voltage is sensed through a resis-

tor divider from the positive DC bus. Over-temperature

protection is obtained using a thermistor inside the power mod-

ule. A FAULT condition occurs inf the temperature of the

power module's IMS substrate exceeds the trip level. The sys-

tem is designed for 150% overload for one minute while

operating with the specified heat sinks. The controller should

shut off the PWM signals if the overload persists for more than

one minute.

The feedback signals used by the protection circuitry are also

available to the controller. The current feedback signal from the

low-side shunt is available on the IFB pin at 0.025 V/A. If filter-

ing of this signal is required, it should be done by adding a

high-impedance buffer stage between signal and filter. The DC

bus reference is provided on VFB. This reference has been

scaled down by a factor of 100 and should also be protected with

a high-impedance buffer stage.

The brake function is implemented by connecting a power

resistor between the terminals on the Brake terminal block. The

value and power of theresistor determines maximum braking ca-

pability along with the rating of the brake IGBT. The input

signal on IN7 is active low and CMOS or LSTTL compatible.

The switching power supply employs an IR2152 self-oscil-

lating driver chip in a buck regulator topology to deliver a

nominal 15V and 5V DC with respect to the negative bus (N).

The power supply feeds the gate drive and protection circuits.

The 15V (V

CC

) and 5V (V

DD

) outputs are available on the con-

trol interface for powering the user's control logic.

Figure 3. IRPT2051D Driver-

Plus

Board

page 4

IRPT2051

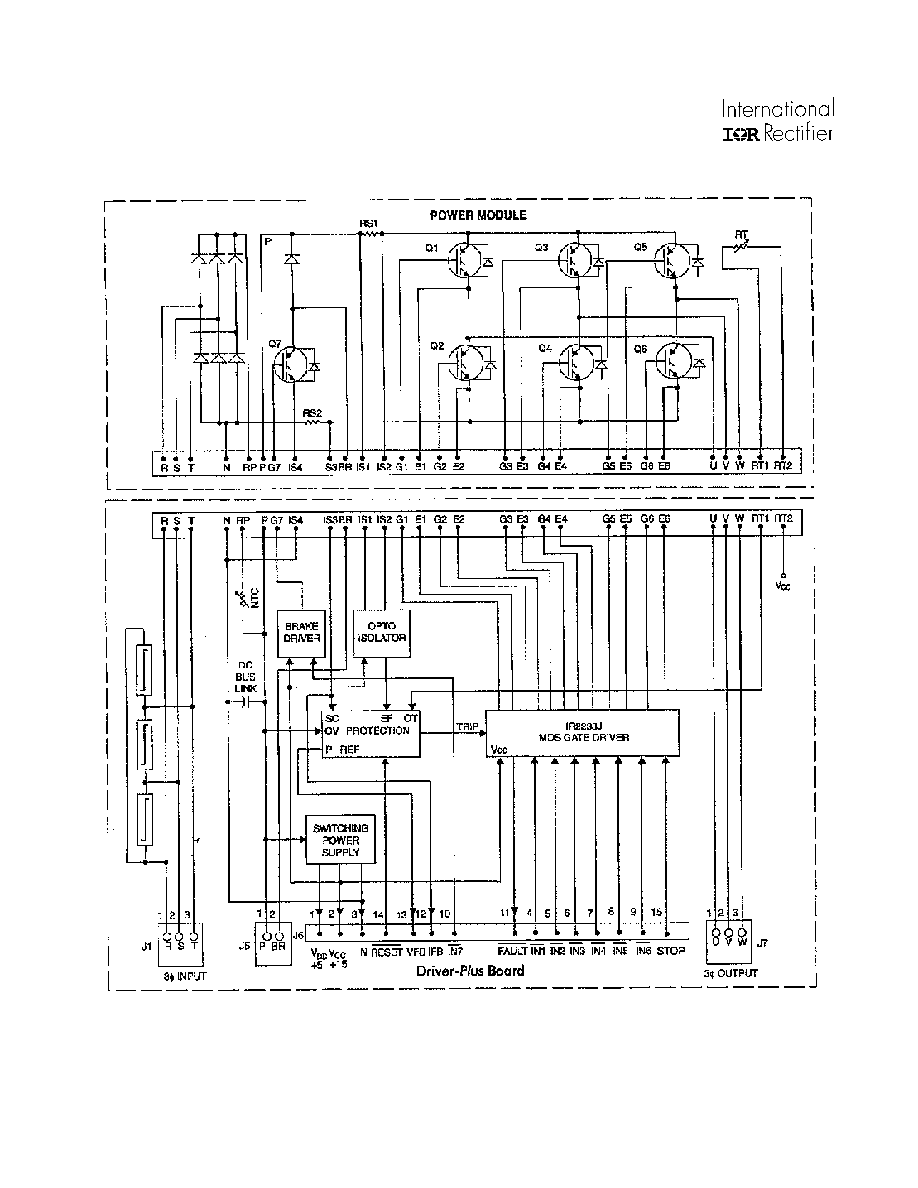

Figure 4. IRPT2051C Basic Architecture

page 5

IRPT2051

PARAMETERS VALUES CONDITIONS

Input Power

Voltage 380V, -15%, 480V +10%

Frequency 50 - 60Hz

Input current 8.26A rms @ nominal output T

A

= 40°C, R

thSA

= 0.59°C/W

125 A peak Initial bus capacitor charging

Output Power

Voltage 0 - 480V rms defined by external PWM control

Nominal motor hp (kW) 3hp (2.2 kW) nominal full load power R

thSA

= 0.59°C/W,

150% overload for 1 minute V

in

=460V AC, f

PWM

= 4kHz,

Nominal motor current 5.90A rms nominal full load current f

°

=60Hz, T

A

= 40°C,

8.85A rms 150% overload for 1 minute Z

thSA

limits ÐT

c

to 10°C during overload

Control Inputs

IN1...IN6, (PWM), IN7 (Brake), 5V maximum, active low CMOS, LSTTL compatible,

RESET open collector

STOP 5V maximum, active high CMOS or LSTTL compatible

Pulse deadtime 0.2

µ

sec typical, set by IR2233

maximum set by controller

Minimum input pulse width 1.0

µ

sec

Protection

Output current trip level 45A peak, ±10% T

C

= 25°C

Earth fault current trip level 50A, ±10% T

C

= 25°C

Overtemperature trip level 100°C, ±5% Case temperature

Overvoltage trip level 850V, ±10%

Maximum DC link voltage 760V user to ensure rating not exceeded >30 sec

Short circuit shutdown time 2.5

µ

sec typical

output terminals shorted

Feedback Signals

Current feedback (IFB) 0.025V/A

BUS

typical T

C

= 25°C

DC bus voltage feedback (VFB)

0.010V/V

BUS

typical T

C

= 25°C

Fault feedback (FAULT) 5V maximum, active low CMOS or LSTTL compatible

On Board Power Supply

V

CC

15V, ±10%

V

DD

5V, ±5%

I

CC

+ I

DD

60 mA available to user

B r a k e

Current 10.5A

Module

Isolation voltage 2500V rms pin-to-baseplate isolation, 60Hz, 1 min.

Operating case temperature -25°C to 125°C 95% RH max. (non-condensing)

Mounting torque 1 N-m M4 screw type

System Environment

Ambient operating temp. range 0 to 40°C 95% RH max. (non-condensing)

Storage temp.range -25 to 60°C

Specifications