Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

PD -2.467 rev. B 02/99

Reduced RFI and EMI

Reduced Snubbing

Extensive Characterization of

Recovery Parameters

Features

Description

HEXFRED

TM

diodes are optimized to reduce losses and EMI/RFI in high frequency

power conditioning systems. An extensive characterization of the recovery

behavior for different values of current, temperature and di/dt simplifies the

calculations of losses in the operating conditions. The softness of the recovery

eliminates the need for a snubber in most applications. These devices are ideally

suited for power converters, motors drives and other applications where

switching losses are significant portion of the total losses.

Ultrafast, Soft Recovery Diode

HEXFRED

TM

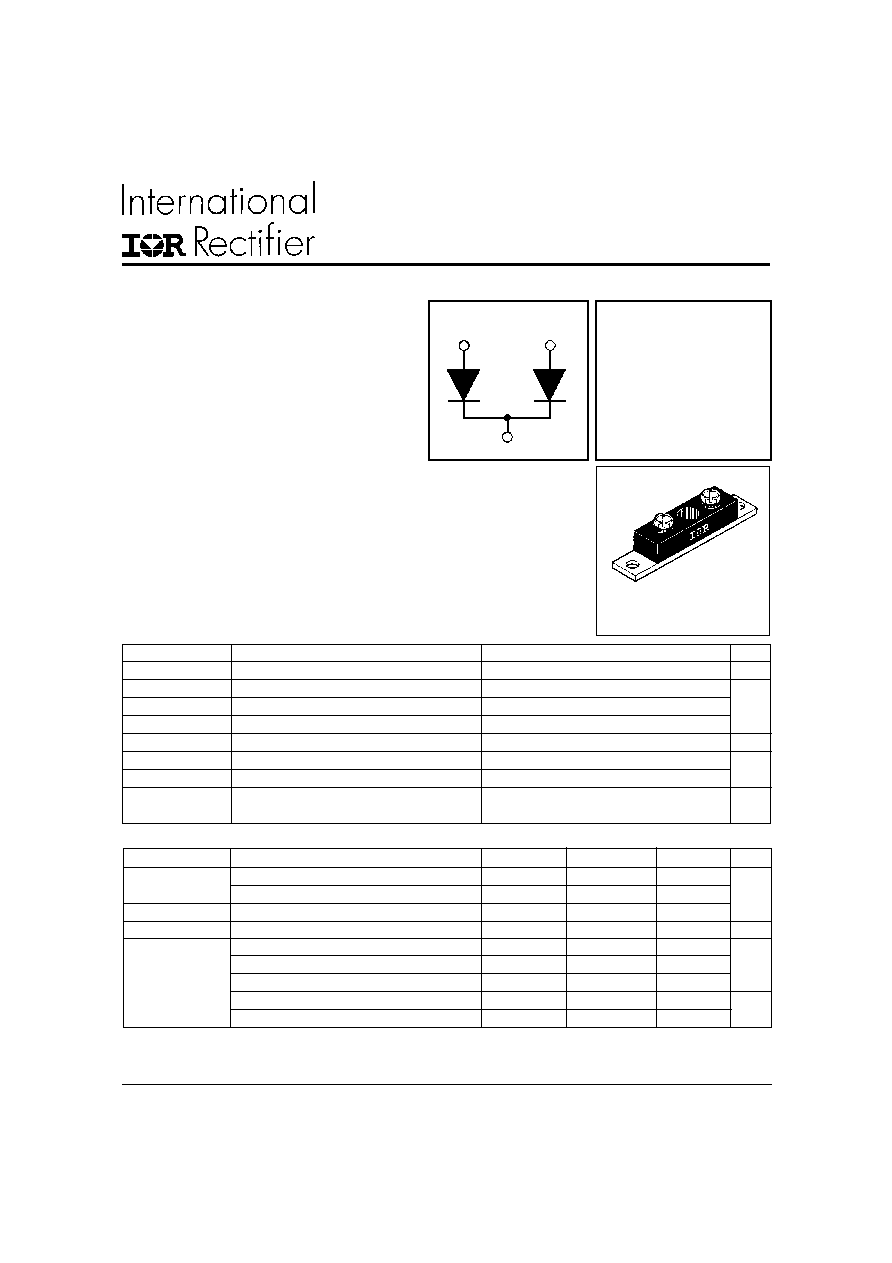

HFA160NJ40C

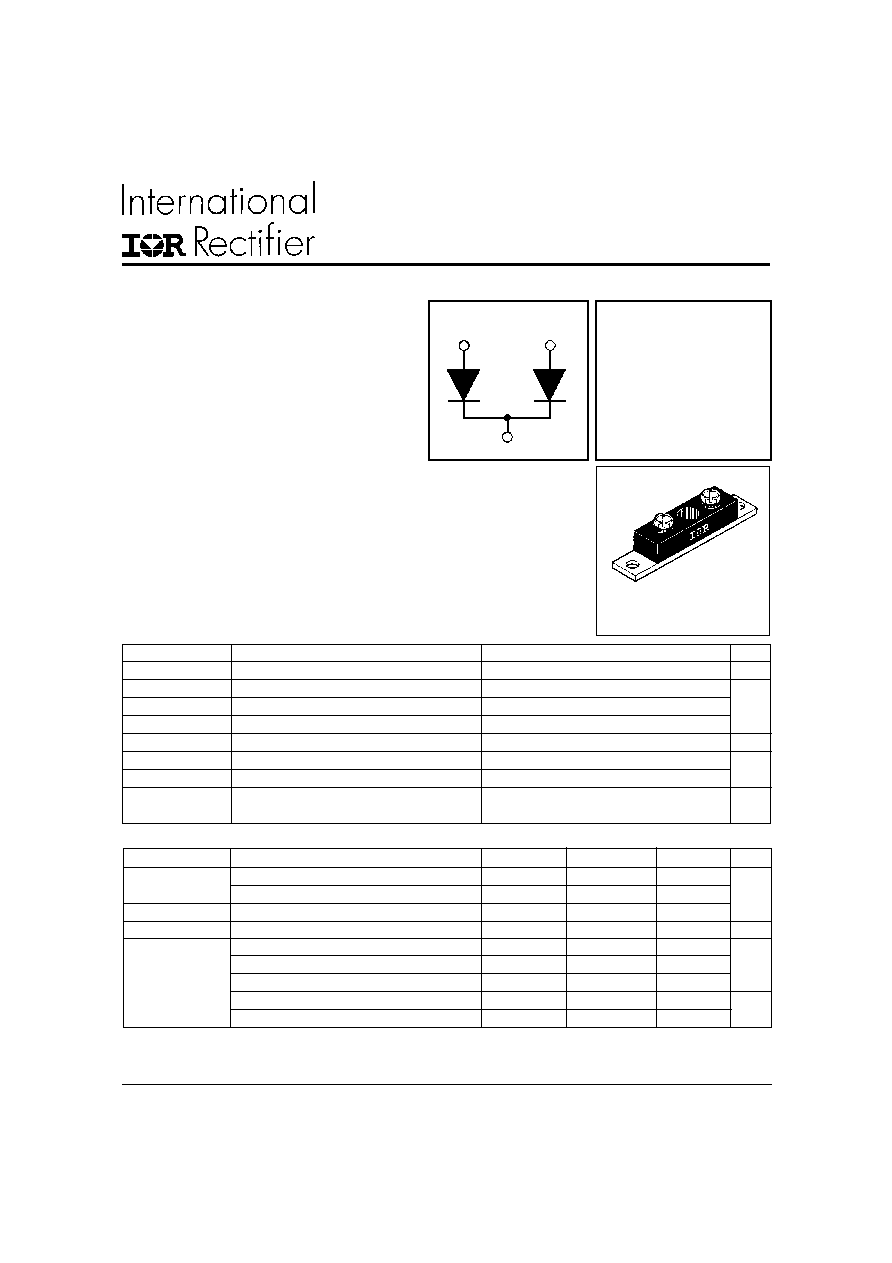

BASE COMMON CATHODE

LUG

TERMINAL

ANODE 1

LUG

TERMINAL

ANODE 2

V

R

= 400V

V

F

(typ.)

= 1V

I

F(AV)

= 160A

Q

rr

(typ.) = 420nC

I

RRM

(typ.)

= 9.3A

t

rr

(typ.)

= 36ns

di

(rec)M

/dt (typ.)

= 260A/µs

TO-244AB

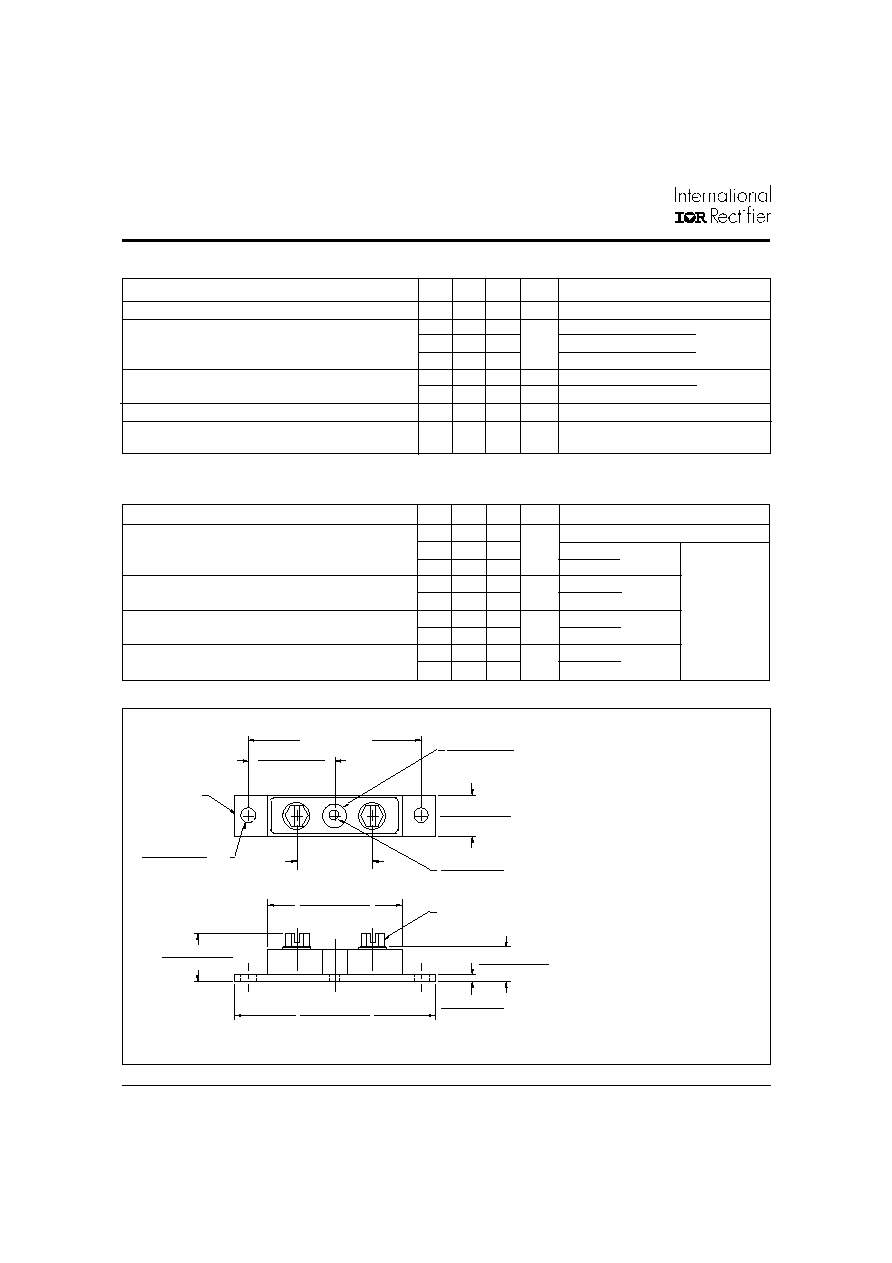

Thermal - Mechanical Characteristics

Absolute Maximum Ratings (per Leg)

lbfin

(Nm)

°C/W

K/W

Parameter

Min.

Typ.

Max.

Units

R

thJC

Junction-to-Case, Single Leg Conducting

0.48

Junction-to-Case, Both Legs Conducting

0.24

R

thCS

Case-to-Sink, Flat, Greased Surface

0.10

Wt

Weight

79 (2.8)

g (oz)

Mounting Torque

30 (3.4)

40 (4.6)

Mounting Torque Center Hole

12 (1.4)

18 (2.1)

Terminal Torque

30 (3.4)

40 (4.6)

Vertical Pull

80

2 inch Lever Pull

35

Parameter

Max.

Units

V

R

Cathode-to-Anode Voltage

400

V

I

F

@ T

C

= 25°C

Continuous Forward Current

170

I

F

@ T

C

= 100°C

Continuous Forward Current

84

I

FSM

Single Pulse Forward Current

600

E

AS

Non-Repetitive Avalanche Energy

1.4

mJ

P

D

@ T

C

= 25°C

Maximum Power Dissipation

310

P

D

@ T

C

= 100°C

Maximum Power Dissipation

125

T

J

Operating Junction and

T

STG

Storage Temperature Range

-55 to +150

W

A

C

lbfin

Note: Limited by junction temperature

Mounting surface must be smooth, flat, free or burrs or other

L = 100µH, duty cycle limited by max T

J

protrusions. Apply a thin even film or thermal grease to mounting

125°C

surface. Gradually tighten each mounting bolt in 5-10 lbfin steps

until desired or maximum torque limits are reached. Module

1

HFA160NJ40C

PD-2.467 rev. B 02/99

2

Electrical Characteristics (per Leg) @ T

J

= 25°C (unless otherwise specified)

Dynamic Recovery Characteristics (per Leg) @ T

J

= 25°C (unless otherwise specified)

A/µs

nC

A

L

S

Series Inductance

7.0

nH

See Fig. 2

Parameter

Min. Typ. Max. Units Test Conditions

t

rr

Reverse Recovery Time

36

I

F

= 1.0A, di

f

/dt = 200A/µs, V

R

= 30V

t

rr1

90

140

ns

T

J

= 25°C See Fig.

t

rr2

160 240

T

J

= 125°C 5

I

F

= 80A

I

RRM1

Peak Recovery Current

9.3

17

T

J

= 25°C See Fig.

I

RRM2

15

30

T

J

= 125°C 6

V

R

= 200V

Q

rr1

Reverse Recovery Charge

420 1100

T

J

= 25°C See Fig.

Q

rr2

1200 3200

T

J

= 125°C 7

di

f

/dt = 200A/µs

di

(rec)M

/dt1

Peak Rate of Fall of Recovery Current

360

T

J

= 25°C See Fig.

di

(rec)M

/dt2

During t

b

260

T

J

= 125°C 8

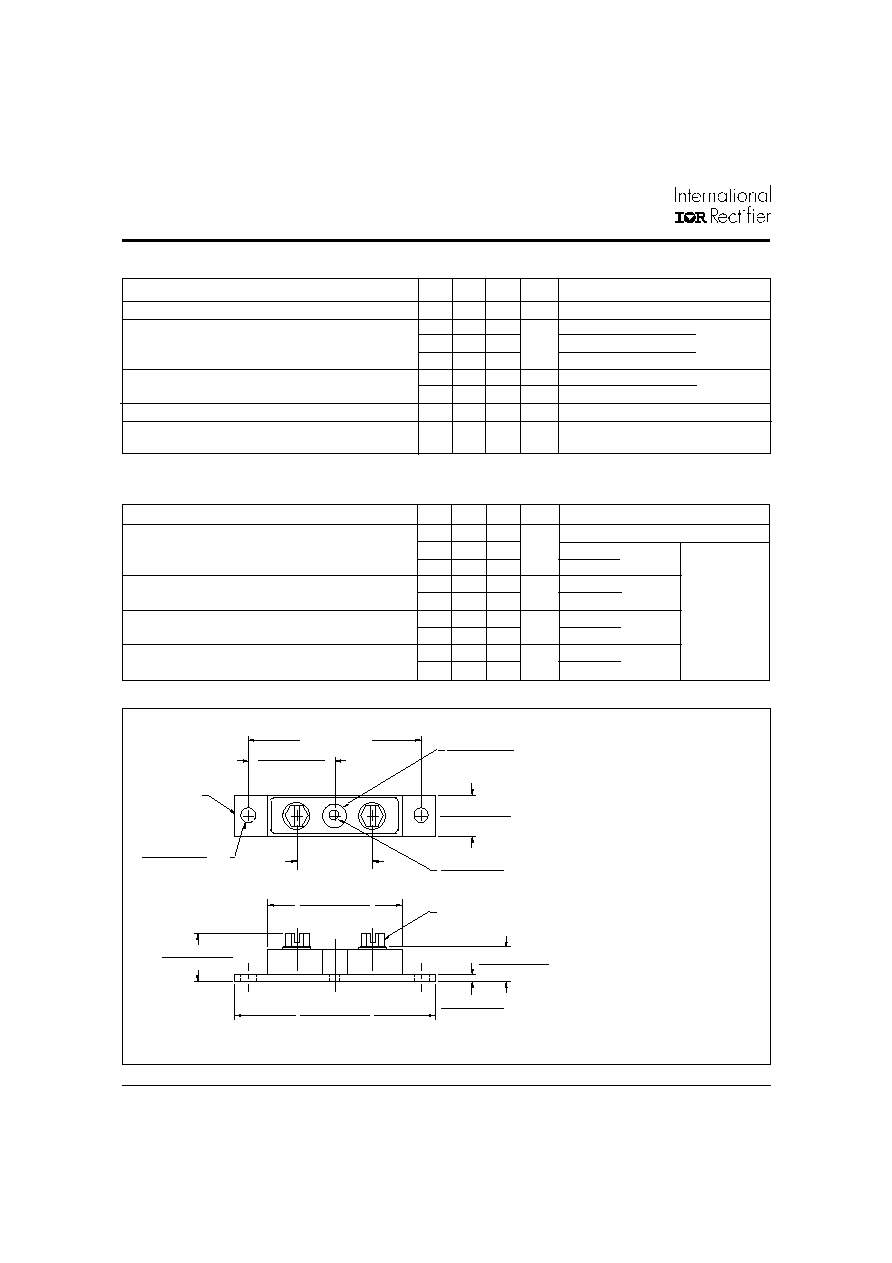

63.50 (2.500)

60.96 (2.400)

23.55 (0.927)

20.42 (0.804)

14.99 (0.590)

15.75 (0.620)

20.32 (0.800)

17.78 (0.700)

39.75 (1.565)

40.26 (1.585)

80.01 (3.150)

34.925 (1.375)

3.35 (0.132)

3.02 (0.119)

90.17 (3.550)

92.71 (3.650)

DIA.

7.49 (0.295)

6.99 (0.275)

(2 PLCS.)

10.41 (0.410)

9.65 (0.380)

DIA.

DIA.

4.70 (0.185)

4.95 (0.195)

1/4-20 SLOTTED HEX

REF.

Dimensions in Millimeters and (Inches)

CONFORMS TO JEDEC

OUTLINE TO-244AB

1

2

3

LEAD ASSIGNMENTS

1 - ANODE

2 - CATHODE

3 - ANODE

Parameter

Min. Typ. Max. Units

Test Conditions

V

BR

Cathode Anode Breakdown Voltage

400

V

I

R

= 100µA

V

FM

Max Forward Voltage

1.1

1.3

I

F

= 80A

1.3

1.5

V

I

F

= 160A

See Fig. 1

1.0

1.2

I

F

= 80A, T

J

= 125°C

I

RM

Max Reverse Leakage Current

1.0

6.0

µA

V

R

= V

R

Rated

1.5

8.0

mA

T

J

= 125°C, V

R

= 320V

C

T

Junction Capacitance

180 260

pF

V

R

= 200V

See Fig. 3

From top of terminal hole to mounting

plane

HFA160NJ40C

PD-2.467 rev. B 02/99

3

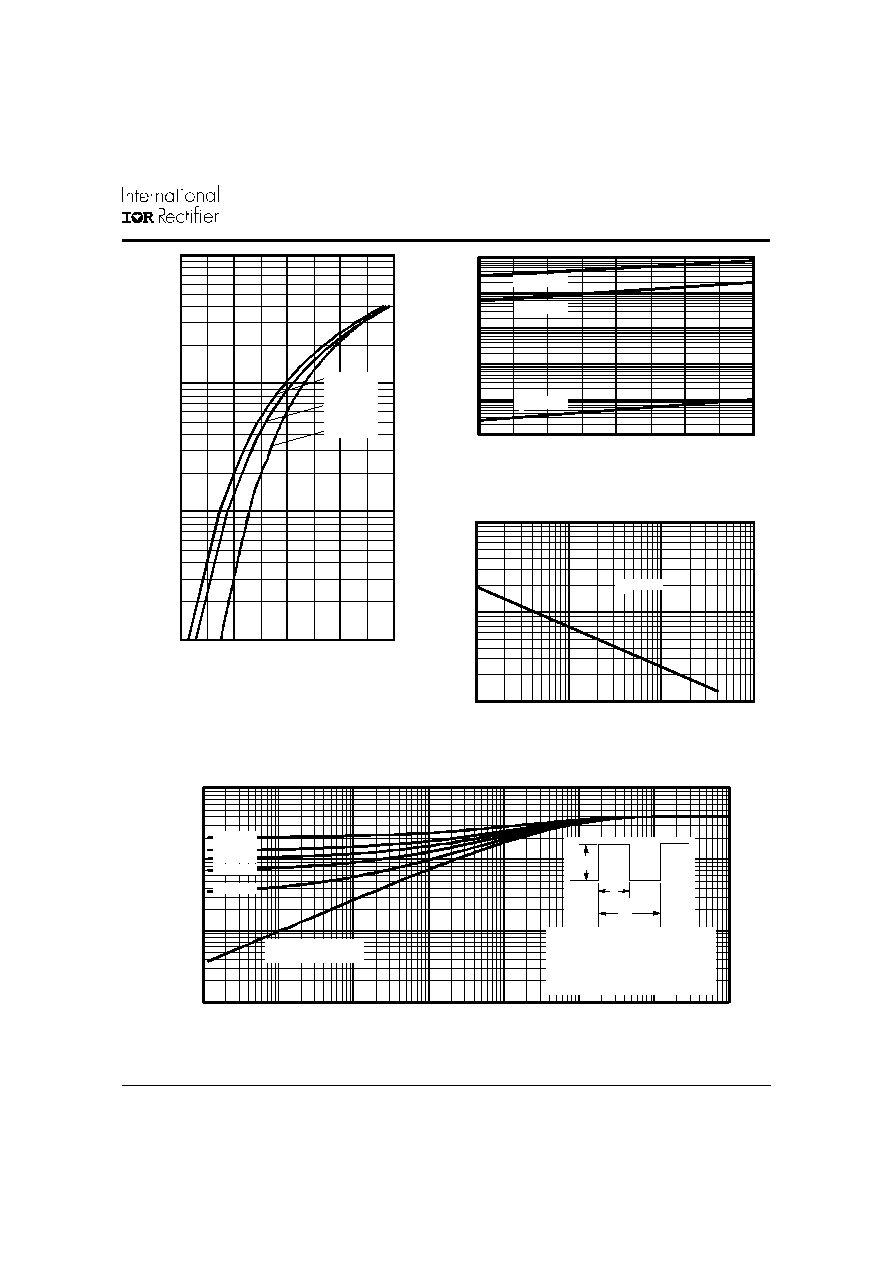

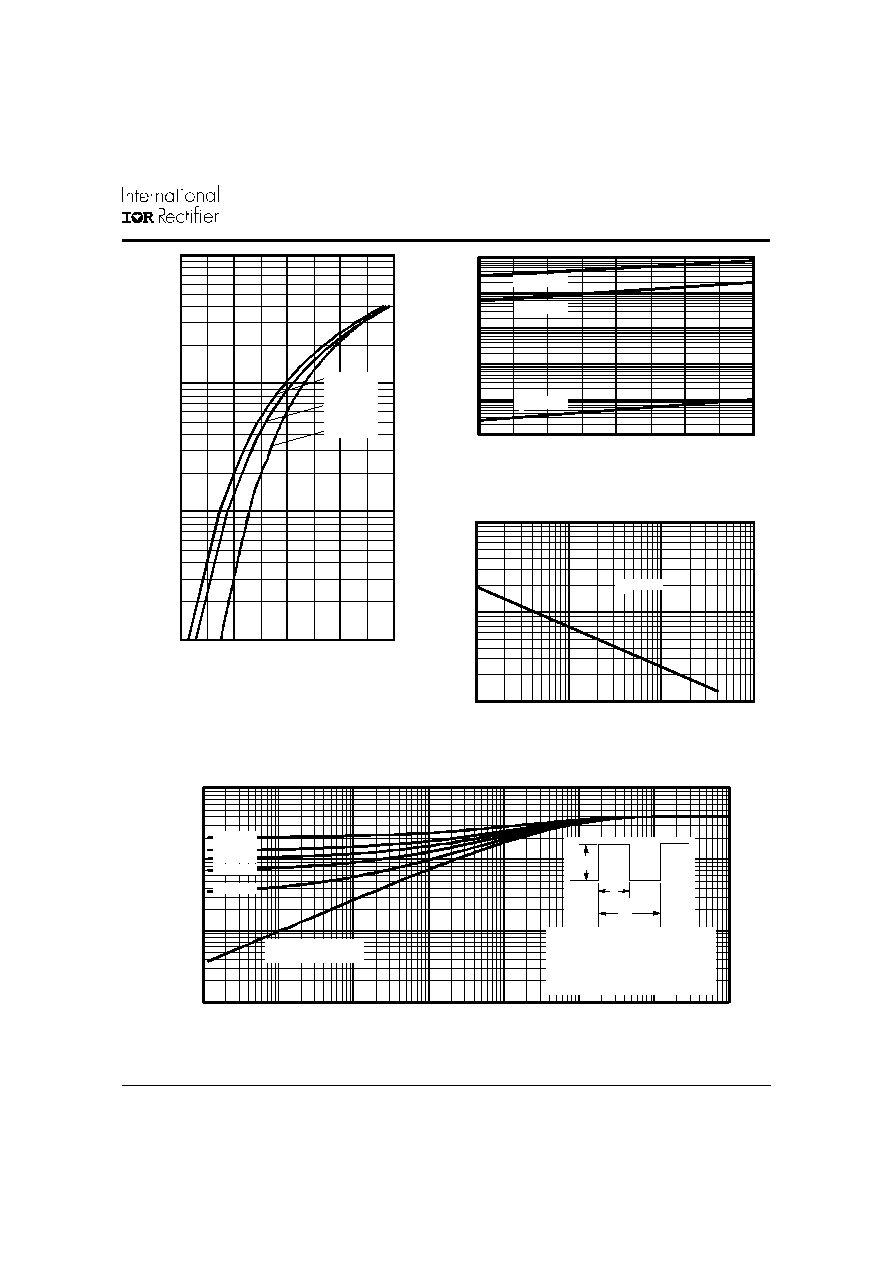

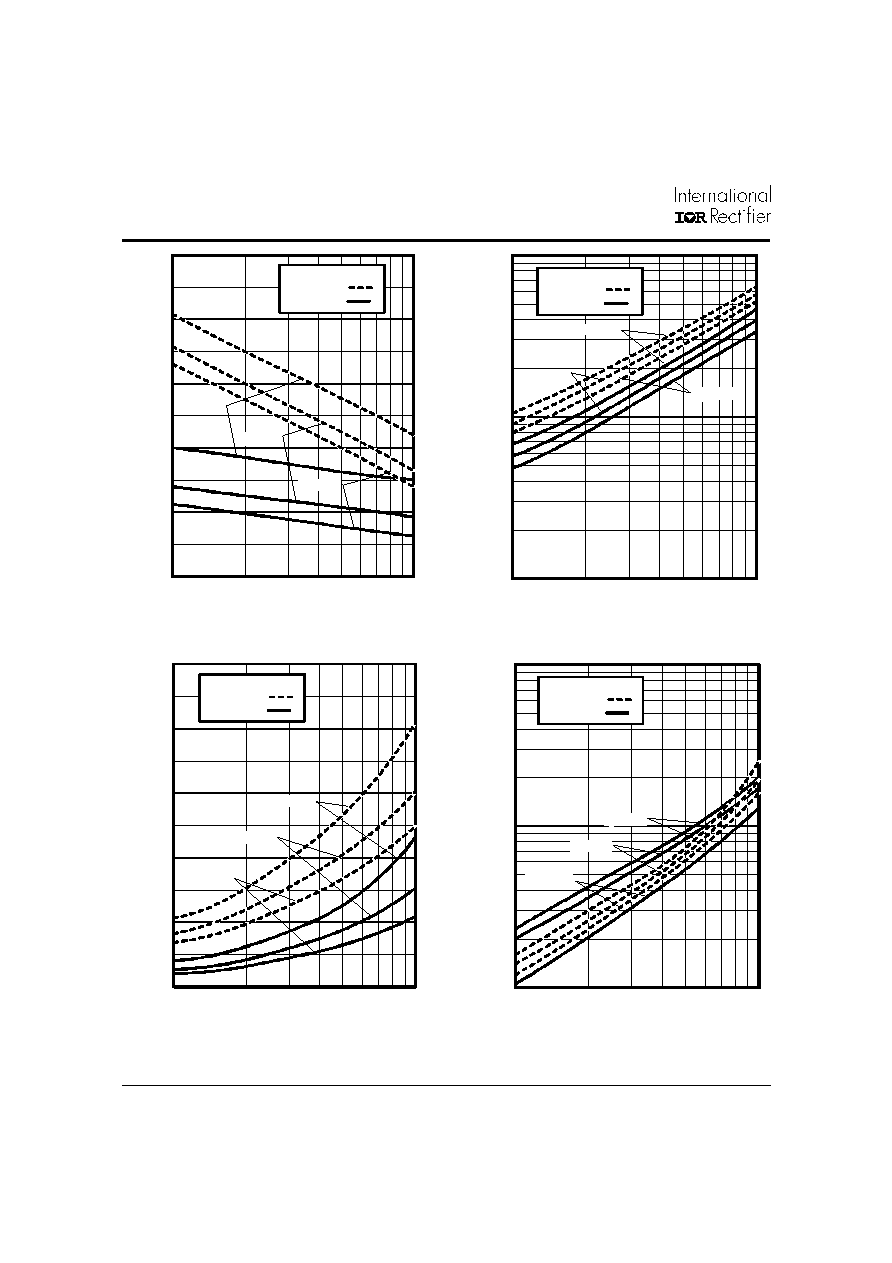

Fig. 4 - Maximum Thermal Impedance Z

thJC

Characteristics, (per Leg)

Fig. 2 - Typical Reverse Current vs. Reverse

Voltage, (per Leg)

Fig. 3 - Typical Junction Capacitance vs.

Reverse Voltage, (per Leg)

Fig. 1 - Maximum Forward Voltage Drop

vs. Instantaneous Forward Current,

(per Leg)

0.1

1

10

100

1000

10000

0

100

200

300

400

R

R

Reverse Voltage - V (V)

T = 150°C

Reverse Cu

rrent -

I (

µA)

T = 125°C

T = 25°C

J

J

J

1

10

100

1000

0.4

0.8

1.2

1.6

2.0

FM

F

Ins

tant

aneo

us F

orward

Curre

nt - I

(A)

Forward Voltage Drop - V (V)

T = 150°C

T = 125°C

T = 25°C

J

J

J

100

1000

10000

1

10

100

1000

T = 25°C

J

Reverse Voltage - V (V)

R

T

Ju

nction

Capacit

ance - C

(pF)

A

0.001

0.01

0.1

1

0.00001

0.0001

0.001

0.01

0.1

1

10

100

1

th

J

C

t , Rectangular Pulse Duration (Seconds)

D = 0.50

D = 0.33

D = 0.25

D = 0.17

D = 0.08

Single Pulse

(Thermal Resistance)

T

her

m

a

l

I

m

pe

danc

e -

Z

(

K

/

W

)

2

t

1

t

P

DM

Notes:

1. Duty factor D = t / t

2. Peak T = P x Z + T

J

DM

thJC

C

2

1

HFA160NJ40C

PD-2.467 rev. B 02/99

4

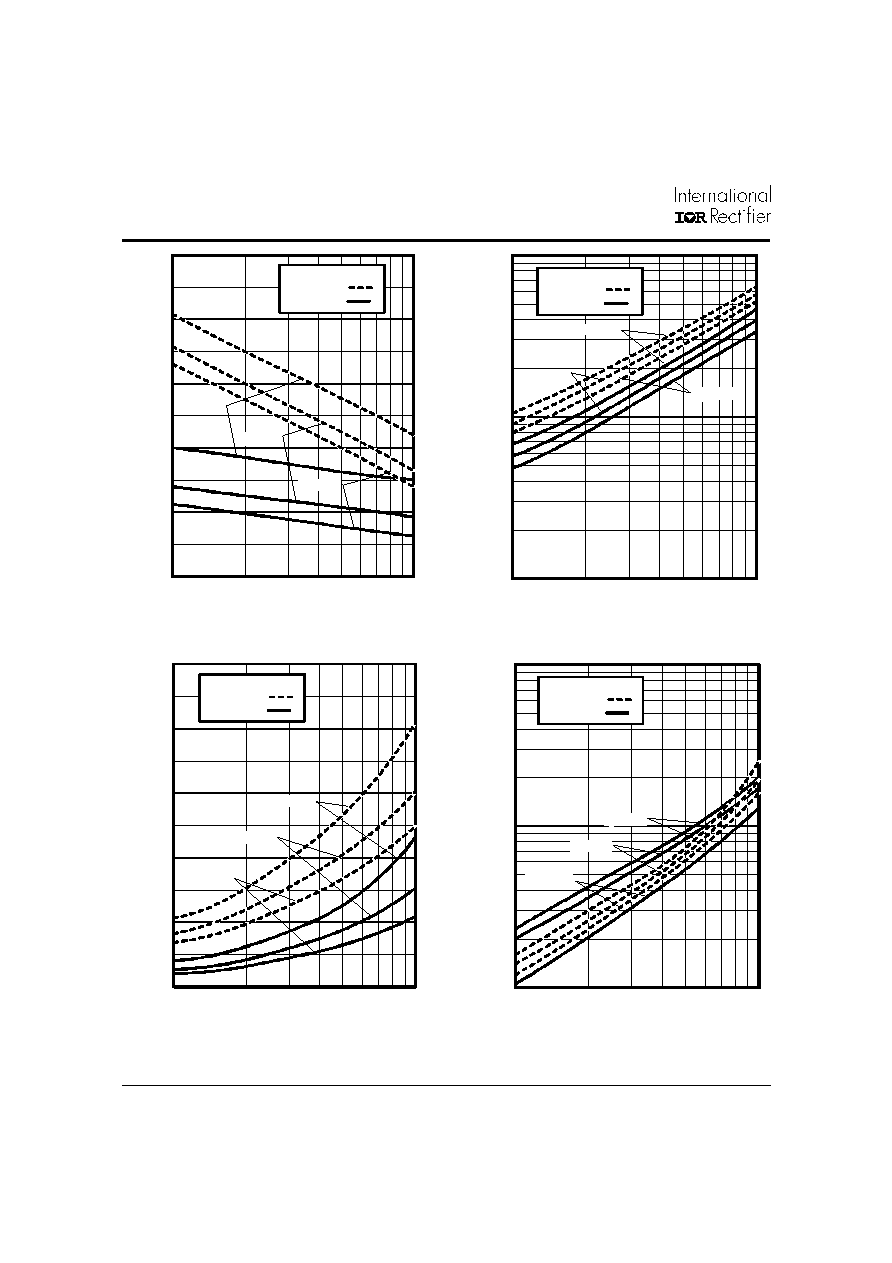

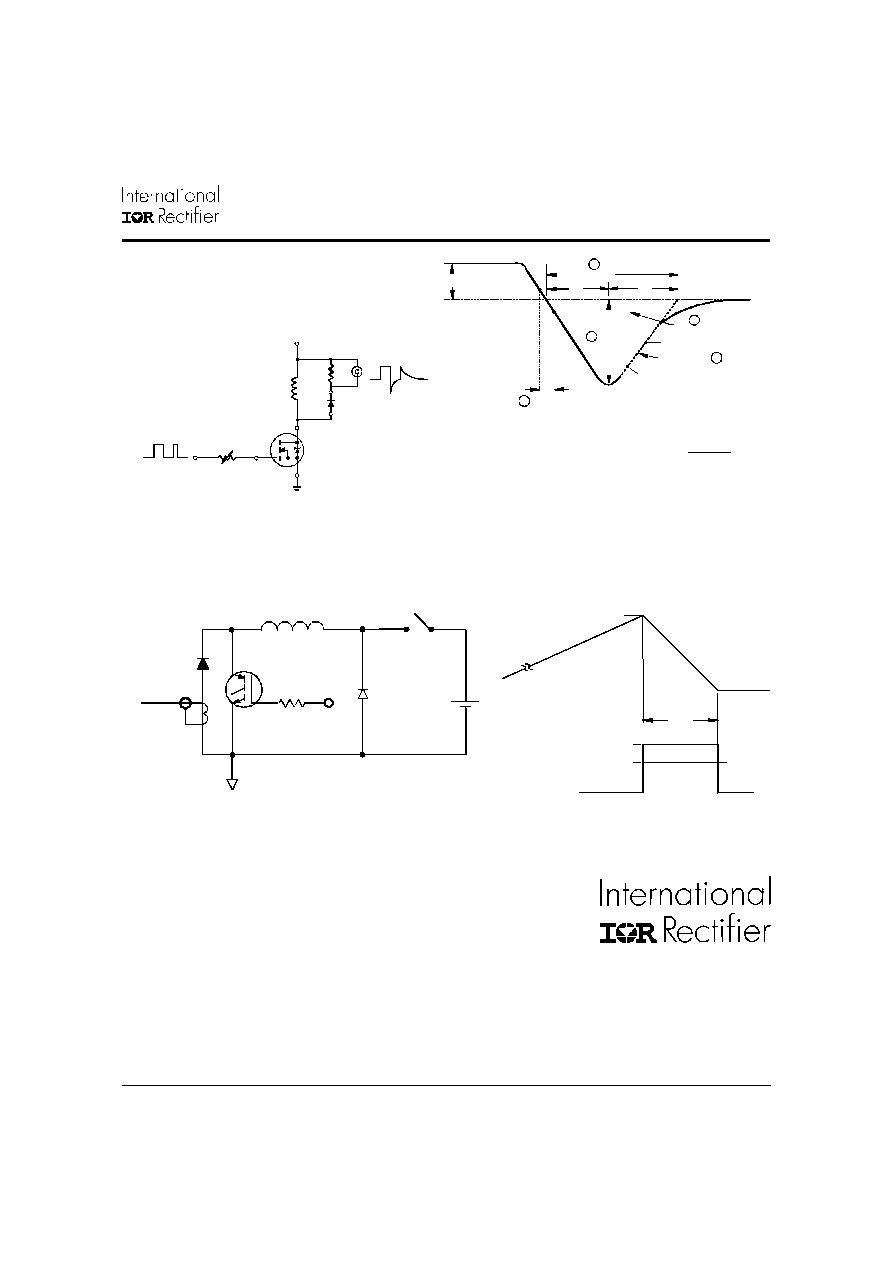

Fig. 7 - Typical Stored Charge vs. di

f

/dt,

(per Leg)

Fig. 8 - Typical di

(rec)M

/dt vs. di

f

/dt,

(per Leg)

Fig. 5 - Typical Reverse Recovery vs. di

f

/dt,

(per Leg)

Fig. 6 - Typical Recovery Current vs. di

f

/dt,

(per Leg)

40

80

120

160

200

240

100

1000

f

di /dt - (A/µs)

t

- (ns)

rr

I = 200A

I = 80A

I = 40A

F

F

F

V = 200V

T = 125°C

T = 25°C

R

J

J

1

10

100

100

1000

f

di /dt - (A/µs)

I

- (A)

IR

R

M

I = 200A

I = 80A

I = 40A

F

F

F

V = 200V

T = 125°C

T = 25°C

R

J

J

0

1000

2000

3000

4000

5000

100

1000

f

di /dt - (A/µs)

RR

Q

- (nC)

I = 40A

I = 80A

I = 200A

V = 200V

T = 125°C

T = 25°C

R

J

J

F

F

F

100

1000

10000

100

1000

f

di /dt - (A/µs)

di(rec)M/dt

- (A/

µs)

I = 200A

I = 80A

I = 40A

V = 200V

T = 125°C

T = 25°C

R

J

J

F

F

F

HFA160NJ40C

PD-2.467 rev. B 02/99

5

4. Q

rr

- Area under curve defined by t

rr

and I

RRM

t

rr

X I

RRM

Q

rr

=

2

5. di

(rec)M

/dt - Peak rate of change of

current during t

b

portion of t

rr

V

(AV AL)

R(RA TED)

I

L(PK)

V

DECAY

TIME

Fig. 11 - Avalanche Test Circuit and Waveforms

Fig. 10 - Reverse Recovery Waveform and

Definitions

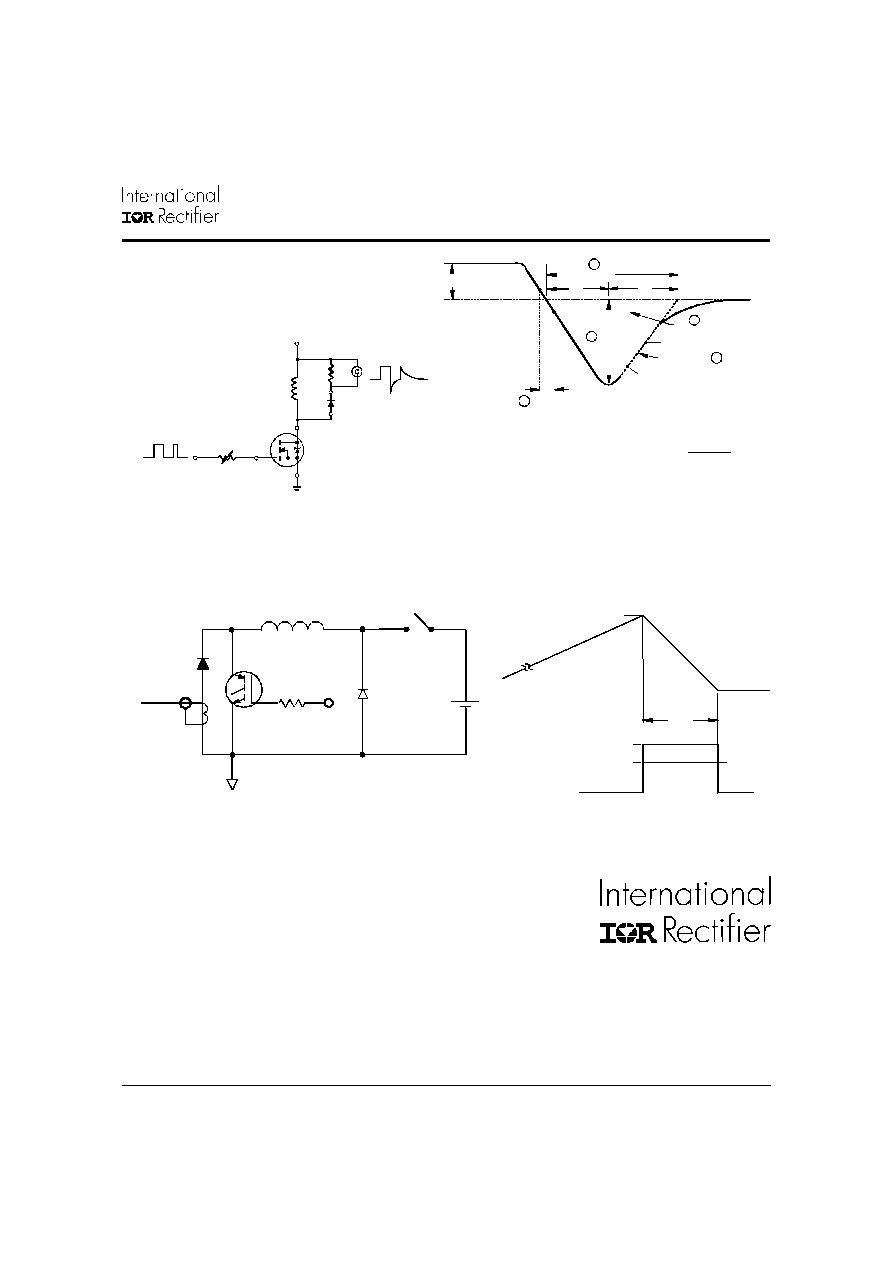

Fig. 9 - Reverse Recovery Parameter Test

Circuit

t

a

t

b

t

rr

Q

rr

I

F

I

RRM

I

RRM

0.5

di(rec)M/dt

0.75 I

RRM

5

4

3

2

0

1

di /dt

f

1. di

f

/dt - Rate of change of current

through zero crossing

2. I

RRM

- Peak reverse recovery current

3. trr - Reverse recovery time measured

from zero crossing point of negative

going I

F

to point where a line passing

through 0.75 I

RRM

and 0.50 I

RRM

extrapolated to zero current

REVERSE RECOVERY CIRCUIT

IRFP250

D.U.T.

L = 70µH

V = 200V

R

0.01

G

D

S

dif/dt

ADJUST

CURRENT

MONITOR

HIGH-SPEED

SWITCH

DUT

Rg = 25 ohm

+

FREE-WHEEL

DIODE

Vd = 50V

L = 100µH

http://www.irf.com Fax-On-Demand: +44 1883 733420 Data and specifications subject to change without notice.

233 Kansas St., El Segundo, California 90245 U.S.A. Tel: (310) 322 3331. Fax: (310) 322 3332.

Hurst Green, Oxted, Surrey RH8 9BB, U.K. Tel: ++ 44 1883 732020. Fax: ++ 44 1883 733408.

15 Lincoln Court, Brampton, Markham, Ontario L6T3Z2. Tel: (905) 453 2200. Fax: (905) 475 8801.

Saalburgstrasse 157, 61350 Bad Homburg. Tel: ++ 49 6172 96590. Fax: ++ 49 6172 965933.

Via Liguria 49, 10071 Borgaro, Torino. Tel: ++ 39 11 4510111. Fax: ++ 39 11 4510220.

K&H Bldg., 2F, 30-4 Nishi-Ikebukuro 3-Chome, Toshima-Ku, Tokyo, Japan 171. Tel: 81 3 3983 0086.

1 Kim Seng Promenade, Great World City West Tower,13-11, Singapore 237994. Tel: ++ 65 838 4630.

16 Fl. Suite D.207, Sec. 2, Tun Haw South Road, Taipei, 10673, Taiwan. Tel: 886 2 2377 9936.

WORLD HEADQUARTERS:

EUROPEAN HEADQUARTERS:

IR CANADA:

IR GERMANY:

IR ITALY:

IR FAR EAST:

IR SOUTHEAST ASIA:

IR TAIWAN: