2-152

HIP6012

Buck and Synchronous-Rectifier

Pulse-Width Modulator (PWM) Controller

The HIP6012 provides complete control and protection for a

DC-DC converter optimized for high-performance

microprocessor applications. It is designed to drive two

N-Channel MOSFETs in a synchronous-rectified buck

topology. The HIP6012 integrates all of the control, output

adjustment, monitoring and protection functions into a single

package.

The output voltage of the converter can be precisely

regulated to as low as 1.27V, with a maximum tolerance of

±

1.5% over temperature and line voltage variations.

The HIP60012 provides simple, single feedback loop,

voltage-mode control with fast transient response. It includes

a 200kHz free-running triangle-wave oscillator that is

adjustable from below 50kHz to over 1MHz. The error

amplifier features a 15MHz gain-bandwidth product and

6V/

µ

s slew rate which enables high converter bandwidth for

fast transient performance. The resulting PWM duty ratio

ranges from 0% to 100%.

The HIP6012 protects against over-current conditions by

inhibiting PWM operation. The HIP6012 monitors the current

by using the r

DS(ON)

of the upper MOSFET which eliminates

the need for a current sensing resistor.

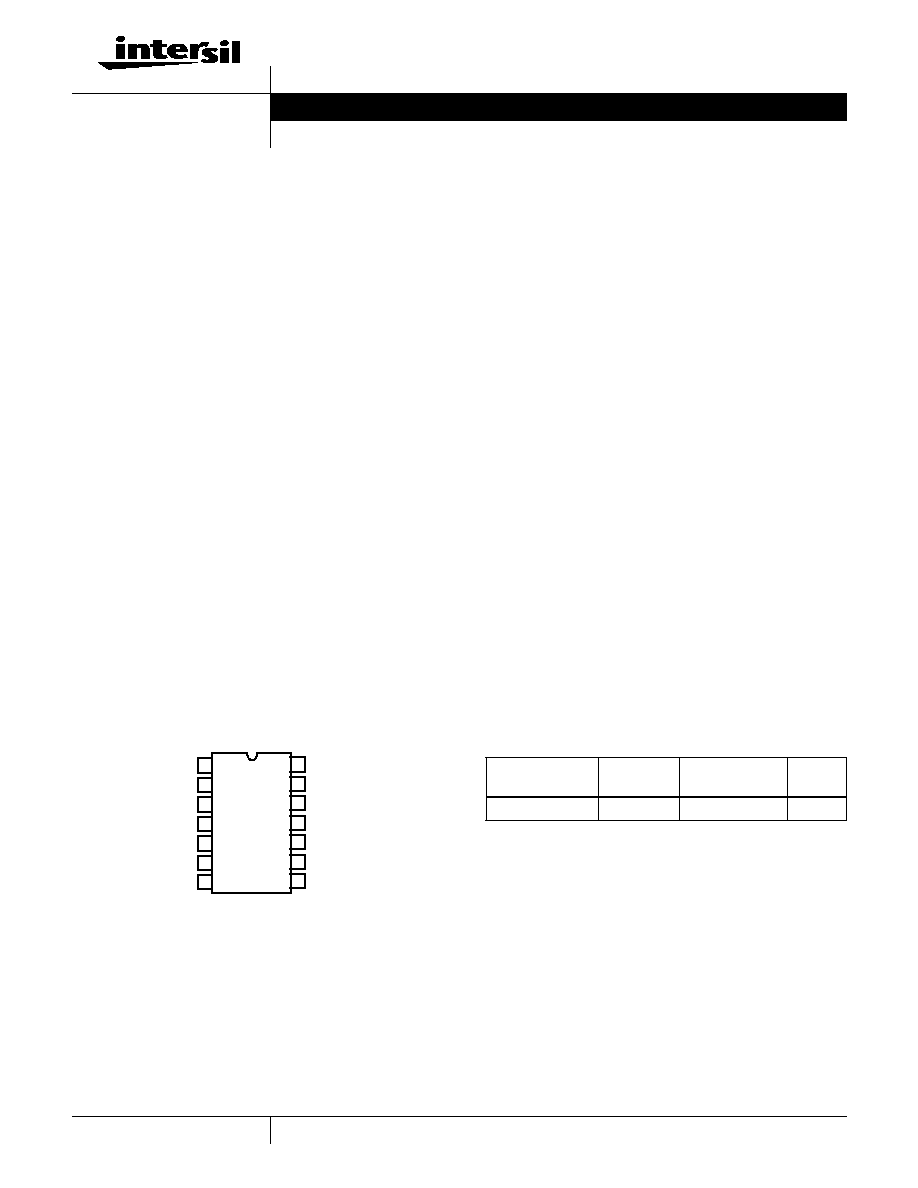

Pinout

HIP6012

(SOIC)

TOP VIEW

Features

· Drives Two N-Channel MOSFETs

· Operates From +5V or +12V Input

· Simple Single-Loop Control Design

- Voltage-Mode PWM Control

· Fast Transient Response

- High-Bandwidth Error Amplifier

- Full 0% to 100% Duty Ratio

· Excellent Output Voltage Regulation

- 1.27V Internal Reference

-

±

1.5% Over Line Voltage and Temperature

· Over-Current Fault Monitor

- Does Not Require Extra Current Sensing Element

- Uses MOSFETs r

DS(ON)

· Small Converter Size

- Constant Frequency Operation

- 200kHz Free-Running Oscillator Programmable from

50kHz to Over 1MHz

· 14 Pin, SOIC Package

Applications

· Power Supply for Pentium®, Pentium Pro, PowerPCTM and

AlphaTM Microprocessors

· High-Power 5V to 3.xV DC-DC Regulators

· Low-Voltage Distributed Power Supplies

PowerPCTM is a trademark of IBM.

AlphaTM is a trademark of Digital Equipment Corporation.

Pentium® is a registered trademark of Intel Corporation.

8

9

10

11

12

13

14

7

6

5

4

3

2

1

OCSET

SS

EN

COMP

FB

RT

VCC

LGATE

PGND

BOOT

UGATE

PHASE

GND

PVCC

Ordering Information

PART NUMBER

TEMP.

RANGE (

o

C)

PACKAGE

PKG.

NO.

HIP6012CB

0 to 70

14 Ld SOIC

M14.15

Data Sheet

June 1997

File Number

4324

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

http://www.intersil.com or 407-727-9207

|

Copyright

©

Intersil Corporation 1999

2-153

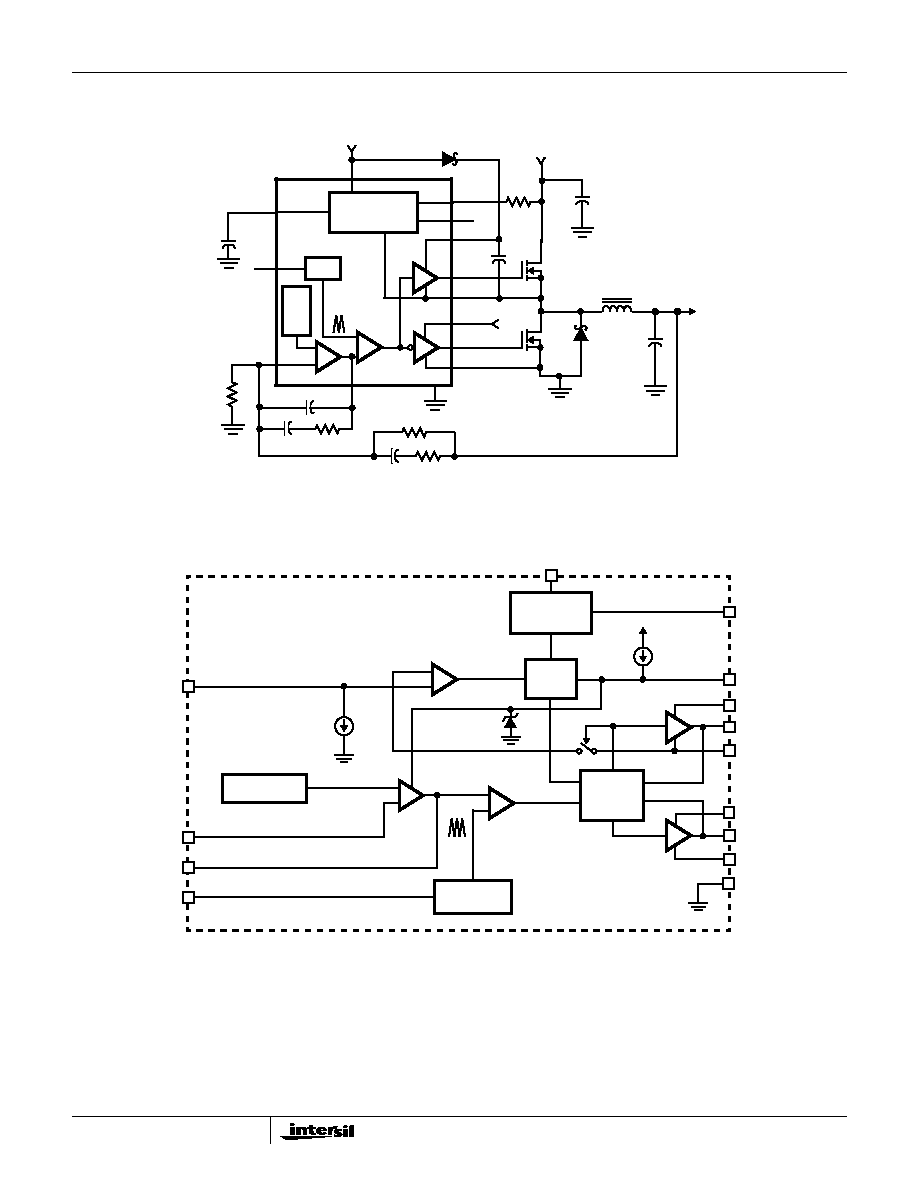

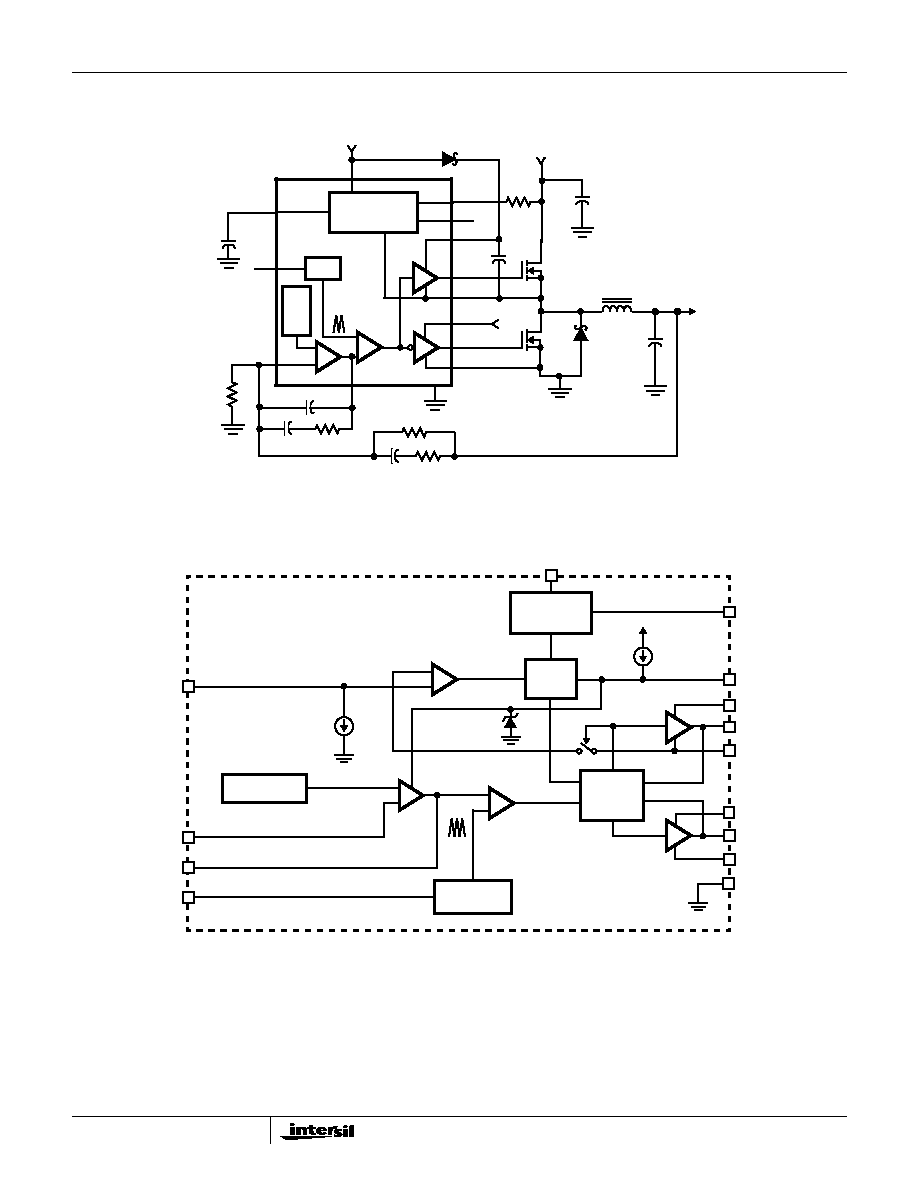

Typical Application

Block Diagram

12V

+V

O

PGND

HIP6012

RT

FB

COMP

SS

GND

OSC

LGATE

UGATE

OCSET

PHASE

BOOT

EN

VCC

+5V OR +12V

PVCC

+12V

MONITOR AND

PROTECTION

REF

+

-

+

-

OSCILLATOR

SOFT-

START

POWER-ON

RESET (POR)

INHIBIT

PWM

COMPARATOR

ERROR

AMP

VCC

SS

PWM

RT

GND

OCSET

FB

COMP

EN

1.27 VREF

OVER-

CURRENT

GATE

CONTROL

LOGIC

BOOT

UGATE

LGATE

PHASE

PGND

200

µ

A

PVCC

10

µ

A

4V

REFERENCE

+

-

+

-

+

-

HIP6012

2-154

Absolute Maximum Ratings

Thermal Information

Supply Voltage, V

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +15.0V

Boot Voltage, V

BOOT

- V

PHASE

. . . . . . . . . . . . . . . . . . . . . . . +15.0V

Input, Output or I/O Voltage . . . . . . . . . . . . GND -0.3V to V

CC

+0.3V

ESD Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class 2

Operating Conditions

Supply Voltage, V

CC

. . . . . . . . . . . . . . . . . . . . . . . . . . . +12V

±

10%

Ambient Temperature Range . . . . . . . . . . . . . . . . . . . . . 0

o

C to 70

o

C

Junction Temperature Range . . . . . . . . . . . . . . . . . . . . 0

o

C to 125

o

C

Thermal Resistance (Typical, Note 1)

JA

(

o

C/W)

SOIC Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

115

Maximum Junction Temperature . . . . . . . . . . . . . . . . . . . . . . 150

o

C

Maximum Storage Temperature Range . . . . . . . . . . -65

o

C to 150

o

C

Maximum Lead Temperature (Soldering 10s) . . . . . . . . . . . . 300

o

C

(Lead tips only)

CAUTION: Stresses above those listed in "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress only rating and operation of the

device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1.

JA

is measured with the component mounted on an evaluation PC board in free air.

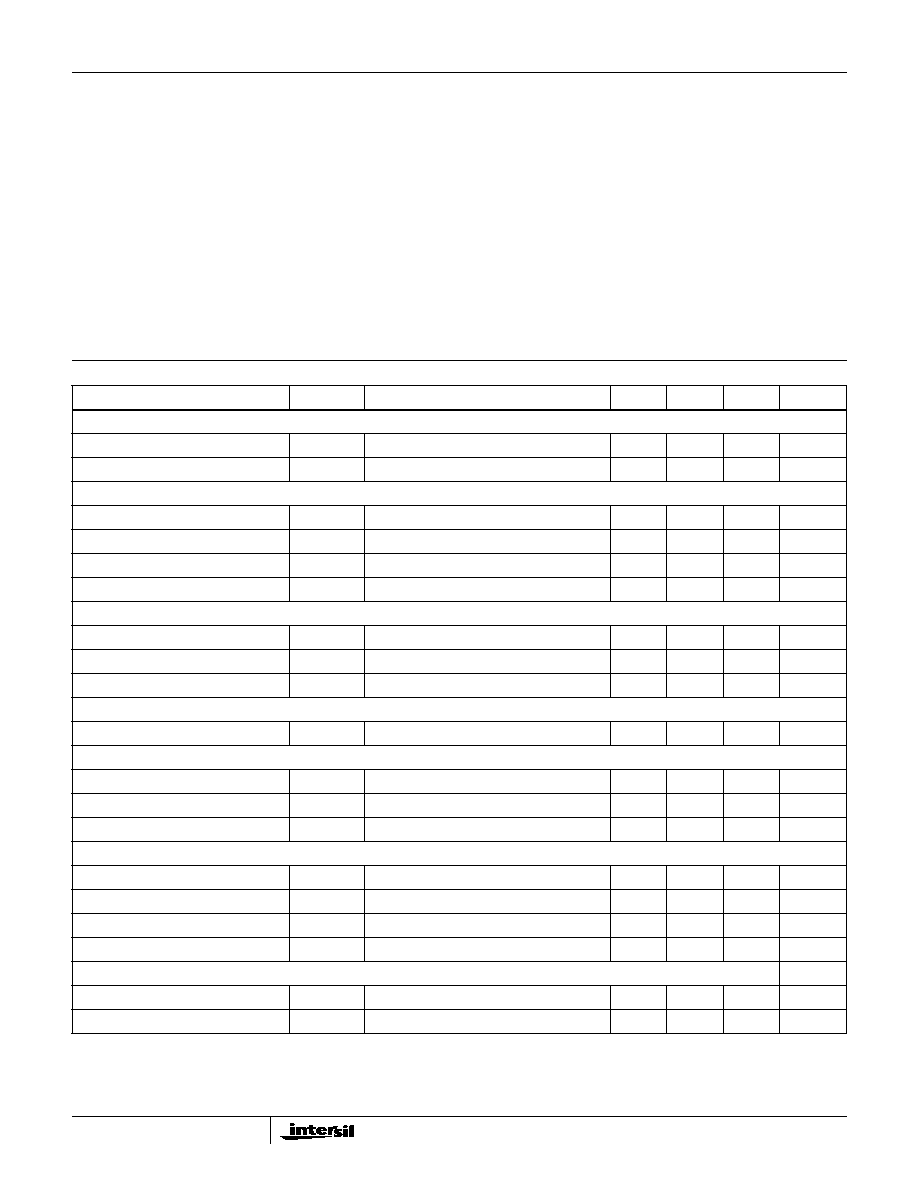

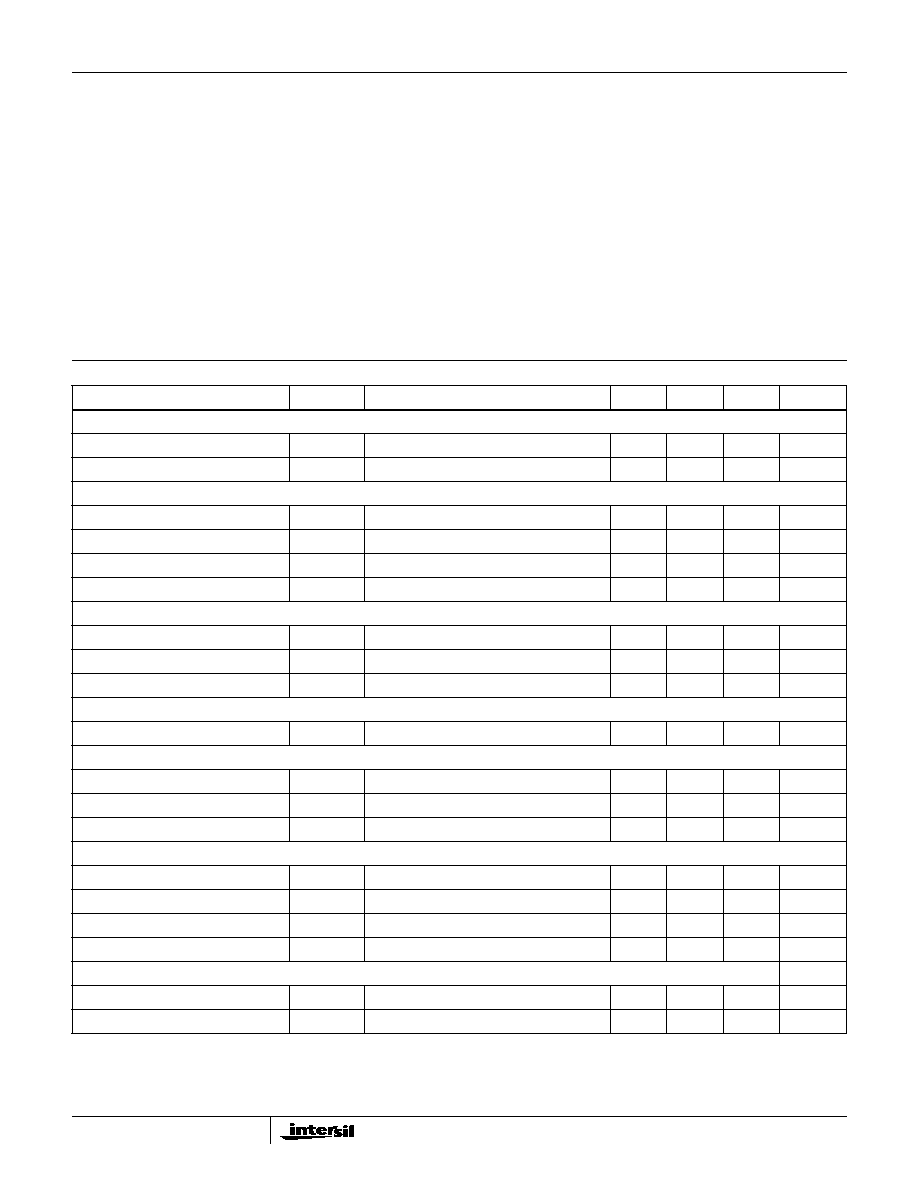

Electrical Specifications

Recommended Operating Conditions, Unless Otherwise Noted

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

TYP

MAX

UNITS

VCC SUPPLY CURRENT

Nominal Supply

I

CC

EN = V

CC

; UGATE and LGATE Open

-

5

-

mA

Shutdown Supply

EN = 0V

-

50

100

µ

A

POWER-ON RESET

Rising V

CC

Threshold

V

OCSET

= 4.5VDC

-

-

10.4

V

Falling V

CC

Threshold

V

OCSET

= 4.5VDC

8.8

-

-

V

Enable - Input threshold Voltage

V

OCSET

= 4.5VDC

0.8

-

2.0

V

Rising V

OCSET

Threshold

-

1.27

-

V

OSCILLATOR

Free Running Frequency

R

T

= OPEN, V

CC

= 12

180

200

220

kHz

Total Variation

6k

< R

T

to GND < 200k

-20

-

+20

%

Ramp Amplitude

V

OSC

R

T

= OPEN

-

1.9

-

V

P-P

REFERENCE

Reference Voltage

1.251

1.270

1.289

V

ERROR AMPLIFIER

DC Gain

-

88

-

dB

Gain-Bandwidth Product

GBW

-

15

-

MHz

Slew Rate

SR

COMP = 10pF

-

6

-

V/

µ

s

GATE DRIVERS

Upper Gate Source

I

UGATE

V

BOOT

- V

PHASE

= 12V, V

UGATE

= 6V

350

500

-

mA

Upper Gate Sink

R

UGATE

I

LGATE

= 0.3A

-

5.5

10

Lower Gate Source

I

LGATE

V

CC

= 12V, V

LGATE

= 6V

300

450

-

mA

Lower Gate Sink

R

LGATE

I

LGATE

= 0.3A

-

3.5

6.5

PROTECTION

OCSET Current Source

I

OCSET

V

OCSET

= 4.5VDC

170

200

230

µ

A

Soft Start Current

I

SS

-

10

-

µ

A

HIP6012

2-155

Functional Pin Description

RT (Pin 1)

This pin provides oscillator switching frequency adjustment.

By placing a resistor (R

T

) from this pin to GND, the nominal

200kHz switching frequency is increased according to the

following equation:

Conversely, connecting a pull-up resistor (R

T

) from this pin

to V

CC

reduces the switching frequency according to the

following equation.:

OCSET (Pin 2)

Connect a resistor (R

OCSET

) from this pin to the drain of the

upper MOSFET. R

OCSET

, an internal 200

µ

A current source

(I

OCS

), and the upper MOSFET on-resistance (r

DS(ON)

) set

the converter over-current (OC) trip point according to the

following equation:

An over-current trip cycles the soft-start function.

SS (Pin 3)

Connect a capacitor from this pin to ground. This capacitor,

along with an internal 10

µ

A current source, sets the soft-

start interval of the converter.

COMP (Pin 4) and FB (Pin 5)

COMP and FB are the available external pins of the error

amplifier. The FB pin is the inverting input of the error

amplifier and the COMP pin is the error amplifier output.

These pins are used to compensate the voltage-control

feedback loop of the converter.

EN (Pin 6)

This pin is the open-collector enable pin. Pull this pin below

1V to disable the converter. In shutdown, the soft start pin is

discharged and the UGATE and LGATE pins are held low.

GND (Pin 7)

Signal ground for the IC. All voltage levels are measured with

respect to this pin.

PHASE (Pin 8)

Connect the PHASE pin to the upper MOSFET source. This

pin is used to monitor the voltage drop across the MOSFET

for over-current protection. This pin also provides the return

path for the upper gate drive.

UGATE (Pin 9)

Connect UGATE to the upper MOSFET gate. This pin

provides the gate drive for the upper MOSFET.

BOOT (Pin 10)

This pin provides bias voltage to the upper MOSFET driver.

A bootstrap circuit may be used to create a BOOT voltage

suitable to drive a standard N-Channel MOSFET.

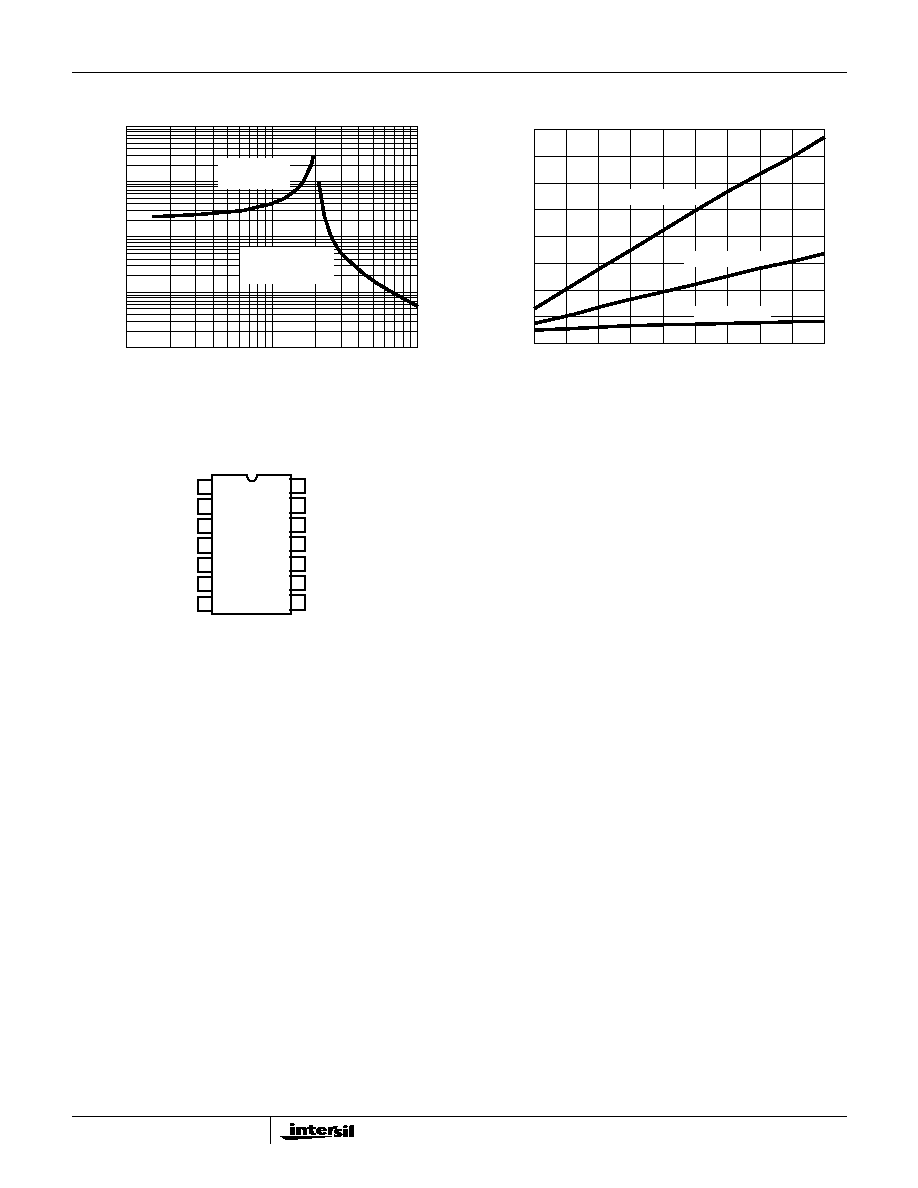

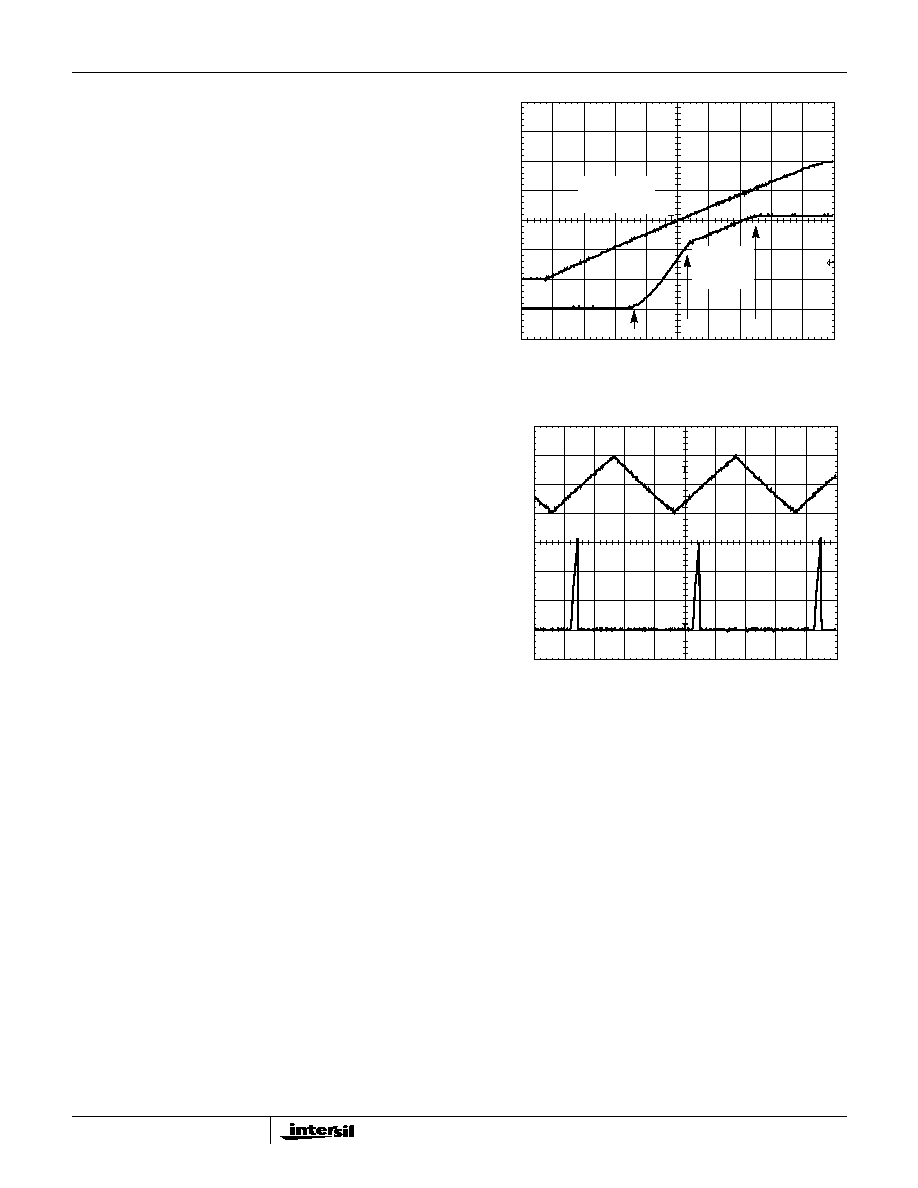

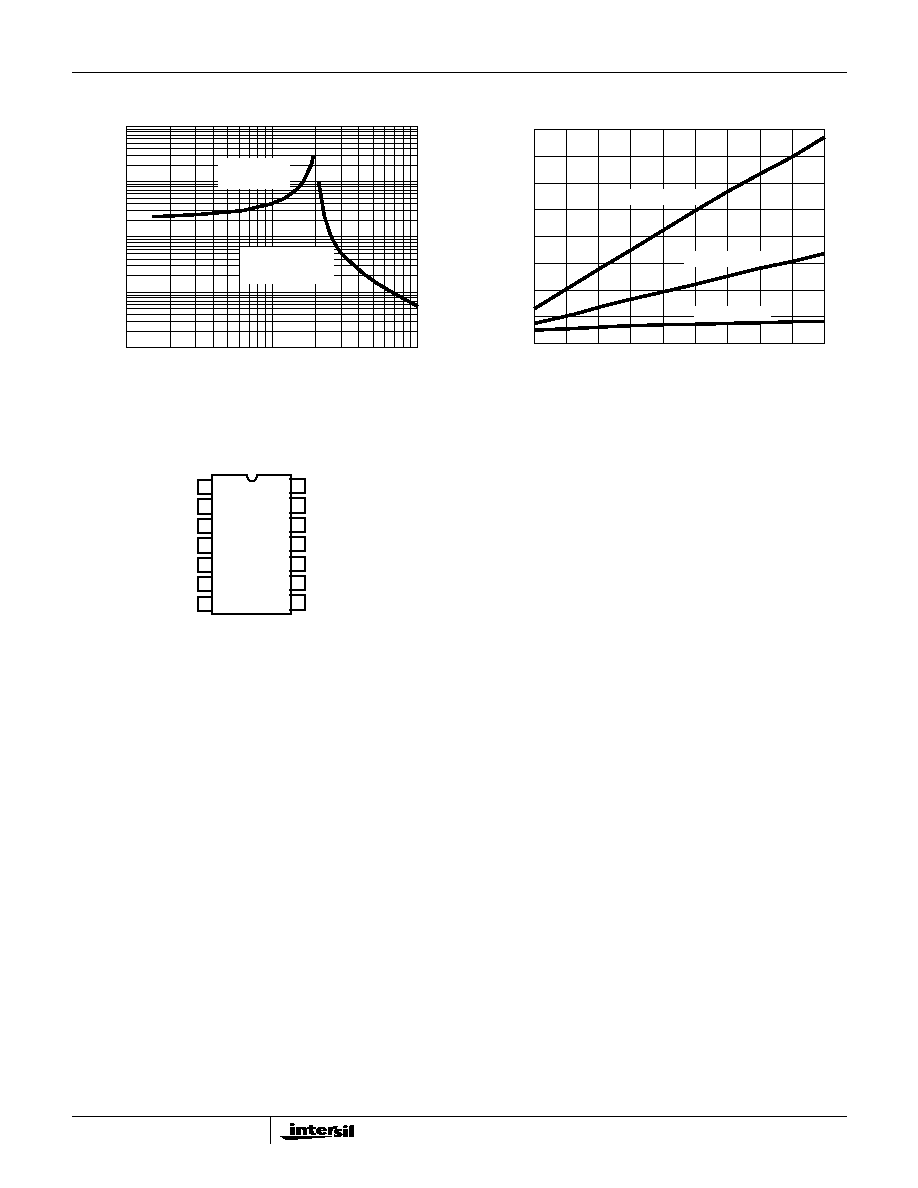

Typical Performance Curves

FIGURE 1. R

T

RESISTANCE vs FREQUENCY

FIGURE 2. BIAS SUPPLY CURRENT vs FREQUENCY

10

100

1000

SWITCHING FREQUENCY (kHz)

RESIST

ANCE (k

)

10

100

1000

R

T

PULLUP

TO +12V

R

T

PULLDOWN

TO V

SS

100

200

300

400

500

600

700

800

900

1000

80

70

60

50

40

30

20

10

0

I

VCC

(mA)

SWITCHING FREQUENCY (kHz)

C

GATE

= 1000pF

C

GATE

= 3300pF

C

GATE

= 10pF

8

9

10

11

12

13

14

7

6

5

4

3

2

1

OCSET

SS

EN

COMP

FB

RT

VCC

LGATE

PGND

BOOT

UGATE

PHASE

GND

PVCC

Fs

200kHz

5

10

6

·

R

T

------------------

+

(R

T

to GND)

Fs

200kHz

4

10

7

·

R

T

------------------

(R

T

to 12V)

I

PEAK

I

OCS

R

OCSET

·

r

DS ON

(

)

--------------------------------------------

=

HIP6012

2-156

PGND (Pin 11)

This is the power ground connection. Tie the lower MOSFET

source to this pin.

LGATE (Pin 12)

Connect LGATE to the lower MOSFET gate. This pin

provides the gate drive for the lower MOSFET.

PVCC (Pin 13)

Provide a bias supply for the lower gate drive to this pin.

VCC (Pin 14)

Provide a 12V bias supply for the chip to this pin.

Functional Description

Initialization

The HIP6012 automatically initializes upon receipt of power.

Special sequencing of the input supplies is not necessary.

The Power-On Reset (POR) function continually monitors

the input supply voltages and the enable (EN) pin. The POR

monitors the bias voltage at the VCC pin and the input

voltage (V

IN

) on the OCSET pin. The level on OCSET is

equal to V

IN

Less a fixed voltage drop (see over-current

protection). With the EN pin held to V

CC

, the POR function

initiates soft start operation after both input supply voltages

exceed their POR thresholds. For operation with a single

+12V power source, V

IN

and V

CC

are equivalent and the

+12V power source must exceed the rising V

CC

threshold

before POR initiates operation.

The Power-On Reset (POR) function inhibits operation with

the chip disabled (EN pin low). With both input supplies

above their POR thresholds, transitioning the EN pin high

initiates a soft start interval.

Soft Start

The POR function initiates the soft start sequence. An internal

10

µ

A current source charges an external capacitor (C

SS

) on

the SS pin to 4V. Soft start clamps the error amplifier output

(COMP pin) and reference input (+ terminal of error amp) to

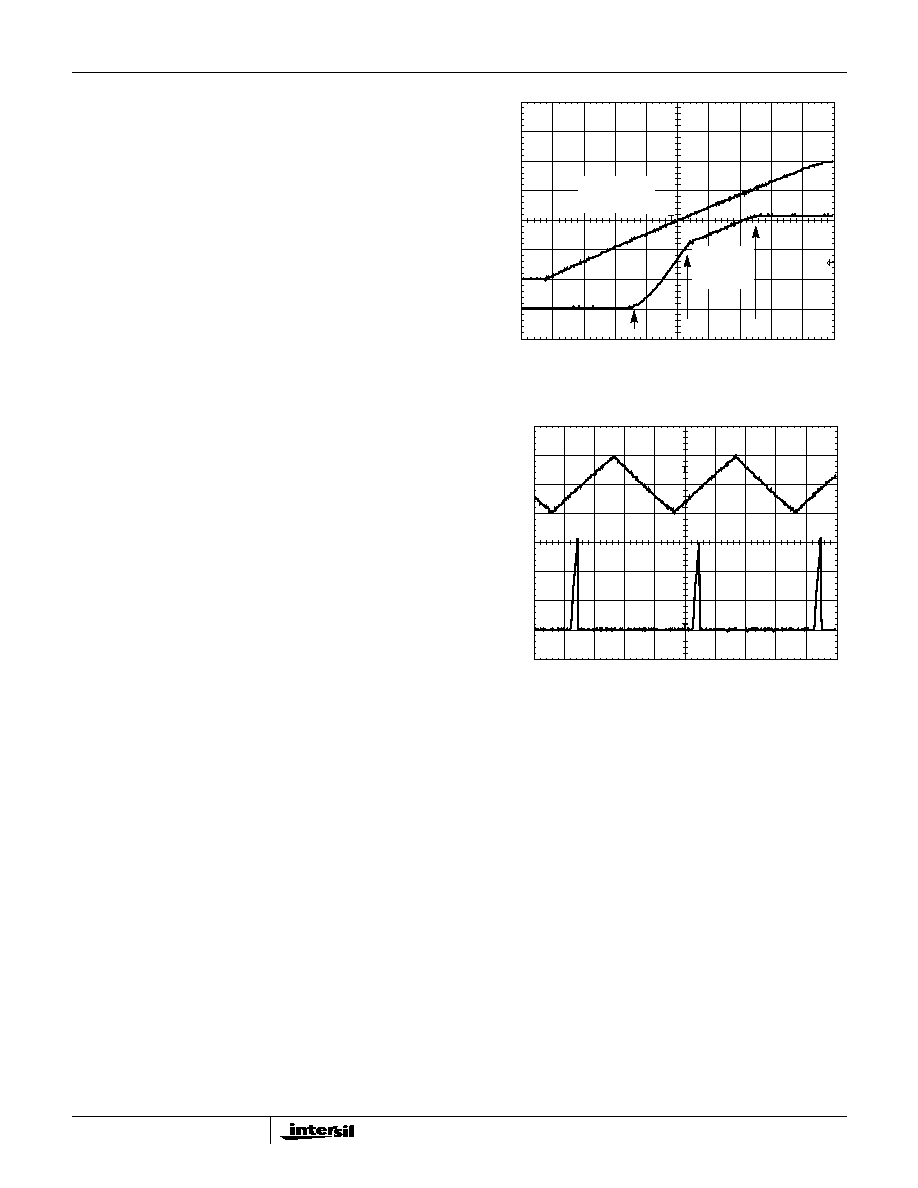

the SS pin voltage. Figure 3 shows the soft start interval with

C

SS

= 0.1

µ

F. Initially the clamp on the error amplifier (COMP

pin) controls the converter's output voltage. At t1 in Figure 3,

the SS voltage reaches the valley of the oscillator's triangle

wave. The oscillator's triangular waveform is compared to the

ramping error amplifier voltage. This generates PHASE

pulses of increasing width that charge the output capacitor(s).

This interval of increasing pulse width continues to t2. With

sufficient output voltage, the clamp on the reference input

controls the output voltage. This is the interval between t2 and

t3 in Figure 3. At t3 the SS voltage exceeds the reference

voltage and the output voltage is in regulation. This method

provides a rapid and controlled output voltage rise.

Over-Current Protection

The over-current function protects the converter from a

shorted output by using the upper MOSFETs on-resistance,

r

DS(ON)

to monitor the current. This method enhances the

converter's efficiency and reduces cost by eliminating a

current sensing resistor.

The over-current function cycles the soft-start function in a

hiccup mode to provide fault protection. A resistor (R

OCSET

)

programs the over-current trip level. An internal 200

µ

A

(typical) current sink develops a voltage across R

OCSET

that

is reference to V

IN

. When the voltage across the upper

MOSFET (also referenced to V

IN

) exceeds the voltage

across R

OCSET

, the over-current function initiates a soft-

start sequence. The soft-start function discharges C

SS

with

a 10

µ

A current sink and inhibits PWM operation. The soft-

start function recharges C

SS

, and PWM operation resumes

with the error amplifier clamped to the SS voltage. Should an

overload occur while recharging C

SS

, the soft start function

inhibits PWM operation while fully charging C

SS

to 4V to

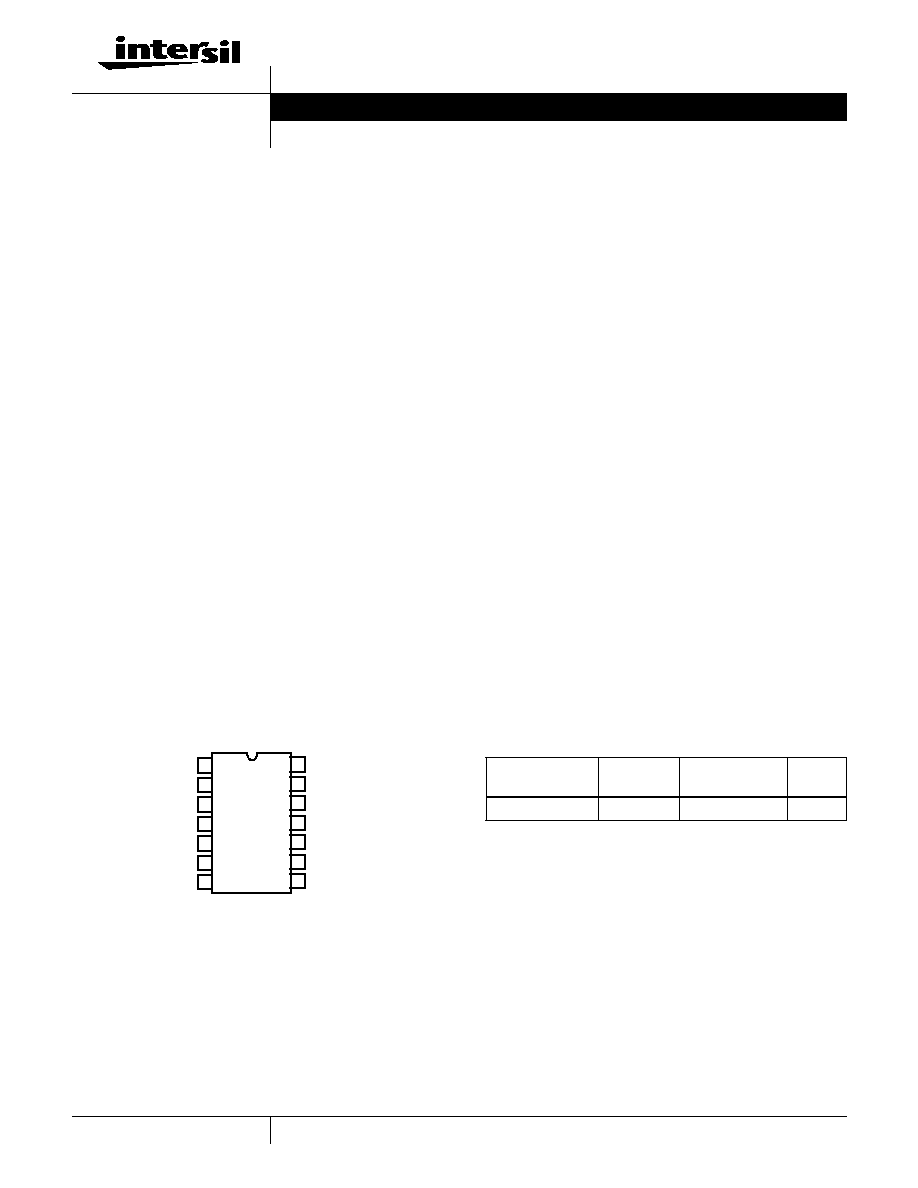

complete its cycle. Figure 4 shows this operation with an

TIME (5ms/DIV)

SOFT-START

(1V/DIV)

0V

0V

t1

t2

t3

OUTPUT

(1V/DIV)

VOLTAGE

FIGURE 3. SOFT-START INTERVAL

OUTPUT INDUCT

OR

SOFT

-ST

AR

T

0A

0V

TIME (20ms/DIV)

5A

10A

15A

2V

4V

FIGURE 4. OVER-CURRENT OPERATION

HIP6012