1

QuickSaver

Motorola HC/HRC705JJ7 Microcontroller Based Eval Board

M-QSC1702-EB, M-QSC1702/RS232-EB

Features

Self contained .6 Amp to 1.8 Amp charger board

Charges 3 to 6 battery Nickel-Cadmium or

Nickel-Metal Hydride packs in one hour

Displays charging status on a bargraph display

Optionally provides detailed charging

information via an RS232 port to a PC for in-

depth evaluation of battery packs and the

QuickSaver charging algorithm (optional

software package is required)

Product Types

Portable computers, PDAs

Cordless Power tools

Audio/video products

Wireless communications devices

RC devices and toys

Medical

Automotive

Description

Galaxy Power, Inc.'s Motorola MCU based

Evaluation Board demonstrates the capabilities of

the GPI QuickSaver charging algorithm when

implemented in a microcontroller. The evaluation

board demonstrates some of the additional features

that a microcontroller can implement in a charging,

monitoring and display solution for Nickel-Cadmium

and Nickel-Metal Hydride Batteries.

A flexible solution is provided for charging from 3 to

6 cells with current capabilities from 600 mA-Hr to to

1800 mA-Hr. Provision is made for monitoring

battery pack temperature during the charging

process to allow for fast, safe charging of the battery

pack.

A LED bargraph display is included to show the

current state of charge of the battery pack and also

display off-normal conditions which may occur

during the charging cycle.

An optional RS232 port is included to permit a PC to

monitor all of the critical charging parameters

associated with the battery during the charging

cycle.

The Galaxy Power, Inc. QuickSaver

Charging Algorithm

Since it was first implemented in 1994, the Galaxy

Power, Inc. QuickSaver algorithm has been

determined to be the best charging algorithm

available for rapidly charging Nickel-Cadmium and

Nickel-Metal Hydride batteries in a way that provides

the longest cycle life obtainable from these cell

technologies. Typically, the QuickSaver algorithm

results in battery life up to 10 times that specified by

battery manufacturers. NASA has evaluated this

technology and uses it exclusively for Space Shuttle

and International Space Station applications. For

detailed information on the studies conducted by

NASA, please visit our website,

www.galaxypower.com

.

Since its inception, Galaxy Power, Inc. has supplied

integrated circuits that implement this QuickSaver

charging algorithm. In response to requests from

customers for additional functionality, Galaxy Power,

Inc. has now ported this algorithm to a number of

microprocessors and microcontrollers including the

Intel Strong ArmŽ, and the Motorola 68HC705

microcontroller utilized on this demo board. This

approach has resulted in an extremely flexible

approach to your power management needs. We

hope that you enjoy working with it as much as we

enjoyed developing this approach.

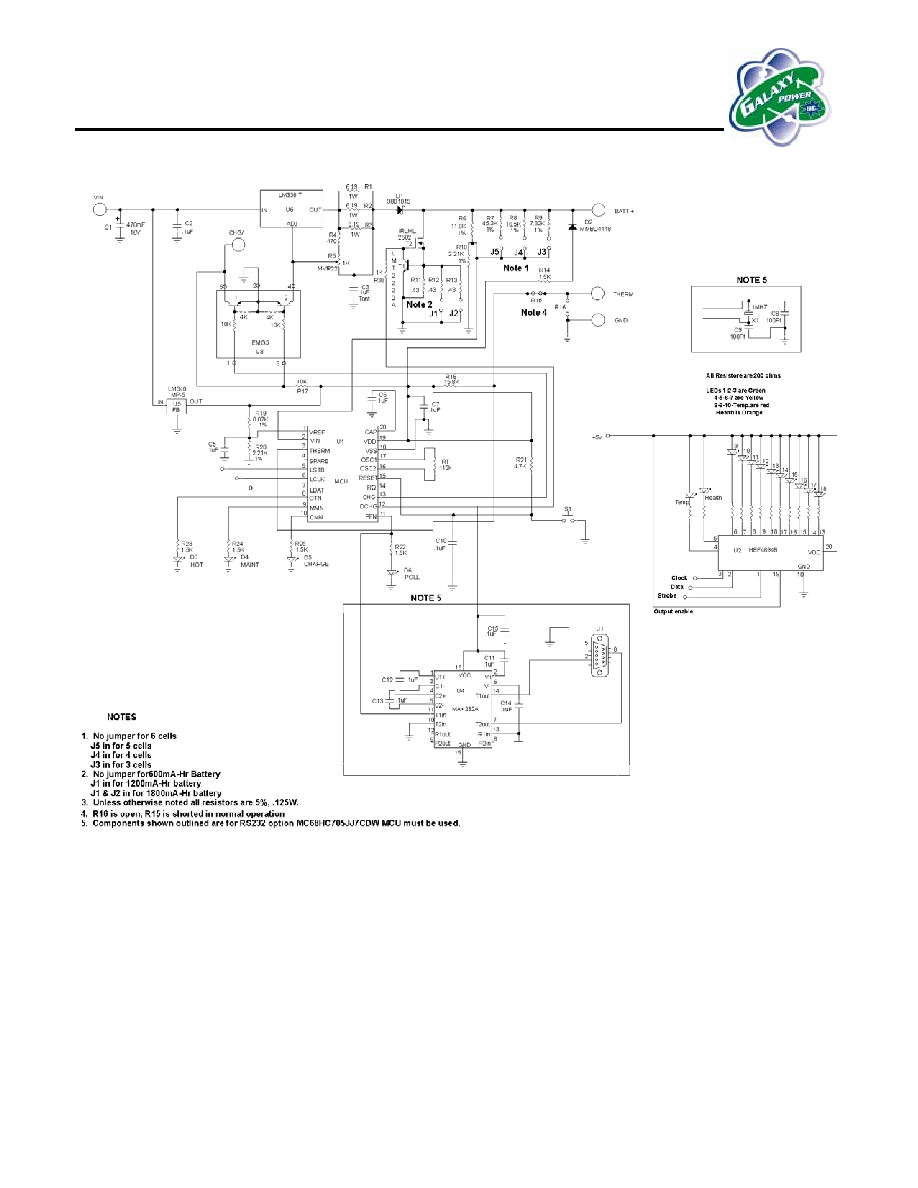

2

Motorola MCU based Quicksaver Evaluation Board

Setting up Your Application

Refer to the evaluation board schematic diagram. By

placing solder globs in the appropriate locations, the

board can be configured for 3 to 6 cells. As supplied,

the board is set up for 6 cells. A solder glob jumper

at J5 sets the board up for 5 cells. Installing a

jumper at J4 sets the board up for 4 cells; a jumper

at J3 sets the board up for 3 cells. Charging current

is determined by the setting of the 1K potentiometer,

R5, and can be continuously set between 600mA

and 1.8 A. This should be set based on the

ampere/hour capabilities of the battery pack. The

discharge pulse depth is also set with solder

jumpers. As supplied, the board is set up for a

600mA-Hr battery pack. Installing J1 sets the board

up for a 1.2 A-Hr pack and installing both J1 and J2

set the board up for a 1.8 A-Hr pack. If the software

battery monitoring feature is implemented, an

RS232 cable must be attached to the connector and

one of the serial ports on your PC.

The board is supplied with a 115K ohm 1% resistor

for timing control. Units that incorporate the RS232

data output feature should use a 1MHz ceramic

resonator to accurately set the baud rate of the

serial port. To convert the board to use the ceramic

resonator, two 100pF capacitors, C8 and C9 must

be installed along with the ceramic resonator.

The evaluation board is set up to monitor battery

pack temperature via a 10K ohm PTC thermistor in

the battery pack. If temperature sensing is not

desired, a 10K resistor must be installed between

the thermistor connector and ground. Pads are

provided to facilitate this (R16). Additional pads are

provided to permit thermistors with different temp

coefficients or values to be used. As supplied, pads

for R15 are shorted together, and pads for R16 are

left open.

The current source can be easily set up for the

proper current for the battery under charge. An

ammeter should be connected between Batt+ and

GND. It should be capable of measuring currents up

to 3 amps. Short the test point marked CHG/ to

GND. Adjust the 1K potentiometer, R5, for the

desired current, and then remove the short and

ammeter.

The MCU charger will normally start a charge cycle

when power is applied. If for some reason the user

decides to restart the cycle or the unit fails to start, a

reset pushbutton is included that will start the charge

cycle.

# Cells

+VDC Input

Install jumper

3 11

VDC

J3

4 13

VDC

J4

5 14.5

VDC

J5

6 16

VDC

None

Note: Do not exceed 16 Volts input

Display Functions

The display functions implemented on the MCU

demo board consist of two groups. The first group is

common to all implementations of the MCU

controlled charger and consist of four LEDs that

indicate the status of the charging process. If the

charger is started and no battery is connected to its

output, the "POLL" LED will light to indicate the

charger is looking for a battery to charge. (During a

charge cycle, this LED will flicker as this line is also

used to transmit serial data to the RS232 port).

When a battery is connected (and the thermistor

circuit is enabled) the MCU will read the temperature

of the battery. If it is too hot to charge, the "HOT"

LED will blink and remain blinking at a half second

rate until the battery has cooled enough to accept a

charge. If the battery is too cold to accept a charge,

the "HOT" LED will turn on and remain on until the

battery has warmed up enough to accept a charge.

If the battery temperature is ok, the "CHARGE" LED

will light to indicate that the battery is being charged.

After the charge cycle is complete the "CHARGE"

LED will extinguish and the "MAINT" LED will light to

indicate the main charge cycle is complete., The

battery is ready to use and the MCU is performing a

topping charge function.

The Bargraph display is implemented on the MCU

demo board to show some of the additional

functionality that an MCU based charger could have.

It consists of ten LEDs, three red, four yellow and

three green LEDs arranged in a thermometer style

bargraph and two additional LEDs that indicate what

the bargraph is currently displaying, one labeled

"HEALTH" and one labeled "TEMP". A legend is

printed on the board to remind the end-user of how

they indicate. When a charge cycle is initiated, the

MCU does a self check of the function by

sequentially lighting and extinguishing the LEDs. It

then measures the battery pack temperature and

lights the "TEMP" LED and an appropriate LED on

the bargraph to indicate the relative temperature of

the battery pack with red indicating hot, yellow

indicating normal temperature, and green cold. If a

3

Motorola MCU based Quicksaver Evaluation Board

defective battery pack is installed, the bargraph will

indicate this by lighting all the LEDs in the bargraph

if it detects an open (or missing) battery, then

extinguishing LEDs in pairs starting from the center

then moving out as if a door was opening. It will

repeat this until the problem is resolved. If a battery

pack with shorted cells is detected, the MCU will

light the LEDs on the ends of the bargraph then

proceed to light additional LEDs in pairs until all the

LEDs are lit, as if a door was closing. The "HEALTH"

and "TEMP" LEDs will flash to indicate that the

battery is suspect.

If a good battery pack is installed, the MCU will

proceed to charge this pack, and the bargraph will

display relative voltage on the display with red

indicating a low state of charge and green indicating

a higher state.

The MCU based charger has three modes of

terminating the charge cycle. The normal mode of

termination is for the voltage slope to reach a

predetermined level. After the charge cycle is

complete, the MCU will flash the "HEALTH" LED,

and indicate the termination method. For a voltage

slope termination, the three green LEDs in the

bargraph will be lit. An additional method of charge

termination is for the rise in temperature to cause a

temperature slope termination. If this happens the

"HEALTH" LED will flash and the three red LEDs will

be lit. If the battery pack fails to charge in the allotted

time, the "HEALTH" LED will flash and the four

yellow LEDs will be lit. This could be caused by a

defective battery or inappropriate current levels to be

selected for the pack under charge.

If the battery pack overheats during the charge

cycle, the charge cycle will suspend until the battery

pack cools down and the "TEMP" LED will flash to

indicate that the battery is too hot to accept charge

safely.

BATT

DISPLAY

HEALTH TEMP

VOLTAGE OFF

OFF

TEMP OFF ON

TERM FLASH

OFF

HEALTH ON

OFF

HOT OFF

FLASH

SUSPECT FLASH FLASH

RS232 Port

An optional RS232 port is included on the board to

facilitate detailed analysis of the charging function.

This is an output only port communicating at 19,200

baud that is intended to be connected to the serial

port of a PC. A software package is available that

displays all of the charging parameters in text and

graphic format. This permits the MCU based charger

to be used to critically evaluate the QuickSaver

charging algorithm as well as to provide a method to

evaluate untested battery packs in an application.

This function will permit the unit to replace

expensive battery evaluation test equipment in the

lab at a fraction of the cost and provide more

detailed information than from units currently

available. Please contact Galaxy Power, Inc. for

pricing and detailed information on this software

package.

QuickChek

Health Algorithm

Galaxy Power's new QuickChek battery health

algorithm is implemented on this evaluation board.

This allows the user to quickly determine the health

of any battery connected to the system. During the

charge cycle, the algorithm estimates the charging

time required for charging a new or healthy battery,

then tracks the actual number of charge pulses

required to actually charge the battery. Based on

these measurements, it determines the actual

condition of the battery under charge and indicates

this on the bargraph display. This health

determination is most accurate on a battery that is

nearly discharged, but will provide valid information

on any battery that is connected regardless of state

of charge. This permits the user to determine if the

battery under charge needs to be replaced.

The QuickSaver charging algorithm is very good at

restoring functionality to old or poorly charged

batteries. Therefore the user should be cautioned

that a suspect battery should be charged several

times using the QuickSaver charging algorithm

before it is discarded. The QuickChek algorithm is a

good way to measure the improvements gained by

using the Galaxy Power QuickSaver charging

algorithm. In many cases batteries that are nearly

unusable can be brought back to near perfect

condition by charging them several times using the

QuickSaver charging algorithm.

4

Motorola MCU based Quicksaver Evaluation Board

QuickChek Health Display

Indications

When the battery completes its charge cycle, the

MAINT LED will light to indicate that charge is

complete. At this point, one of the three color groups

will light to indicate the method of charge termination

that QuickSaver utilized to terminate the charge

cycle. The HEALTH LED will flash to indicate that

the termination method is being displayed. If three

green LEDs light, this indicates that the voltage

slope method of termination was used by

QuickSaver to terminate charge. For NiCd batteries,

this will be the usual method of charge termination

as this type of battery is endothermic and actually

cools down unless it is overcharged.

Three red LEDs indicates that the charge was

terminated on temperature slope. For NiMH cells this

method may occur around 50% of the time and is

normal for this cell chemistry. NiMH cells are

exothermic and heat up under normal charging

conditions. There is a race between voltage slope

and temperature slope at the end of the charging

cycle and factors such as initial cell temperature and

initial state of charge have a strong influence on the

termination method utilized. With the QuickSaver

algorithm, the user can be assured that cell

temperature (and internal cell pressure) is safely

controlled.

Four yellow LEDs indicate that QuickSaver

determined that an unusual amount of charging time

was required to charge the cell. This could be

caused by several factors. If the charging current

was set improperly for the cells under charge

(1200mA for a 1600mA cell for example) and the

battery never was fully charged. It is also possible

that the battery has serious problems and is not

properly accepting charge.

This indication will be displayed for approximately 15

seconds, then the HEALTH LED will light steadily

and for an additional 15 seconds, the bargraph will

indicate the health of the battery pack by lighting one

of the bargraph LEDs to indicate the health of the

battery. The display will alternate between displaying

the termination method and battery health on a 15

second interval.

NOTE:

It is absolutely essential for the charging current to

be accurately set for the QuickChek health

algorithm's output to have any validity. Please set up

the charging current carefully. This evaluation board

is only set up for a 1 hour charging rate. The

charging current must be set up for the rated 1 hour

current rating of the battery as specified by the

battery manufacturers data sheet for this to have

any meaning.

Summary

The MCU based evaluation board is intended to

demonstrate the capabilities of the QuickSaver

charging algorithm when implemented in a

microcontroller based charger. Galaxy Power, Inc.

feels that end-users will quickly discover the

flexibility that this approach permits and suggest

many additional functions that could be implemented

with this approach. Although a Motorola

microcontroller was used to implement this design,

virtually any of the microcontrollers that are available

in the marketplace could be used to implement our

patented QuickSaver algorithm. Tradeoffs between

functionality and price can be easily implemented

using this approach. The present unit has

considerably more code space available so that

additional functions could be implemented that you

might desire in a battery charging system. This

system was implemented in assembly language;

however, Galaxy Power, Inc. has also implemented

our algorithm in "C" language and has implemented

this in Windows based systems, Win CE, Pocket PC

and other operating systems. The possibilities for

using the QuicksSaver charging algorithm in

embedded systems are virtually endless, and limited

only by your imagination.

5

Motorola MCU based Quicksaver Evaluation Board

Schematic Diagram

CAUTION!

Do not touch current sense resistors R1, R2, and R3 while unit is operating. They will be very

hot! This is normal, but could cause burns.

6

Motorola MCU based Quicksaver Evaluation Board

Ordering Information

M-QSC1702-EB Standard version

M-QSC1702/RS232-EB Version with RS232 data port

Galaxy Power, Inc.

2500 Eisenhower Avenue

PO Box 890

Valley Forge, PA 19482-0890

Phone: 610-676-0188

FAX: 610-676-0189

http://www.galaxypower.com/

e-mail:

rogers@galaxypower.com

NOTES