H04-004-07

Fuji Electric Co.,Ltd.

Matsumoto Factory

SPECIFICATION

Device Name :

Type Name :

Spec. No. :

IGBT Module

6MBI75UB-120

MS5F 5497

1

13

MS5F 5497

Jun. 18 '03 Y.Kobayashi

T.Miyasaka

K.Yamada

T.Fujihira

Jun. 18 '03

H04-004-06

R e v i s e d R e c o r d s

Date

Classi-

fication

Ind.

Content

Applied

date

Drawn

Checked

Approved

enactment

Issued

date

MS5F 5497

2

13

T.Miyasaka

K.Yamada

T.Fujihira

Jun.- 18 -'03

H04-004-03

13

MS5F 5497

3

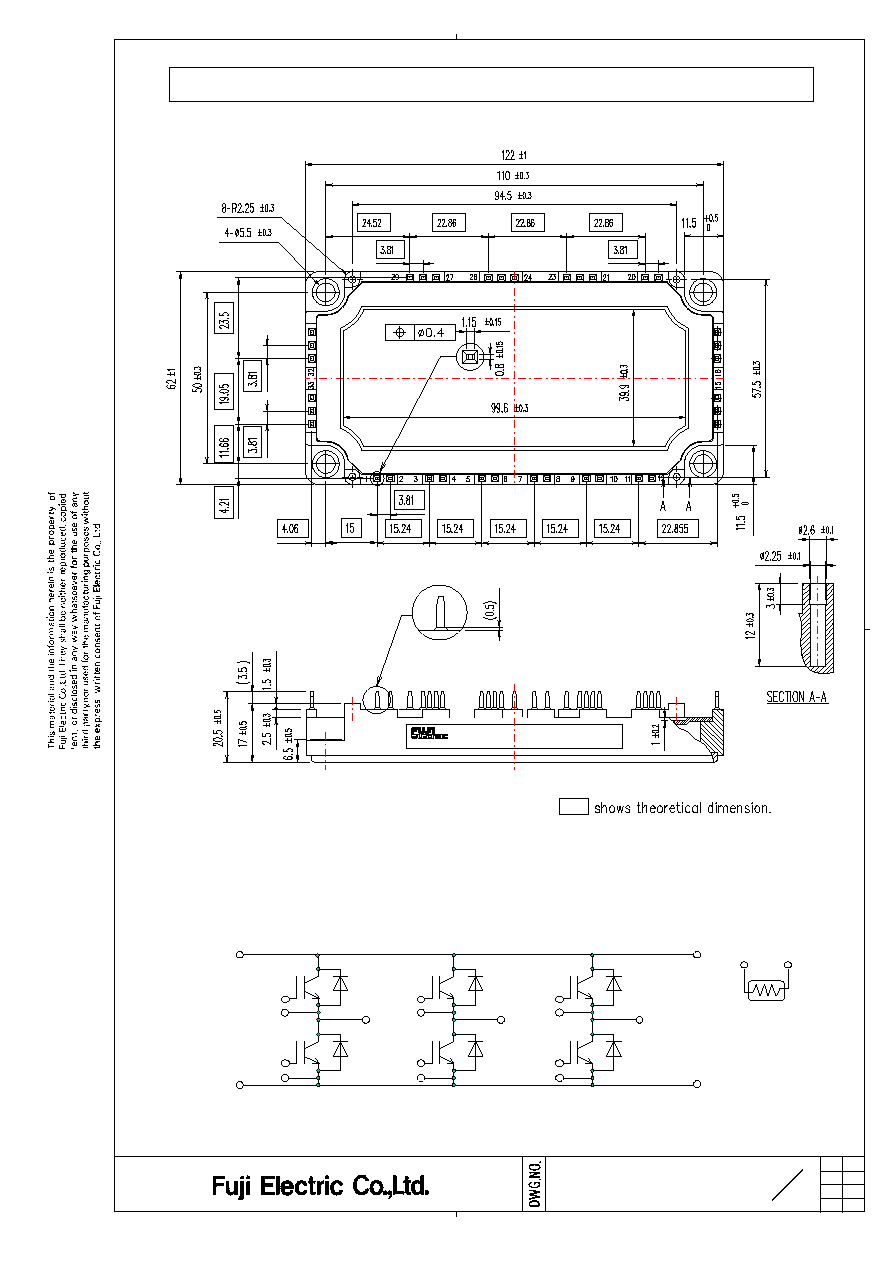

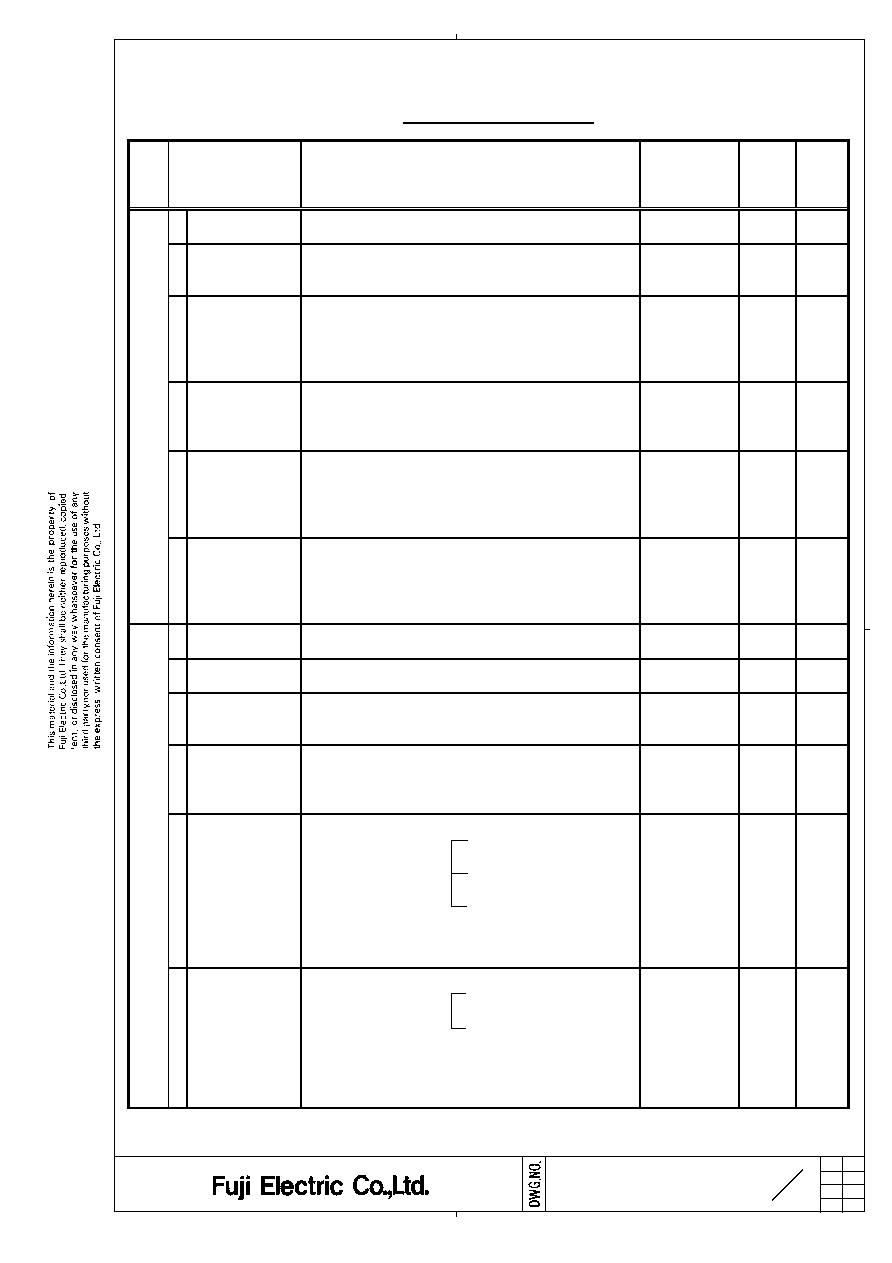

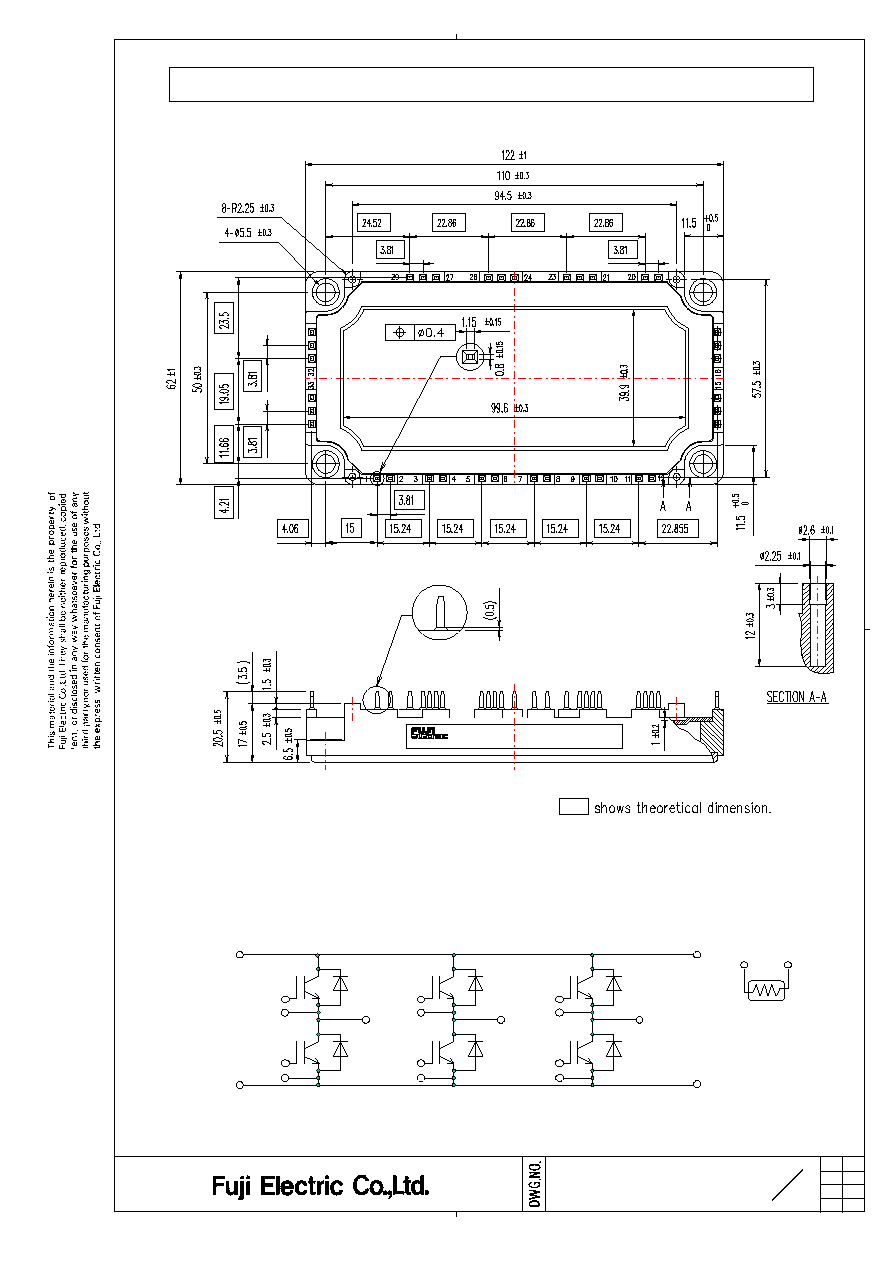

6MBI75UB-120

2. Equivalent circuit

1. Outline Drawing ( Unit : mm )

U

V

W

1

2

3

4

5

6

7

8

9

10

11

12

13,14,15

16,17,18

21,22,23

24,25,26

19

20

27,28,29

30,31,32

33,34,35

( ) shows reference dimension.

H04-004-03

13

MS5F 5497

4

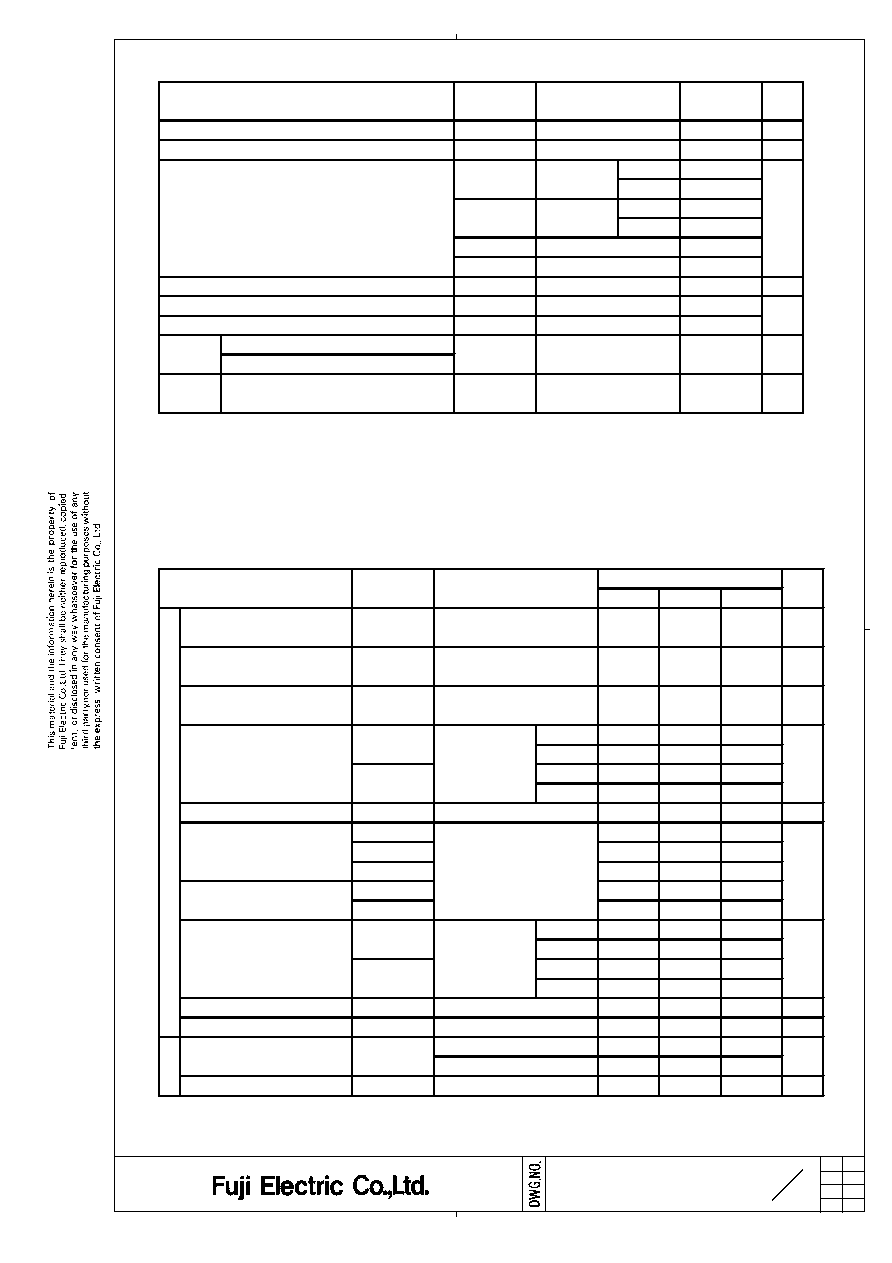

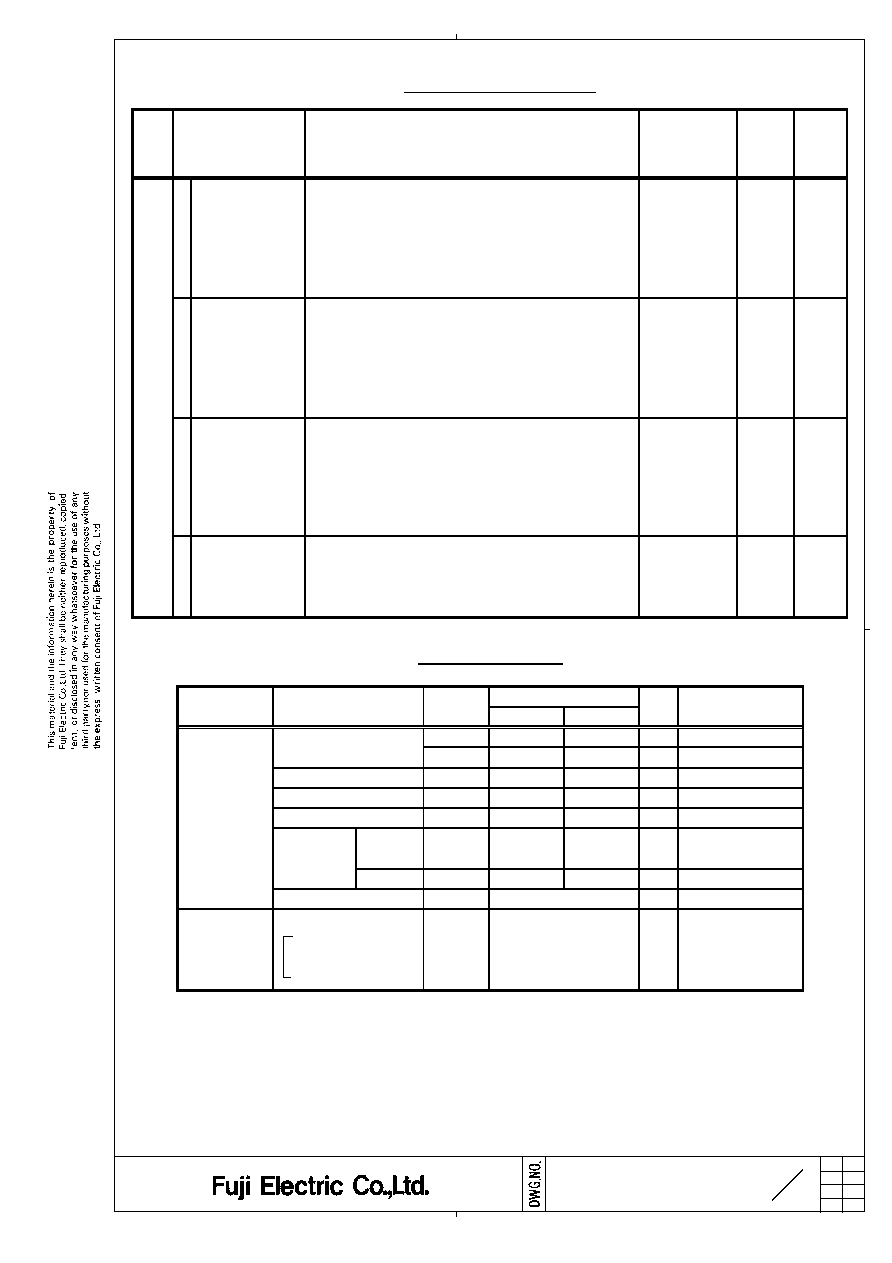

3.Absolute Maximum Ratings ( at Tc= 25 unless otherwise specified

Tc=25

Tc=80

Tc=25

Tc=80

(*1) All terminals should be connected together when isolation test will be done.

(*2) Two termistor terminals should be connected together, each other terminals should be connected together

and shorted to base plate when isolation test will be done.

(*3) Recommendable Value : 2.5~3.5 Nm (M5)

4. Electrical characteristics ( at Tj= 25 unless otherwise specified)

(*)

Biggest internal terminal resistance among arm.

3.4

-

m

Lead resistance, terminal-chip *

R lead

-

Inverter

IGES

Zero gate voltage

Collector current

ICES

ton

tr

tr (i)

Collector-Emitter

saturation voltage

VGE=15V

Ic = 75A

VGE = 0V

toff

tf

Rg = 9.1

VGE(th)

520

Turn-on time

Turn-off time

Gate-Emitter

leakage current

Gate-Emitter

threshold voltage

VGE=0V

VCE(sat)

(

terminal)

-

-

2.00

µs

IF = 75A

-

5000

-

-

0.35

T =100

465

-

1.60

1.90

Tj=125

-

Reverse recovery time

-

VF

(chip)

Tj= 25

-

Tj=125

IF = 75A

µs

Forward on voltage

VF

(terminal)

Tj= 25

-

1.90

2.20

V

1.70

1.00

1.20

0.60

-

-

0.36

-

0.21

Vcc = 600V

Ic = 75A

VGE=±15V

1200

Ic

Icp

100

75

200

150

V

±20

V

Items

Symbols

Conditions

VCES

Collector-Emitter voltage

VGES

AC : 1min.

Continuous

1ms

2500

VAC

Nm

-Ic pulse

Pc

Tj

A

W

1 device

150

Gate-Emitter voltage

Collector current

Junction temperature

Collector Power Dissipation

-Ic

75

150

390

1ms

Units

max.

typ.

Screw

Torque

-

min.

Characteristics

Tstg

Mounting *3

3.5

Conditions

between terminal and copper base *1

between thermistor and others *2

Storage temperature

Isolation

voltage

Viso

-40 +125

Ic = 75mA

200

VCE = 20V

Items

Symbols

VGE=±20V

VCE = 0V

-

-

-

nA

1.0

mA

V

-

8.5

V

4.5

6.5

Units

-

1.75

2.10

Maximum

Ratings

-

2.05

2.40

-

2.30

2.00

-

-

0.03

-

0.37

-

0.07

0.30

Input capacitance

Cies

VCE=10V,VGE=0V,f=1MHz

-

8

-

nF

K

Thermistor

Resistance

R

T = 25

B

3305

3375

3450

495

VCE = 1200V

-

B value

T = 25/50

VCE(sat)

(chip)

Tj= 25

Tj=125

Tj= 25

Tj=125

-

H04-004-03

13

MS5F 5497

5

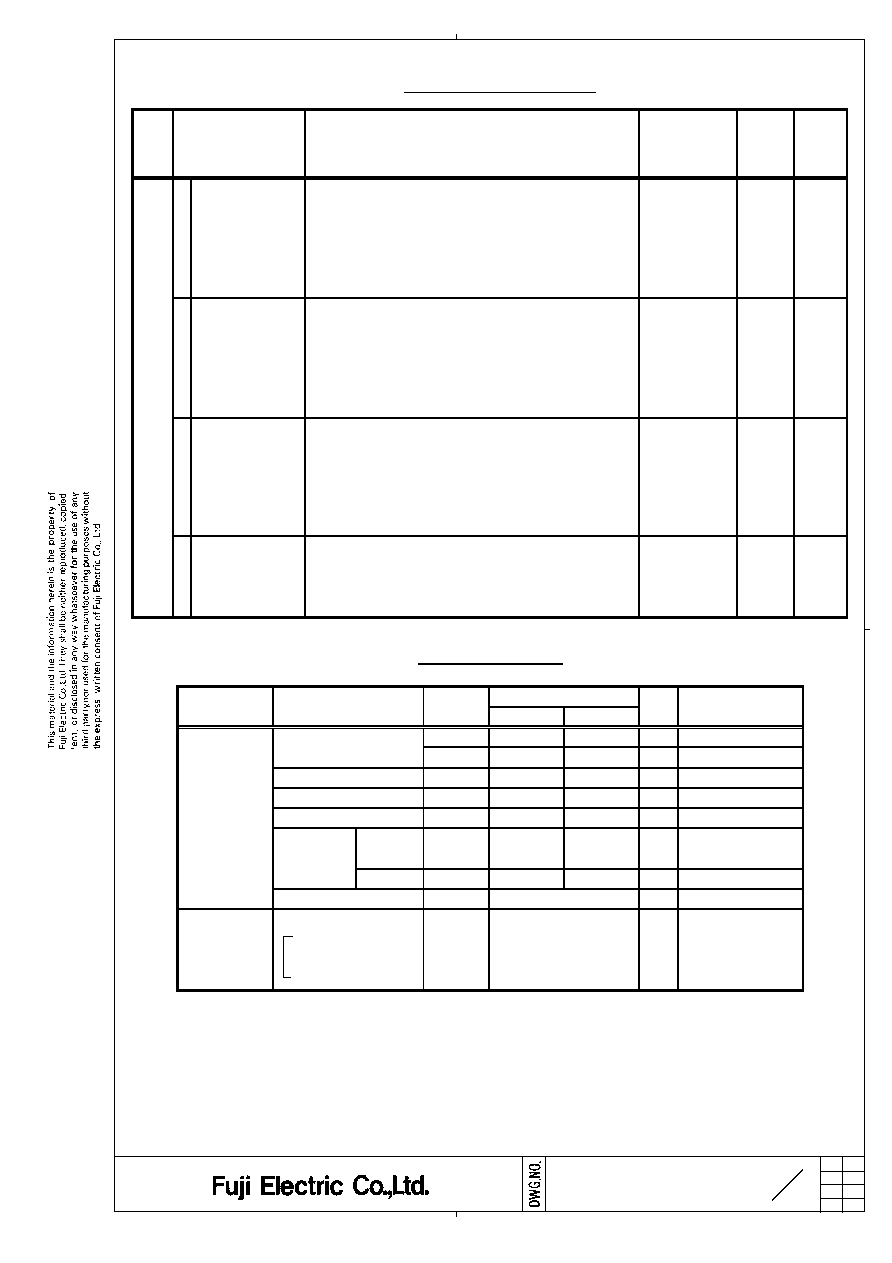

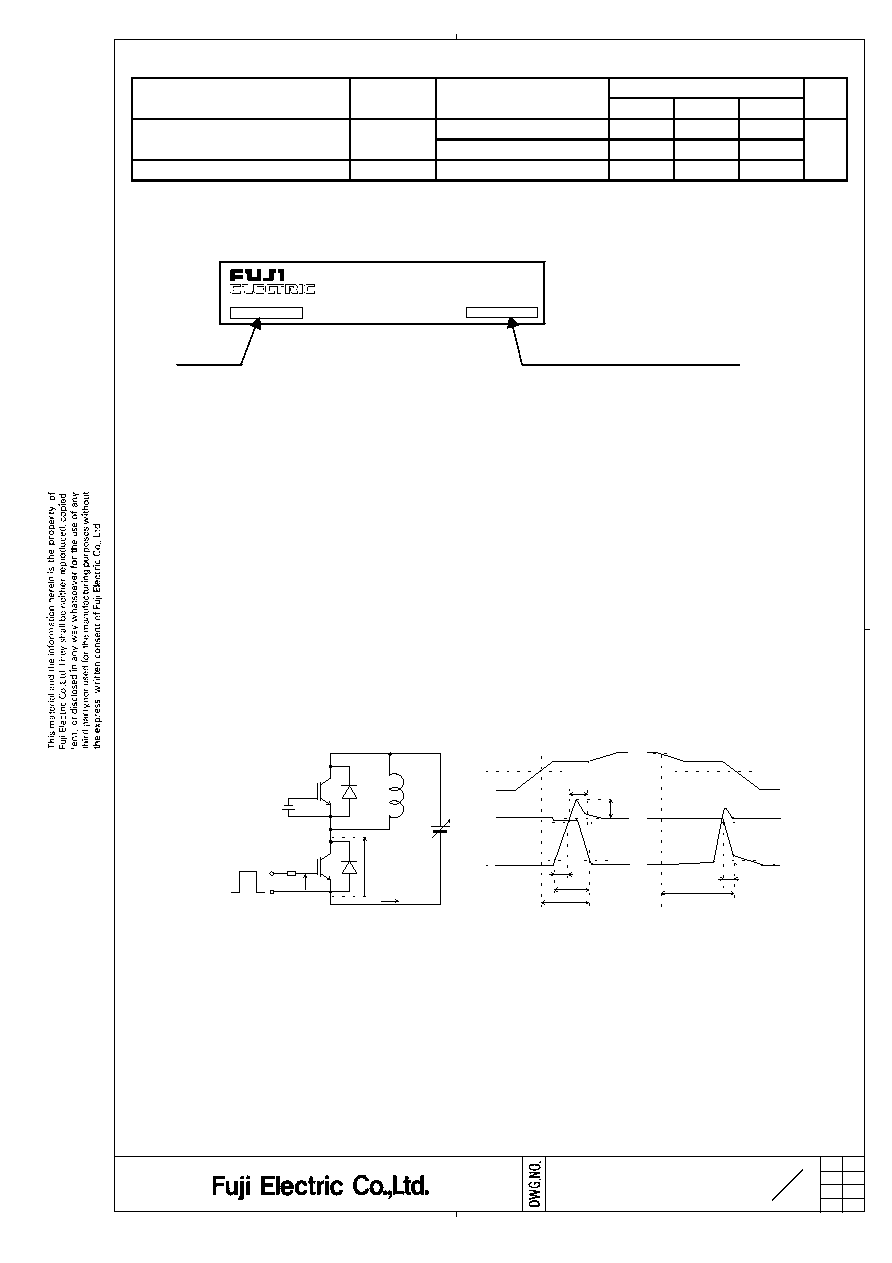

5. Thermal resistance characteristics

This is the value which is defined mounting on the additional cooling fin with thermal compound.

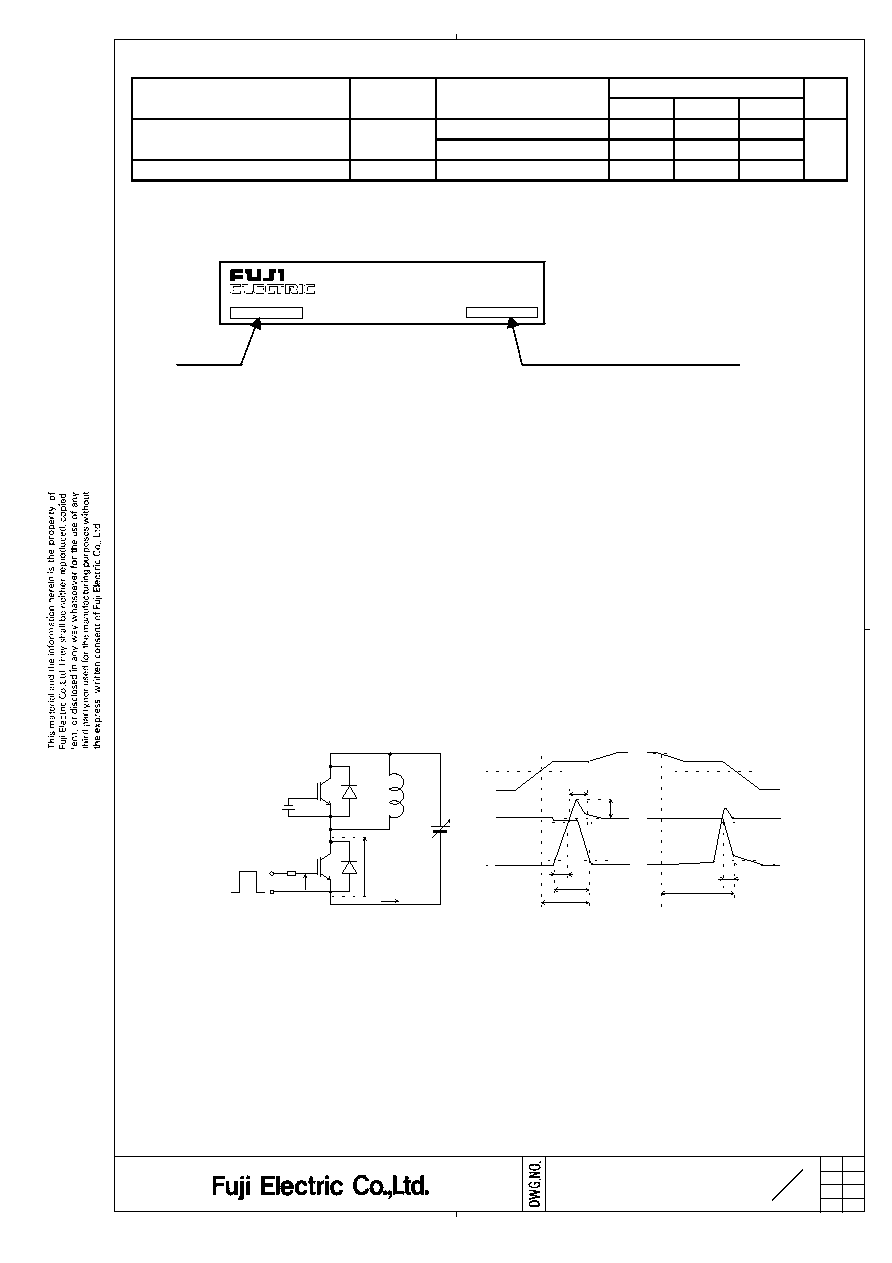

6. Indication on module

7.Applicable category

This specification is applied to IGBT Module named 6MBI75UB-120 .

8.Storage and transportation notes

The module should be stored at a standard temperature of 5 to 35 and humidity of 45 to 75% .

Store modules in a place with few temperature changes in order to avoid condensation on the module surface.

Avoid exposure to corrosive gases and dust.

Avoid excessive external force on the module.

Store modules with unprocessed terminals.

Do not drop or otherwise shock the modules when transporting.

9. Definitions of switching time

10. Packing and Labeling

Display on the packing box

- Logo of production

- Type name

- Lot No

- Products quantity in a packing box

Lot.No.

Items

Symbols

Conditions

Characteristics

Units

min.

typ.

max.

FWD

-

Thermal resistance(1device)

Contact Thermal resistance(1device)

Rth(j-c)

Rth(c-f)

with Thermal Compound ()

-

-

0.05

Place of manufacturing (code)

/W

75A 1200V

6MBI75UB-120

-

0.32

-

-

0.49

IGBT

L

Vcc

Ic

V

CE

R

G

V

GE

V

GE

V

CE

Ic

0V

0A

0V

10%

90%

10%

10%

90%

90%

0V

Ic

V

CE

on

on

on

on

t

t

t

t

r

r

r

r

t

t

t

t

r(i)

r(i)

r(i)

r(i)

t

t

t

t

off

off

off

off

t

t

t

t

f

f

f

f

t

t

t

t

rr

rr

rr

rr

I

I

I

I

rr

rr

rr

rr

t

t

t

t

H04-004-03

13

MS5F 5497

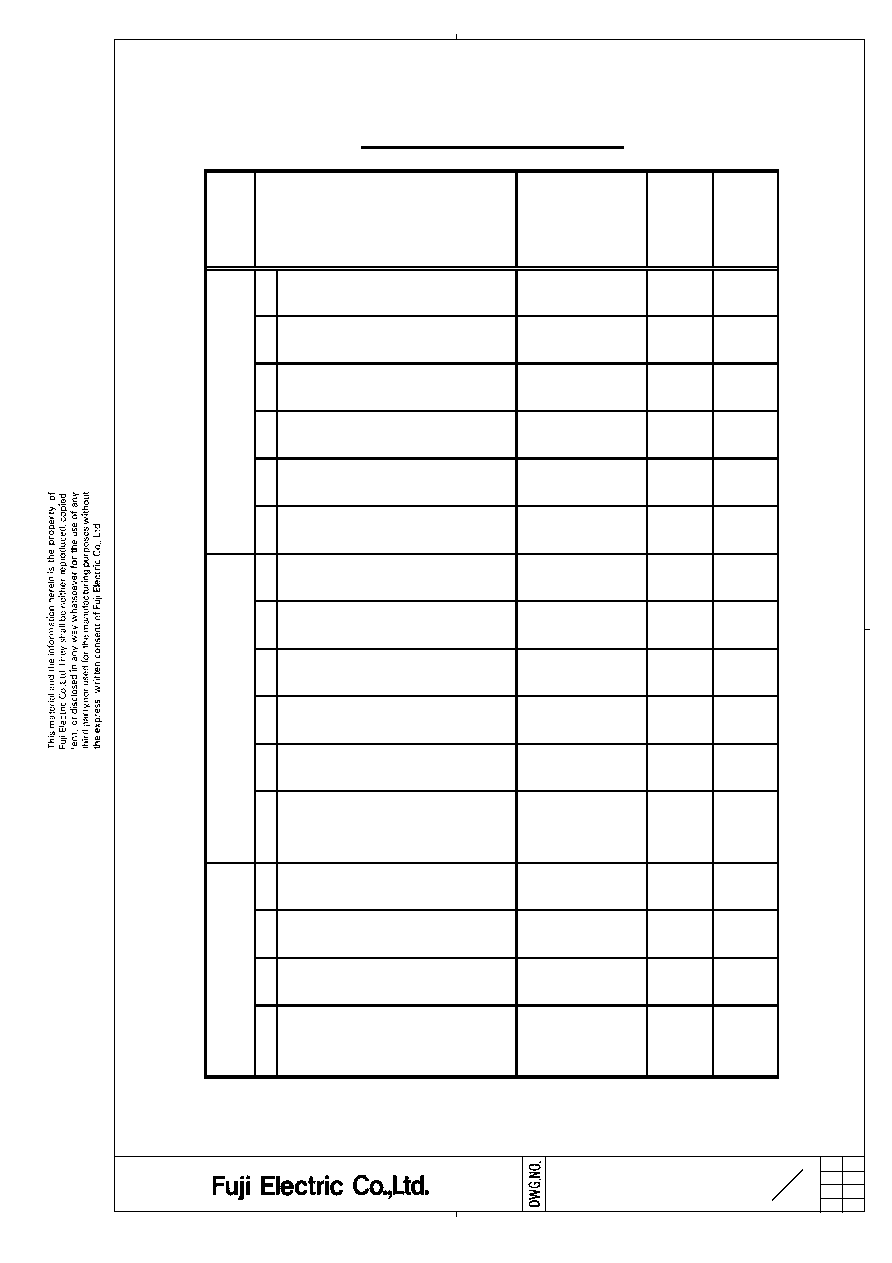

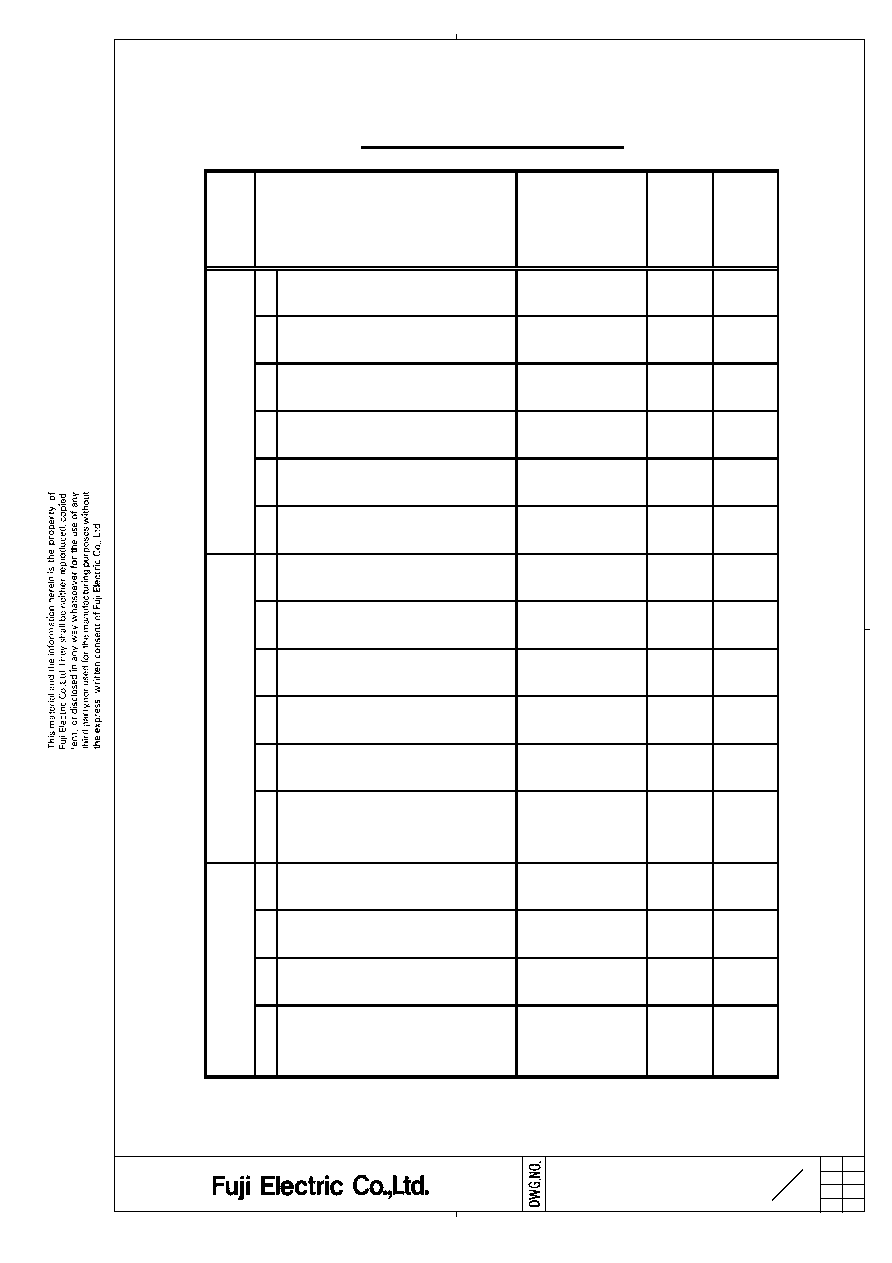

11. Reliability test results

6

Reliability Test Items

Test

cate-

gories

Test items

Test methods and conditions

Reference

norms

EIAJ ED-4701

(Aug.-2001 edition)

Number

of

sample

Accept-

ance

number

1 Terminal Strength Pull force

: 20N

Test Method 401

5

( 0 : 1 )

(Pull test)

Test time

: 10±1 sec.

Method

2 Mounting Strength Screw torque

: 2.5 ~ 3.5 Nm (M5)

Test Method 402

5

( 0 : 1 )

Test time

: 10±1 sec.

method

3 Vibration

Range of frequency : 10 ~ 500Hz

Test Method 403

5

( 0 : 1 )

Sweeping time

: 15 min.

Reference 1

Acceleration

: 100m/s

2

Condition code B

Sweeping direction : Each X,Y,Z axis

Test time

: 6 hr. (2hr./direction)

4 Shock

Maximum acceleration : 5000m/s

2

Test Method 404

5

( 0 : 1 )

Pulse width

: 1.0msec.

Condition code B

Direction

: Each X,Y,Z axis

Test time

: 3 times/direction

5 Solderabitlity

Solder temp.

: 235±5

Test Method 303

5

( 0 : 1 )

Immersion time

: 5±0.5sec.

Condition code A

Test time

: 1 time

Each terminal should be Immersed in solder

within 1~1.5mm from the body.

6 Resistance to

Solder temp.

: 260±5

Test Method 302

5

( 0 : 1 )

Soldering Heat

Immersion time

: 10±1sec.

Condition code A

Test time

: 1 time

Each terminal should be Immersed in solder

within 1~1.5mm from the body.

1 High Temperature Storage temp.

: 125±5

Test Method 201

5

( 0 : 1 )

Storage

Test duration

: 1000hr.

2 Low Temperature Storage temp.

: -40±5

Test Method 202

5

( 0 : 1 )

Storage

Test duration

: 1000hr.

3 Temperature

Storage temp.

: 85±2

Test Method 103

5

( 0 : 1 )

Humidity

Relative humidity

: 85±5%

Test code C

Storage

Test duration

: 1000hr.

4 Unsaturated

Test temp.

: 120±2

Test Method 103

5

( 0 : 1 )

Pressure Cooker Atmospheric pressure : 1.7 × 10

5

Pa

Test code E

Test humidity

: 85±5%

Test duration

: 96hr.

5 Temperature

Test Method 105

5

( 0 : 1 )

Cycle

Test temp.

: Low temp. -40±5

High temp. 125 ±5

RT 5 ~ 35

Dwell time

: High ~ RT ~ Low ~ RT

1hr. 0.5hr. 1hr. 0.5hr.

Number of cycles

: 100 cycles

6 Thermal Shock

+0

Test Method 307

5

( 0 : 1 )

Test temp.

: High temp. 100

-5

method

+5

Condition code A

Low temp. 0

-0

Used liquid : Water with ice and boiling water

Dipping time

: 5 min. par each temp.

Transfer time

: 10 sec.

Number of cycles

: 10 cycles

Mechanical Tests

Environment Tests

H04-004-03

13

MS5F 5497

7

Reliability Test Items

Test

cate-

gories

Test items

Test methods and conditions

Reference

norms

EIAJ ED-4701

(Aug.-2001 edition)

Number

of

sample

Accept-

ance

number

1 High temperature

Test Method 101

5

( 0 : 1 )

Reverse Bias

Test temp.

: Ta = 125±5

(Tj

150 )

Bias Voltage

: VC = 0.8×VCES

Bias Method

: Applied DC voltage to C-E

VGE = 0V

Test duration

: 1000hr.

2 High temperature

Test Method 101

5

( 0 : 1 )

Bias (for gate)

Test temp.

: Ta = 125±5

(Tj

150 )

Bias Voltage

: VC = VGE = +20V or -20V

Bias Method

: Applied DC voltage to G-E

VCE = 0V

Test duration

: 1000hr.

3 Temperature

Test Method 102

5

( 0 : 1 )

Humidity Bias

Test temp.

: 85±2

o

C

Condition code C

Relative humidity

: 85±5%

Bias Voltage

: VC = 0.8×VCES

Bias Method

: Applied DC voltage to C-E

VGE = 0V

Test duration

: 1000hr.

4 Intermitted

ON time

: 2 sec.

Test Method 106

5

( 0 : 1 )

Operating Life

OFF time

: 18 sec.

(Power cycle)

Test temp.

: Tj=100±5 deg

( for IGBT )

Tj

150 , Ta=25±5

Number of cycles

: 15000 cycles

Endurance Tests

Failure Criteria

Item

Characteristic

Symbol

Failure criteria

Unit

Note

Lower limit Upper limit

Electrical

Leakage current

ICES

-

USL×2

mA

characteristic

±IGES

-

USL×2

µA

Gate threshold voltage VGE(th)

LSL×0.8

USL×1.2

mA

Saturation voltage

VCE(sat)

-

USL×1.2

V

Forward voltage

VF

-

USL×1.2

V

Thermal

IGBT

VGE

-

USL×1.2

mV

resistance

or

VCE

FWD

VF

-

USL×1.2

mV

Isolation voltage

Viso

Broken insulation

-

Visual

Visual inspection

inspection

Peeling

-

The visual sample

-

Plating

and the others

LSL : Lower specified limit.

USL : Upper specified limit.

Note : Each parameter measurement read-outs shall be made after stabilizing the components

at room ambient for 2 hours minimum, 24 hours maximum after removal from the tests.

And in case of the wetting tests, for example, moisture resistance tests, each component

shall be made wipe or dry completely before the measurement.

Each parameter measurement read-outs shall be made after stabilizing the components

at room ambient for 2 hours minimum, 24 hours maximum after removal from the tests.

And in case of the wetting tests, for example, moisture resistance tests, each component

shall be made wipe or dry completely before the measurement.

H04-004-03

13

MS5F 5497

8

Reliability Test Results

Test

cate-

gorie

s

Test items

Reference

norms

EIAJ ED-4701

(Aug.-2001 edition)

Number

of test

sample

Number

of

failure

sample

1 Terminal Strength

Test Method 401

5

0

(Pull test)

Method

2 Mounting Strength

Test Method 402

5

0

method

3 Vibration

Test Method 403

5

0

Condition code B

4 Shock

Test Method 404

5

0

Condition code B

5 Solderabitlity

Test Method 303

5

0

Condition code A

6 Resistance to Soldering Heat

Test Method 302

5

0

Condition code A

1 High Temperature Storage

Test Method 201

5

0

2 Low Temperature Storage

Test Method 202

5

0

3 Temperature Humidity

Test Method 103

5

0

Storage

Test code C

4 Unsaturated

Test Method 103

5

0

Pressure Cooker

Test code E

5 Temperature Cycle

Test Method 105

5

0

6 Thermal Shock

Test Method 307

5

0

method

Condition code A

1 High temperature Reverse Bias

Test Method 101

5

0

2 High temperature Bias

Test Method 101

5

0

( for gate )

3 Temperature Humidity Bias

Test Method 102

5

0

Condition code C

4 Intermitted Operating Life

Test Method 106

5

0

(Power cycling)

( for IGBT )

Endurance Tests

Mechanical Tests

Environment Tests

H04-004-03

13

MS5F 5497

9

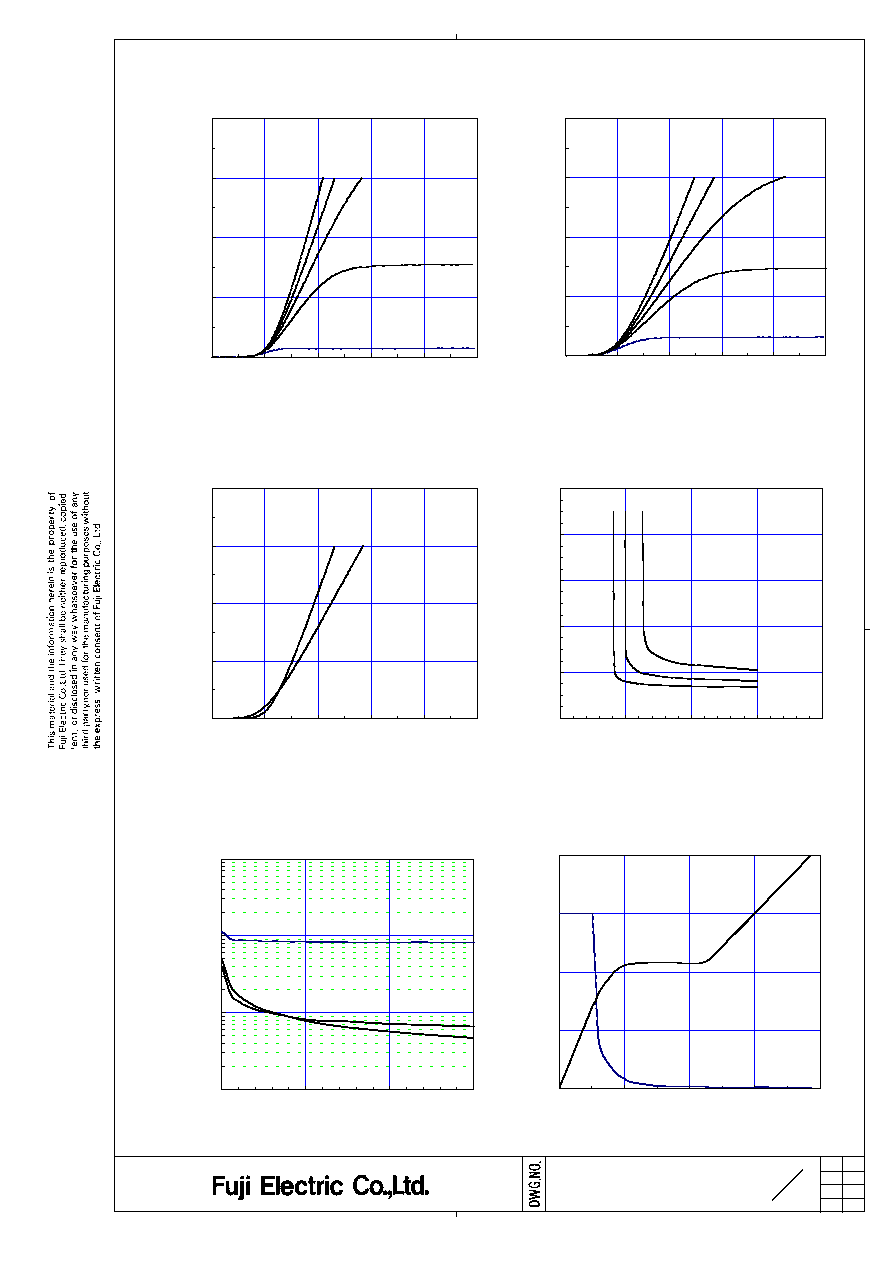

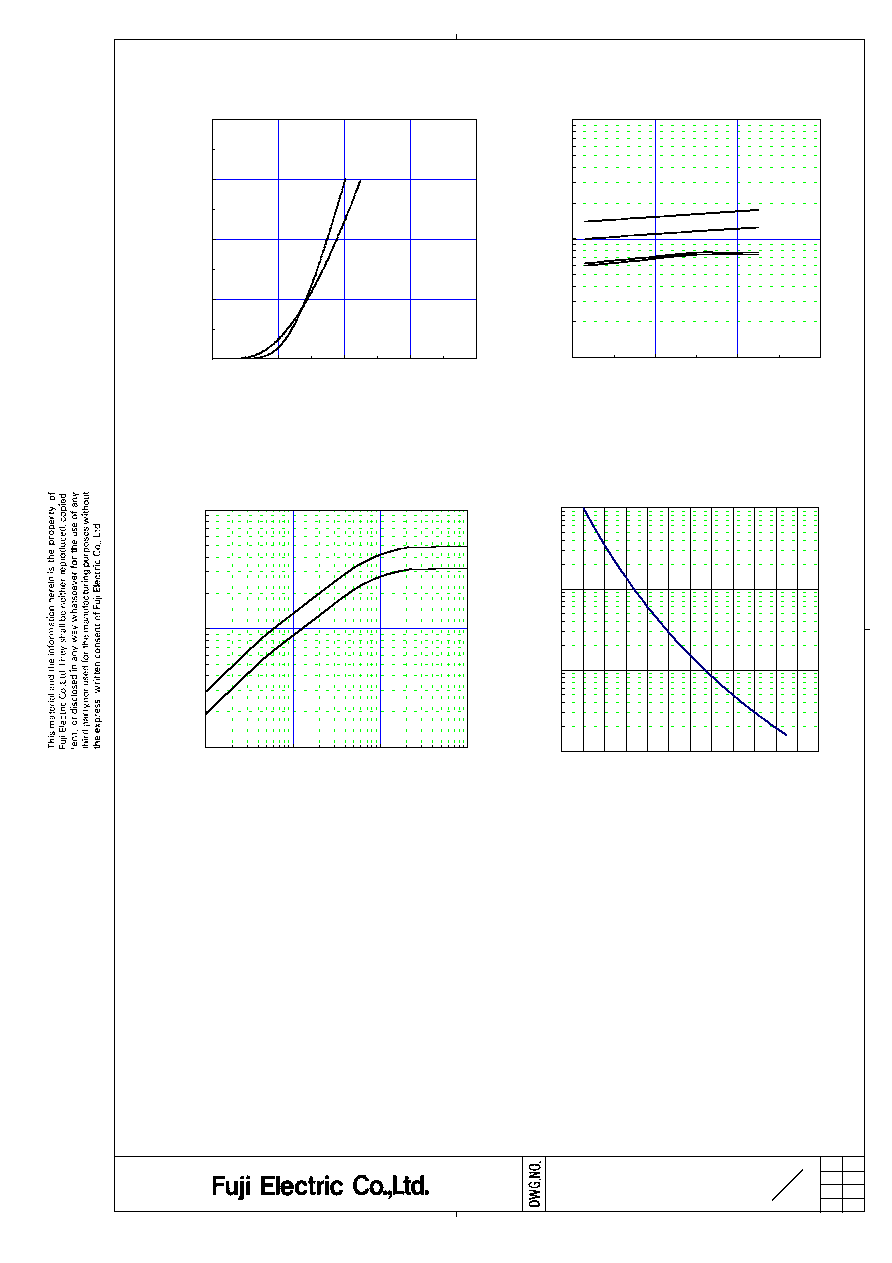

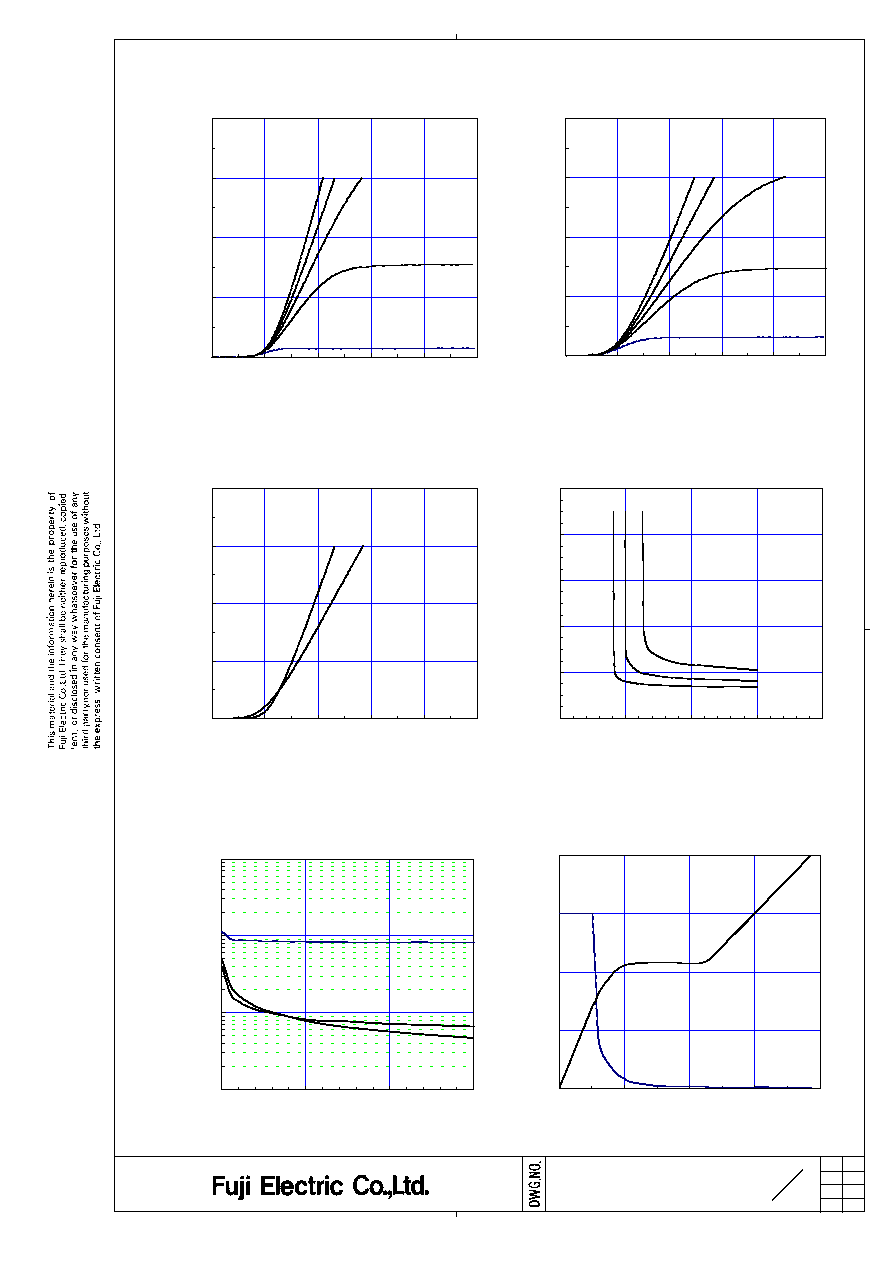

Vcc=600V Ic=75ATj= 25

VGE=0V, f= 1MHz, Tj= 25

Dynamic Gate charge (typ.)

Collector current vs. Collector-Emitter voltage (typ.)

Tj= 25 / chip

Collector current vs. Collector-Emitter voltage (typ.)

VGE=15V / chip

Collector current vs. Collector-Emitter voltage (typ.)

Tj= 125 / chip

Collector-Emitter voltage vs. Gate-Emitter voltage (typ.)

Tj=25C / chip

Capacitance vs. Collector-Emitter voltage (typ.)

0

50

100

150

200

0

1

2

3

4

5

Collector current : Ic [A]

Collector-Emitter voltage : VCE [V]

VGE=20V

15V

12V

10V

8V

0

50

100

150

200

0

1

2

3

4

5

Collector current : Ic [A]

Collector-Emitter voltage : VCE [V]

VGE=20V

15V

12V

10V

8V

0

50

100

150

200

0

1

2

3

4

5

Collector current : Ic [A]

Collector-Emitter voltage : VCE [V]

Tj=125

Tj=25

0

2

4

6

8

10

5

10

15

20

25

Collector - Emitter voltage : VCE [ V ]

Gate - Emitter voltage : VGE [ V ]

Ic=150A

Ic=75A

Ic= 37.5A

0.1

1.0

10.0

100.0

0

10

20

30

Capacitance : Cies, Coes, Cres [ nF ]

Collector-Emitter voltage : VCE [V]

Cies

Coes

Cres

0

100

200

300

400

Collector-Emitter voltage : VCE [ 200V/div ]

Gate - Emitter voltage : VGE [ 5V/div ]

Gate charge : Qg [ nC ]

0

VGE

VCE

H04-004-03

13

MS5F 5497

10

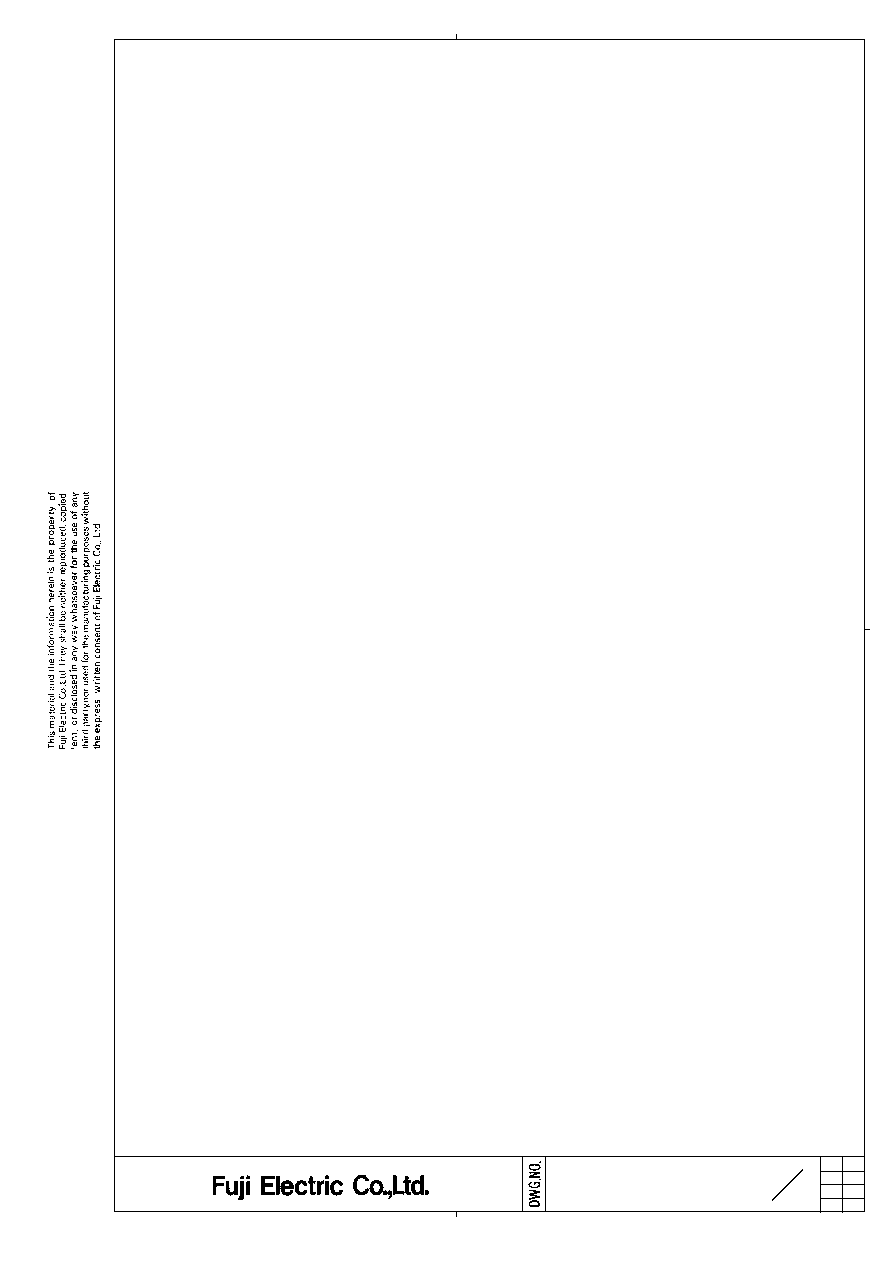

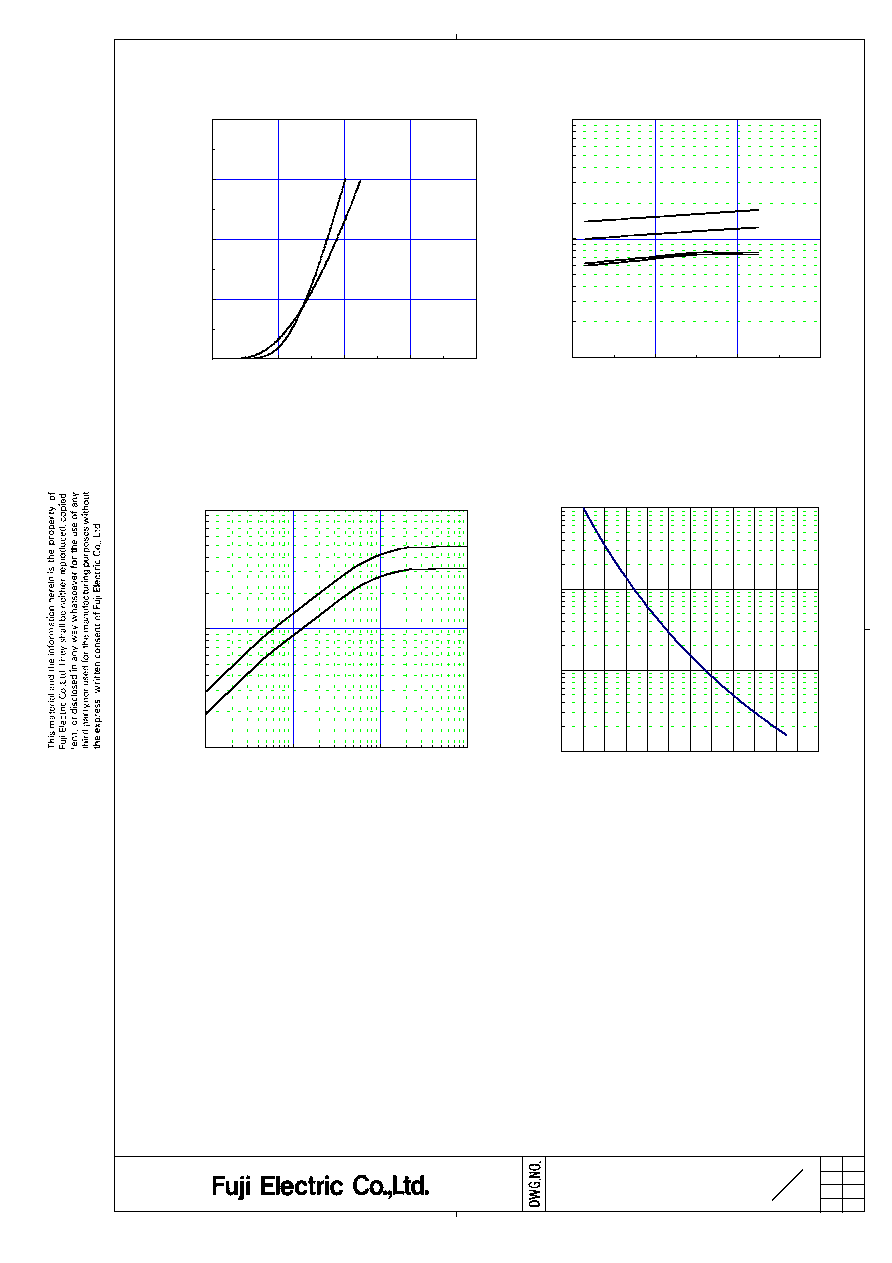

+VGE=15V,-VGE15V, RG9.1 ,Tj125

Switching loss vs. Collector current (typ.)

Vcc=600V, VGE=±15V, Rg=9.1

Switching loss vs. Gate resistance (typ.)

Switching time vs. Collector current (typ.)

Vcc=600V, VGE=±15V, Rg=9.1, Tj= 25

Vcc=600V, Ic=75A, VGE=±15V, Tj= 25

Switching time vs. Collector current (typ.)

Vcc=600V, VGE=±15V, Rg=9.1, Tj=125

Switching time vs. Gate resistance (typ.)

Vcc=600V, Ic=75A, VGE=±15V, Tj= 125

Reverse bias safe operating area (max.)

10

100

1000

10000

0

50

100

150

Switching time : ton, tr, toff, tf [ nsec ]

Collector current : Ic [ A ]

ton

toff

tr

tf

10

100

1000

10000

0

50

100

150

Switching time : ton, tr, toff, tf [ nsec ]

Collector current : Ic [ A ]

toff

ton

tr

tf

10

100

1000

10000

1

10

100

1000

Switching time : ton, tr, toff, tf [ nsec ]

Gate resistance : Rg [ ]

tr

tf

toff

ton

0

5

10

15

0

25

50

75

100

125

150

Switching loss : Eon, Eoff, Err [ mJ/pulse ]

Collector current : Ic [ A ]

Eon(125)

Eon(25)

Eoff(125)

Err(125)

Err(25)

Eoff(25)

0

25

50

75

1

10

100

1000

Switching loss : Eon, Eoff, Err [ mJ/pulse ]

Gate resistance : Rg [ ]

Eoff

Err

Eon

0

50

100

150

200

0

400

800

1200

Collector current : Ic [ A ]

Collector - Emitter voltage : VCE [ V ]

H04-004-03

13

MS5F 5497

11

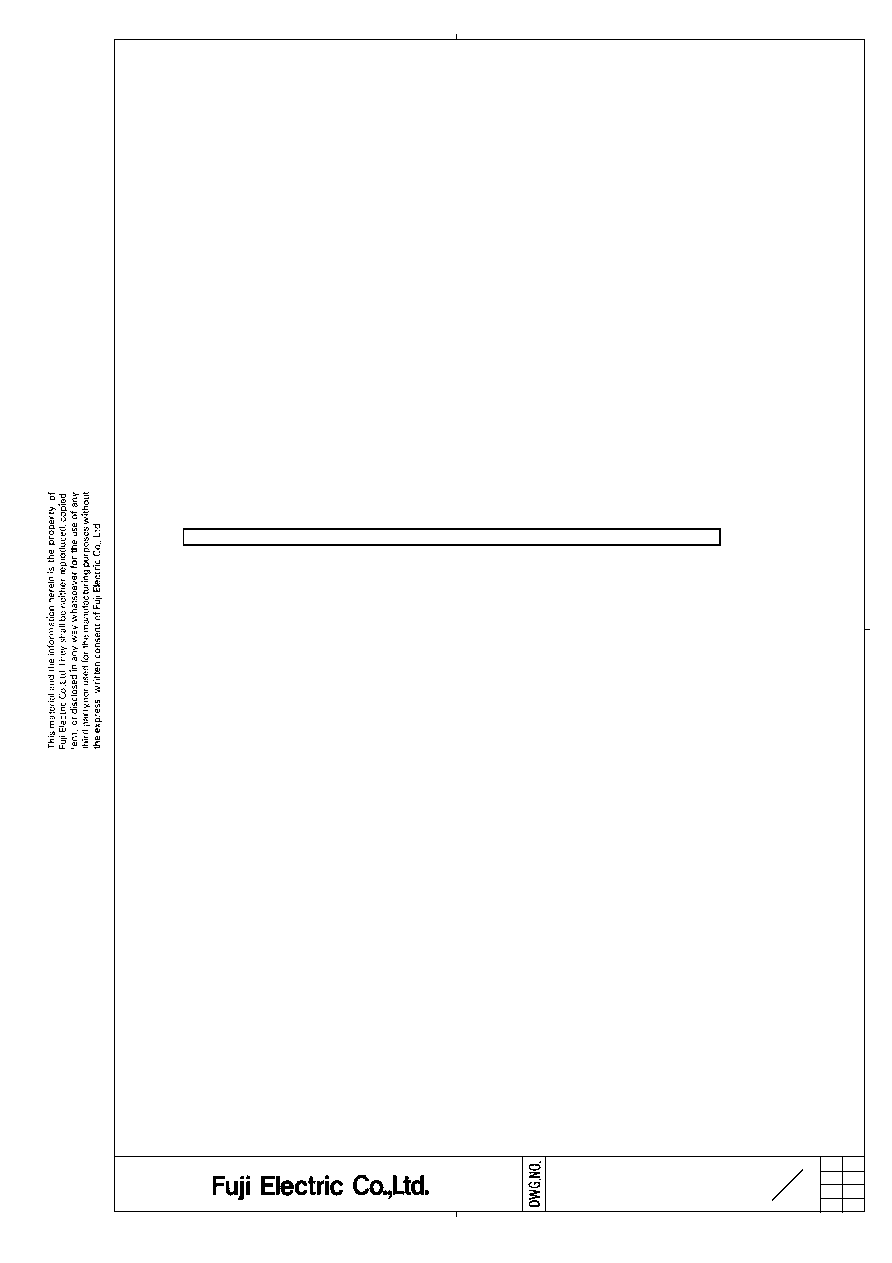

Transient thermal resistance (max.)

Reverse recovery characteristics (typ.)

Vcc=600V, VGE=±15V, Rg=9.1

Forward current vs. Forward on voltage (typ.)

chip

Temperature characteristic (typ.)

0.1

1

10

100

-60 -40 -20 0

20 40 60 80 100 120 140 160 180

Temperature [ ]

Resistance : R [ k

]

0

50

100

150

200

0

1

2

3

4

Forward current : IF [ A ]

Forward on voltage : VF [ V ]

Tj=125

Tj=25

10

100

1000

0

50

100

150

Reverse recovery current : Irr [ A ]

Reverse recovery time : trr [ nsec ]

Forward current : IF [ A ]

trr (125)

trr (25)

Irr (125)

Irr (25)

0.01

0.10

1.00

0.001

0.010

0.100

1.000

Thermal resistanse : Rth(j-c) [

/W ]

Pulse width : Pw [ sec ]

FWD

IGBT

H04-004-03

13

MS5F 5497

12

Warnings

Warnings

Warnings

Warnings

- This product shall be used within its absolute maximum rating (voltage, current, and temperature).

This product may be broken in case of using beyond the ratings.

- Connect adequate fuse or protector of circuit between three-phase line and

this product to prevent the equipment from causing secondary destruction.

- Use this product after realizing enough working on environment and considering of product's reliability life.

This product may be broken before target life of the system in case of using beyond the product's reliability life.

- If the product had been used in the environment with acid, organic matter, and corrosive gas ( hydrogen sulfide,

sulfurous acid gas), the product's performance and appearance can not be ensured easily.

- Use this product within the power cycle curve (Technical Rep.No. : MT5F12959)

(No.: MT5F12959)

- Never add mechanical stress to deform the main or control terminal.

The deformed terminal may cause poor contact problem.

- Use this product with keeping the cooling fin's flatness between screw holes within 100um at 100mm and the

roughness within 10um. Also keep the tightening torque within the limits of this specification.

Improper handling may cause isolation breakdown and this may lead to a critical accident.

100mm100um10um

- It shall be confirmed that IGBT's operating locus of the turn-off voltage and current are within the RBSOA

specification. This product may be broken if the locus is out of the RBSOA.

RBSOA

RBSOA

- If excessive static electricity is applied to the control terminals, the devices may be broken.

Implement some countermeasures against static electricity.

- Never add the excessive mechanical stress to the main or control terminals

when the product is applied to equipments. The module structure may be broken.

- In case of insufficient -VGE, erroneous turn-on of IGBT may occur.

-VGE shall be set enough value to prevent this malfunction. (Recommended value : -VGE = -15V)

-VGE

-VGE : -VGE = -15V)

- In case of higher turn-on dv/dt of IGBT, erroneous turn-on of opposite arm IGBT may occur.

Use this product in the most suitable drive conditions, such as +VGE, -VGE, RG to prevent the malfunction.

dv/dt

+VGE, -VGE, RG

- This product may be broken by avalanche in case of VCE beyond maximum rating VCES is applied between

C-E terminals. Use this product within its absolute maximum voltage.

VCES

VCE

H04-004-03

13

MS5F 5497

13

Cautions

Cautions

Cautions

Cautions

- Fuji Electric is constantly making every endeavor to improve the product quality and reliability.However,

semiconductor products may rarely happen to fail or malfunction. To prevent accidents causing injury or

death, damage to property like by fire, and other social damage resulted from a failure or malfunction of

the Fuji Electric semiconductor products, take some measures to keep safety such as redundant design,

spread-fire-preventive design, and malfunction-protective design.

- The application examples described in this specification only explain typical ones that used the Fuji Electric

products. This specification never ensure to enforce the industrial property and other rights, nor license the

enforcement rights.

- The product described in this specification is not designed nor made for being applied to the equipment or

systems used under life-threatening situations. When you consider applying the product of this specification

to particular used, such as vehicle-mounted units, shipboard equipment, aerospace equipment, medical devices,

atomic control systems and submarine relaying equipment or systems,please apply after confirmation

of this product to be satisfied about system construction and required reliability.

If there is any unclear matter in this specification, please contact Fuji Electric Co.,Ltd.