Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

©2004 Fairchild Semiconductor Corporation

1

www.fairchildsemi.com

May 2005

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

w

e

r

A

m

pli

f

ier

Mo

du

le 19

2019

80 M

H

z

(P

r

e

l

i

m

i

n

a

r

y

)

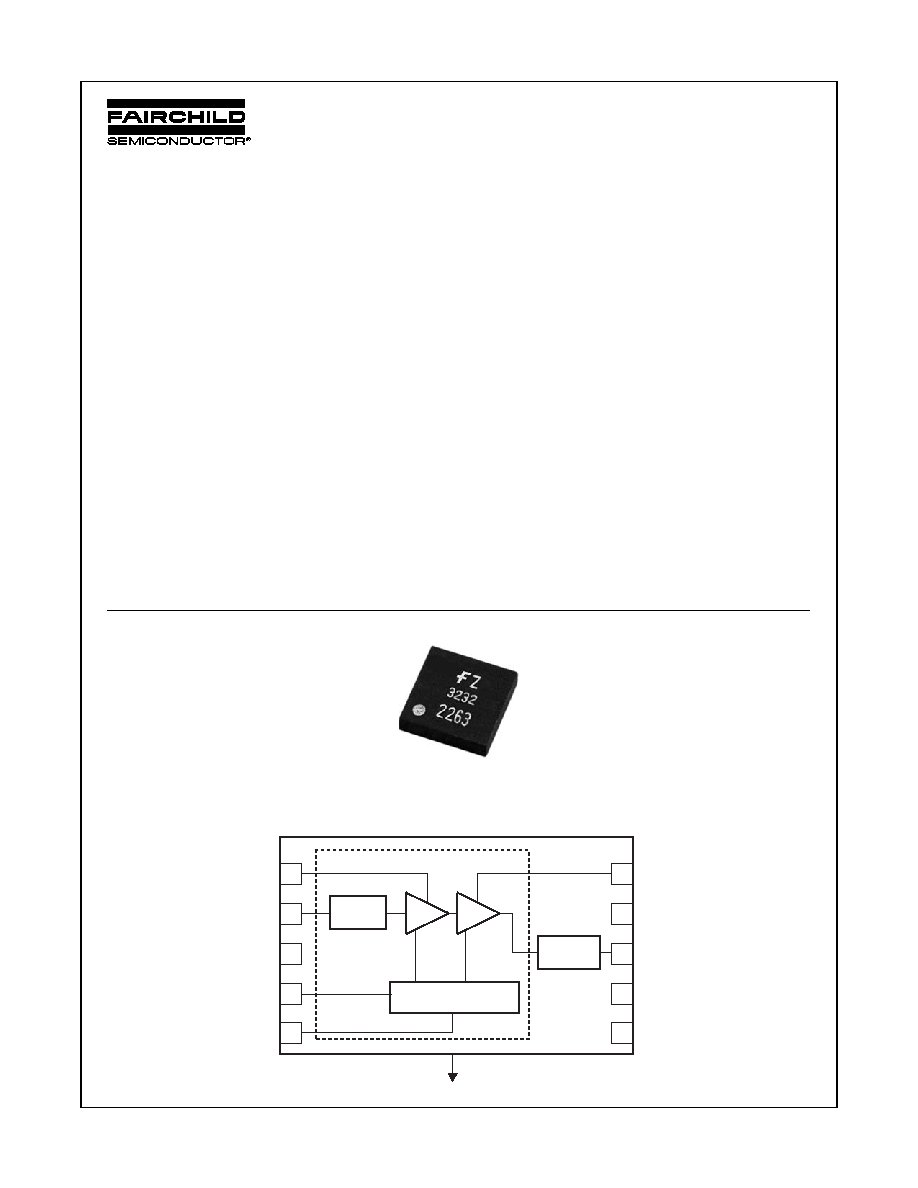

RMPA2263

i-LoTM

Rev. G

RMPA2263

i-LoTM

WCDMA Power Amplifier Module

19201980 MHz

Features

40% WCDMA efficiency at +28 dBm Pout

14% WCDMA efficiency (85 mA total current) at +16 dBm

Pout

Linear operation in low-power mode up to +19 dBm

Low quiescent current (Iccq): 25 mA in low-power mode

Meets UMTS/WCDMA performance requirements

Meets HSDPA performance requirements

Single positive-supply operation with low power and shut-

down modes

3.4V typical Vcc operation

Low Vref (2.85V) compatible with advanced handset

chipsets

Compact Lead-free compliant LCC package

(4.0 x 4.0 x 1.5 mm nominal)

Industry standard pinout

Internally matched to 50 Ohms and DC blocked RF input/

output

General Description

The RMPA2263 Power Amplifier Module (PAM) is Fairchild's

latest innovation in 50 Ohm matched, surface mount modules

targeting UMTS/WCDMA/HSDPA applications. Answering the

call for ultra-low DC power consumption and extended battery

life in portable electronics, the RMPA2263 uses novel

proprietary circuitry to dramatically reduce amplifier current at

low to medium RF output power levels (< +16 dBm), where the

handset most often operates. A simple two-state Vmode control

is all that is needed to reduce operating current by more than

50% at 16 dBm output power, and quiescent current (Iccq) by

as much as 70% compared to traditional power-saving

methods. No additional circuitry, such as DC-to-DC converters,

are required to achieve this remarkable improvement in

amplifier efficiency. Further, the 4

x

4

x

1.5 mm LCC package is

pin-compatible and a drop-in replacement for last generation 4

x

4 mm PAMs widely used today, minimizing the design time to

apply this performance-enhancing technology. The multi-stage

GaAs Microwave Monolithic Integrated Circuit (MMIC) is

manufactured using Fairchild RF's InGaP Heterojunction

Bipolar Transistor (HBT) process.

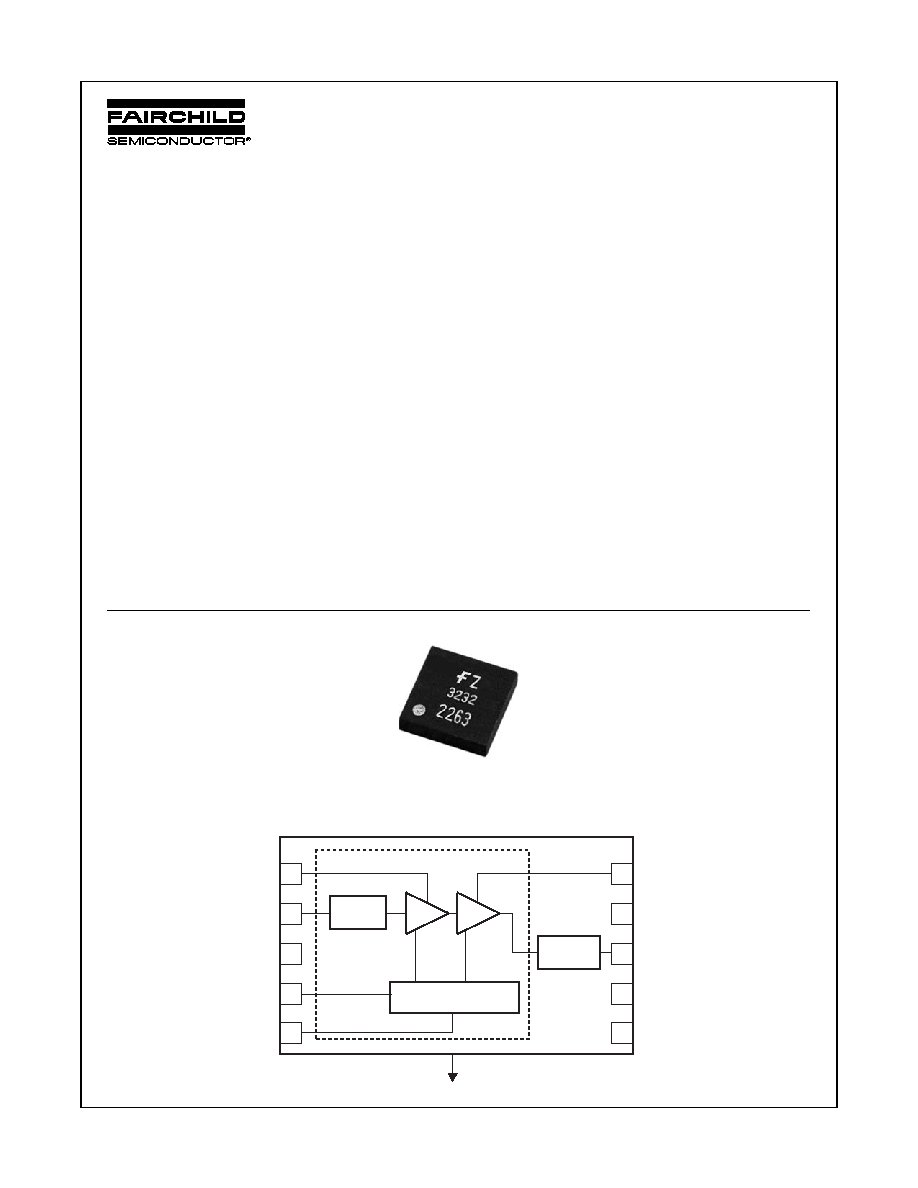

Device

Functional Block Diagram

Vref

Vmode

RF IN

GND

Vcc1

RF OUT

GND

GND

GND

7

6

8

9

10

4

3

2

BIAS/MODE SWITCH

1

5

Vcc2

11 (paddle ground on package bottom)

INPUT

MATCH

OUTPUT

MATCH

MMIC

(Top View)

PRELIMINARY

2

www.fairchildsemi.com

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

we

r

A

m

plif

ier

Mo

dul

e 192

0198

0 MH

z (

P

r

e

lim

in

ar

y

)

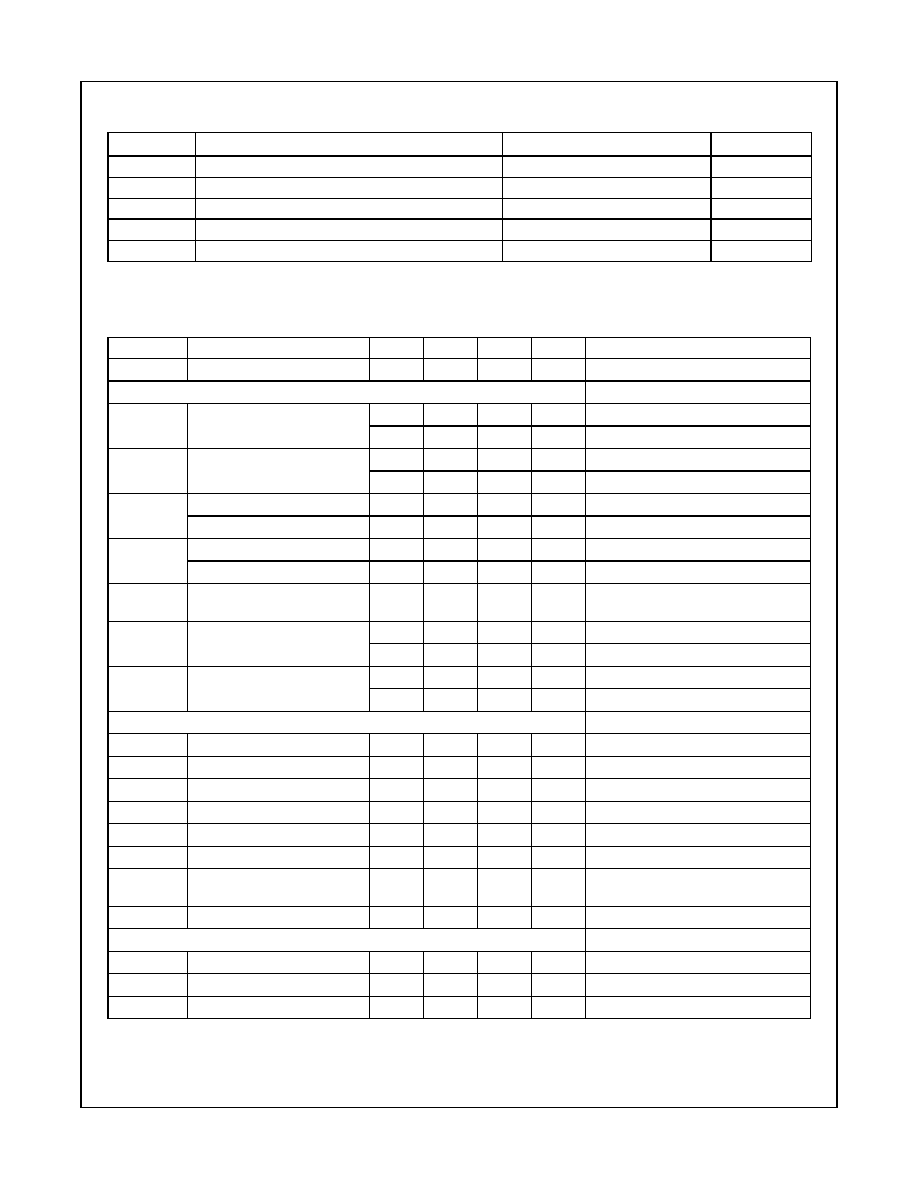

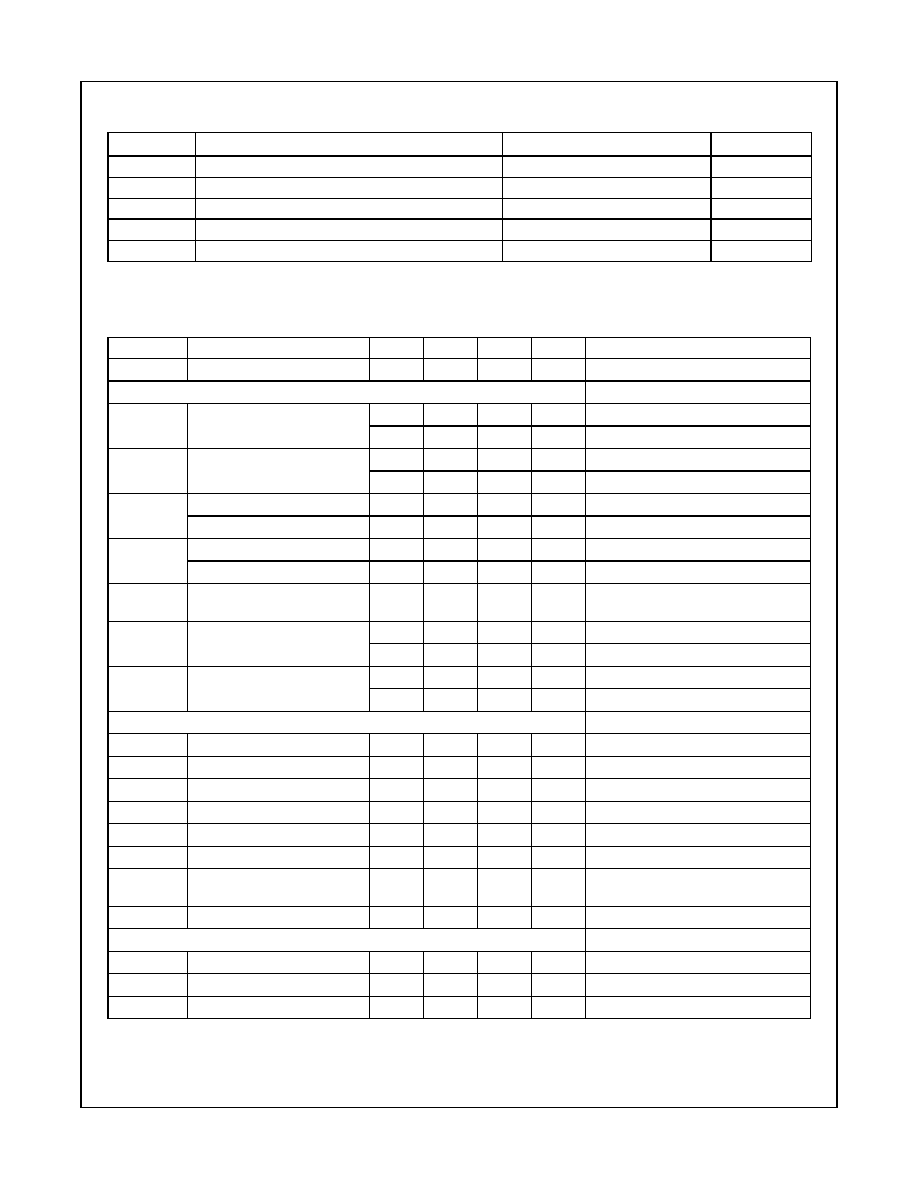

Absolute Ratings

1

Note:

1: No permanent damage with only one parameter set at extreme limit. Other parameters set to typical values.

Electrical Characteristics

1

Notes:

1. All parameters met at Tc = +25°C, Vcc = +3.4V, Vref = 2.85V and load VSWR

1.2:1, unless otherwise noted.

2. All phase angles.

3. Guaranteed by design.

Symbol

Parameter

Ratings

Units

Vcc1, Vcc2

Supply Voltages

5.0

V

Vref

Reference Voltage

2.6 to 3.5

V

Vmode

Power Control Voltage

3.5

V

Pin

RF Input Power

+10

dBm

Tstg

Storage Temperature

-55 to +150

°C

Symbol

Parameter

Min

Typ

Max

Units

Comments

f

Operating Frequency

1920

1980

MHz

WCDMA Operation

Gp

Power Gain

27.5

dB

Po=+28dBm, Vmode=0V

23

dB

Po=+16dBm, Vmode

2.0V

Po

Linear Output Power

28

dBm

Vmode=0V

16

dBm

Vmode

2.0V

PAEd

PAEd (digital) @ 28dBm

40

%

Vmode=0V

PAEd (digital) @ 16dBm

13

%

Vmode

2.0V

Itot

High Power Total Current

460

mA

Po=+28dBm, Vmode=0V

Low Power Total Current

85

mA

Po=+16dBm, Vmode

2.0V

Adjacent Channel Leakage

Ratio

WCDMA Modulation 3GPP

3.2 03-00 DPCCH+1 DCDCH

ACLR1

±5.00MHz Offset

-40

dBc

Po=+28dBm, Vmode=0V

-46

dBc

Po=+16dBm, Vmode

2.0V

ACLR2

±10.0MHz Offset

-52

dBc

Po=+28dBm, Vmode=0V

-57

dBc

Po=+16dBm, Vmode

2.0V

General Characteristics

VSWR

Input Impedance

2.0:1

2.5:1

NF

Noise Figure

4

dB

Rx No

Receive Band Noise Power

-139

dBm/Hz Po

+28dBm, 2110 to 2170 MHz

2fo

Harmonic Suppression

-38

dBc

Po

+28dBm

3fo5fo

Harmonic Suppression

-55

dBc

Po

+28dBm

S

Spurious Outputs

2, 3

-60

dBc

Load VSWR

5.0:1

Ruggedness with Load

Mismatch

3

10:1

No permanent damage

Tc

Case Operating Temperature

-30

85

°C

DC Characteristics

Iccq

Quiescent Current

25

mA

Vmode

2.0V

Iref

Reference Current

7

mA

Po

+28dBm

Icc(off)

Shutdown Leakage Current

1

5

µA

No applied RF signal

3

www.fairchildsemi.com

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

we

r

A

m

plif

ier

Mo

dul

e 192

0198

0 MH

z (

P

r

e

lim

in

ar

y

)

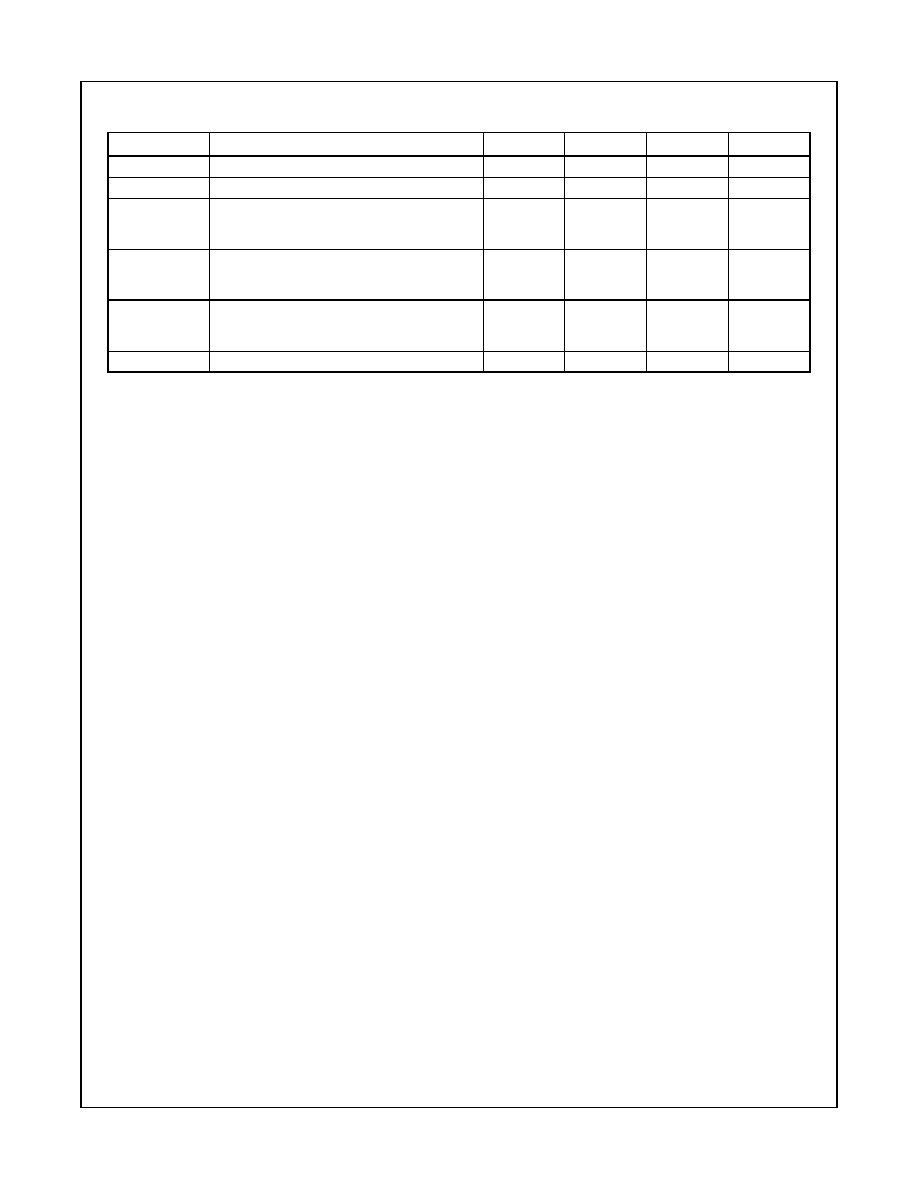

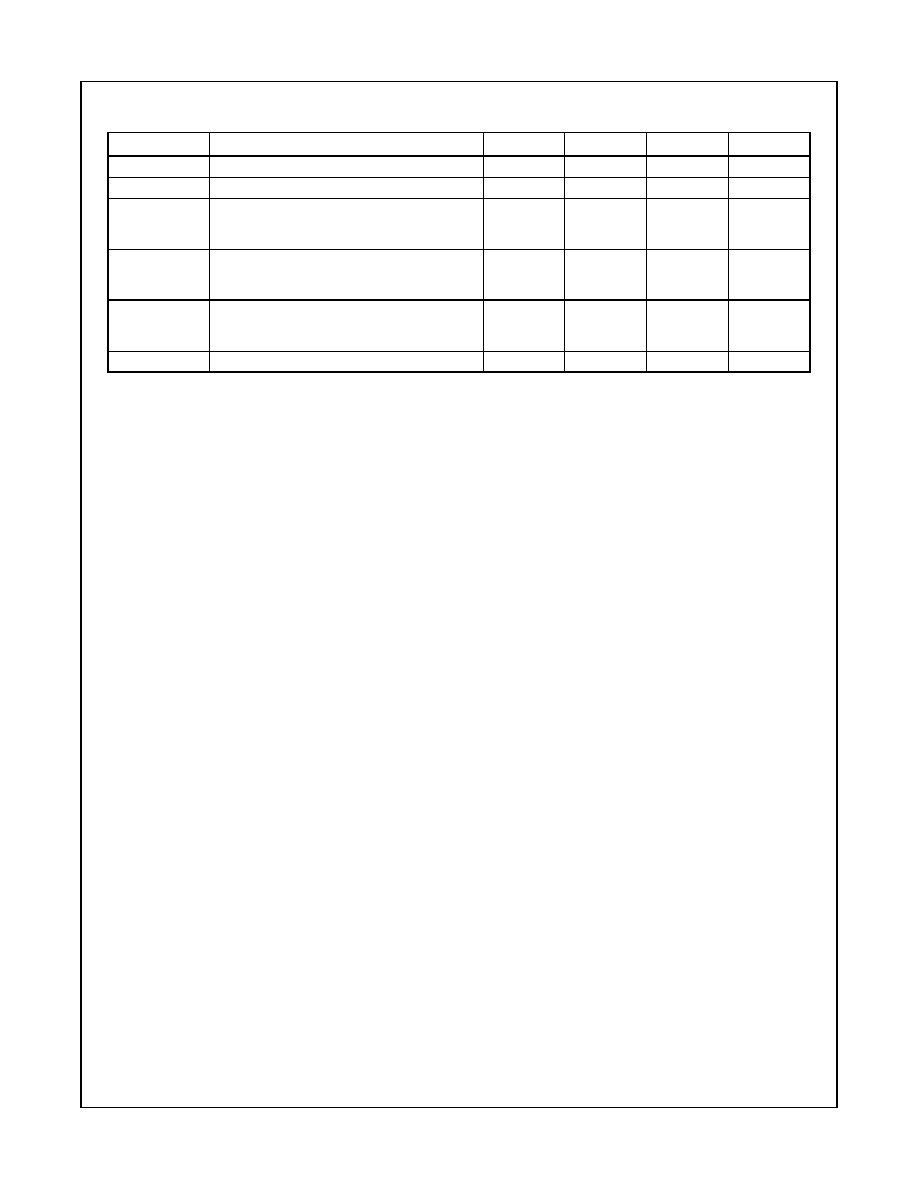

Recommended Operating Conditions

DC Turn On Sequence:

1. Vcc1 = Vcc2 = 3.4V (typical)

2. Vref = 2.85V (typical)

3. High-Power: Vmode = 0V (Pout > 16dBm)

Low-Power: Vmode = 2.0V (Pout < 16dBm)

Symbol

Parameter

Min

Typ

Max

Units

f

Operating Frequency

1920

1980

MHz

Vcc1, Vcc2

Supply Voltage

3.0

3.4

4.2

V

Vref

Reference Voltage

Operating

Shutdown

2.7

0

2.85

3.1

0.5

V

V

Vmode

Bias Control Voltage

Low-Power

High-Power

1.8

0

2.0

3.0

0.5

V

V

Pout

Linear Output Power

High-Power

Low-Power

+16

+28

+19

dBm

dBm

Tc

Case Operating Temperature

-30

+85

°C

4

www.fairchildsemi.com

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

we

r

A

m

plif

ier

Mo

dul

e 192

0198

0 MH

z (

P

r

e

lim

in

ar

y

)

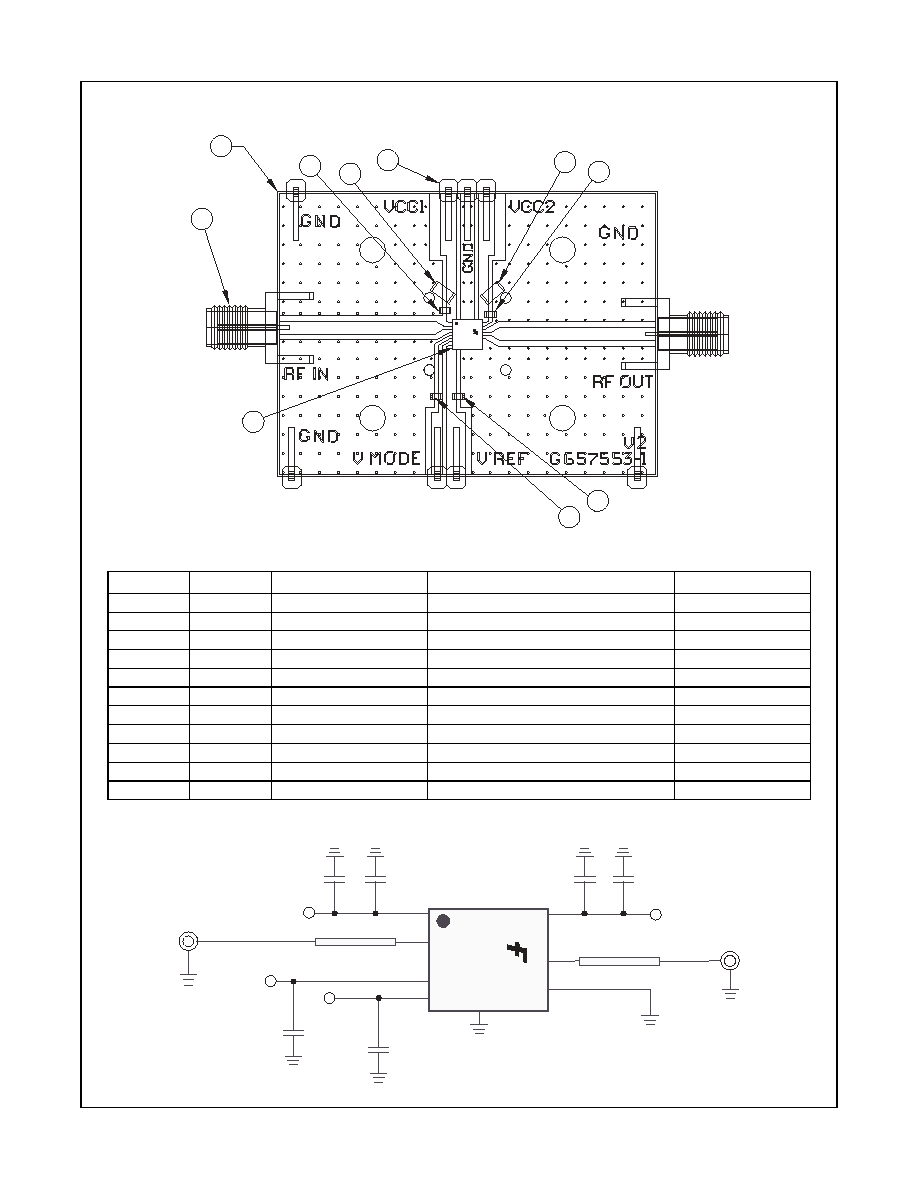

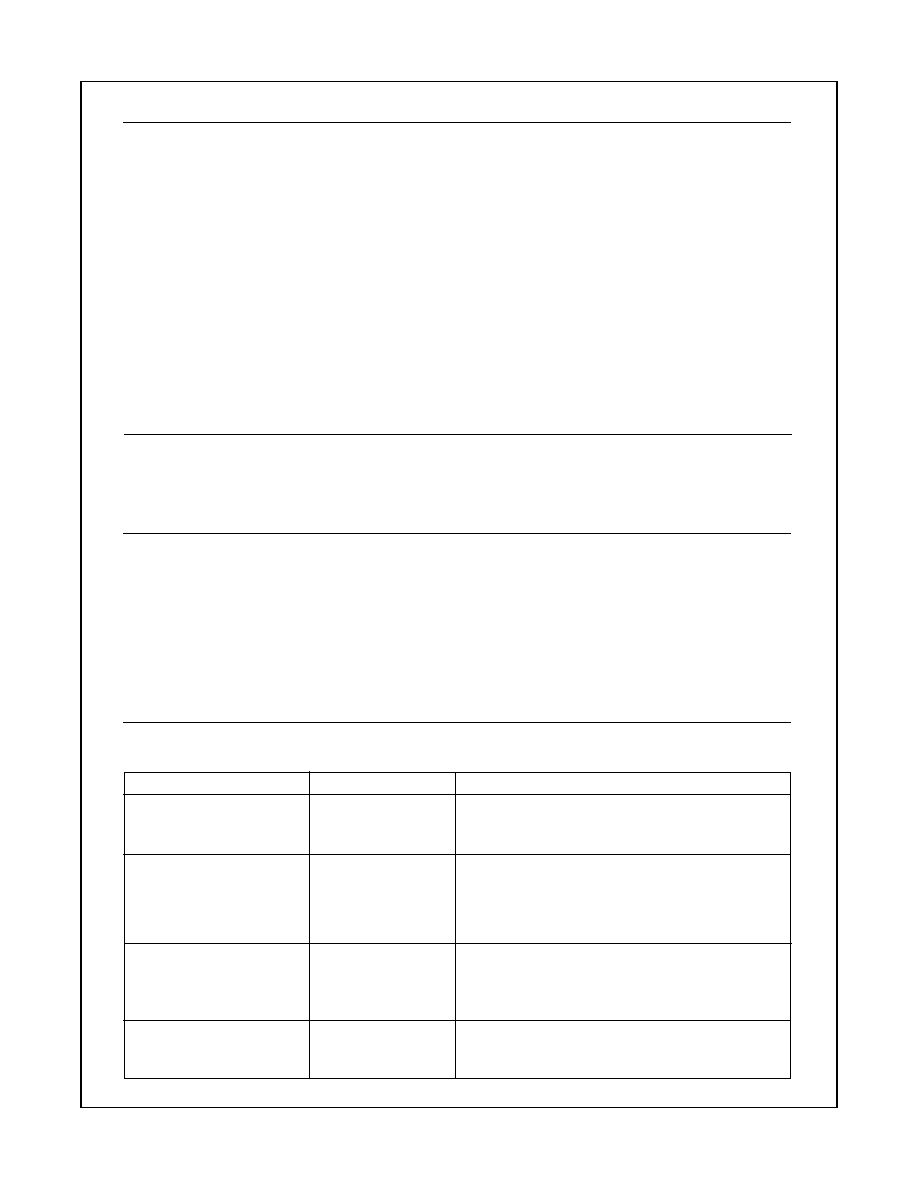

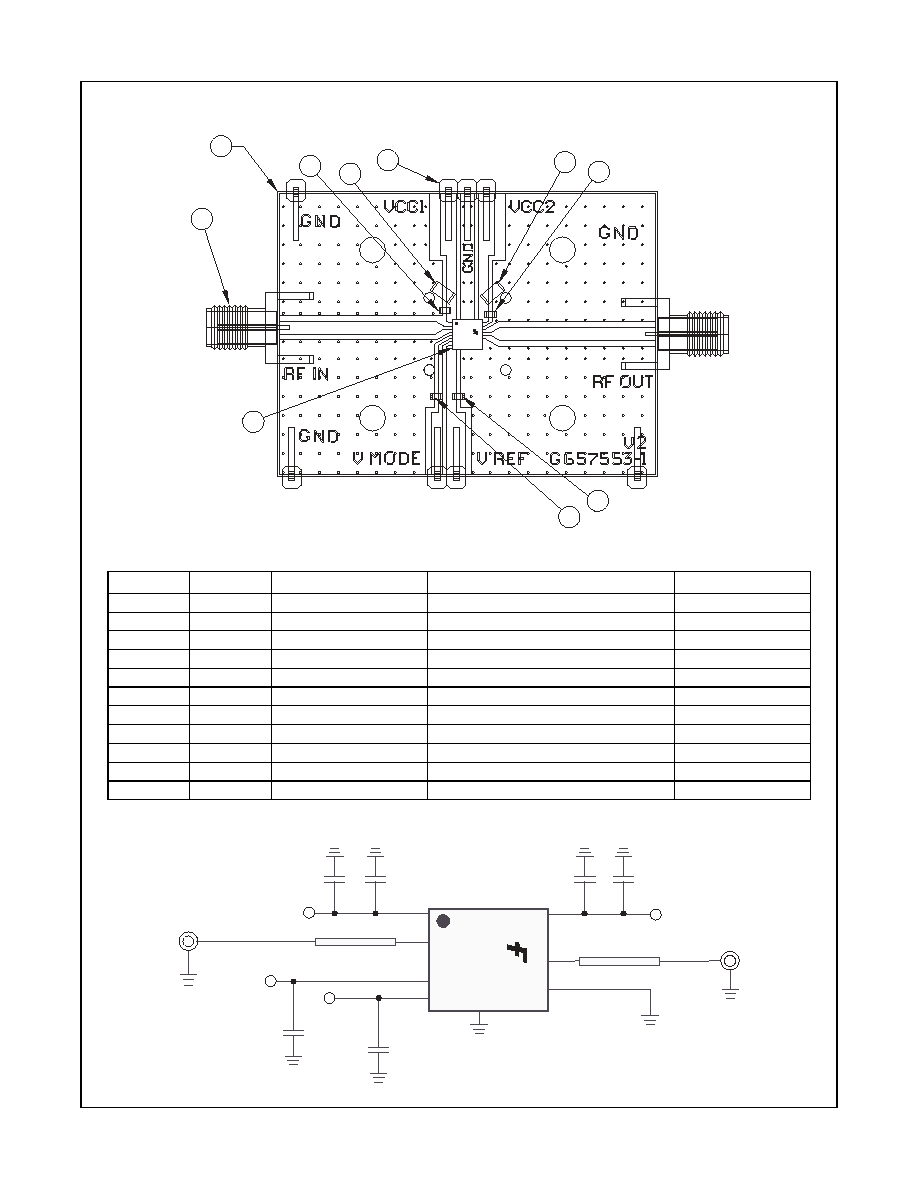

Evaluation Board Layout

Materials List

Evaluation Board Schematic

Qty

Item No.

Part Number

Description

Vendor

1

1

G657553-1 V2

PC Board

Fairchild

2

2

#142-0701-841

SMA Connector

Johnson

5

3

#2340-5211TN

Terminals

3M

Ref

4

Assembly, RMPA2263

Fairchild

3

5

GRM39X7R102K50V

1000pF Capacitor (0603)

Murata

3

5 (Alt)

ECJ-1VB1H102K

1000pF Capacitor (0603)

Panasonic

2

6

C3216X5R1A335M

3.3µF Capacitor (1206)

TDK

1

7

GRM39Y5V104Z16V

0.1µF Capacitor (0603)

Murata

1

7 (Alt)

ECJ-1VB1C104K

0.1µF Capacitor (0603)

Panasonic

A/R

8

SN63

Solder Paste

Indium Corp.

A/R

9

SN96

Solder Paste

Indium Corp.

XYTT

Z

2263

3

6

5

1

2

4

5

7

6

5

2

10

8

3, 6, 7, 9

VCC2

(PACKAGE BASE)

50 Ohm TRL

50

SMA2

RF OUT

SMA1

RF IN

Ohm TRL

3.3

µ

F

VREF

3.3

µ

F

1000 pF

1000 pF

1000 pF

0.1

µ

F

4

VMODE

11

5

VCC1

1

XYTT

Z

2263

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

we

r

A

m

plif

ier

Mo

dul

e 192

0198

0 MH

z (

P

r

e

lim

in

ar

y

)

5

www.fairchildsemi.com

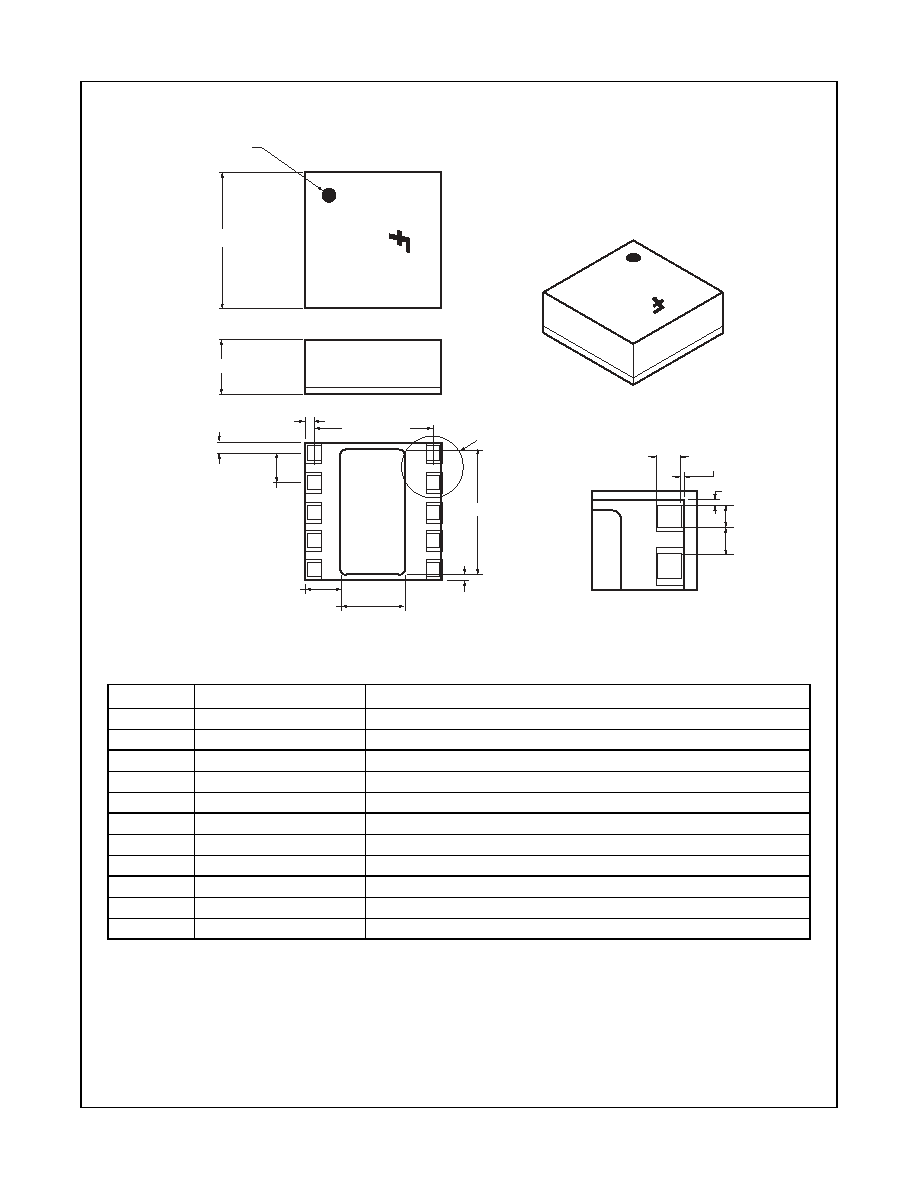

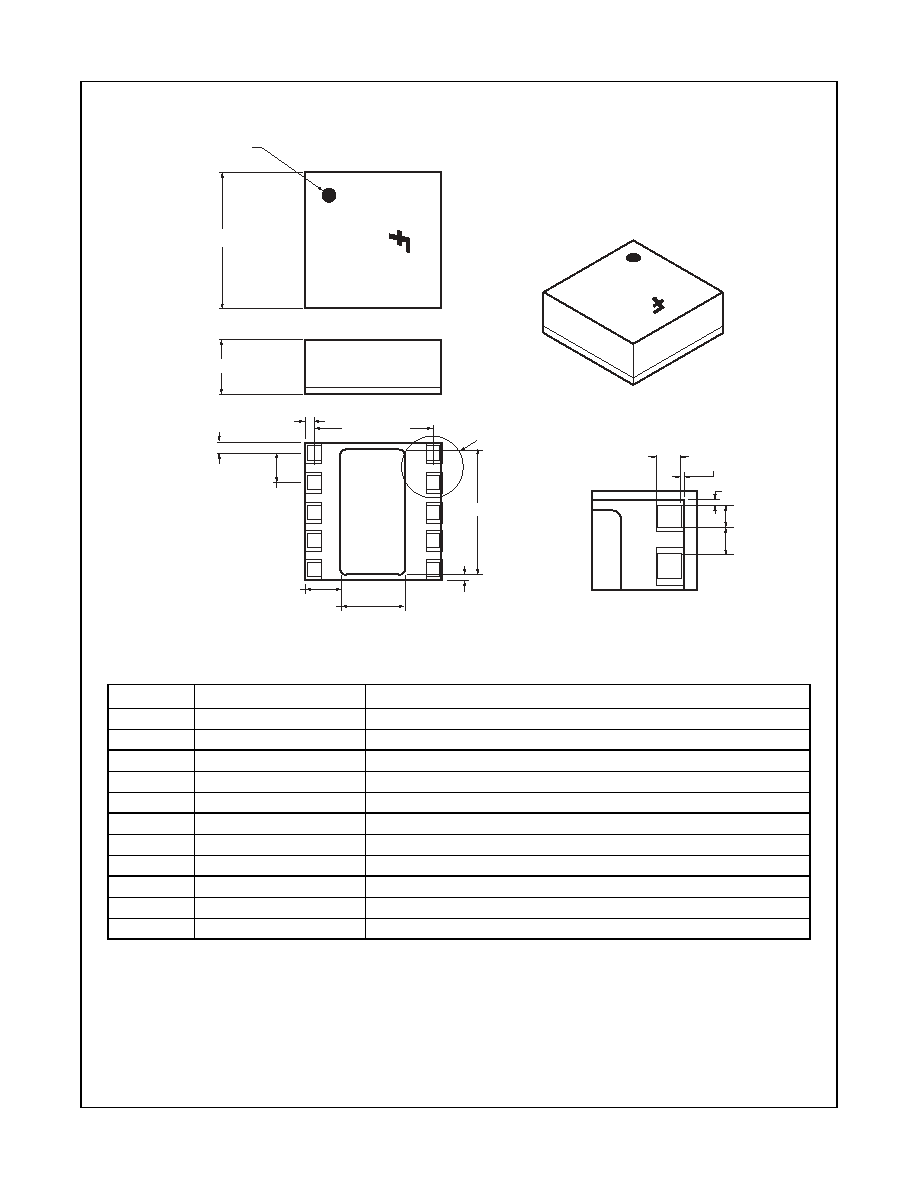

Package Outline

Signal Descriptions

Pin #

Signal Name

Description

1

Vcc1

Supply Voltage to Input Stage

2

RF In

RF Input Signal

3

GND

Ground

4

Vmode

High Power/Low Power Mode Control

5

Vref

Reference Voltage

6

GND

Ground

7

GND

Ground

8

RF Out

RF Output Signal

9

GND

Ground

10

Vcc2

Supply Voltage to Output Stage

11

GND

Paddle Ground

1

I/O 1 INDICATOR

TOP VIEW

FRONT VIEW

BOTTOM VIEW

DETAIL A. TYP.

(4.00mm

1.60mm MAX.

.30mm TYP.

.18mm

3.65mm

.85mm TYP.

.25mm TYP.

1.08mm

1.84mm

3.50mm TYP.

See Detail A

) SQUARE

+.100

.050

2

3

4

5

10

9

8

7

6

11

1

2

.40mm

.10mm

.10mm

.40mm

.45mm

XYTT

Z

2263

XYTT

Z

2263

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

we

r

A

m

plif

ier

Mo

dul

e 192

0198

0 MH

z (

P

r

e

lim

in

ar

y

)

6

www.fairchildsemi.com

Applications Information

CAUTION: THIS IS AN ESD SENSITIVE DEVICE.

Precautions to Avoid Permanent Device Damage:

· Cleanliness: Observe proper handling procedures to ensure

clean devices and PCBs. Devices should remain in their

original packaging until component placement to ensure no

contamination or damage to RF, DC and ground contact

areas.

· Device Cleaning: Standard board cleaning techniques should

not present device problems provided that the boards are

properly dried to remove solvents or water residues.

· Static Sensitivity: Follow ESD precautions to protect against

ESD damage:

A properly grounded static-dissipative surface on which to

place devices.

Static-dissipative floor or mat.

A properly grounded conductive wrist strap for each person

to wear while handling devices.

· General Handling: Handle the package on the top with a

vacuum collet or along the edges with a sharp pair of bent

tweezers. Avoiding damaging the RF, DC, and ground

contacts on the package bottom. Do not apply excessive

pressure to the top of the lid.

· Device Storage: Devices are supplied in heat-sealed,

moisture-barrier bags. In this condition, devices are protected

and require no special storage conditions. Once the sealed

bag has been opened, devices should be stored in a dry

nitrogen environment.

Device Usage:

Fairchild recommends the following procedures prior to

assembly.

· Assemble the devices within 7 days of removal from the dry

pack.

· During the 7-day period, the devices must be stored in an

environment of less than 60% relative humidity and a

maximum temperature of 30°C

· If the 7-day period or the environmental conditions have been

exceeded, then the dry-bake procedure, at 125°C for 24 hours

minimum, must be performed.

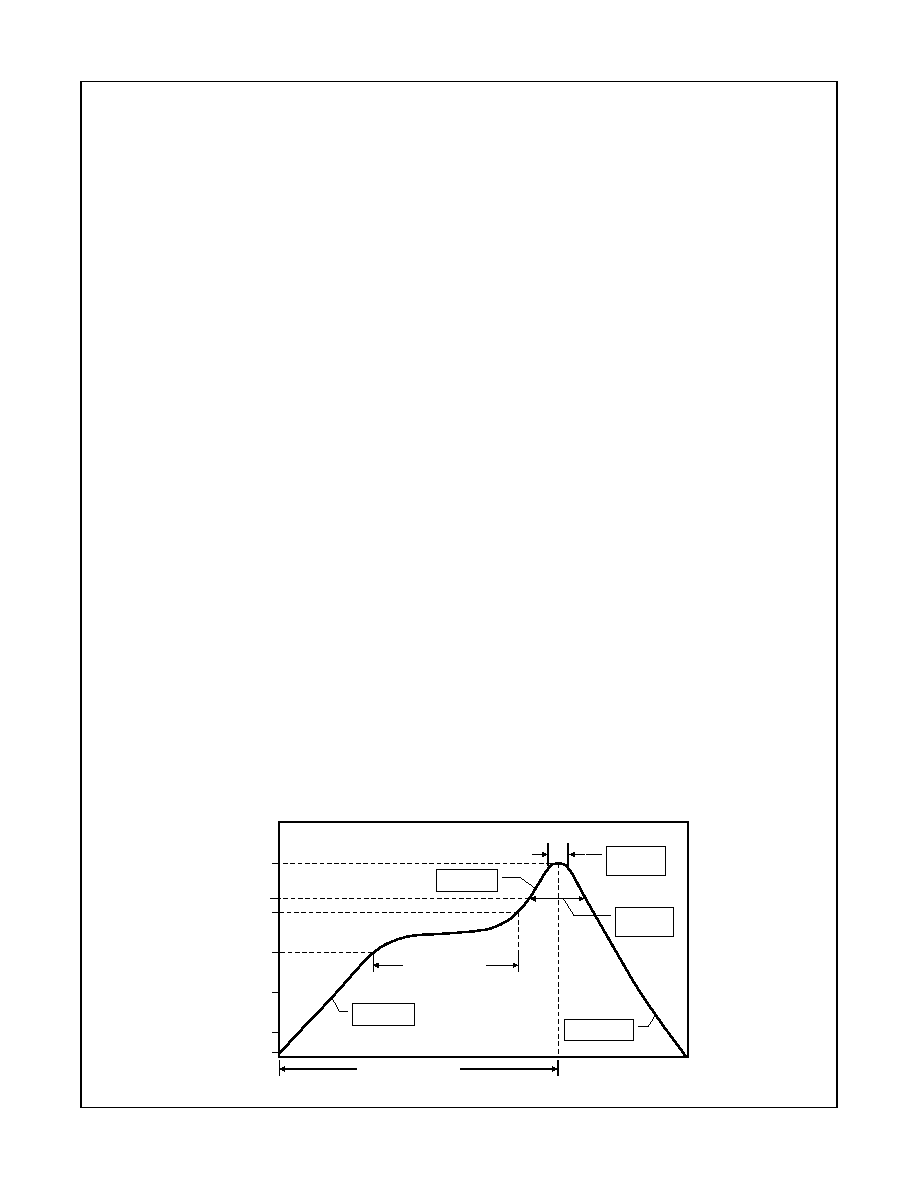

Solder Materials & Temperature Profile:

Reflow soldering is the preferred method of SMT attachment.

Hand soldering is not recommended.

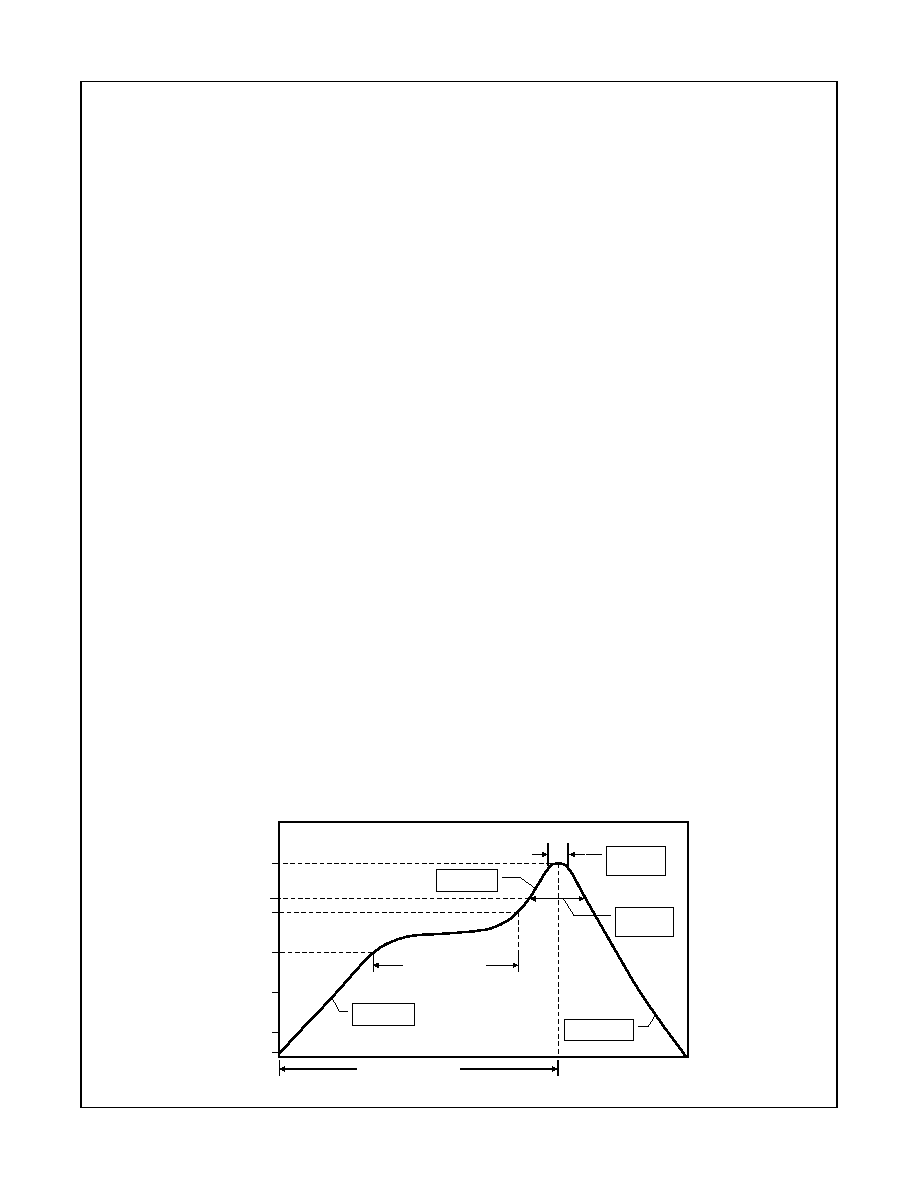

Reflow Profile

· Ramp-up: During this stage the solvents are evaporated from

the solder paste. Care should be taken to prevent rapid

oxidation (or paste slump) and solder bursts caused by violent

solvent out-gassing. A maximum heating rate is 3°C/sec.

· Pre-heat/soak: The soak temperature stage serves two

purposes; the flux is activated and the board and devices

achieve a uniform temperature. The recommended soak

condition is: 60-180 seconds at 150-200°C.

· Reflow Zone: If the temperature is too high, then devices may

be damaged by mechanical stress due to thermal mismatch or

there may be problems due to excessive solder oxidation.

Excessive time at temperature can enhance the formation of

inter-metallic compounds at the lead/board interface and may

lead to early mechanical failure of the joint. Reflow must occur

prior to the flux being completely driven off. The duration of

peak reflow temperature should not exceed 20 seconds.

Soldering temperatures should be in the range 255260°C,

with a maximum limit of 260°C.

· Cooling Zone: Steep thermal gradients may give rise to

excessive thermal shock. However, rapid cooling promotes a

finer grain structure and a more crack-resistant solder joint.

The illustration below indicates the recommended soldering

profile.

Solder Joint Characteristics:

Proper operation of this device depends on a reliable void-free

attachment of the heat sink to the PWB. The solder joint should

be 95% void-free and be a consistent thickness.

Rework Considerations:

Rework of a device attached to a board is limited to reflow of the

solder with a heat gun. The device should be subjected to no

more than 15°C above the solder melting temperature for no

more than 5 seconds. No more than 2 rework operations should

be performed.

Recommended Solder Reflow Profile

150

Ramp-Up Rate

3 °C/sec max

25

Temperature (°C)

Time 25 °C/sec to peak temp

6 minutes max

Ramp-Down Rate

6 °C/sec max

Preheat, 150 to 200 °C

60 - 180 sec

200

217

Time above

liquidus temp

60 - 150 sec

100

260

Peak temp

260 +0/-5 °C

10 - 20 sec

Time (Sec)

Ramp-Up Rate

3 °C/sec max

50

7

www.fairchildsemi.com

RMPA2263

i-LoTM

Rev. G

R

M

P

A

2

263

i

-

L

o

TM

W

C

D

M

A

P

o

w

e

r

A

m

pli

f

ier

Mo

du

le 19

2019

80 M

H

z

(P

r

e

l

i

m

i

n

a

r

y

)

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY

PRODUCTS HEREIN TO IMPROVE RELIABILITY, FUNCTION OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY

ARISING OUT OF THE APPLICATION OR USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT

CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR THE RIGHTS OF OTHERS.

TRADEMARKS

The following are registered and unregistered trademarks Fairchild Semiconductor owns or is authorized to use and is

not intended to be an exhaustive list of all such trademarks.

LIFE SUPPORT POLICY

FAIRCHILD'S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant into

the body, or (b) support or sustain life, or (c) whose

failure to perform when properly used in accordance

with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the

user.

2. A critical component is any component of a life

support device or system whose failure to perform can

be reasonably expected to cause the failure of the life

support device or system, or to affect its safety or

effectiveness.

PRODUCT STATUS DEFINITIONS

Definition of Terms

Datasheet Identification

Product Status

Definition

Advance Information

Preliminary

No Identification Needed

Obsolete

This datasheet contains the design specifications for

product development. Specifications may change in

any manner without notice.

This datasheet contains preliminary data, and

supplementary data will be published at a later date.

Fairchild Semiconductor reserves the right to make

changes at any time without notice in order to improve

design.

This datasheet contains final specifications. Fairchild

Semiconductor reserves the right to make changes at

any time without notice in order to improve design.

This datasheet contains specifications on a product

that has been discontinued by Fairchild semiconductor.

The datasheet is printed for reference information only.

Formative or

In Design

First Production

Full Production

Not In Production

IntelliMAXTM

ISOPLANARTM

LittleFETTM

MICROCOUPLERTM

MicroFETTM

MicroPakTM

MICROWIRETM

MSXTM

MSXProTM

OCXTM

OCXProTM

OPTOLOGIC

OPTOPLANARTM

PACMANTM

FAST

FASTrTM

FPSTM

FRFETTM

GlobalOptoisolatorTM

GTOTM

HiSeCTM

I

2

CTM

i-LoTM

ImpliedDisconnectTM

Rev. I15

ACExTM

ActiveArrayTM

BottomlessTM

CoolFETTM

CROSSVOLTTM

DOMETM

EcoSPARKTM

E

2

CMOSTM

EnSignaTM

FACTTM

FACT Quiet SeriesTM

POPTM

Power247TM

PowerEdgeTM

PowerSaverTM

PowerTrench

QFET

QSTM

QT OptoelectronicsTM

Quiet SeriesTM

RapidConfigureTM

RapidConnectTM

µ

SerDesTM

SILENT SWITCHER

SMART STARTTM

SPMTM

StealthTM

SuperFETTM

SuperSOTTM-3

SuperSOTTM-6

SuperSOTTM-8

SyncFETTM

TinyLogic

TINYOPTOTM

TruTranslationTM

UHCTM

UltraFET

UniFETTM

VCXTM

Across the board. Around the world.TM

The Power Franchise

Programmable Active DroopTM

Document Outline