XR-T56L22

...the analog plus company

TM

Low Power

Repeater/Receiver

Rev. 1.02

E

1997

EXAR Corporation, 48720 Kato Road, Fremont, CA 94538

z

(510) 668-7000

z

FAX (510) 668-7017

1

June 1997-3

FEATURES

D

Contains All The Active Components For A PCM

Repeater Or Long Haul Line Receiver

D

Low Voltage Operation (5.1V)

D

Low Power Consumption (8.75mA Max)

D

2Mbps Operation Capability

D

Dual Matched ALBO Ports

D

Internal Adjustable Phase Shift Circuitry

D

Extracted Clock Output

D

Internal Shunt Regulator

D

Temperature Independent Current Biasing

APPLICATIONS

D

T1 PCM Repeater/Receiver

D

T148C PCM Repeater/Receiver

D

European 2.048Mbps PCM Repeater/Receiver

D

Digital Multiplexers, CSUs, Switching Equipment

D

ISDN Compatible Equipment: Fax Machines,

Computers etc.

GENERAL DESCRIPTION

The XR-T56L22 is a very low power monolithic repeater/

receiver IC designed for PCM carrier systems operating

between 1.544Mbps and 2.37Mbps. The IC provides all

the active circuitry required to implement one side of a

PCM repeater. The XR-T56L22 features on-chip

adjustable phase shifting, an extracted clock output and

an on-board shunt regulator. The very low power

consumption of the device makes it ideal for long haul

"tandem" repeater applications.

ORDERING INFORMATION

Part No.

Package

Operating

Temperature Range

XR-T56L22AP

18 Lead 300 Mil PDIP

-40

°

C to +85

°

C

XR-T56L22AN

18 Lead 300 Mil CDIP

-40

°

C to +85

°

C

XR-T56L22AD

18 Lead 300 Mil Jedec SOIC

-40

°

C to +85

°

C

XR-T56L22

2

Rev. 1.02

BLOCK DIAGRAM

ALBO1

ALBO2

ANA GND

AMP + I/P

AMP - I/P

LC I/P

REG Cont.

V

CC

DIG GND

LC Bias

Phase Cont.

2

3

1

5

4

+

-

16

17

15

13

14

12

8

+5

18

6

7

11

9

10

ALBO FIL

AMP -O/P

AMP +O/P

Clock O/P

Data +

Data -

ALBO

PEAK

DET.

AMP

Clock

Comparators

Clock

Bias

GEN.

Clock

AMP

Clock

Driver

Data

Comparators

D

CLK

Q

Data

Latches

Output

Drivers

D

CLK

Q

Voltage

Ref.

Gen.

Volt.

Reg.

Figure 1. XT-T56L22 Block Diagram

V

REF

XR-T56L22

3

Rev. 1.02

PIN CONFIGURATION

1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

ALBO FIL

LC BIAS

LC I/P

PHASE CONT.

REG CONT.

V

REF

V

CC

CLOCK O/P

ANA GND

ALBO1

ALBO2

AMP-I/P

AMP +I/P

AMP -O/P

AMP +O/P

DIG GND

DATA-

DATA+

18 Lead PDIP, CDIP (0.300")

18

1

10

9

2

3

4

5

6

7

15

14

13

12

11

17

16

8

ALBO FIL

LC BIAS

LC I/P

PHASE CONT.

ANA GND

ALBO1

ALBO2

AMP-I/P

REG CONT.

VREF

V

CC

CLOCK O/P

AMP +I/P

AMP -O/P

AMP +O/P

DIG GND

DATA-

DATA+

18 Lead SOIC (Jedec, 0.300")

PIN DESCRIPTION

Pin #

Symbol

Description

1

ANA GND

Ground for Analog Sections of IC and Substrate.

2

ALBO 1

ALBO PORT 1 Output. Port impedance varies between 25W and 20kW proportional to input signal

level.

3

ALBO 2

ALBO PORT 2 Output. Similar to pin 2.

4

AMP - I/P

Inverting Input of Signal Preamp RIN > 20kW.

5

AMP + I/P

Non-Inverting Input of Signal Preamp. RIN > 20kW.

6

AMP - O/P

Inverting Output of Signal Pre-amp. Rout < 200W. DC level typically 3.2V.

7

AMP + O/P

Non-inverting Output of Signal Pre-amp. Similar to pin 6.

8

DIG GND

Ground for Digital Portion of IC.

9

DATA+

Positive Data Driver Output (Open Collector). V

OL

< 0.95V @ l

OUT

= 32mA.

10

DATA-

Negative Data Driver Output (Open Collector). V

OL

< 0.95V @ l

OUT

= 32mA.

11

CLOCK O/P

Phase Shifted Clock Output (Open Collector). Decouple to GND with 0.1mF if not required. With

Rpull-up = 1K, V

OL

< 1.1V @ I

OUT

= 4mA.

12

V

CC

Input Pin of Shunt Regulator and Supply Pin for IC. For voltage feed applications the regulator

must be disabled and a 5V + 5% supply connected. For line feed a current of 48-120mA is required.

ICC < 8.75mA @ RON, ALBO = 25W typical.

13

VREF

Output Voltage of Internal Reference of Shunt Regulator. For parallel operation of regulators

should be tied to pin 13 of 2nd T56L22 device. V

REF

approxi-mately V

CC

/2. Decouple to GND with

0.1mF.

14

REG CONT

Input Voltage of Shunt Regulator Amp. To inhibit regulator, pin should be tied to ground. For line

feed operation decouple to GND with 0.1mF. For parallel operation of regulators tie pin 14 of 2nd

T56L22 device. VREG approximately V

REF

.

15

PHASE

CONT

Phase Shift Adjust Input. A resistor to GND from the pin allows adjustment of phase shift from 905

to approximately 05. RP typical 1.8K to 1K. Vphase typical 340mV.

16

LC I/P

Clock Amplifier Input. Pulsed with current from clock comparator. Connect LC tank between 16, 17

for clock recovery. Ickon = --110mA typical.

17

LC BIAS

Clock Amplifier Reference Voltage. VLC = 3.6V typical.

18

ALBO FIL

Control Pin for ALBO Ports. Voltage developed across a capacitor on this pin defines ALBO on

impedance VALBO = 1.5V typical.

XR-T56L22

4

Rev. 1.02

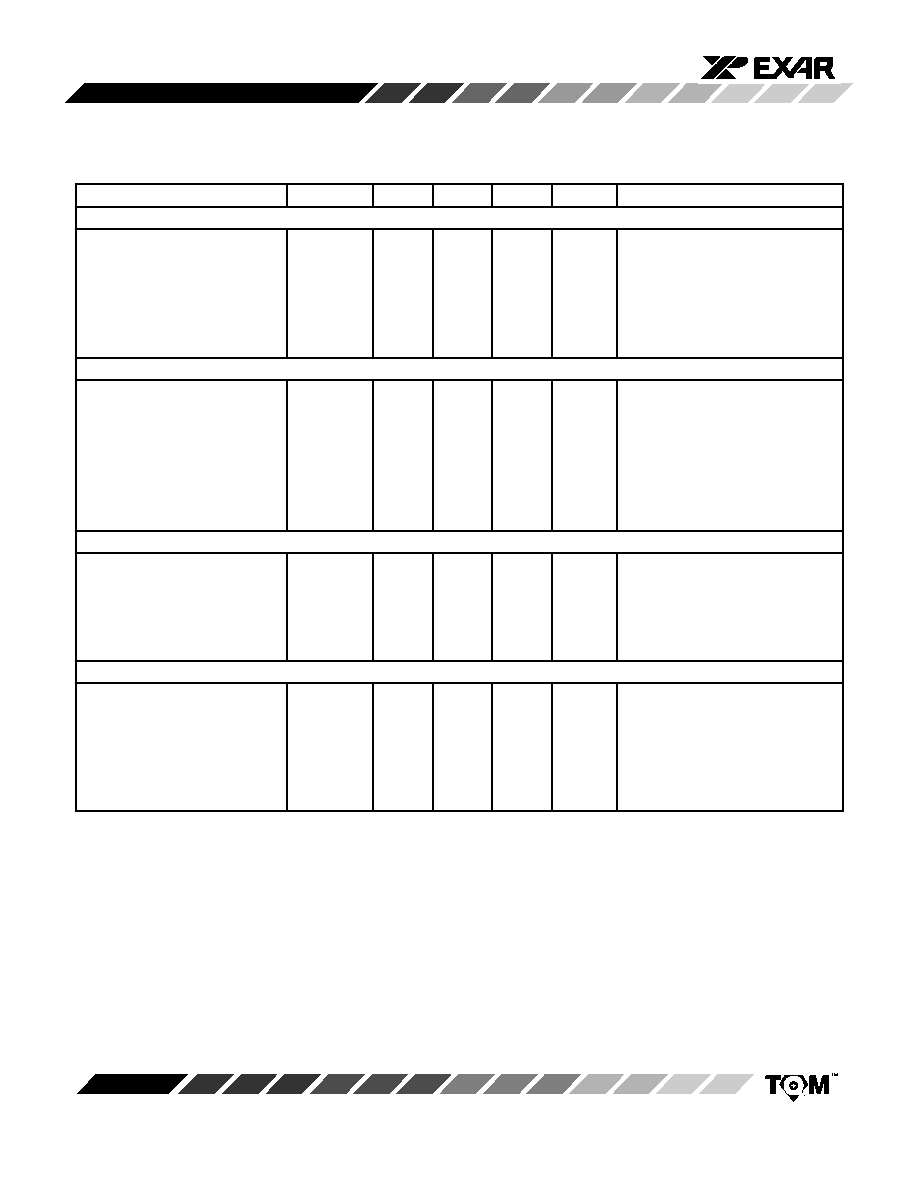

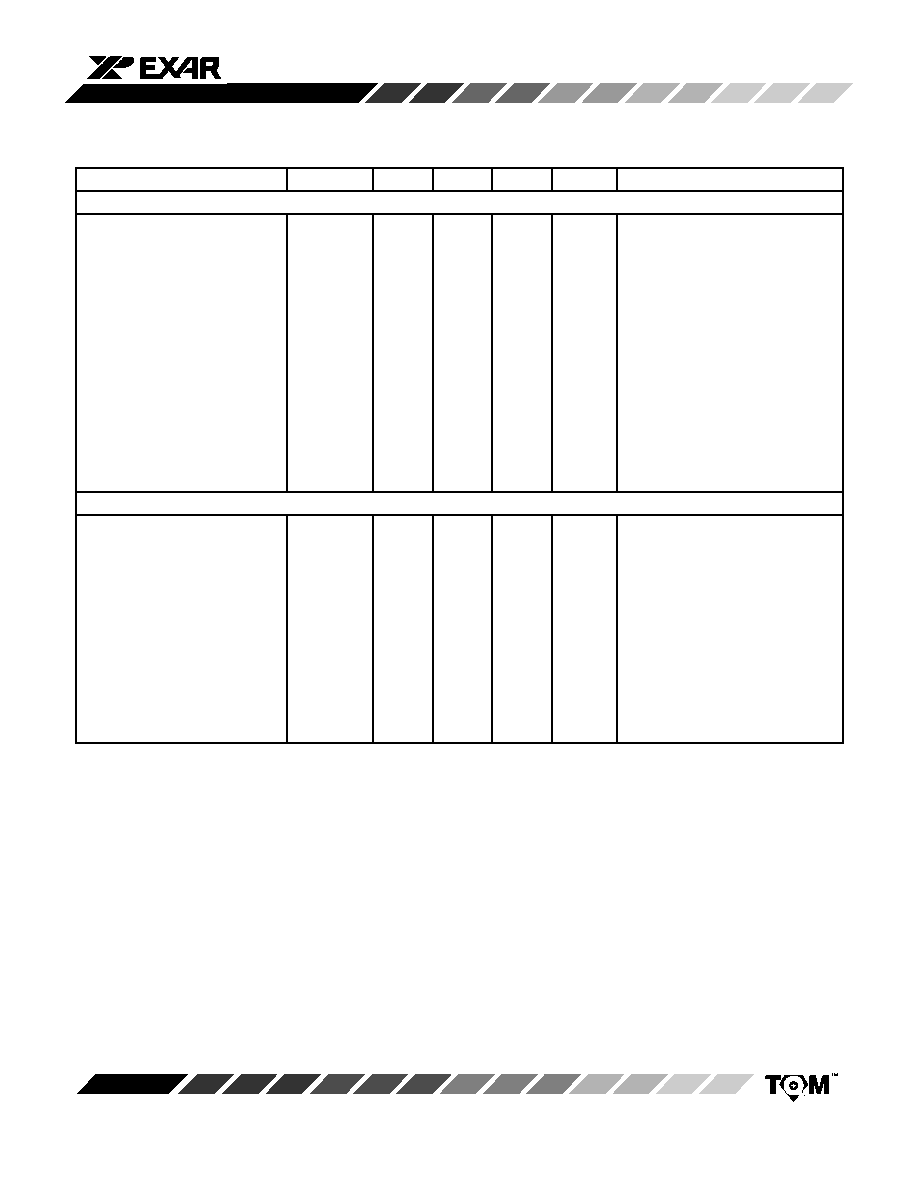

ELECTRICAL CHARACTERISTICS

Test Conditions: TA = -40

°

C to

+

85

°

C, V

CC

= 5.1V

±

5% unless otherwise specified - refer to test circuit (Figure 6).

Parameter

Pin

Min.

Typ.

Max.

Unit

Conditions

General

Supply Voltage

12

4.85

5.35

V

Pin 12, 13 to V

CC

1

Supply Current

12

7

8.75

mA

Data Output Leakage Current

9, 10

100

m

A

V

pull-up

= 8V

ALBO Port Off Voltage

2, 3

0.1

V

V

CC

= 5.35 V

1

Amplifier Pin Voltage

4, 5

2.7

3.2

3.7

V

Amplifier Pin Voltage

6, 7

Amplifier

Input Impedance

4, 5

40

K

W

Input Offset Voltage

4, 5

-10

10

mV

R

S

= 8.2K

2

Input Bias Current

4, 5

5

m

A

R

S

= 8.2K

2

Input Offset Current

4, 5

-1

1

mV

R

S

= 8.2K

2

Output Offset Voltage

6, 7

-50

50

W

R

S

= 8.2K

2

Common Mode Rejection Ratio

4, 5, 6, 7

40

dB

Output Volage Swing

6, 7

1.9

V

Clock Amplifier

Input Offset Voltage

17, 16

0.5

6

mV

R

S

= 10K

3

Input Bias Current

17, 16

5

m

A

4

AC Gain

40

dB

-3db bandwidth

10

MHz

Delay

35

ns

ALBO

ALBO Filter Resistance

18-1

31

57

K

W

ALBO Impedance Match

2, 3

10

%

On Current

1

1.3

2.4

mA

Drive Current

18

0.4

1.4

mA

Maximum On Impedance

2, 3-1

25

W

5

Minimum Off Inpedance

2, 3-1

20

KW

5

Notes

1

Internal regulator disabled.

2

Source Resistance.

3

R

S

= Wou4d3 43wiw5qnd3 PIN 16 positive with respect to Pin 17

4

Pin 16 = Pin 17 = 3.6V

5

f

test

= 1MHz

Specifications are subject to change without notice

XR-T56L22

5

Rev. 1.02

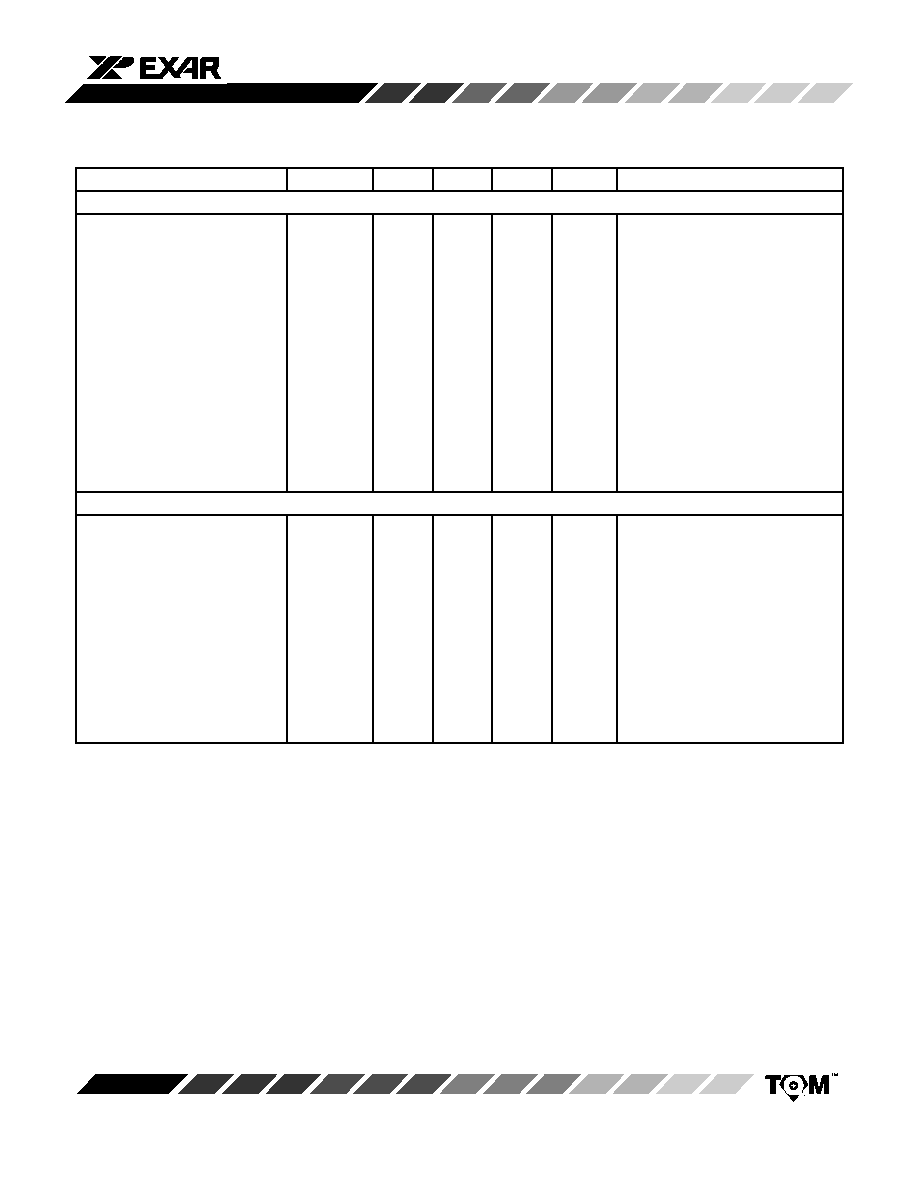

ELECTRICAL CHARACTERISTICS

(CON'T)

Parameter

Pin

Min.

Typ.

Max.

Unit

Conditions

Threshold Voltages

ALBO Threshold +Ve

7, 6

1.4

1.6

V

1, 2

ALBO Threshold -Ve

7, 6

1.4

1.6

V

1, 2

ALBO Threshold Difference

-3

3

%

3

Clock Drive on Current + Ve

80

140

m

A

4

Clock Drive on Current -Ve

80

140

m

A

4

Clock Drive Difference

-3

3

%

3

Clock Threshold +Ve

7, 6

69

79

%

5

Clock Threshold -Ve

7, 6

69

79

%

5

Clock Threshold Difference

-3

3

%

3

Data Threshold +Ve

7, 6

41

50

%

3

Data Threshold -Ve

7, 6

41

50

%

5

Data Threshold Difference

-3

3

%

3

Data Output Stages

Output Pulse Rise Time + Ve (Tr)

9

40

nS

10%-90%

6

Output Pulse Rise -Time-Ve(Tr)

10

40

nS

10%-90%

6

Output Pulse Fall Time+Ve(Tf)

9

40

nS

10%-90%

6

Output Pulse Fall Time -Ve (Tf)

10

40

nS

10%-90%

6

Output Pulse Width +Ve (Tw)

9

224

264

nS

at 50%

Output Pulse Width -Ve (Tw)

10

224

264

nS

at 50%

Output Pulse Width Difference

(dTw)

-12

12

nS

at 50%

Output Voltage (low) (V

OL

)

9, 10

0.6

0.95

V

6

Output Voltage Difference (V

OL

)

9, 10

-0.15

0.15

V

6

Notes

1

Pk/pk voltage at Pins 6 and 7 of a 1MHz sine wave derived through amplifier and measured differentially.

2

Pk/pk voltage at Pins 6 and 7 adjusted for a current increase of 2mA at pin 1.

3

Calculation only: percentage difference = [higher value/lower value]-1 x 100%.

4

V

6

- V

7

adjusted to ALBO threshold voltage (Pin 16 = 3.6V)

5

Figure taken as a percentage of ALBO threshold.

6

Using a 130

W

pull up resistor between 9, 10 and V

CC

and 15pF capacitance to GND.

Specifications are subject to change without notice

XR-T56L22

6

Rev. 1.02

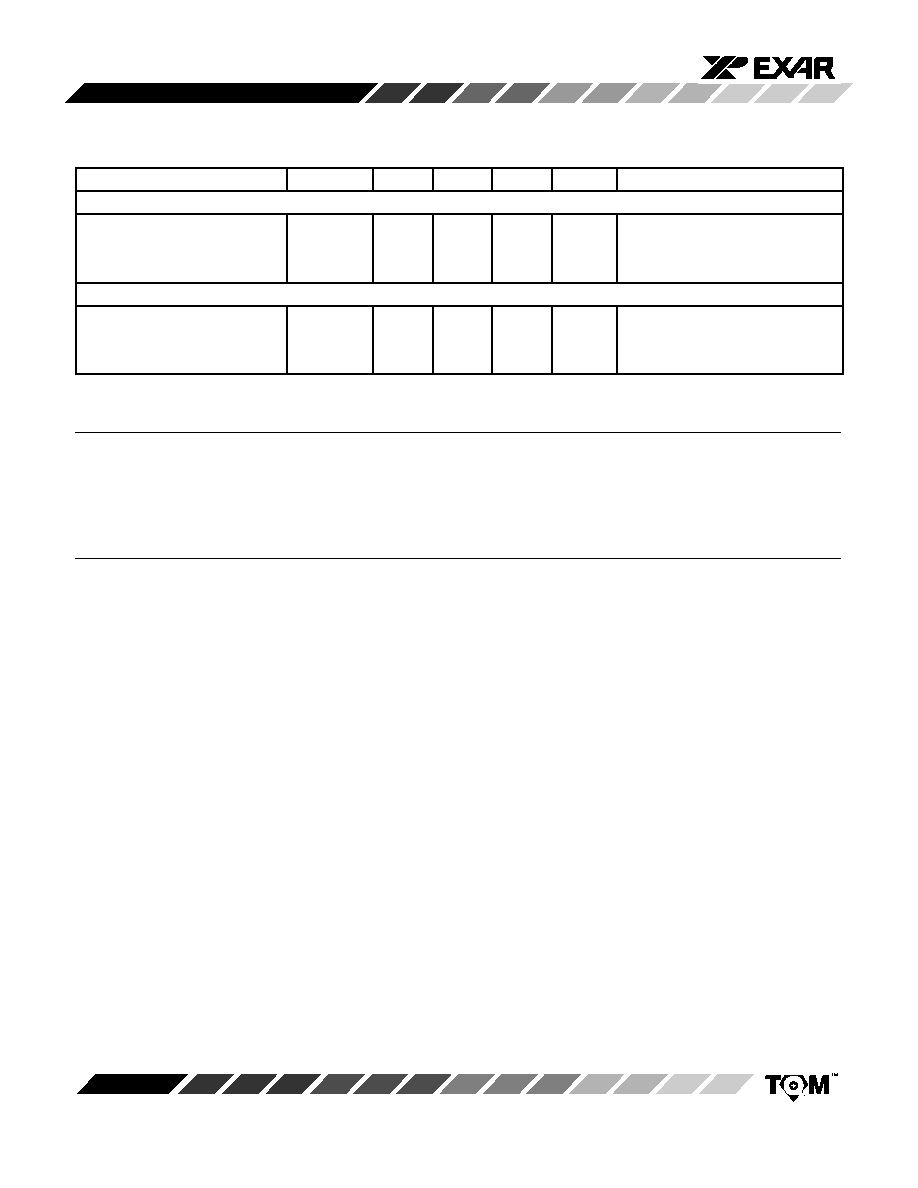

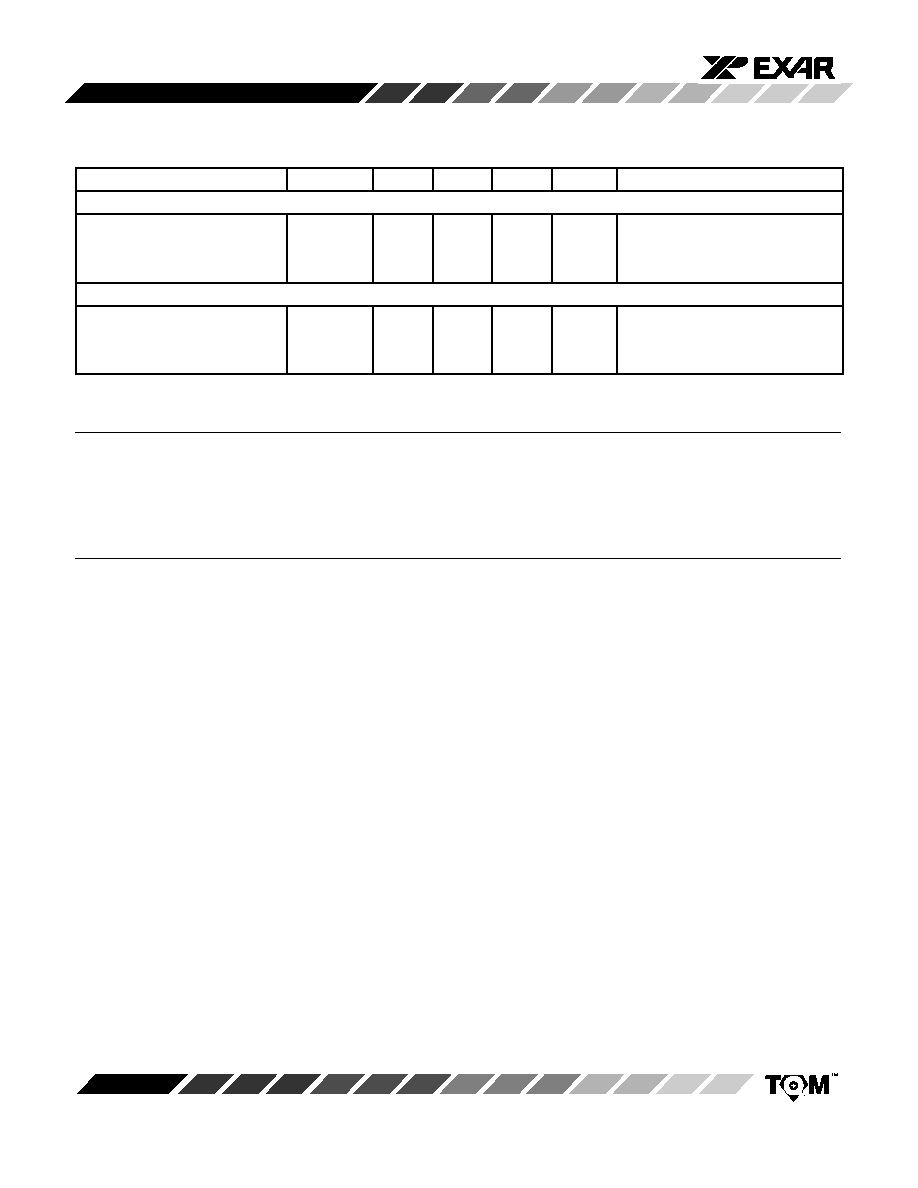

ELECTRICAL CHARACTERISTICS

(CONT'D)

Parameter

Pin

Min.

Typ.

Max.

Unit

Conditions

Clock Output Stage

Output Pulse Rise Time (Tr)

11

40

ns

1

Output Pulse Fall Time (Tf)

11

40

ns

Output Pulse Width (Tw)

11

224

264

ns

Shunt Regulator

Output Voltage

12

4.85

5.1

5.35

V

Pin 13, 14 floating

Voltage Regulation Over Temp.

12

-0.02

%/

°

C

Pin 13, 14 floating

Load Regulation

12

0.027

%/mA

1mA to 100mA load

Note

1

Using a 2K pull up resistor between 11 and V

CC

and 15pF capacitance to GND.

ABSOLUTE MAXIMUM RATINGS

Storage Temperature

-65

°

C to 150

°

C

. . . . . . . . . . . . . .

Operating Temperature

-40

°

C to 85

°

C

. . . . . . . . . . . . .

Supply Voltage

-0.5 to 7V

. . . . . . . . . . . . . . . . . . . . . . . .

Supply Voltage Surge (10ms)

25V

. . . . . . . . . . . . . . . . .

Data Output Voltage (pin 9, 10)

12V

. . . . . . . . . . . . . . .

SYSTEM DESCRIPTION

With reference to the functional block diagram, the basic

operation of the XR-T56L22 may be described as follows:

The received bipolar signal, is applied to a linear amplifier

and automatic equalizer. These circuits provide the

necessary amount of gain and phase equalization to

recover the transmitted data, and band limit the signal, to

optimize repeater performance for near-end crosstalk

produced by other systems operating within the same

cable bundle.

The preamplifier output signals which are balanced and of

opposite phase, are applied to the clock extraction and

pulse regenerator circuits. Here they are rectified and

then applied to a high Q resonant circuit which extracts

the 1.544/2.048 Mbps frequency component from the

received signal. This signal is then sliced and fed to an

adjustable phase shift circuit. A second slicer is used to

control the time at which the output signals from the

preamplifier are sampled by the pulse regenerator

circuits. The phase shifted clock signal is made available

as an output from the circuit for interface applications. The

clock phase adjustment is performed with a single pin

using an external resistor. Adjustment of the position of

the clock sampling edge by the phase shift circuit allows

performance of the pulse regenerator to be optimized.

The pulse regenerator performs the sampling and data

slicing to regenerate the appropriate output pulse. These

pulses are applied to an external output transformer to

create the bipolar signal that drives the next section of

twisted pair.

XR-T56L22

7

Rev. 1.02

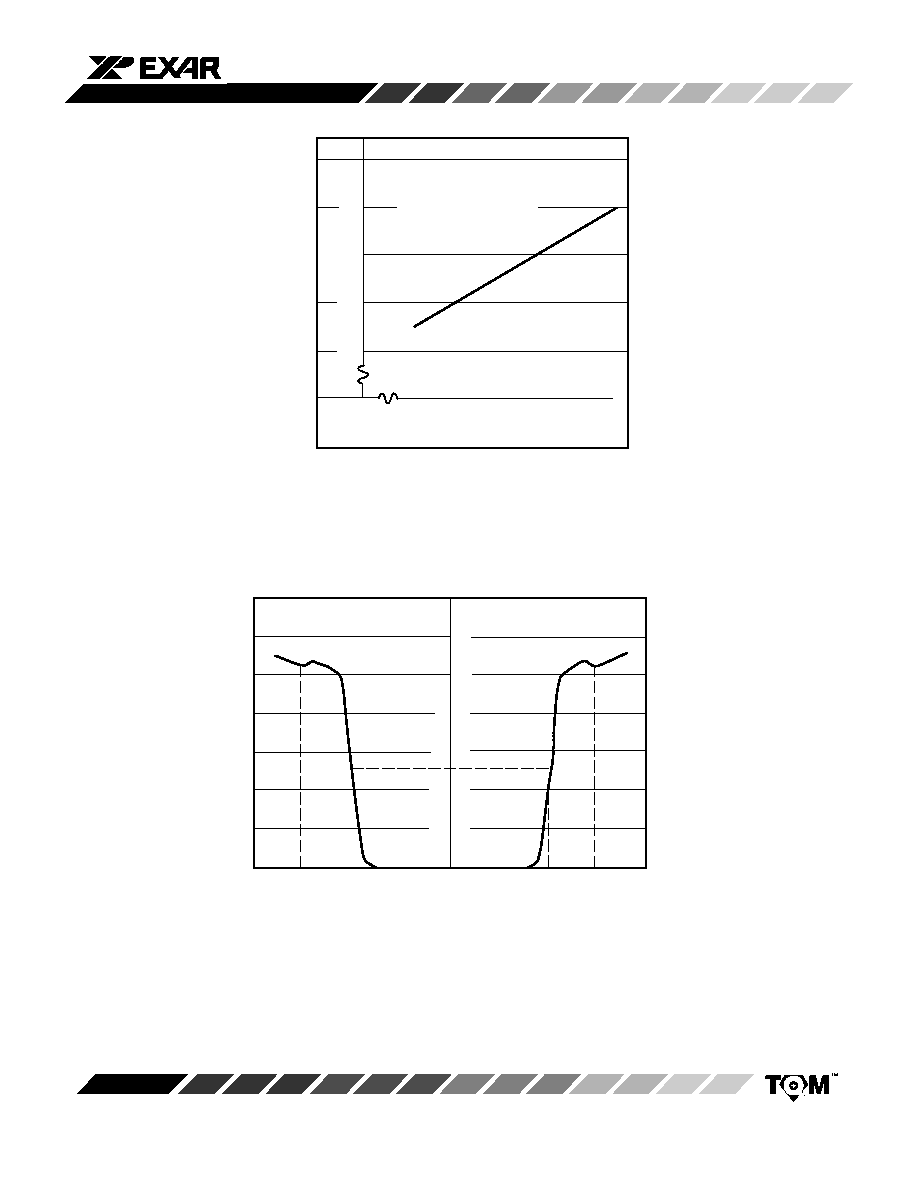

Figure 2. Supply Current Variation

with V

CC

(Regulator Inhibited)

Figure 3. Clock Drive Current Against Preamp Output Voltage

Typical I

CC

Vs. V

CC

Variation at T=25

°

C

(Clock, Data Outputs

(V

IN

=6V p-p (@2.04MBPS)

+ ALBO all Operating)

4.7

4.8

4.9

5.0

5.1

5.2

5.3

5.4

5.5

6.4

6.6

6.8

7.0

7.2

7.4

7.6

7.8

V

CC

in Volts

I

CC

in (mA)

Max Clock Drive

Current = 100

m

A

@ Albo Thresholds

50% CLK Drive Max

Clk Drive (

A)

m

1.8

1.6

1.4

1.2

1.0

.8

.6

.4

.2

0

1.8 1.6 1.4 1.2 1.0

.8

.6

.4

.2

10

20

30

40

50

60

70

80

90

100

110

120

V

ALBOTHLD

= 1.44 CLK

V

CLKTHLD

= 1.02v

V

PREAMP

OUT (V)

CLK

THLD(+)

ALBO

THLD(+)

XR-T56L22

8

Rev. 1.02

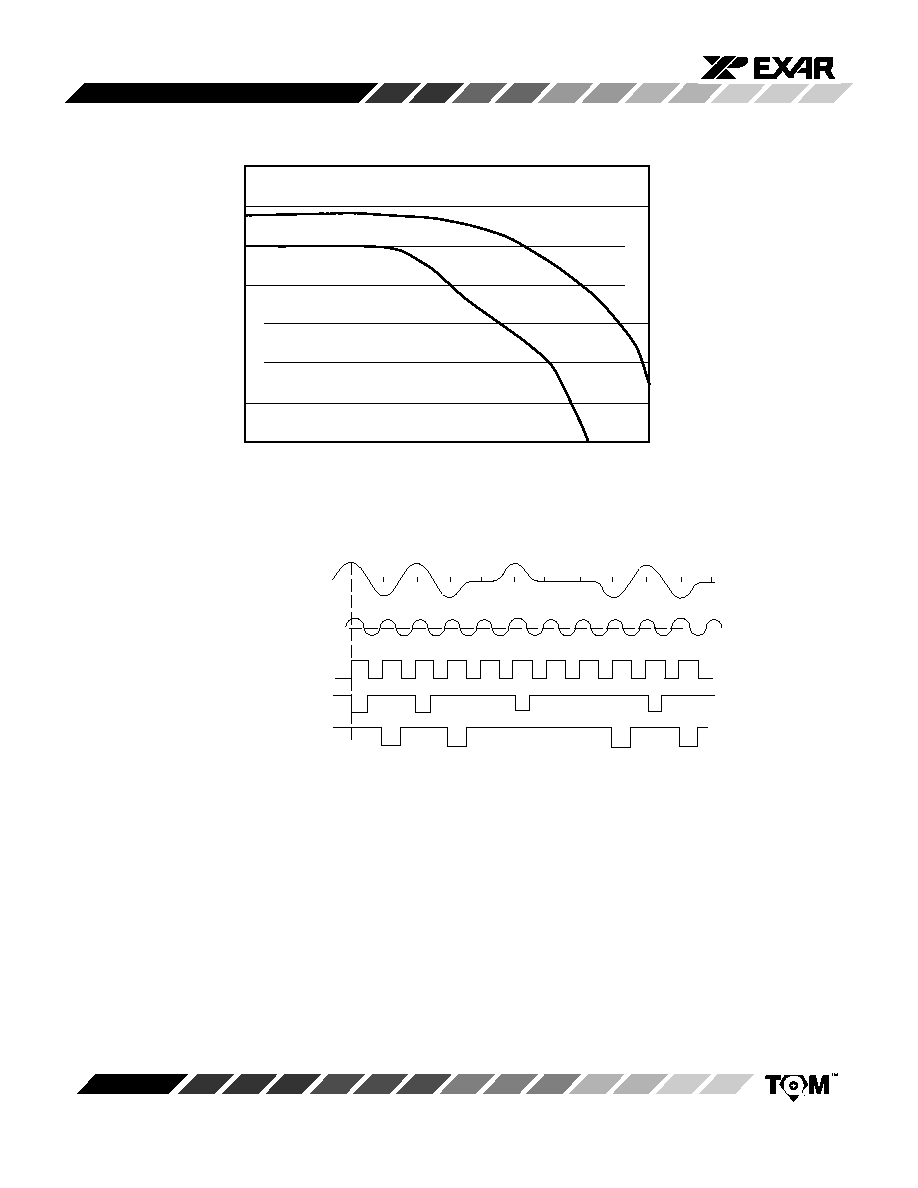

Figure 4. Typical T56L22 Waveforms

Preamp Output

(Approx. 1.5 pK to pK)

Oscillator Input

Pin 16

Clock Output

Pin 12

Data Pos.

Pin 18

Data Neg.

Pin 1

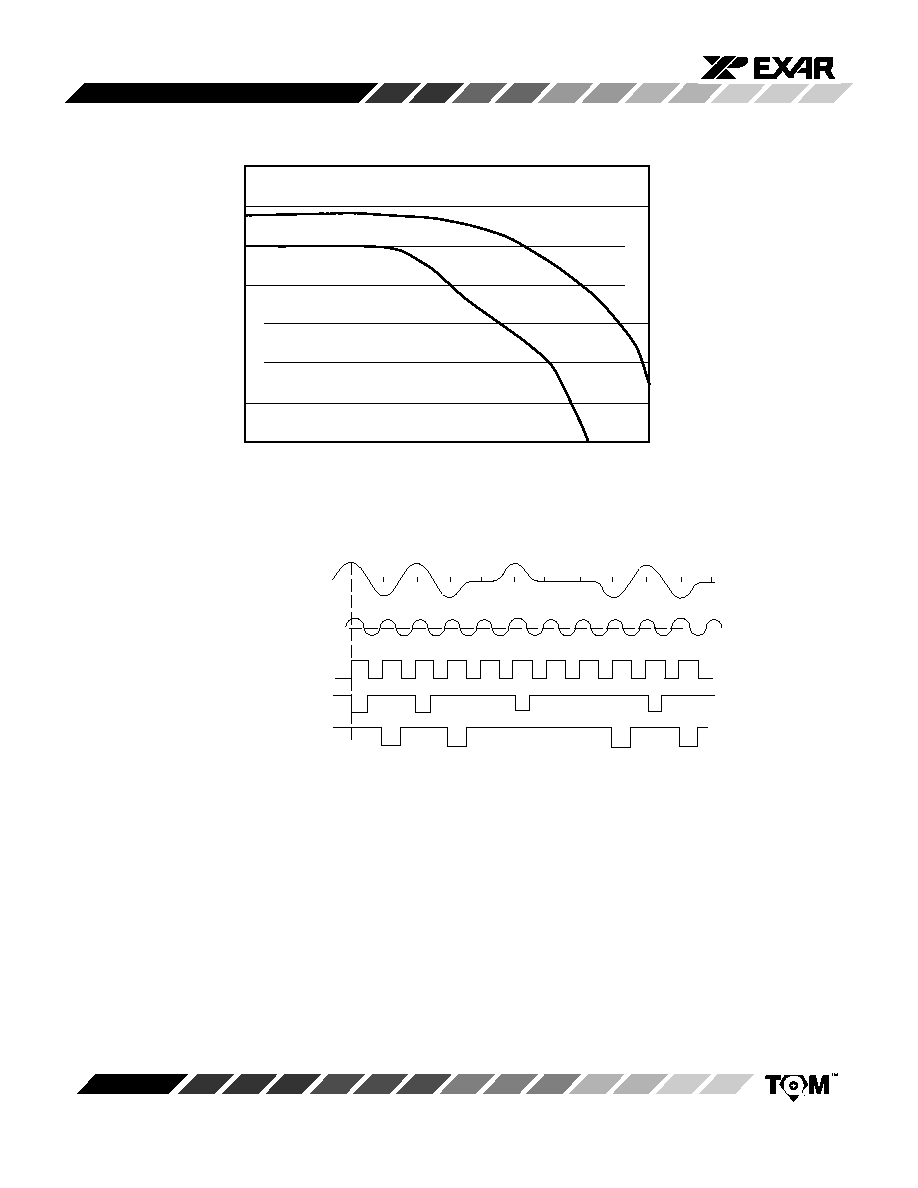

Figure 5. Preamp Gain/Phase Characteristics

0

45

90

135

180

10

4

10

5

10

6

10

7

10

8

Frequency In Hertz

Phase

Differential Gain

Gain A

V

IN DS

40

30

20

40

30

20

10

0

10

50

60

Phase in Degrees

XR-T56L22

9

Rev. 1.02

Figure 6. AC Parameter Test Circuit

1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

IM

R1

3.9K

R2

100

R3

51

C3

1

µ

F

1

µ

F

R5

100

C2

8.22UF

C1

8.22UF

R4

8.2K

R6

7.5K

R8

130

V

CC

D

+

C4

+

+

C6

47

µ

F

C11

15

µ

F

R13

51

C18

1

µ

F

C7

8.1

µ

F

R11

1.8K

C9

8.1

µ

F

R9

138

C5

8.22

µ

F

C8

8.22

µ

F

D- CLK

R18

1K

V

CC

R7

680

XR-T56L22

10

Rev

. 1.02

Figure 8. XRT56L22 E1 Evaluation Circuit

XR-T56L22

11

Rev

. 1.02

Figure 9. XRT56L22 T1 Evaluation Circuit

XR-T56L22

12

Rev. 1.02

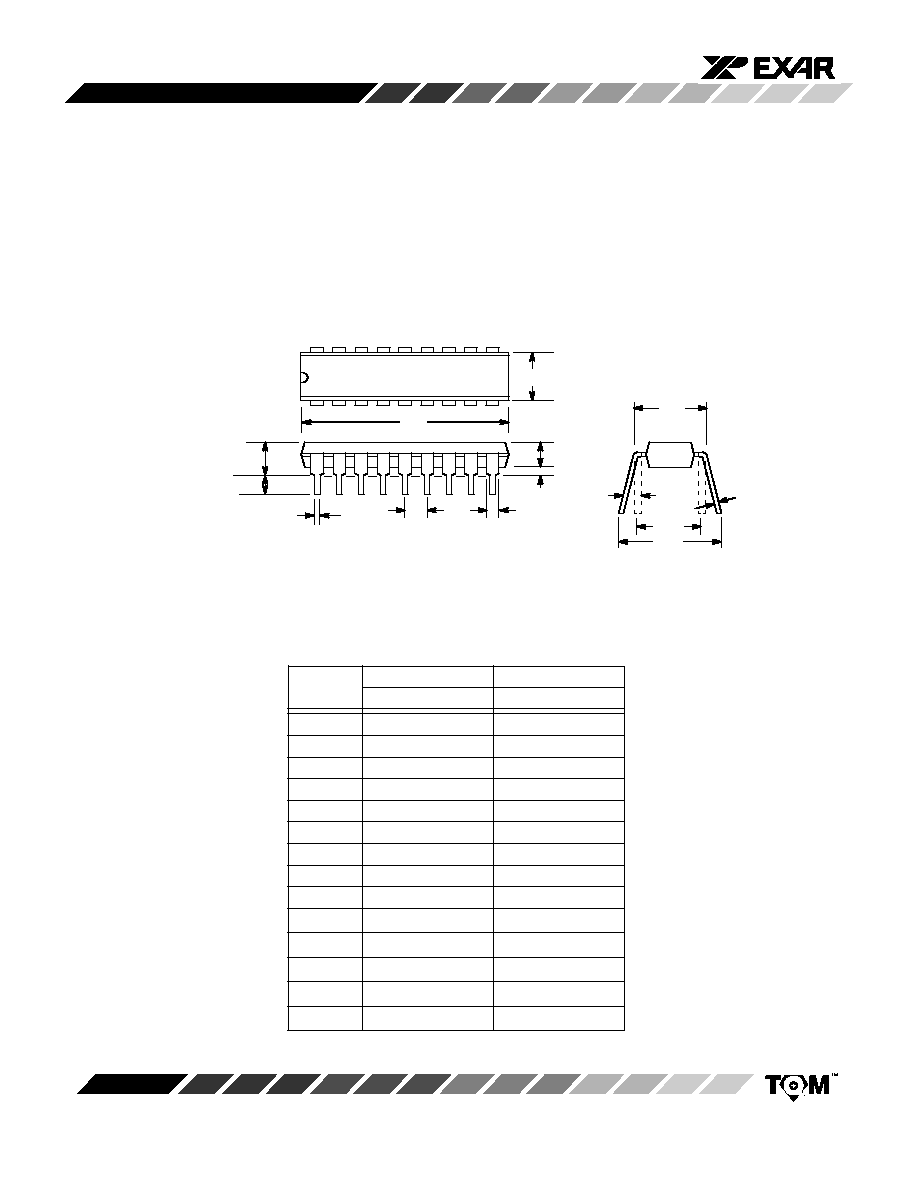

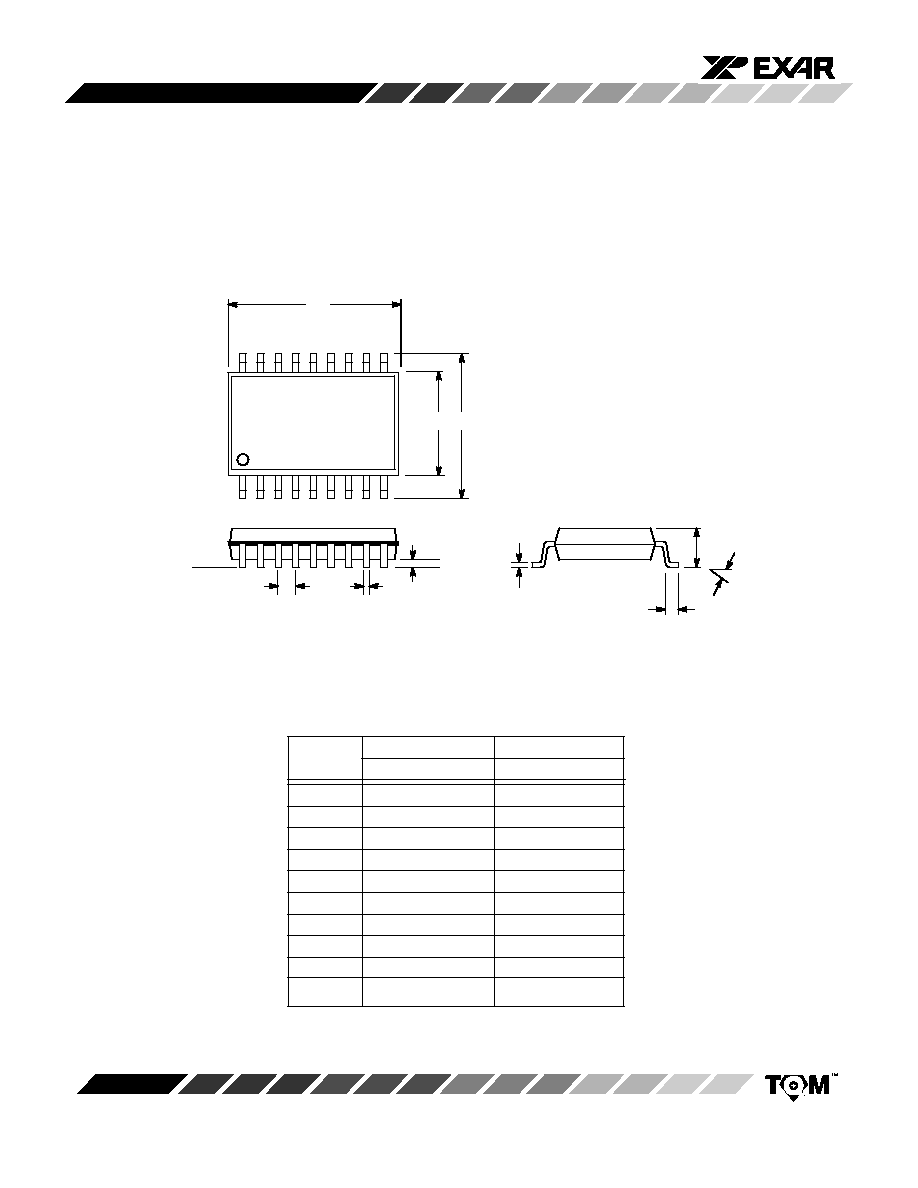

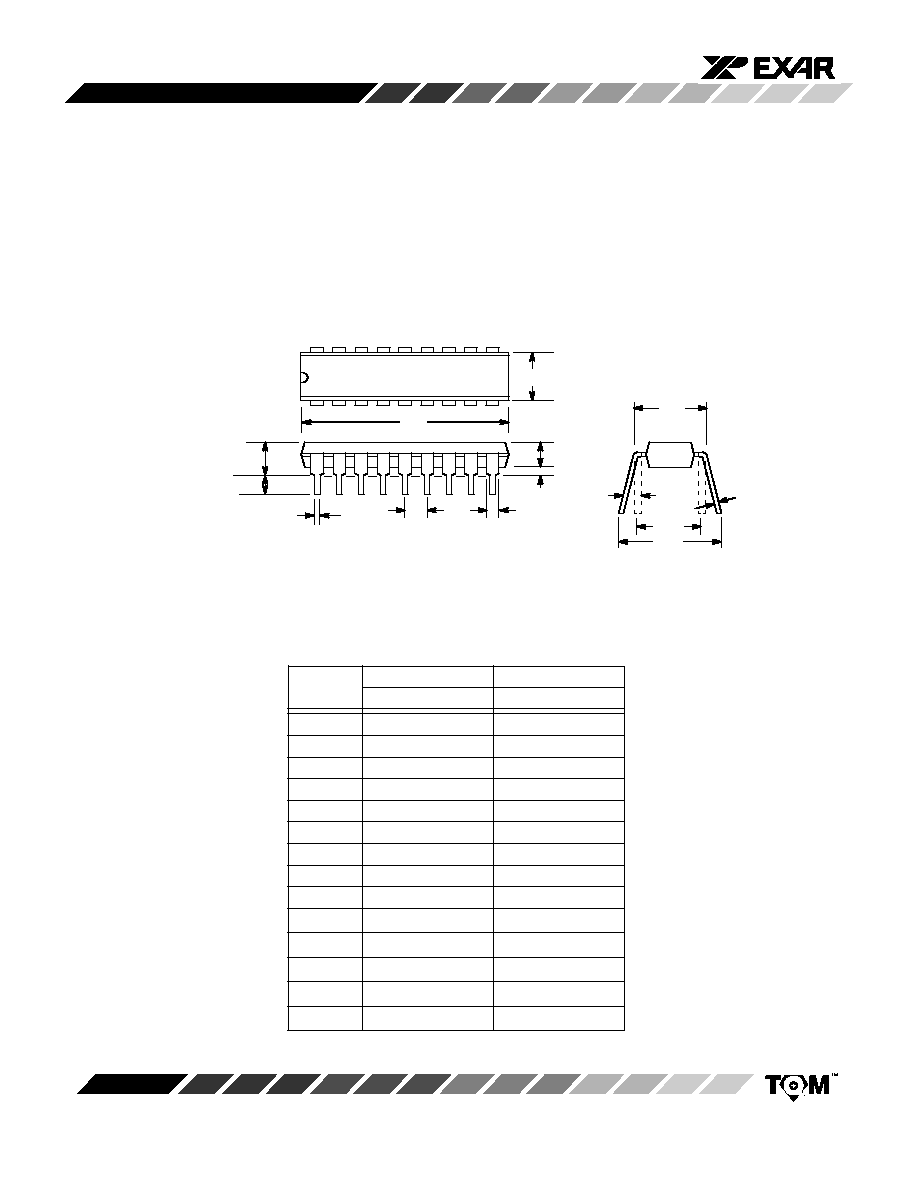

18 LEAD PLASTIC DUAL-IN-LINE

(300 MIL PDIP)

Rev. 1.00

18

1

10

9

D

e

B

1

A

1

E

1

C

E

A

2

L

B

Seating

Plane

SYMBOL

MIN

MAX

MIN

MAX

INCHES

A

0.145

0.210

3.68

5.33

A

1

0.015

0.070

0.38

1.78

A2

0.115

0.195

2.92

4.95

B

0.014

0.024

0.36

0.56

B

1

0.030

0.070

0.76

1.78

C

0.008

0.014

0.20

0.38

D

0.845

0.925

21.46

23.50

E

0.300

0.325

7.62

8.26

E

1

0.240

0.280

6.10

7.11

e

0.100 BSC

2.54 BSC

e

A

0.300 BSC

7.62 BSC

e

B

0.310

0.430

7.87

10.92

L

0.115

0.160

2.92

4.06

0

°

15

°

0

°

15

°

MILLIMETERS

A

Note: The control dimension is the inch column

e

B

e

A

XR-T56L22

13

Rev. 1.02

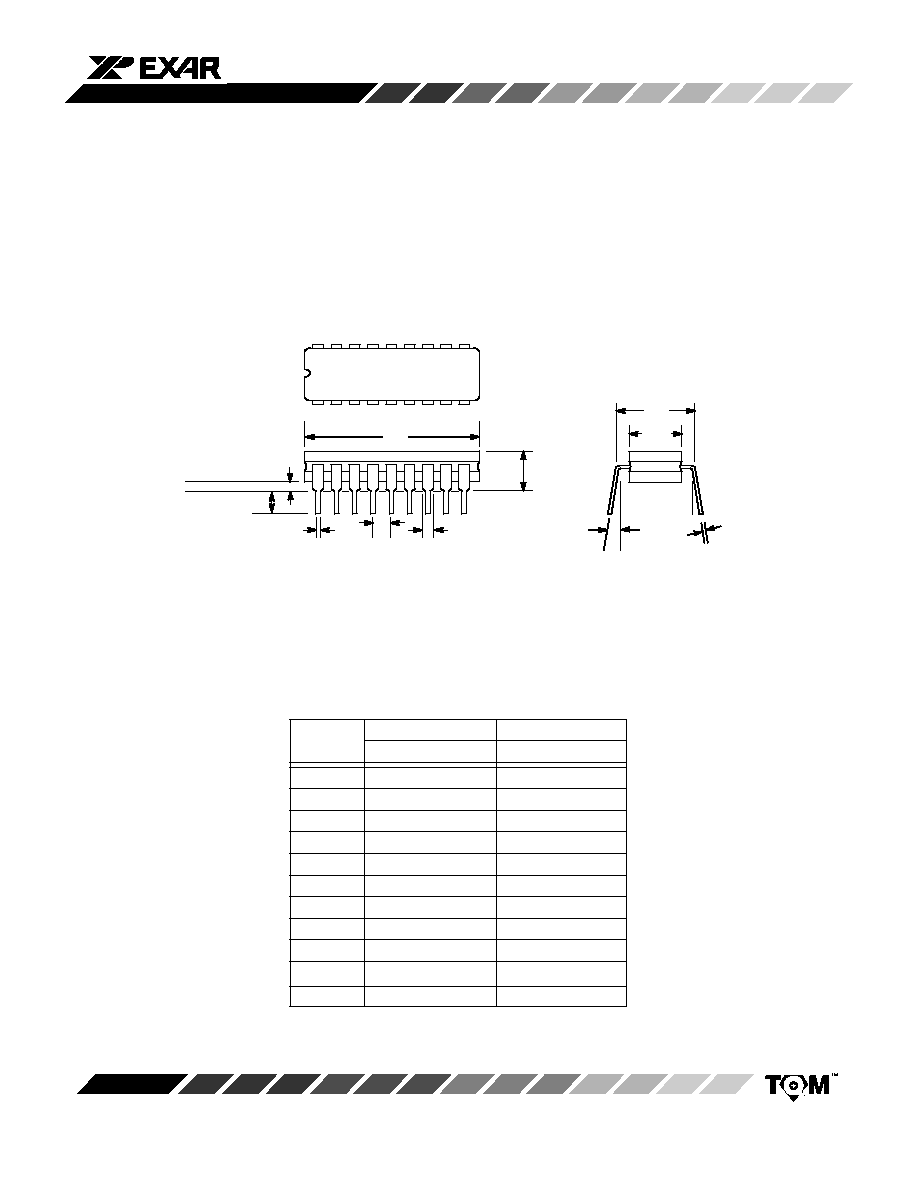

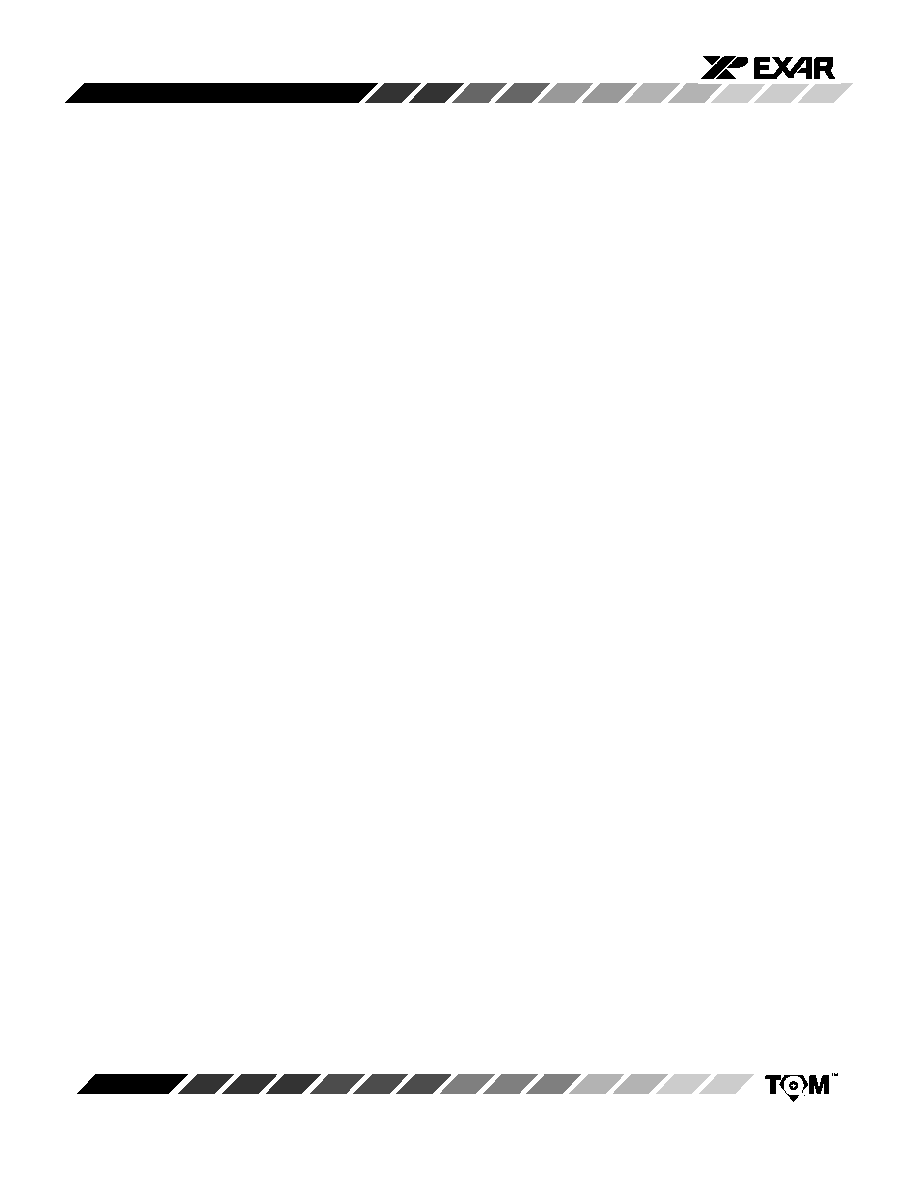

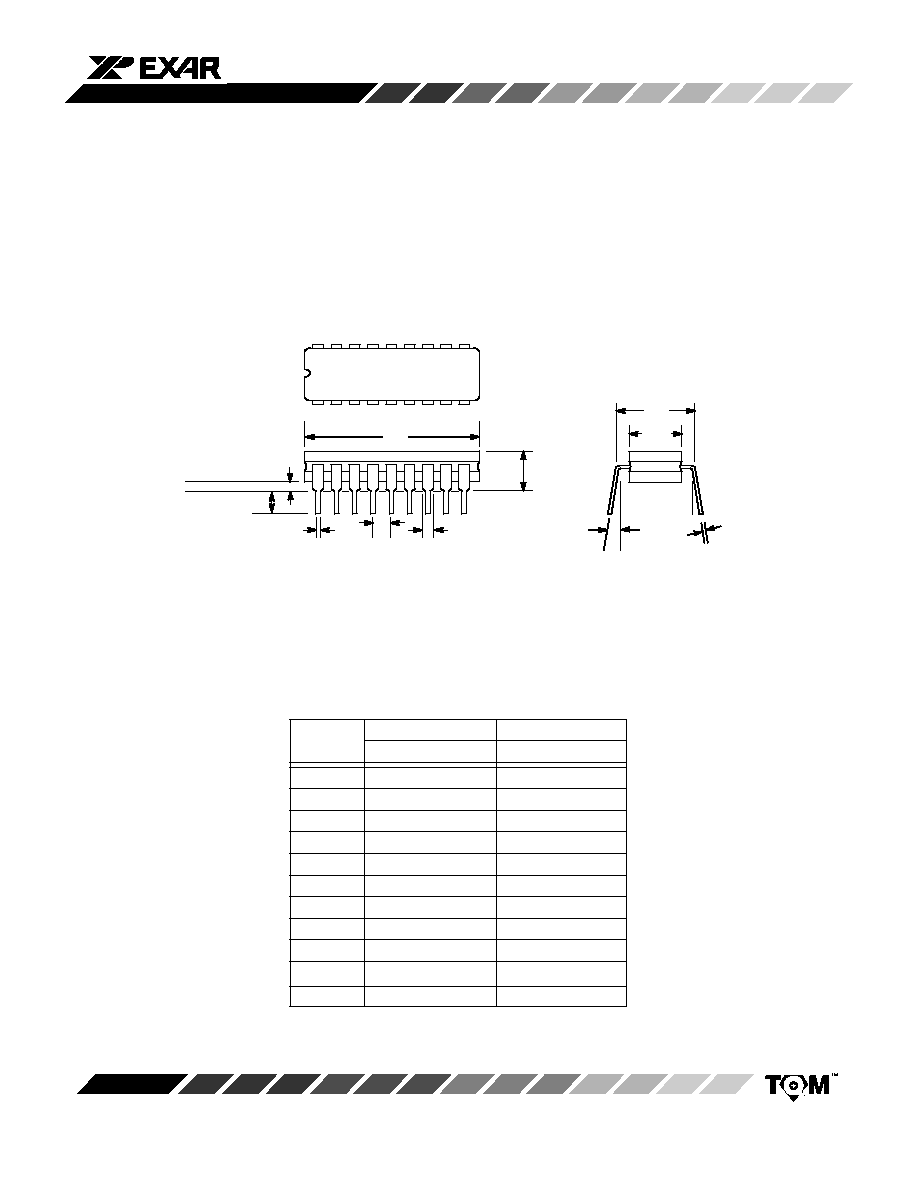

A

0.100

0.200

2.54

5.08

A

1

0.015

0.070

0.38

1.78

B

0.014

0.026

0.36

0.66

B

1

0.045

0.065

1.14

1.65

c

0.008

0.018

0.20

0.46

D

0.860

0.960

21.84

24.38

E

1

0.250

0.310

6.35

7.87

E

0.300 BSC

7.62 BSC

e

0.100 BSC

2.54 BSC

L

0.125

0.200

3.18

5.08

0

°

15

°

0

°

15

°

D

B

e

B

1

18 LEAD CERAMIC DUAL-IN-LINE

(300 MIL CDIP)

Rev. 1.00

SYMBOL

MIN

MAX

MIN

MAX

INCHES

MILLIMETERS

18

1

9

10

c

E

1

L

A

1

Seating

Plane

Base

Plane

A

E

Note: The control dimension is the inch column

XR-T56L22

14

Rev. 1.02

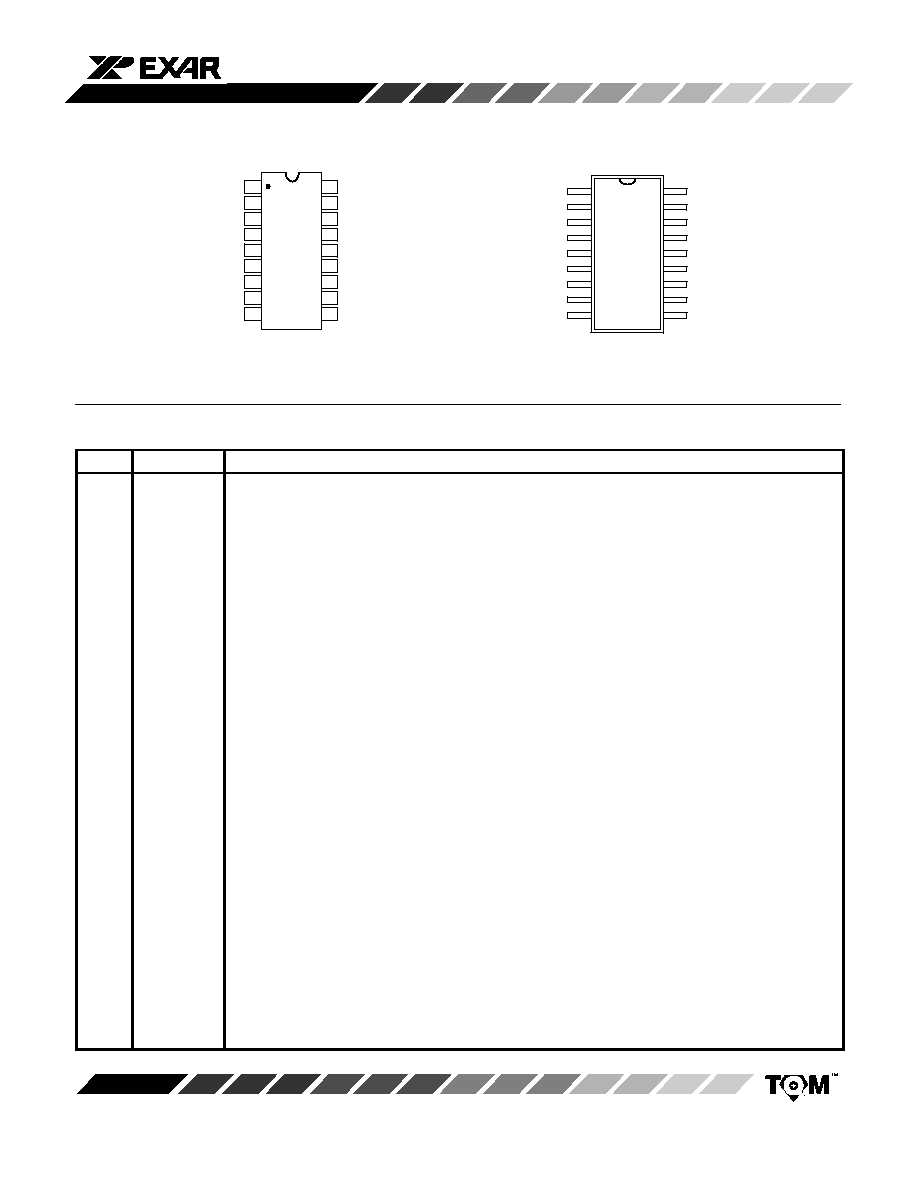

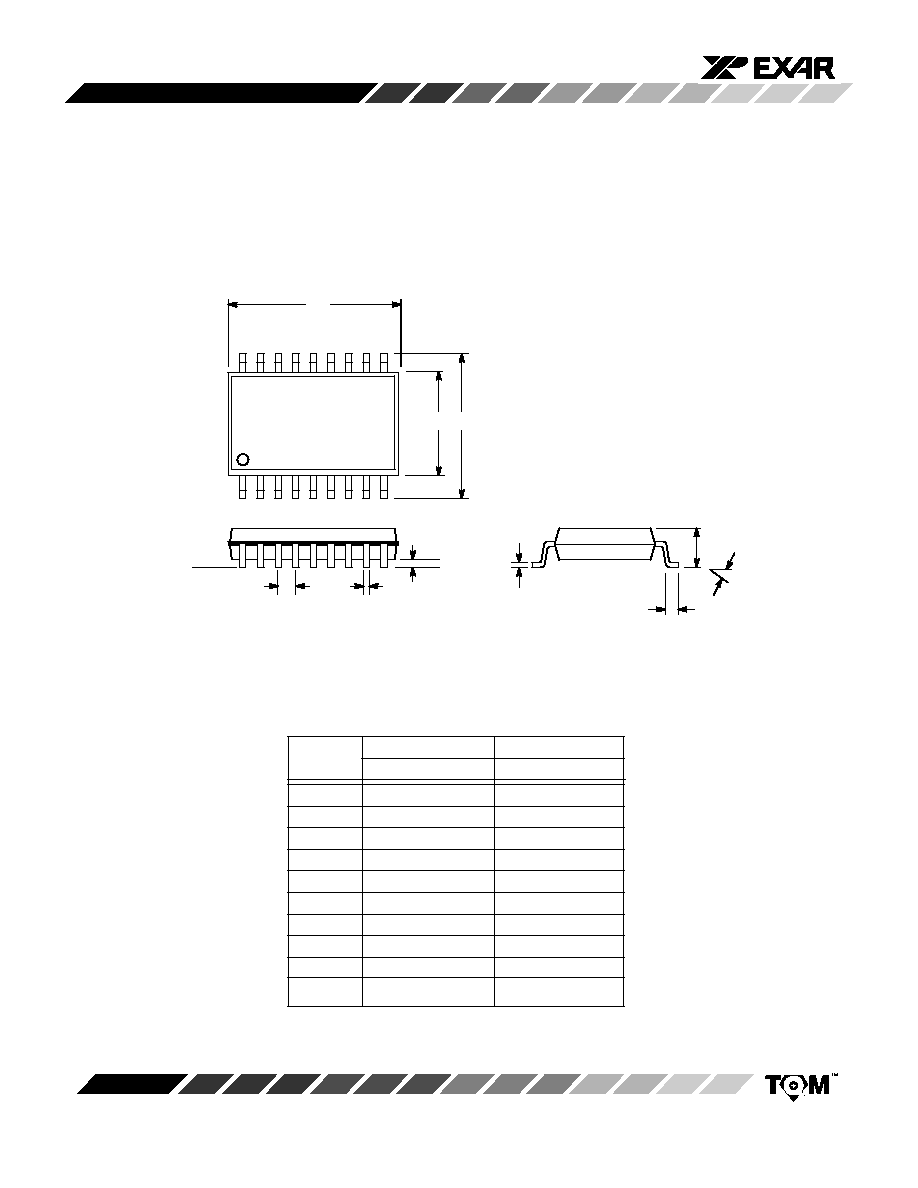

SYMBOL

MIN

MAX

MIN

MAX

A

0.093

0.104

2.35

2.65

A

1

0.004

0.012

0.10

0.30

B

0.013

0.020

0.33

0.51

C

0.009

0.013

0.23

0.32

D

0.447

0.463

11.35

11.75

E

0.291

0.299

7.40

7.60

e

0.050 BSC

1.27 BSC

H

0.394

0.419

10.00

10.65

L

0.016

0.050

0.40

1.27

0

°

8

°

0

°

8

°

INCHES

MILLIMETERS

18 LEAD SMALL OUTLINE

(300 MIL JEDEC SOIC)

Rev. 1.00

e

18

10

9

D

E

H

B

A

L

C

A

1

Seating

Plane

Note: The control dimension is the millimeter column

1

XR-T56L22

15

Rev. 1.02

Notes

XR-T56L22

16

Rev. 1.02

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to im-

prove design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits de-

scribed herein, conveys no license under any patent or other right, and makes no representation that the circuits are

free of patent infringement. Charts and schedules contained here in are only for illustration purposes and may vary

depending upon a user's specific application. While the information in this publication has been carefully checked;

no responsibility, however, is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure or

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly

affect its safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation

receives, in writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the

user assumes all such risks; (c) potential liability of EXAR Corporation is adequately protected under the circum-

stances.

Copyright 1997 EXAR Corporation

Datasheet June 1997

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.