32K x 8

Radiation Hardened

Static RAM 5 V

167A690

182A934

BAE SYSTEMS · 9300 Wellington Road · Manassas, Virginia 20110-4122

Product Description

Radiation

· Fabricated with Bulk CMOS 0.8 µm Process

· Total Dose Hardness through 1x10

6

rad(Si)

· Neutron Hardness through 1x10

14

N/cm

2

· Dynamic and Static Transient Upset Hardness

through 1x10

9

rad(Si)/s

· Soft Error Rate of < 1x10

-11

Upsets/Bit-Day

· Dose Rate Survivability through 1x10

12

rad(Si)/s

· Latchup Free

Features

Other

· Read/Write Cycle Times

30 ns (-55 °C to 125°C)

· SMD Number 5962H92153

· Asynchronous Operation

· CMOS or TTL Compatible I/O

· Single 5 V ±10% Power Supply

· Low Operating Power

· Packaging Options

· 36-Lead Flat Pack (0.630" x 0.650")

· 28-Lead DIP, MIL-STD-1835, CDIP2-T28

General Description

The 32K x 8 radiation hardened static RAM is a

high performance, low power device designed

and fabricated in 0.8 µm Radiation Hardened

Complementary Metal Oxide Semiconductor

(RHCMOS) technology. BAE SYSTEMS' device

is designed for radiation environments using

industry standard functionality. The memory can

be personalized for either CMOS or Transistor

Transistor Logic (TTL) input receivers. The

SRAM operates over the full military temperature

range and requires a single 5 V ±10% power

supply. Power consumption is typically less than

20 mW/MHz in operation, and less than 10 mW in

the low power disabled mode. The SRAM read

operation is fully asynchronous, with an

associated typical access time of 20

nanoseconds.

BAE SYSTEMS' bulk CMOS technology achieves

radiation hardening via a combination of process

technology enhancements and specific circuit

improvements.

2

Functional Diagram

Signal Definitions

A: 0-14

DQ: 0-7

S

Address input pins that select a particular

eight-bit word within the memory array.

Bi-directional data pins that serve as data

outputs during a read operation and as data

inputs during a write operation.

Negative chip select, when at a low level,

allows normal read or write operation. When

at a high level, S forces the SRAM to a

precharge condition, holds the data output

drivers in a high impedance state and

disables the data input buffers only. If this

signal is not used, it must be connected to

GND.

Negative write enable, when at a low level, activates a

write operation and holds the data output drivers in a

high impedance state. When at a high level, W allows

normal read operation.

Negative output enable, when at a high level holds the

data output drivers in a high impedance state. When at

a low level, the data output driver state is defined by S,

W, and E. If this signal is not used it must be connected

to GND.

Chip enable, when at a high level allows normal

operation. When at a low level, E forces the SRAM to a

precharge condition, holds the data output drivers in a

high impedance state and disables all the input buffers

except the S input buffer. If this signal is not used, it

must be connected to V

DD

.

W

G

E

Notes:

1) V

IN

for don't care (X) inputs = V

IL

or V

IH

.

2) When G = high, I/O is high-Z.

3) To dissipate the minimum amount of

standby power when in standby mode:

S= V

DD

and E = GND. All other input

levels may float.

4) E is tied high internally to the chip for

the 28-DIP package.

Truth Table

Mode

Inputs

(1),(2)

E

(4)

High

High

X

Low

S

Low

Low

High

X

W

Low

High

X

X

G

X

Low

X

X

I/O

Data-In

Data-Out

High-Z

High-Z

Power

Active

Active

Standby

Standby

Write

Read

Standby

Standby

(3)

· · ·

·

·

·

A:11

W

G

S

E

Column Decoder

Data Input/Output

32,768 x 8

Memory Array

Row Decoder

DQ:8

A:4

3

Notes:

Note:

1)All voltages referenced to GND.

The substrate of this module is connected directly to Ground.

Power shall be applied to the device only in the following

sequences to prevent damage due to excessive currents:

· Power-Up Sequence: GND, V

DD

, Inputs

· Power-Down Sequence: Inputs, V

DD

, GND

Absolute Maximum Ratings

Recommended Operating Conditions

Power Sequencing

Minimum

+4.5

0.0

-55

0.0

0.0

+2.0

+3.5

Units

Volt

Volt

Celsius

Volt

Volt

Supply Voltage

Parameters

(1)

Supply Voltage Reference

Case Temperature

Input Logic "Low" - CMOS

Input Logic "Low" - TTL

Input Logic "High" - TTL

Input Logic "High" - CMOS

Symbol

V

DD

GND

T

C

V

IL

V

IH

Maximum

+5.5

0.0

+125

+1.5

+0.8

V

DD

V

DD

Minimum

-65°C

-55°C

-0.5 V

-0.5 V

-0.5 V

(Class II)

Storage Temperature Range (Ambient)

Applied Conditions

(1)

Operating Temperature Range (T

CASE

)

Positive Supply Voltage

Input Voltage

(2)

Output Voltage

(2)

Power Dissipation

(3)

Lead Temperature (Soldering 5 sec)

Electrostatic Discharge Sensitivity

(4)

Maximum

+150°C

+125°C

+7.0 V

V

DD

+ 0.5 V

2.0 W

+250°C

V

DD

+ 0.5 V

1) Stresses above the absolute maximum rating may cause permanent

damage to the device. Extended operation at the maximum levels may

degrade performance and affect reliability. All voltages are with

reference to the module ground leads.

2) Maximum applied voltage shall not exceed +7.0 V.

3) Guaranteed by design; not tested.

4) Class as defined in MIL-STD-883, Method 3015.

4

1) Typical operating conditions: V

DD

= 5.0V; TA = 25 °C, pre-radiation.

-55°C

T

case

+125°C; 4.5 V

V

DD

5.5 V; unless otherwise specified.

2) The worst case timing sequence of t

WLZQ

+ t

DUWH

+ t

WHWL

= t

AVAV

.

300 ± 10%

2.8V

50 pF + 10%

Output Load Circuit

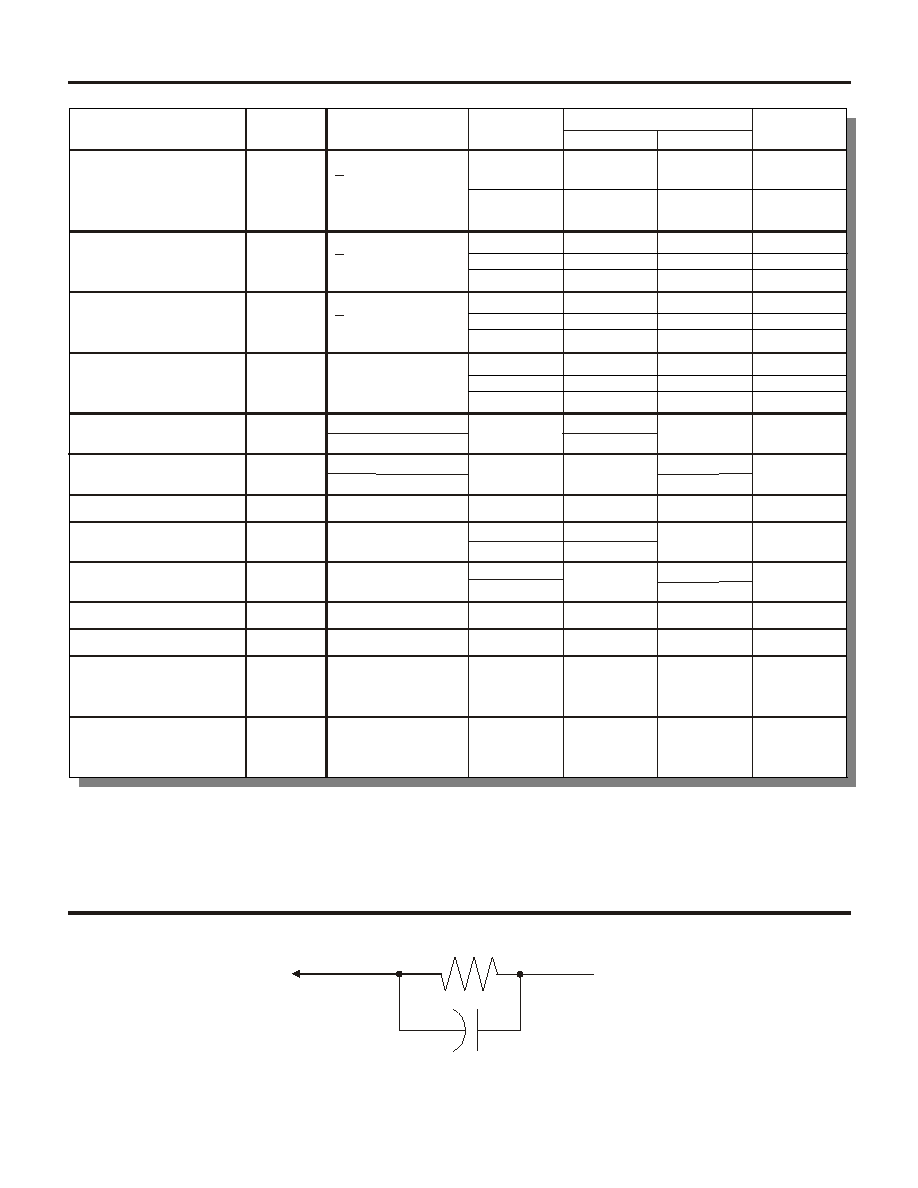

DC Electrical Characteristics

Note:

Symbol

Test Conditions

(1)

Device Type

Limits

Minimum

Maximum

Units

I

DD1

V

OH

F = F

MAX

= 1/t

AVAV(min)

S = V

IL

= GND

E = V

IH

= V

DD

No Output Load

S = V

IH

= V

DD

E = V

IL

= GND

F = F

MAX

= 1/t

AVAV(min)

V

DD

= 2.5 V

V

DD

= V

DR

0 V

V

IN

5.5 V

By Design/

Verified By

Characterization

I

OH

= -200 µA

I

OH

= -4 mA

I

OL

= 200 µA

I

OL

= 8 mA

X3X

X4X

X6X

All

All

All

All

All

All

All

2.0

1.2

2.0

4.2

2.5

3.5

2.0

-5

-10

0.4

V

DD

- 0.5 V

0.05

1.5

0.8

5

10

4

7

X3X

180

mA

mA

mA

mA

V

V

V

µA

µA

pF

pF

V

V

Test

Supply Current

(Cycling Selected)

Supply Current

(Cycling De-Selected)

Supply Current

(Standby)

Data Retention Current

Data Retention Voltage

High Level Input Voltage

Low Level Input Voltage

Input Leakage

Output Leakage

C

in

C

out

High Level Output Voltage

Low Level Output Voltage

CMOS

TTL

I

DD2

I

DD3

I

DR

V

OL

V

DR

V

IH

V

IL

I

ILK

I

OLK

F = F

MAX

= 1/t

AVAV(min)

S = V

IH

= V

DD

E = V

IL

= GND

0 V

V

OUT

5.5 V

By Design/

Verified By

Characterization

CMOS

TTL

X4X

X6X

130

mA

X3X

X4X

X6X

2.0

1.2

2.0

mA

mA

mA

X3X

X4X

X6X

1.0

0.4

1.0

mA

mA

mA

(2)

(2)

Note:

1)Test conditions: input switching levels V

IL

/V

IH

= 0.5 V/V

DD

-0.5 V (CMOS), V

IL

/V

IH

= 0 V/3 V (TTL), input rise

and fall times < 5 ns, input and output timing reference levels shown in the Tester AC Timing Characteristics

table, capacitive output loading C

L

= 50 pF. For C

L

> 50 pF, derate access times by 0.02 ns/pF (typical).

-55 °C

T

case

+125°C; 4.5 V

V

DD

5.5 V; unless otherwise specified.

5

Read Cycle AC Timing Characteristics

(1)

Read Cycle Timing Diagram

Valid Address

Valid Data

High Impedance

Address

E

S

G

Data

Out

t

AVAV

t

AVQV

t

SLQV

t

SLQX

t

EHQV

t

EHQX

t

GLQV

t

GLQX

t

AXQX

t

SHQZ

t

ELQZ

t

SHQZ

Worst Case By Speed

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Test

Read Cycle Time

Output Hold After Address Change

Chip Select to Output Active

Chip Enable to Output Active

Output Enable to Output Active

Address Access Time

Chip Select Access Time

Chip Enable Access Time

Chip Select to Output Disable

Chip Disable to Output Disable

Output Enable to Output Disable

Output Enable Access Time

Minimum or

Maximum

Minimum

Minimum

Minimum

Minimum

Minimum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Maximum

Symbol

t

AVAV

t

AVQV

t

AXQX

t

SLQV

t

SLQX

t

SHQZ

t

EHQV

t

EHQX

t

ELQZ

t

GLQV

t

GLQX

t

GHQZ

-60

60

3

3

3

60

60

60

15

15

15

15

5

-40

40

3

3

3

40

40

40

15

15

15

5

CMOS - 15

TTL - 18

-30

30

5

3

3

3

30

30

30

CMOS - 10

TTL - 12

CMOS - 10

TTL - 12

CMOS - 12

TTL - 15

CMOS - 10

TTL - 12

Note:

1) Test conditions: input switching levels V

IL

/V

IH

= 0.5 V/V

DD

- 0.5 V (CMOS), V

IL

/V

IH

= 0 V/3 V (TTL), input rise and

fall times < 5 ns, input and output timing reference levels shown in the Tester AC Timing Characteristics table,

capacitive output loading = 50 pF. -55°C

T

case

+125°C; 4.5 V

V

DD

5.5 V; unless otherwise specified.

t

AVAV

Valid Address

Valid Data

High Impedance

High Impedance

High Impedance

High Impedance

Address

t

AVWH

t

SLWH

t

EHWH

t

WLWH

t

AVWL

t

WLQZ

t

WHQX

t

WHDX

t

WHWL

t

DVWH

S

E

W

Data

Out

Data

In

t

WHAX

6

Write Cycle AC Timing Characteristics

(1)

Write Cycle Timing Diagram

Worst Case By Speed

Minimum or

Maximum

Minimum

Minimum

Minimum

Minimum

Minimum

Minimum

Minimum

Minimum

Maximum

Minimum

Minimum

Minimum

-40

40

35

35

5

35

30

0

3

15

35

1

0

0

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Test

Write Cycle Time

Chip Select to End of Write

Address Setup to End of Write

Write Pulse Width Access Time

Write Pulse Width

Data Setup to End of Write

Address Setup to Start of Write

Data Hold After End of Write

Write Enable to Output Disable

Chip Enable to End of Write

Output Active After End of Write

Address Hold After End of Write

Address Hold After End of Write

Minimum

-60

40

55

55

5

55

40

0

5

15

55

3

0

0

-30

35

30

30

5

30

25

0

3

12

30

1

0

0

Symbol

t

AVAV

t

WLWH

t

SLWH

t

DVWH

t

AVWH

t

WHDX

t

AVWL

t

WHAX

t

WLQZ

t

WHQX

t

WHWL

t

EHWH

t

ELWH

7

Dynamic Electrical Characteristics

Read Cycle

The RAM is asynchronous in operation, allowing the read

cycle to be controlled by address, chip select (S), or chip

enable (E) (refer to Read Cycle Timing diagram). To

perform a valid read operation, both chip select and output

enable (G) must be low and chip enable and write enable

(W) must be high. The output drivers can be controlled

independently by the G signal. Consecutive read cycles can

be executed with S held continuously low, and with E held

continuously high, and toggling the addresses.

For an address-activated read cycle, S and E must be valid

prior to or coincident with the activating address edge

transition(s). Any amount of toggling or skew between

address edge transitions is permissible; however, data

outputs will become valid t

AVQV

time following the latest

occurring address edge transition. The minimum address

activated read cycle time is t

AVQV

. When the RAM is

operated at the minimum address-activated read cycle time,

the data outputs will remain valid on the RAM I/O until t

AXQX

time following the next sequential address transition.

To control a read cycle with S, all addresses and E must be

valid prior to or coincident with the enabling S edge

transition. Address or E edge transitions can occur later

than the specified setup times to S; however, the valid data

access time will be delayed. Any address edge transition,

that occurs during the time when S is low, will initiate a new

read access, and data outputs will not become valid until

t

AVQV

time following the address edge transition. Data

outputs will enter a high impedance state t

SHQZ

time

following a disabling S edge transition.

To control a read cycle with E, all addresses and S must be

valid prior to or coincident with the enabling E edge

transition. Address or S edge transitions can occur later

than the specified setup times to E; however, the valid data

access time will be delayed. Any address edge transition

that occurs during the time when E is high will initiate a new

read access, and data outputs will not become valid until

t

AVQV

time following the address edge transition. Data

outputs will enter a high impedance state t

ELQZ

time

following a disabling E edge transition.

Write Cycle

The write operation is synchronous with respect to the

address bits, and control is governed by write enable (W),

chip select (S), or chip enable (E) edge transitions (refer

to Write Cycle Timing diagrams). To perform a write

operation, both W and S must be low, and E must be

high. Consecutive write cycles can be performed with W

or S held continuously low, or E held continuously high. At

least one of the control signals must transition to the

opposite state between consecutive write operations.

The write mode can be controlled via three different

control signals: W, S, and E. All three modes of control

are similar except the S and E controlled modes actually

disable the RAM during the write recovery pulse. Only the

W controlled mode is shown in the table and diagram on

the previous page for simplicity. However, each mode of

control provides the same write cycle timing

characteristics. Thus, some of the parameter names

referenced below are not shown in the write cycle table or

diagram, but indicate which control pin is in control as it

switches high or low.

To write data into the RAM, W and S must be held low

and E must be held high for at least t

WLWH

/t

SLSH

/t

EHEL

time.

Any amount of edge skew between the signals can be

tolerated and any one of the control signals can initiate or

terminate the write operation. For consecutive write

operations, write pulses must be separated by the

minimum specified t

WHWL

/t

SHSL

/t

ELEH

time. Address inputs

must be valid at least t

AVWL

/t

AVSL

/t

AVEH

time before the

enabling W/S/E edge transition, and must remain valid

during the entire write time. A valid data overlap of write

pulse width time of t

DVWH

/t

DVSH

/t

DVEL

, and an address valid to

end of write time of t

AVWH

/t

AVSH

/t

AVEL

also must be provided

for during the write operation. Hold times for address

inputs and data inputs with respect to the disabling W/S/E

edge transition must be a minimum of t

WHAX

/t

SHAX

/t

ELAX

time

and t

WHDX

/t

SHDX

/t

ELDX

time, respectively. The minimum write

cycle time is t

AVAV

.

8

Radiation Characteristics

Total Ionizing Radiation Dose

The SRAM will meet all stated functional and electrical

specifications over the entire operating temperature range

after a total ionizing radiation dose of 1x10

6

rad(Si). All

electrical and timing performance parameters will remain

within specifications after rebound at V

DD

= 5.5 V and T =

125°C extrapolated to ten years of operation. Total dose

hardness is assured by wafer level testing of process monitor

transistors and RAM product using 10 keV X-ray and Co60

radiation sources. Transistor gate threshold shift correlations

have been made between 10 keV X-rays applied at a dose

rate of 1x10

5

rad(Si)/min at T = 25°C and gamma rays (Cobalt

60 source) to ensure that wafer level X-ray testing is

consistent with standard military radiation test environments.

Transient Pulse Ionizing Radiation

The SRAM is capable of writing, reading, and retaining stored

data during and after exposure to a transient ionizing radiation

pulse of

50 ns duration up to 1x10

9

rad(Si)/s, when applied

under recommended operating conditions. To ensure validity

of all specified performance parameters before, during, and

after radiation (timing degradation during transient pulse

radiation is

10%), stiffening capacitance can be placed on

the package between the package (chip) V

DD

and GND with

the inductance between the package (chip) and stiffening

capacitance kept to a minimum. If there are no operate-

through or valid stored data requirements, typical de-coupling

capacitors should be mounted on the circuit board as close as

possible to each device.

The SRAM will meet any functional or electrical

specification after exposure to a radiation pulse of

50 ns

duration up to 1x10

12

rad(Si)/s, when applied under

recommended operating conditions. Note that the current

conducted during the pulse by the RAM inputs, outputs,

and power supply may significantly exceed the normal

operating levels. The application design must

accommodate these effects.

Neutron Radiation

The SRAM will meet any functional or timing specification

after a total neutron fluence of up to 1x10

14

cm

-2

applied

under recommended operating or storage conditions. This

assumes an equivalent neutron energy of 1 MeV.

Soft Error Rate

The SRAM has a soft error rate (SER) performance of

<1x10

-11

upsets/bit-day, under recommended operating

conditions. This hardness level is defined by the Adams

90% worst case cosmic ray environment.

Latchup

The SRAM will not latch up due to any of the above

radiation exposure conditions when applied under

recommended operating conditions.

Radiation Hardness Ratings

(1),(2)

Notes:

1) Measured at room temperature unless otherwise stated. Verification test per TRB approved test plan.

2) Device electrical characteristics are guaranteed for post irradiation levels at 25°C.

3) 90% worst case particle environment, geosynchronous orbit, 0.025'' of aluminum shielding.

Specification set using the CREME code upset rate calculation method with a 2 µm epi thickness.

4) Immune for LET

120 MeV/mg/cm

2

.

Conditions

Characteristics

Total Dose

Single Event Upset

(3)

Prompt Dose Upset

Single Event Induced Latchup

Survivability

Single Event Upset

(3)

Neutron Fluence

Units

rad(Si)

Upsets/Bit-Day

rad(Si)/s

Immune

(4)

rad(Si)/s

Upsets/Bit-Day

N/cm

2

Maximum

1E - 10

1E - 11

Symbol

RTD

SEU2

RPRU

SEL

RS

SEU1

RNF

Minimum

1E + 06

1E + 09

1E + 12

1E + 14

20 - 50 ns Pulse Width

T

case

= 25°C and 125°C

MIL-STD-883, TM 1019.5

Condition A

20 - 50 ns Pulse Width

T

case

= 125°C

-55°C

T

case

80°C

-55°C

T

case

125°C

-55°C

T

case

125°C

V

DD

= 5.5 V

9

*Input rise and fall times <5 ns

Tester AC Timing Characteristics

Radiation Hardness Assurance

Reliability

BAE SYSTEMS' reliability starts with an overall product

assurance system that utilizes a quality system involving all

employees including operators, process engineers and

product assurance personnel. An extensive wafer lot

acceptance methodology, using in-line electrical data as well

as physical data, assures product quality prior to assembly. A

continuous reliability monitoring program evaluates every lot

at the wafer level, utilizing test structures as well as product

testing. Test structures are placed on every wafer, allowing

correlation and checks within-wafer, wafer-to-wafer, and from

lot-to-lot.

Reliability attributes of the CMOS process are characterized

by testing both irradiated and non-irradiated test structures.

The evaluations allow design model and process changes to

be incorporated for specific failure mechanisms, i.e., hot

carriers, electromigration, and time dependent dielectric

breakdown. These enhancements to the operation create a

more reliable product.

The process reliability is further enhanced by accelerated

dynamic life tests of both irradiated and non-irradiated test

structures. Screening and testing procedures from the

customer are followed to qualify the product.

A final periodic verification of the quality and reliability of the

product is validated by a TCI (Technology Conformance

Inspection).

BAE SYSTEMS has two QML screen levels (Q and V) to meet

full compliant space applications. For limited performance and

evaluation situations, BAE SYSTEMS offers an engineering

screen level.

Screening Levels

BAE SYSTEMS provides a superior quality level of radiation

hardness assurance for our products. The excellent product

quality is sustained via the use of our qualified QML operation

which requires process control with statistical process control,

radiation hardness assurance procedures and a rigid

computer controlled manufacturing operation monitoring and

tracking system.

The BAE SYSTEMS technology is built with resistance to

radiation effects. Our product is designed to exhibit < 1e

-11

fails/bit-day in a 90% worst case geosynchronous orbit under

worst case operating conditions. Total dose hardness is

assured by irradiating test structures on every lot and total

dose exposure with Cobalt 60 testing performed quarterly on

TCI lots to assure the product is meeting the QML radiation

hardness requirements.

TTL I/O Configuration

CMOS I/O Configuration

3 V

V

DD

- 0.4 V

3.4 V

0.4 V

2.4 V

1.5 V

High Z

High Z

High Z = 2.9 V

0 V

1.5 V

. . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . . . . .

. . . . . . . .

. . . .

. . . .

. . . .

. . . .

0.5 V

Input

Levels*

Output

Sense

Levels

3.4 V

0.4 V

2.4 V

High Z

High Z

High Z = 2.9 V

V

DD

/2

V

DD

- 0.4 V

V

DD

/2

V

DD

- 0.5 V

10

Pin Listing

Standard Screening Procedure

Stress Methodology

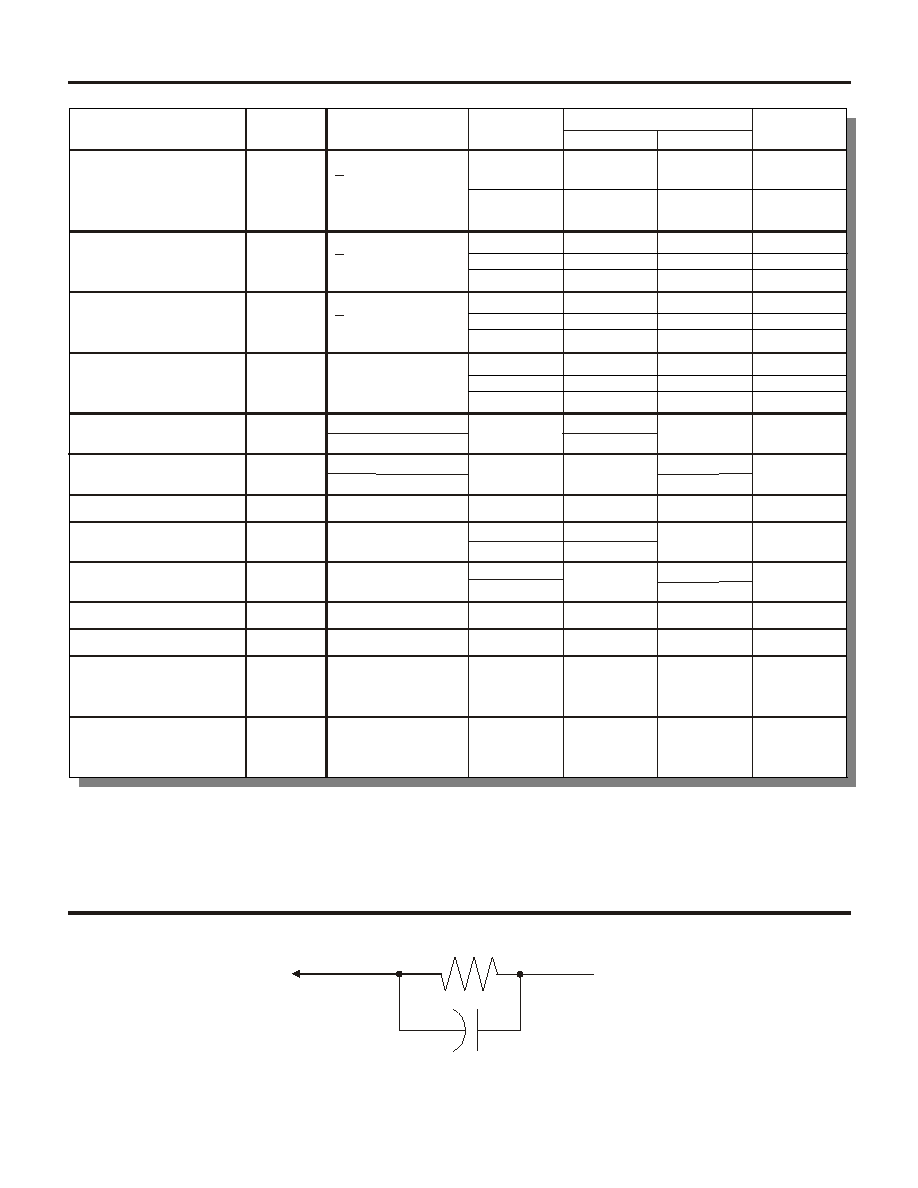

There are two methods of burn-in defined. For "Static" burn-in,

all possible addresses are written with a logic "1" for half of the

burn-in duration and a logic "0" for the remaining half. For

"Dynamic" burn-in, all possible addresses are written with

alternating high and low data.

All I/O pins specified in the static and dynamic burn-in pin lists

are driven through individual series resistors (1.6K

±10%).

The burn-in circuit diagram is shown at right.

Voltage Levels

· Vin(0): 0.0 V to + 0.4 V

V

IL

= Low level for all programmed signals

·Vin(1): + 5.4 V to + 6.0 V

V

IH

= High level for all programmed signals

· V1: + 5.5 V (-0% / +10%)

All V

DD

pins are tied to this level

·Vsx: Float or GND

All GND pins are tied to this level

V1

C1

C1 = 0.1 µF (±10%)

R = 1.6K

(±10%)

S

E

W

G

DQ0

DIN

DQ7

A0

A14

·

·

·

·

·

·

·

·

R

R

R

R

R

R

R

R

32K x 8

SRAM

The dynamic

burn-in pin listing

is shown at right.

F = square wave,

100 KHz to

1.0 MHz.

X

X

Sample

X

X

X

X

X

X

X

X

X

X

X

X

Sample

X

X

X

X

X

X

X

X

X

X

X

X

X

Alternate Method Used

Die Traceability

MIL-STD-883, TM 2010

5.5 V, 125°C, 144 Hours

Meets Group A

< 5% Fallout

MIL-STD-883, TM 2009

Wafer Lot Acceptance

Serialization

Destructive Bond Pull

Internal Visual

Temperature Cycle

Constant Acceleration

PIND

Radiography

Electrical Test

Dynamic Burn-In

Electrical Test

Static Burn-In

Final Electrical

PDA

Fine and Gross Leak

External Visual

Comments

Q

V

Flow

QML Level

Burn-In Circuit

Input

A0

A1

A2

A3

A4

Signal

F/2

F/4

F/8

F/16

F/32

Input

W

D

IN

S

G

E

Input

A11

A12

A13

A14

A10

Signal

F/131072

F

V

IL

V

IH

F/65536

Signal

F/8192

F/16384

F/32768

F/4096

F/2048

Input

A6

A7

A8

A9

A5

Signal

F/128

F/256

F/512

F/1024

F/64

11

Packaging

36-Lead Flat Pack Pinout

28-Lead DIP Pinout

36-Lead Flat Pack

The 32K x 8 SRAM is offered in a custom 36-lead FP,

36-lead FPP or standard 28-lead DIP. All packages are

constructed of multilayer ceramic (AI

2

O

3

) and feature

internal power and ground planes. The FP also features

a non-conductive ceramic tie bar on the lead frame.

The purpose of the tie bar is to allow electrical testing of

the device, while preserving the lead integrity during

shipping and handling, up to the point of lead forming

and insertion.

Optional capacitors can be mounted to the package to

maximize supply noise decoupling and increase board

packing density. These capacitors attach directly to the

internal package power and ground planes. This design

minimizes resistance and inductance of the bond wire

and package, both of which are critical in a transient

radiation environment. All NC pins must be connected to

either V

DD

, GND or an active driver to prevent charge

build up in the radiation environment. (NC = no connect.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

GND

Top

View

28

27

26

25

24

23

22

21

20

19

18

17

16

15

A13

A8

A9

A11

A10

DQ7

DQ6

DQ5

DQ4

DQ3

W

G

S

V

DD

Top

View

GND

36

W

34

E

33

A13

32

A8

31

A9

30

A11

29

G

28

A10

27

S

26

DQ7

25

DQ6

24

DQ5

23

DQ4

22

DQ3

21

GND

19

20

V

DD

35

V

DD

1

GND

3

A14

4

A12

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

DQ0

14

DQ1

15

DQ2

16

NC

18

GND

17

V

DD

2

V

DD

Q

R

GND

GND

V

DD

Lead 1 Indicator

Lead 36

Lead 1

Lead 19

Lead 18

J

M

D

G

F

H

(2)

(1)

Q

M

L

(

U

S

A

)

D

a

t

e

C

o

d

e

B

(Width)

E

(Pitch)

K

N

A

P

C

L

V

DD

GND

GND

V

DD

V

DD

Notes:

1) Part mark per device specification.

2) "QML" may not be required per device

specification.

3) Dimensions are in inches.

4) Lead width: .008 ± .002.

5) Lead height: .006 ± .002.

6) Unless otherwise specified, all

tolerances are ± .005".

A=.085 ± .010

B=.008 ± .002

C=.013 ± .004

D=.650 ± .010

E=.025 ± .002

F=.630 ± .007

G=.425 ± .004

H=1.490

J=.135

K=.080

L=.020

M=.285

N=.100

P=.040

Q=.130

R=.260

Cleared for Public Domain Release

©2001 BAE SYSTEMS, All Rights Reserved

BAE SYSTEMS · 9300 Wellington Road · Manassas, Virginia 20110-4122

BAE SYSTEMS

An ISO 9001, AS9000, ISO 14001,

and SEI CMM Level 4 Company

9300 Wellington Road, Manassas, VA 20110-4122

866-530-8104

http://www.iews.na.baesystems.com/space/

0041_32K_8_SRAM.ppt

BAE SYSTEMS reserves the right to make

changes to any products herein to improve

reliability, function or design. BAE

SYSTEMS does not assume liability arising

out of the application or use of any product

or circuit described herein, neither does it

convey any license under its patent rights

nor the rights of others.

Ordering Information

For 28-Lead DIP description, see

MIL-STD-1835, type CDIP2-T28,

configuration C, dimensions D-10.

36-Lead Flat Pack with Pedestal Package

Notes:

1) Part mark per device specification.

2) "QML" may not be required per device

specification.

3) Dimensions are in inches.

4) Lead width: .008 ± .002.

5) Lead height: .006 ± .002.

6) Unless otherwise specified, all

tolerances are ± .005".

A=.137 ± .010

B=.008 ± .002

C=.013 ± .004

D=.650 ± .010

E=.025 ± .002

F=.630 ± .007

G=.425 ± .004

H=1.490

J=.135

K=.450

L=.285

28-Lead DIP

32K x 8 CMOS Memory Device

·Part Number 167A690

32K x 8 TTL Memory Device

·Part Number 182A934

X

Y

Z

X

Y

Z

Z

Screen

Designation

1=QML VV

3=Engineering

4=QML VQ

5=QML QQ

7=Customer Specific

Y

Speed

Designation

3 = 30 ns

4 = 40 ns

X

Package

Designation

1 = 36-Lead FP

2 = 36-Lead FPP

3 = 28-Lead DIP

-

-

Lead 1 Indicator

K

A

C

V

DD

V

DD

GND

(1)

Lead 1

Lead 18

J

L

D

G

F

H

Lead 36

Lead 19

B

E

QML (USA) Date Code

(2)

6 = 60 ns