1 of 18

102199

FEATURES

§

Low impedance coupler to create large

common-ground, multi-level MicroLAN

networks

§

Keeps inactive branches pulled high to 5V

§

Simplifies network topology analysis by

logically decoupling devices on active

network segments

§

Conditional search for fast event signaling

§

Auxiliary 1-Wire

TM

line to connect a memory

chip or to be used as digital input

§

Programmable, general purpose open drain

control output

§

Communicates at 16.3k bits per second

§

Unique, factory-lasered and tested 64-bit

registration number (8-bit family code + 48-

bit serial number + 8-bit CRC tester) assures

absolute traceability because no two parts are

alike

§

8-bit family code specifies device

communication requirements to bus master

§

Built-in multidrop controller ensures

compatibility with other MicroLAN products

§

Operating temperature range from -40°C to

+85°C

§

Compact, low cost 6-pin TSOC surface mount

package

PIN ASSIGNMENT

PIN DESCRIPTION

Pin 1

GND

Pin 2

1-Wire in

Pin 3

Main 1-Wire out

Pin 4

Auxiliary 1-Wire out

Pin 5

Control Output

Pin 6

V

DD

ORDERING INFORMATION

DS2409P

6-pin TSOC package

DESCRIPTION

The MicroLAN coupler is an essential component to build and control 1-Wire MicroLAN networks with

multi-level branching. In contrast to approaches that switch the ground line, the coupler maintains a

common ground level for the whole network and keeps the inactive segments powered. This simplifies

supplying central or local power for additional circuitry and prevents loss of status of parasitically

powered devices. It also avoids disrupting communication caused by the parasitic power supply of 1-Wire

devices after activating a branch. The coupler does not contain any user-programmable memory. To label

a branch one can connect any 1-Wire memory device to the auxiliary 1-Wire output of the coupler. Both

the main and the auxiliary 1-Wire output are supported by a "smart-on" command. This command

generates a reset/presence sequence on the selected output before the electronic switch closes the contact

to the 1-Wire bus. This way the bus master can apply a ROM function command (optionally followed by

a memory function) to the devices on the just activated segment with all other devices in the network

DS2409

MicroLAN Coupler

www.dalsemi.com

1

2

3

6

5

4

TOP VIEW

3.7 X 4.0 X 1.5 mm

SIDE VIEW

6-PIN TSOC PACKAGE

DS2409

102199

2 of 18

remaining deselected. This significantly speeds up the analysis of topology and population in a

continuously changing network. The coupler also supports the bus master in detecting arrivals on the

inactive segments of the network by responding to the conditional search command. The control output

can be used to optically signal the on/off state of a branch or, together with the auxiliary output, for

handshaking in dual-master applications. The network size can be maximized by using a DS2480 line

driver at the bus master's serial interface. The DS2480 compensates for the rising ground level caused by

the non-zero on-resistance of couplers in multi-level networks.

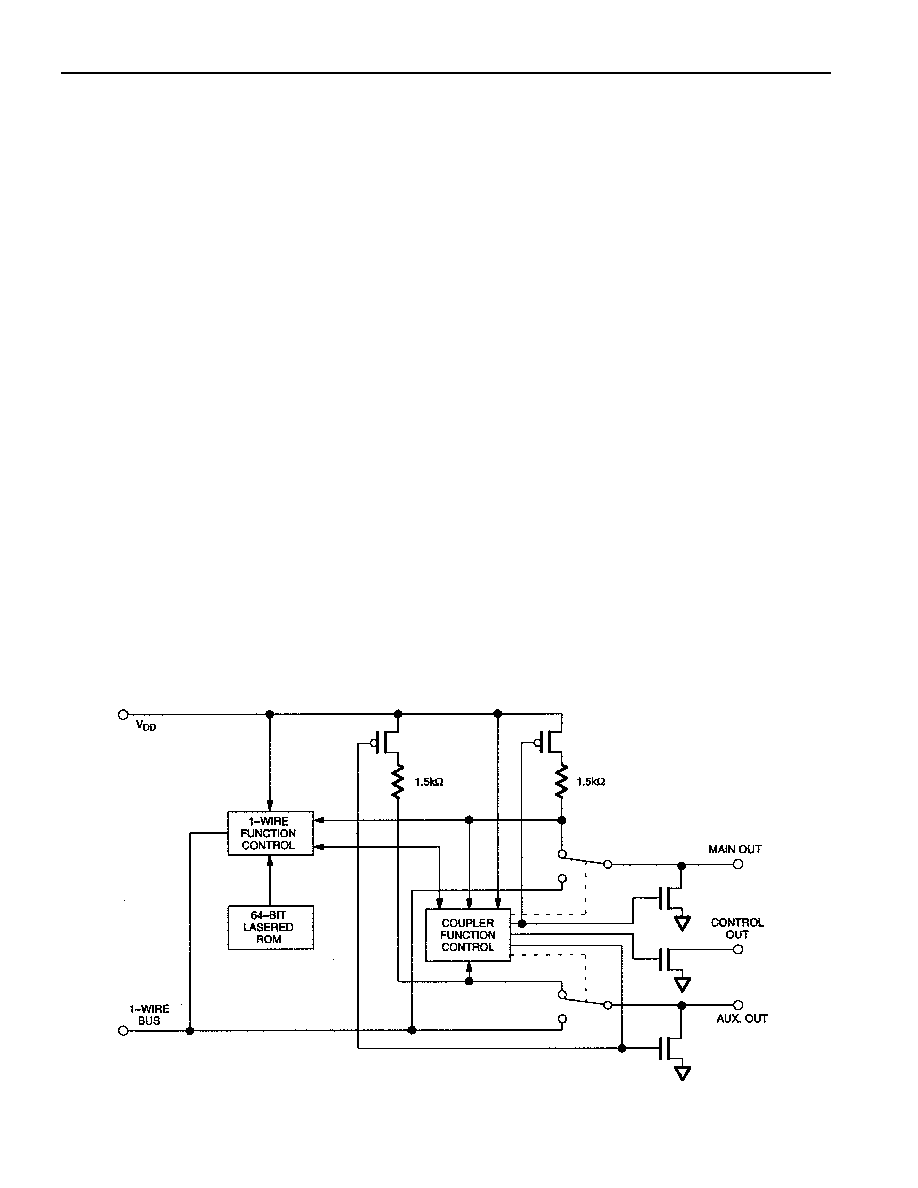

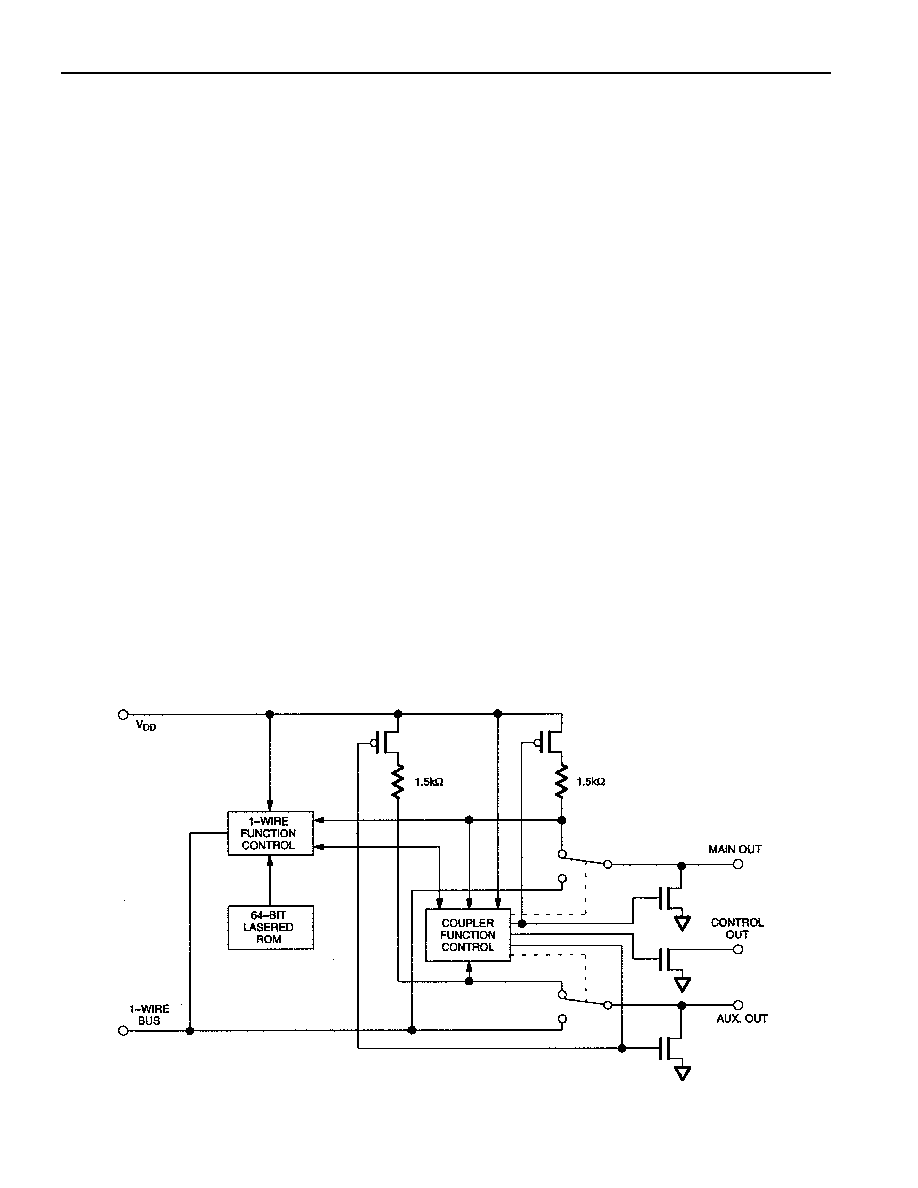

OVERVIEW

The DS2409 Coupler provides a means to create large MicroLAN networks with additional control

capability provided by an open-drain N-channel MOSFET that can be remotely switched via

communication over the 1-Wire bus (Figure 1). An auxiliary output can be used to label the branch by

connecting a programmed 1-Wire memory chip or as digital input. The DS2409 contains a factory-lasered

registration number that includes a unique 48-bit serial number, an 8-bit CRC, and an 8-bit family code

(1FH). The 64-bit ROM portion of the DS2409 not only creates an absolutely unique electronic

identification for the device itself but also is a means to locate and address the device in order to exercise

its control functions.

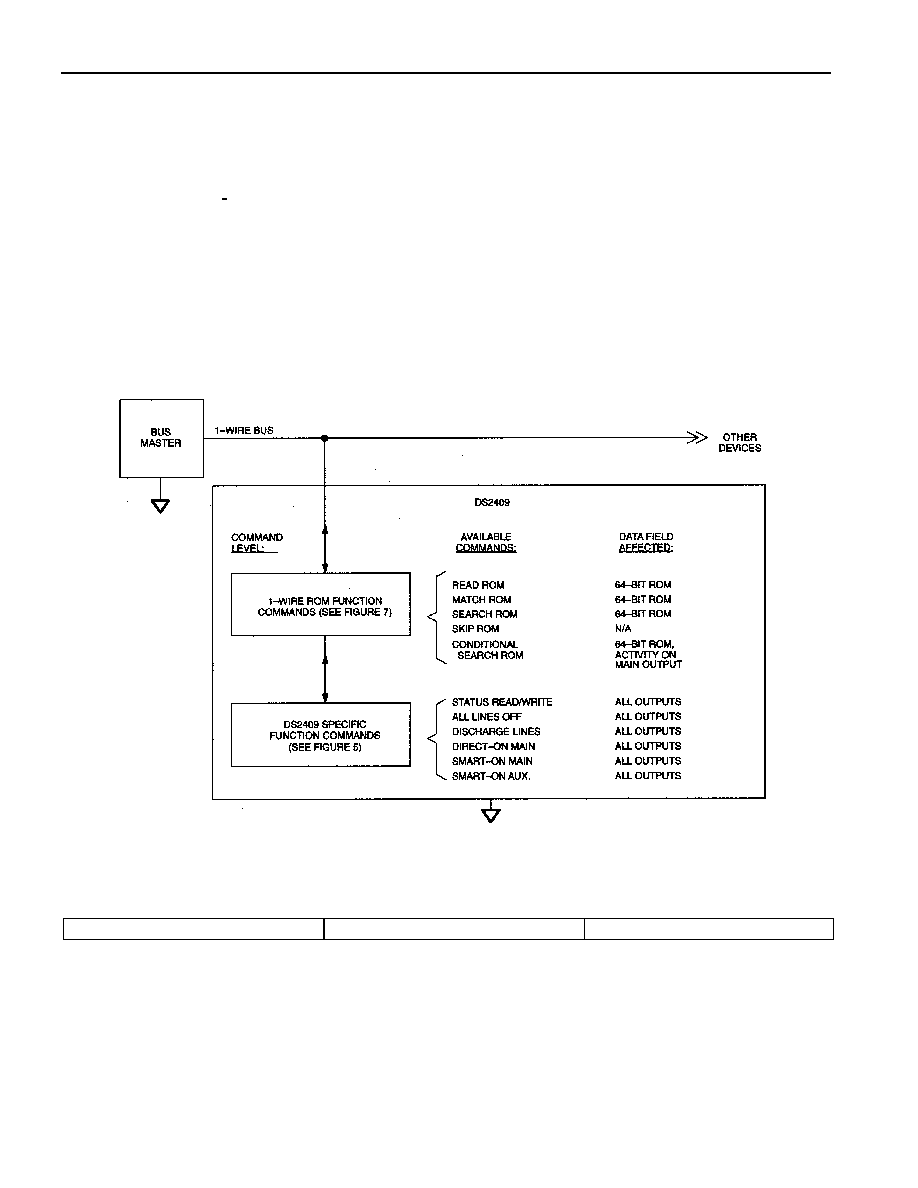

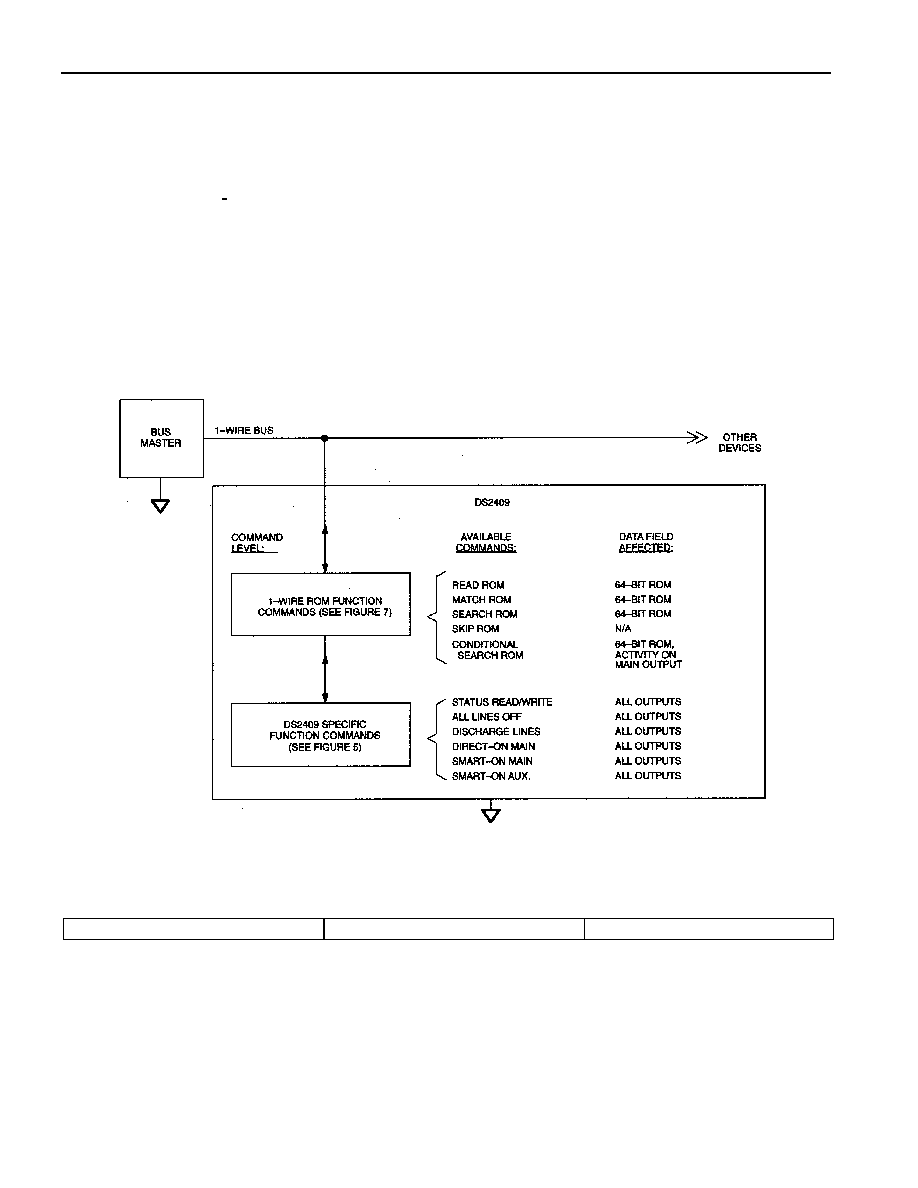

The DS2409 uses the standard Dallas Semiconductor 1-Wire protocol for data transfers (Figure 2), with

all data being read and written least significant bit first. Communication to and from the DS2409 requires

a single bi-directional line that is typically a port pin of a microcontroller. The 1-Wire bus master

(microcontroller) must first issue one of five ROM function commands: 1) Read ROM, 2) Match ROM,

3) Search ROM, 4) Skip ROM, or 5) Conditional Search ROM. These commands operate on the 64-bit

lasered ROM portion of each device and can singulate a specific device if many are present on the 1-Wire

line as well as indicate to the bus how many and what type of each device is present. After a ROM

function command is successfully executed, the control functions of the device can be exercised via the 1-

Wire bus.

BLOCK DIAGRAM Figure 1

DS2409

102199

3 of 18

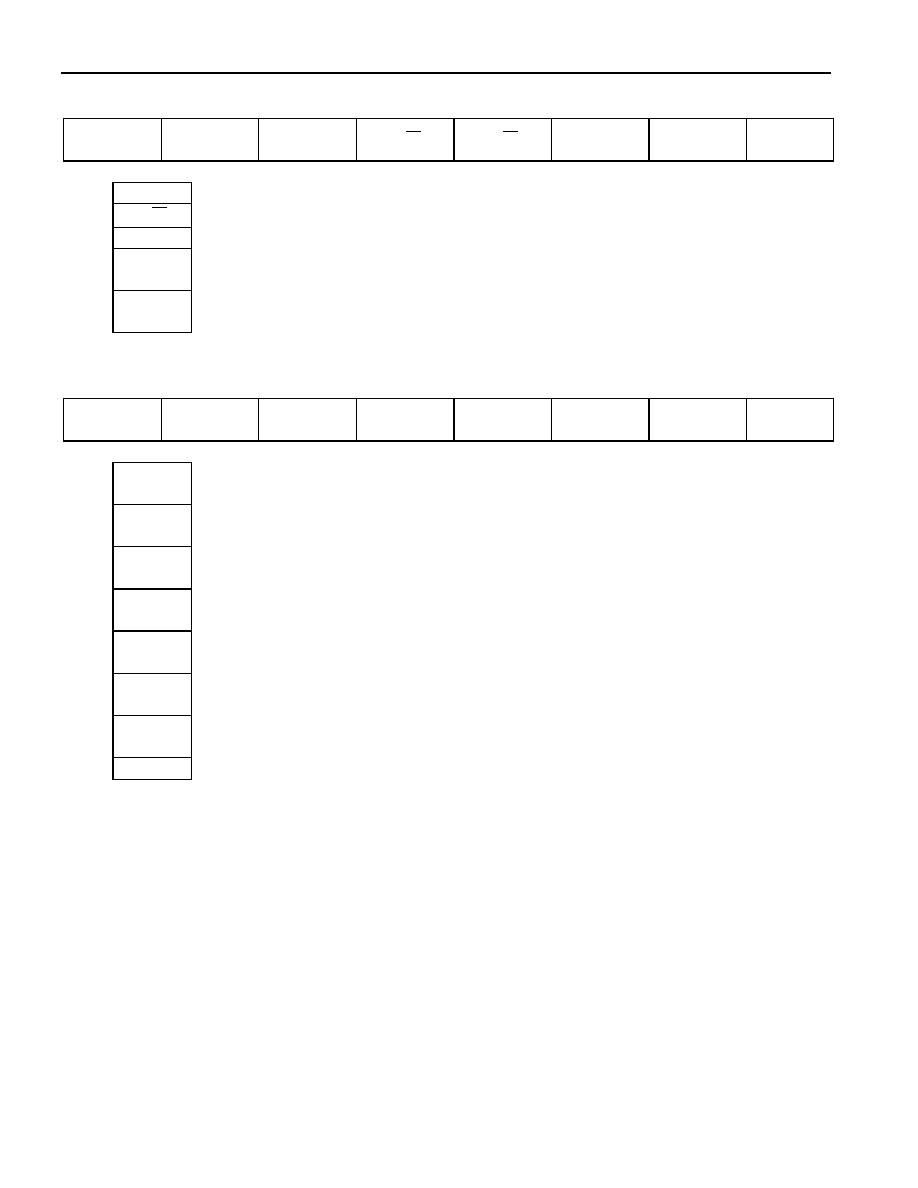

64-BIT LASERED ROM

Each DS2409 contains a unique ROM code that is 64 bits long. The first eight bits are a 1-Wire family

code. The next 48 bits are a unique serial number. The last eight bits are a CRC of the first 56 bits. (See

Figure 3.) The 1-Wire CRC of the lasered ROM is generated using the polynomial X

8

+ X

5

+ X

4

+ 1.

Additional information about the Dallas Semiconductor 1-Wire Cyclic Redundancy Check is available in

the Book of DS19xx iButton Standards. The 64-bit ROM and ROM Function Control section allow the

DS2409 to operate as a 1-Wire device and follow the 1-Wire protocol detailed in the section "1-Wire Bus

System". The functions required to exercise the control functions of the DS2409 are not accessible until

the ROM function protocol has been satisfied. This protocol is described in the ROM functions flow

chart (Figure 7). The 1-Wire bus master must first provide one of the five ROM function commands.

After a ROM function sequence has been successfully executed, the bus master may then provide any one

of the function commands specific to the DS2409 (Figure 5).

HIERARCHICAL STRUCTURE FOR 1-WIRE PROTOCOL Figure 2

64-BIT LASERED ROM Figure 3

MSB

LSB

8-Bit CRC Code

48-Bit Serial Number

8-Bit Family Code (1FH)

MSB

LSB MSB

LSB MSB

LSB

DS2409

102199

4 of 18

1-WIRE CRC GENERATOR Figure 4

CONTROL FUNCTION COMMANDS

The "Control Function Flow Chart" (Figure 5) describes the protocols necessary for controlling the main

and auxiliary output as well as the control output of the DS2409. The 1-Wire Function Control section

and the Coupler Function Control section combine to interpret the commands issued by the bus master

and create the correct control signals within the device. Depending on the complexity of function to be

exercised, the 1-byte command code may require one or two more bytes being sent by the bus master.

Switching one branch on implies that the other branch is automatically switched off. At power-on, both

branches are switched off. Each command flow includes at least one byte of feedback information for the

bus master to check if the command was understood and executed.

STATUS READ/WRITE [5Ah]

This command should be sent to the device after powering up unless the default settings are adequate for

the application. Following the command code, the bus master has to send the status control byte. The bus

master will then read the status info byte from the device. The confirmation byte is identical to the status

info byte. Tables 1 and 2 show the bit assignments in both bytes.

At power-on the device will be in the auto-control mode and the control output will be assigned to the

main output. The control output can be assigned to the auxiliary output by setting bit 6 of the status

control byte to a 1. For manual operation of the control output one has to select manual mode (bit 5 = 1).

The value of bit 7 of the status control byte will then determine the status of the control output. A 1 for bit

7 will make the transistor conducting, a 0 will turn it off (non-conducting). To change the status of the

device, both bits 3 and 4 of the status control byte have to be 0. Otherwise the settings will remain

unchanged. In any case, the status info byte will reflect the currently valid settings including the changes

that might have been made with the status control byte.

The status info byte allows the bus master to verify the actual status of each output (STAT,

active/inactive, on/off) and the static level at the main and auxiliary output (LEVL, 1 for normal, 0 in case

of a short). If a 1-Wire output is inactive and a low-going edge is encountered during this time, the

DS2409 will set the event flag (EVNT) the status info byte. Each output has its own event flag. The event

flags are cleared with the All Lines Off command. Bit 7 of the status info byte tells if the device is auto-

control mode or manual mode. Depending on the value of this bit, the information in bit 6 (CNTR.

STAT) either reports the association of the control output to a particular output (auto-control mode) or the

status of the transistor at the control output.

DS2409

102199

5 of 18

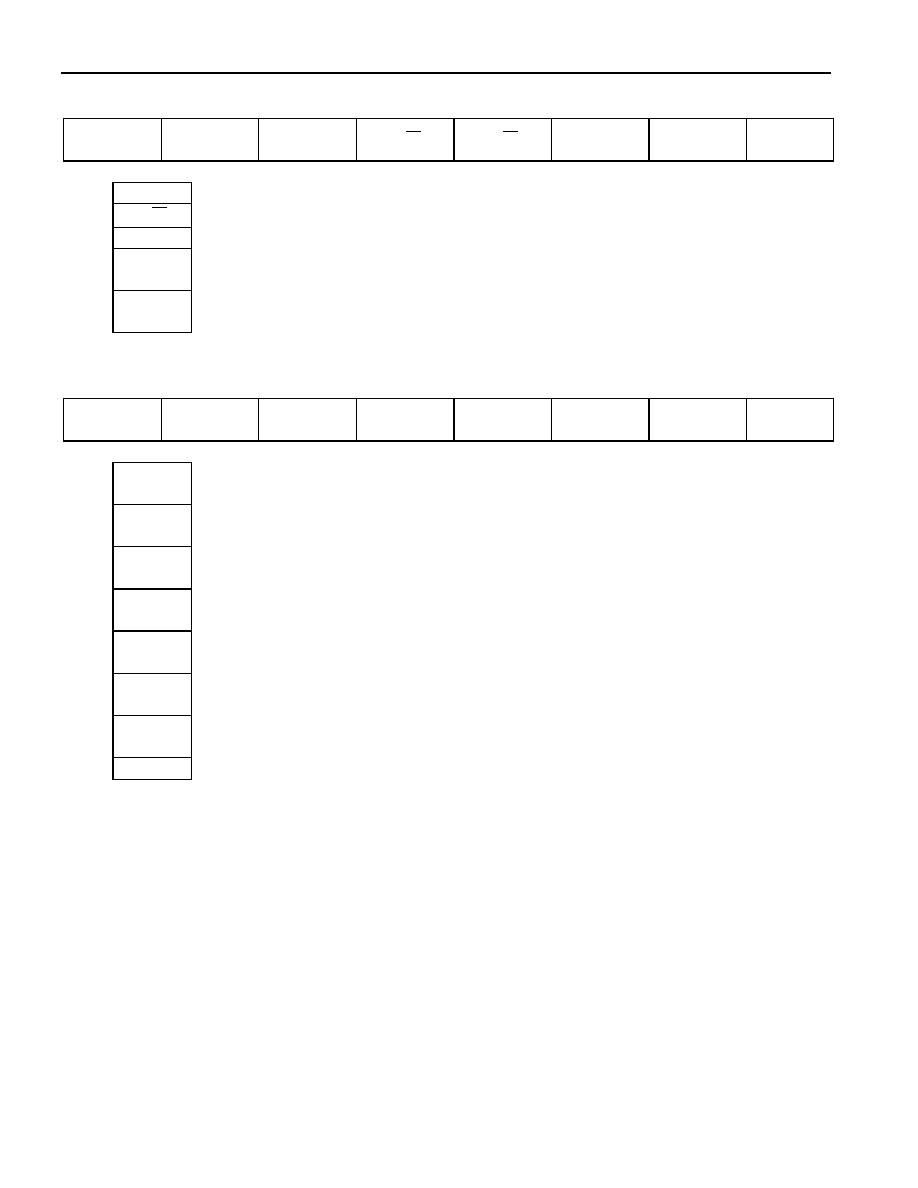

STATUS CONTROL BYTE Table 1

7

6

5

4

3

2

1

0

DATA

X

CNTR.

SEL.

MODE

R/

W

R/

W

X

X

X

0-2

X

don't care

3-4

R/

W

Write control: both bits must be 0 to change the status.

5

MODE

control output mode selection: 0 = auto-control mode (default), 1 = manual mode

6

CNTR.

SEL.

control output association (auto-control mode): 0 = main (default), 1 = auxiliary

7

DATA

X

Value to be written to control output (manual mode only): don't care otherwise

STATUS INFO BYTE Table 2

7

6

5

4

3

2

1

0

MODE

CNTR.

STAT

EVNT

AUX.

EVNT

MAIN

AUX.

LEVL

AUX.

STAT

MAIN

LEVL

MAIN

STAT

0

MAIN

STAT

status of main output: 0 = active (connected to bus master), 1 = inactive

1

MAIN

LEVL

voltage sensed at main output: 0 = low, 1 = high (see note)

2

AUX.

STAT

status of auxiliary output: 0 = active (connected to bus master), 1 = inactive

3

AUX.

LEVL

voltage sensed at auxiliary output: 0 = low, 1 = high (see note)

4

EVNT

MAIN

event flag for main output: 0 = no event, 1 = negative edge sensed since inactive

5

EVNT

AUX.

event flag for aux. Output: 0 = no event, 1 = negative edge sensed since inactive

6

CNTR.

STAT

if auto-control mode: control output association, 0 = main, 1 = auxiliary

if manual mode: 0 = output transistor off, 1 = output transistor on

7

MODE

control output mode: 0 = auto-control mode, 1 = manual mode

Note: Data is valid only if the output is decoupled from the 1-Wire input.

ALL LINES OFF [66h]

This command is used to deactivate the currently active 1-Wire output and to clear both event flags or to

end a discharge cycle initiated by the Discharge Lines command. Before issuing this command, one

should read the status and check the event flags of both, the main and the auxiliary output. Otherwise one

might inadvertently clear the event flag without having taken appropriate action. If the DS2409 is in auto-

control mode, the transistor at the control output will be switched off (non-conducting). At power-on, the

device will automatically perform the All Lines Off command. In contrast to a power-on cycle, the All

Lines Off command does not clear the Mode and Control Select bits.