Document Outline

- Features

- Description

- 1. characteristics/specifications

- 2. general description

- 3. System Design

- 3.1 Power Supply Voltages

- VDD1, GND1 - Pins 54, 53

- VDD2, GND2 - Pins 11, 25, 24, 38

- VD, GND - Pins 7, 40, 6, 23, 39

- 3.2 Clock and Synchronization Signals

- 3.3 EEPROM Programming

- 3.4 Boundary Scan Testing

- 3.5 Functional Testing

- 3.6 System Registers

- 4. Reset Control

- 5. Serial Peripheral Interface 1

- 6. Serial Peripheral Interface 2

- 7. Modulator Data Interface

- 8. Digital Decimation Filter

- 9. Gain and Offset Correction

- 10. Serial Data Output Port

- 11. Time Break Function

- 12. System Synchronization

- 13. Test Bit Stream Generator

- 14. General Purpose I/O Pins

- 15. JTAG Test Port (IEEE 1149.1)

- 16. Watchdog Timer

- 17. Register Summary

- 18. Pin Descriptions

- 19. Package Dimensions

Advance Product Information

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

1

Copyright

Cirrus Logic, Inc. 2001

(All Rights Reserved)

P.O. Box 17847, Austin, Texas 78760

(512) 445 7222 FAX: (512) 445 7581

http://www.cirrus.com

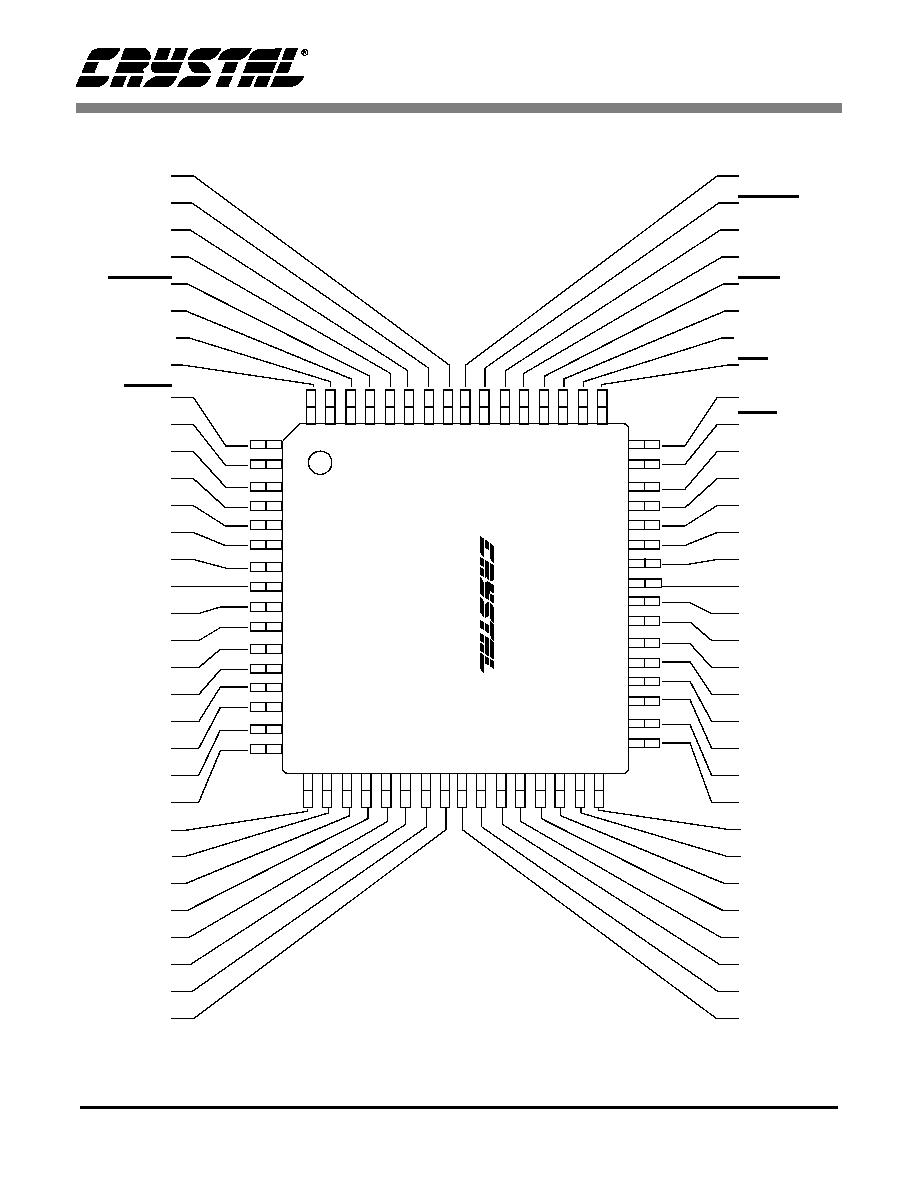

CS5376

Low Power Multi-Channel Decimation Filter

Features

l

1 to 4 Channel Digital Decimation Filters

s

Coefficient Programmable FIR Filters

s

Coefficient Programmable IIR Filters

s

On-chip FIR and IIR Coefficient Set

l

62.5 sps - 4000 sps Output Word Rate

l

Programmable Offset and Gain Correction

l

High Speed Serial Data Output Port

l

DAC Test Bit Stream Generator

l

12 General Purpose I/O Pins

l

Secondary Master Mode Serial Port

l

IEEE 1149.1 JTAG Test Access Port

l

Configuration by Microcontroller or EEPROM

l

Small Footprint 64 Pin TQFP Package

l

Low Power at < 6 mW per Channel

l

3.0 V or 5.0 V Operation

Description

The CS5376 is a multi-function digital filter utilizing a low-

power signal processing architecture to achieve efficient

filtering for up to four

- modulators. Used in combina-

tion with the CS5371 and CS5372

- modulators, a

unique high resolution A/D measurement system results.

Digital filter coefficients for the CS5376 FIR and IIR filters

can be programmed for custom applications, or the on-

chip coefficient set can be used for a simple setup. Filter

configuration is initialized through a serial port using a

microcontroller or a configuration EEPROM.

The CS5376 includes a test bit stream generator that

produces a 1-bit

- modulated output suitable for driv-

ing a test DAC. It also includes 12 general purpose I/O

pins for local hardware control, a secondary master

mode SPI port to communicate with serial peripherals,

and an IEEE 1149.1 JTAG test port for boundary scan.

ORDERING INFORMATION

CS5376-BS

-40 to +85

o

C

64-pin TQFP

I

SDC

L

K

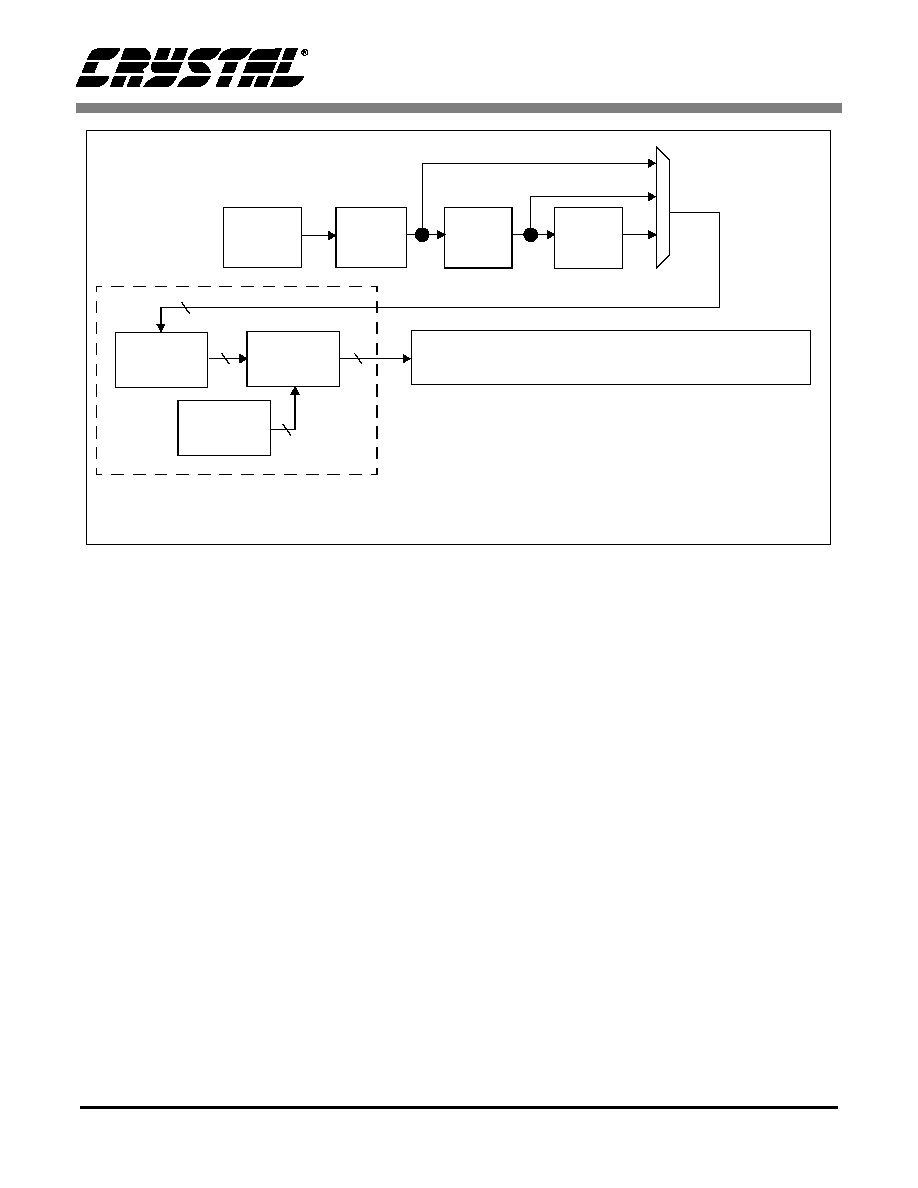

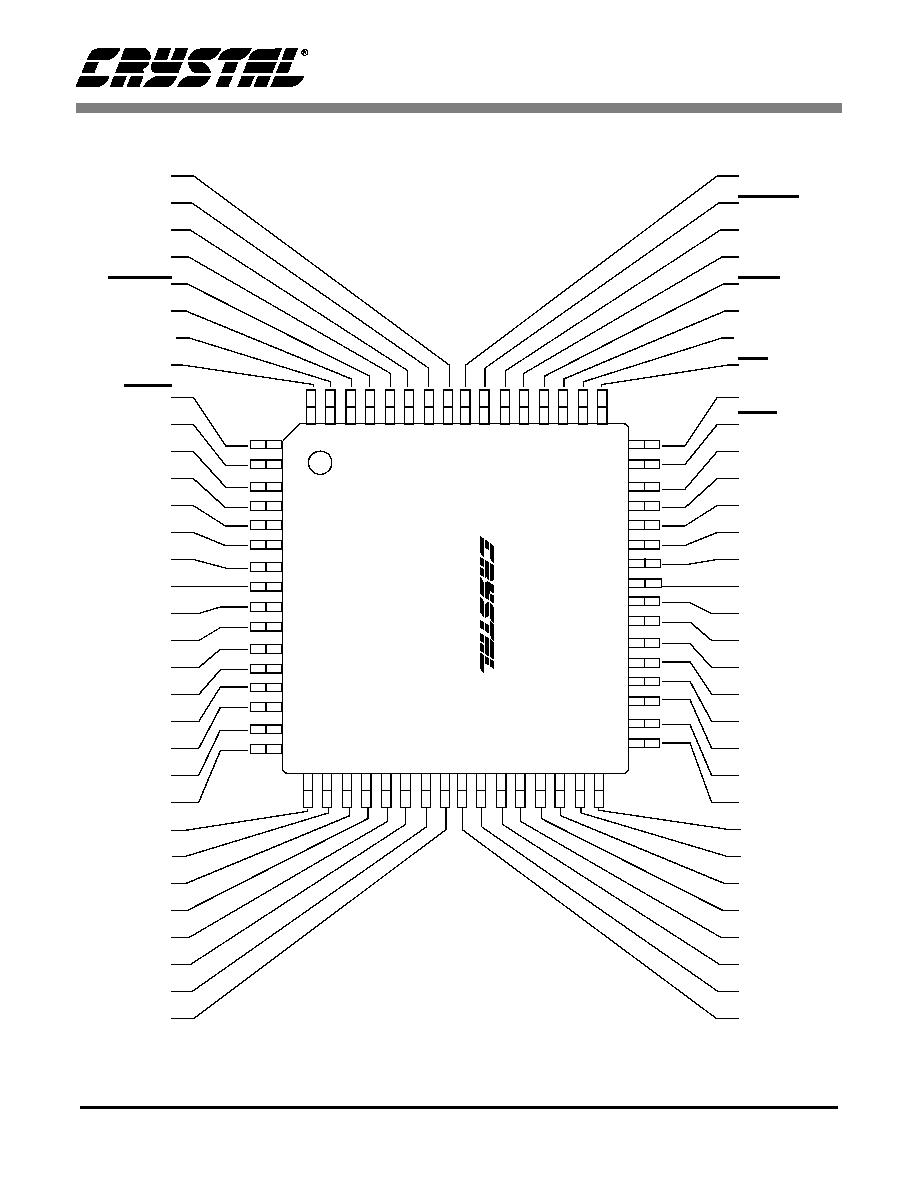

Decimation and

Filtering Engine

Clock and MSYNC

Generation

TBS Buffer and Filter

GPIO

(General Purpose I/O)

MSYNC

CLK

MCLK

SYNC

TBSCLK

TBSDATA

SCK1

MISO

MOSI

SINT

SSI

SSO

Serial Data Output

Register

Watchdog

Timer

SDR

D

Y

SDD

A

T

SD

TKI

RES

E

T

VD

(

x

2

)

VD

D1

V

DD2

(

x

2

)

Modular Data

Interface

SINC

Control

JTAG

Interface

TD

O

TD

I

TM

S

TC

K

M

D

A

T

A

[

4:

1]

M

F

LA

G

[

4:

1]

SI4

SI3

SCK2

SO

SI1

SI2

GPIO4: CS4

GPIO3: CS3

GPIO2: CS2

GPIO1: CS1

GPIO0: CS0

GPIO9: CS9

GPIO7

GPIO6

GPIO5

GPIO8: CS8

GPIO10: CS10

GPIO11: CS11

GND

(

x

2

)

GND1

G

ND2

(

x

2

)

Time Break Controller

I/O Address and Data Bus

SDTKO

SPI 1

Serial Peripheral Interface 1

SPI 2

Serial Peripheral Interface 2

TR

ST

BO

O

T

TIME B

AUG `01

DS256PP1

CS5376

DS256PP1

2

TABLE OF CONTENTS

1. CHARACTERISTICS/SPECIFICATIONS ................................................................................. 7

5.0 V AND 3.0 V DIGITAL CHARACTERISTICS ..................................................................... 7

POWER SUPPLY CHARACTERISTICS .................................................................................. 7

ABSOLUTE MAXIMUM RATINGS ........................................................................................... 7

SWITCHING CHARACTERISTICS .......................................................................................... 8

2. GENERAL DESCRIPTION ..................................................................................................... 10

2.1 System Configurations .................................................................................................... 10

2.2 Digital Filter Description ................................................................................................... 11

2.3 Integrated Hardware Peripherals ..................................................................................... 12

2.4 Register Descriptions ...................................................................................................... 13

3. SYSTEM DESIGN ................................................................................................................... 15

3.1 Power Supply Voltages ................................................................................................... 15

3.1.1 Bypass Capacitors .............................................................................................. 15

3.2 Clock and Synchronization Signals ................................................................................. 15

3.2.1 Master Clock Jitter and Skew ............................................................................. 16

3.2.2 Synchronization Jitter and Skew ......................................................................... 16

3.3 EEPROM Programming .................................................................................................. 16

3.4 Boundary Scan Testing ................................................................................................... 16

3.4.1 TRST and RESET Pins ....................................................................................... 17

3.5 Functional Testing ........................................................................................................... 17

3.5.1 Analog Test DAC ................................................................................................ 17

3.5.2 Step Input and Group Delay ............................................................................... 17

3.6 System Registers ............................................................................................................ 17

4. RESET CONTROL ................................................................................................................. 20

4.1 Reset Pin Descriptions .................................................................................................... 20

4.2 Boot Configurations ......................................................................................................... 20

4.3 Reset Self-Tests .............................................................................................................. 21

5. SERIAL PERIPHERAL INTERFACE 1 .................................................................................. 23

5.1 SPI 1 Pin Descriptions ..................................................................................................... 24

5.2 SPI 1 Stand-Alone Mode ................................................................................................. 24

5.2.1 EEPROM Organization ....................................................................................... 25

5.2.2 EEPROM Commands ......................................................................................... 25

5.2.3 CS5376 to EEPROM Transactions ..................................................................... 28

5.3 SPI 1 Coprocessor Mode ................................................................................................ 28

5.3.1 SPI 1 Registers ................................................................................................... 29

6. SERIAL PERIPHERAL INTERFACE 2 .................................................................................. 43

6.1 SPI 2 Pin Descriptions ..................................................................................................... 43

6.2 SPI 2 Physical Interface .................................................................................................. 43

Contacting Cirrus Logic Support

For a complete listing of Direct Sales, Distributor, and Sales Representative contacts, visit the Cirrus Logic web site at:

http://www.cirrus.com/corporate/contacts/

Preliminary product information describes products which are in production, but for which full characterization data is not yet available. Advance product infor-

mation describes products which are in development and subject to development changes. Cirrus Logic, Inc. has made best efforts to ensure that the information

contained in this document is accurate and reliable. However, the information is subject to change without notice and is provided "AS IS" without warranty of

any kind (express or implied). No responsibility is assumed by Cirrus Logic, Inc. for the use of this information, nor for infringements of patents or other rights

of third parties. This document is the property of Cirrus Logic, Inc. and implies no license under patents, copyrights, trademarks, or trade secrets. No part of

this publication may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical, photographic, or

otherwise) without the prior written consent of Cirrus Logic, Inc. Items from any Cirrus Logic website or disk may be printed for use by the user. However, no

part of the printout or electronic files may be copied, reproduced, stored in a retrieval system, or transmitted, in any form or by any means (electronic, mechanical,

photographic, or otherwise) without the prior written consent of Cirrus Logic, Inc. Furthermore, no part of this publication may be used as a basis for manufacture

or sale of any items without the prior written consent of Cirrus Logic, Inc. The names of products of Cirrus Logic, Inc. or other vendors and suppliers appearing

in this document may be trademarks or service marks of their respective owners which may be registered in some jurisdictions. A list of Cirrus Logic, Inc. trade-

marks and service marks can be found at http://www.cirrus.com.

CS5376

DS256PP1

3

6.3 SPI 2 Registers ................................................................................................................ 44

6.3.1 SPI 2 Command Register ................................................................................... 44

6.3.2 SPI 2 Data Register ............................................................................................ 44

6.3.3 SPI 2 Configuration Register .............................................................................. 45

7. MODULATOR DATA INTERFACE ........................................................................................ 52

7.1 Modulator Interface Pin Descriptions ............................................................................... 52

7.2 Modulator Data Inputs ..................................................................................................... 52

7.3 Modulator Flag Inputs ...................................................................................................... 52

7.4 Modulator Clock Generation ............................................................................................ 53

7.4.1 Modulator Clock Enables .................................................................................... 53

7.5 Modulator Synchronization .............................................................................................. 54

7.5.1 Modulator Sync Enable ....................................................................................... 54

8. DIGITAL DECIMATION FILTER ............................................................................................ 56

8.1 Filter Initialization ............................................................................................................. 56

8.1.1 Decimation Engine Clock .................................................................................... 56

8.1.2 Channel Enable .................................................................................................. 57

8.1.3 Output Filter Selection ........................................................................................ 57

8.1.4 Output Word Rate ............................................................................................... 58

8.2 Hardware Sinc Filter ........................................................................................................ 61

8.2.1 SINC1 Filter ........................................................................................................ 61

8.2.2 SINC2 Filter ........................................................................................................ 61

8.2.3 Sinc Filter Synchronization ................................................................................. 63

8.3 FIR Filters ........................................................................................................................ 63

8.3.1 FIR1 Filter ........................................................................................................... 63

8.3.2 FIR2 Filter ........................................................................................................... 63

8.3.3 Maximum FIR Coefficients .................................................................................. 64

8.3.4 FIR Coefficient Upload ........................................................................................ 64

8.3.5 FIR Filter Synchronization ................................................................................... 64

8.4 IIR Filter ........................................................................................................................... 64

8.4.1 1st Order IIR ....................................................................................................... 65

8.4.2 2nd Order IIR ...................................................................................................... 65

8.4.3 3rd Order IIR ....................................................................................................... 65

8.4.4 IIR coefficient upload .......................................................................................... 65

8.4.5 IIR Filter Synchronization .................................................................................... 65

8.5 Reference Coefficients .................................................................................................... 66

8.5.1 Reference FIR coefficients .................................................................................. 66

8.5.2 Reference IIR coefficient set ............................................................................... 67

9. GAIN AND OFFSET CORRECTION ...................................................................................... 68

9.1 Gain Correction ............................................................................................................... 68

9.1.1 Gain Register Calculation ................................................................................... 68

9.2 Offset Correction ............................................................................................................. 69

9.2.1 Offset Register Calculation ................................................................................. 69

9.3 Offset Calibration ............................................................................................................. 69

10. SERIAL DATA OUTPUT PORT ........................................................................................... 74

10.1 SD Port Pin Descriptions ............................................................................................... 74

10.2 Serial Data Transactions ............................................................................................... 75

10.3 SD Port Configurations .................................................................................................. 75

10.4 SD Port Data Format ..................................................................................................... 76

11. TIME BREAK FUNCTION .................................................................................................... 78

11.1 Time Break Pin Description ........................................................................................... 78

11.2 Time Break Delay .......................................................................................................... 78

11.3 TB Flag Output .............................................................................................................. 78

12. SYSTEM SYNCHRONIZATION ........................................................................................... 80

CS5376

DS256PP1

4

12.1 Synchronous Clocking ................................................................................................... 80

12.2 Synchronization Signals ................................................................................................ 80

12.3 CS5376 Internal Synchronization .................................................................................. 81

12.3.1 Sinc Filter Synchronization ............................................................................... 81

12.3.2 Decimation Engine Synchronization ................................................................. 82

12.3.3 SD Port Synchronization ................................................................................... 82

12.3.4 Time Break Synchronization ............................................................................. 82

12.3.5 Test Bit Stream Synchronization ....................................................................... 82

12.4 Modulator Synchronization ........................................................................................... 82

13.1 TBS Generator Architecture .......................................................................................... 84

13.2 TBS Pin Descriptions ..................................................................................................... 84

13.3 TBS Data Source ........................................................................................................... 85

13.3.1 TBS ROM Data ................................................................................................. 85

13.3.2 TBS Uploaded Data .......................................................................................... 85

13.4 TBS Configuration ......................................................................................................... 85

13.4.1 Interpolation Factor ........................................................................................... 86

13.4.2 Clock Rate ........................................................................................................ 86

13.4.3 Clock Delay ....................................................................................................... 86

13.4.4 Loopback Enable .............................................................................................. 86

13.4.5 Run Enable ....................................................................................................... 86

13.4.6 Data Delay ........................................................................................................ 86

14. GENERAL PURPOSE I/O PINS ........................................................................................... 88

14.1 GPIO Input Mode ........................................................................................................... 88

14.2 GPIO Output Mode ........................................................................................................ 88

14.2.1 GPIO Read In Output Mode .............................................................................. 88

14.3 GPIO Chip Select .......................................................................................................... 89

14.4 GPIO Pin Descriptions ................................................................................................... 89

15. JTAG TEST PORT (IEEE 1149.1) ........................................................................................ 92

15.1 JTAG Pin Definitions ..................................................................................................... 92

15.2 JTAG Architecture ......................................................................................................... 92

15.2.1 TAP Controller .................................................................................................. 92

15.2.2 Boundary Scan Cells ........................................................................................ 93

16. WATCHDOG TIMER ............................................................................................................ 94

16.1 Watchdog Timer Initialization ........................................................................................ 94

16.2 Watchdog Timer Restart ................................................................................................ 94

17. REGISTER SUMMARY ........................................................................................................ 97

CS5376

DS256PP1

5

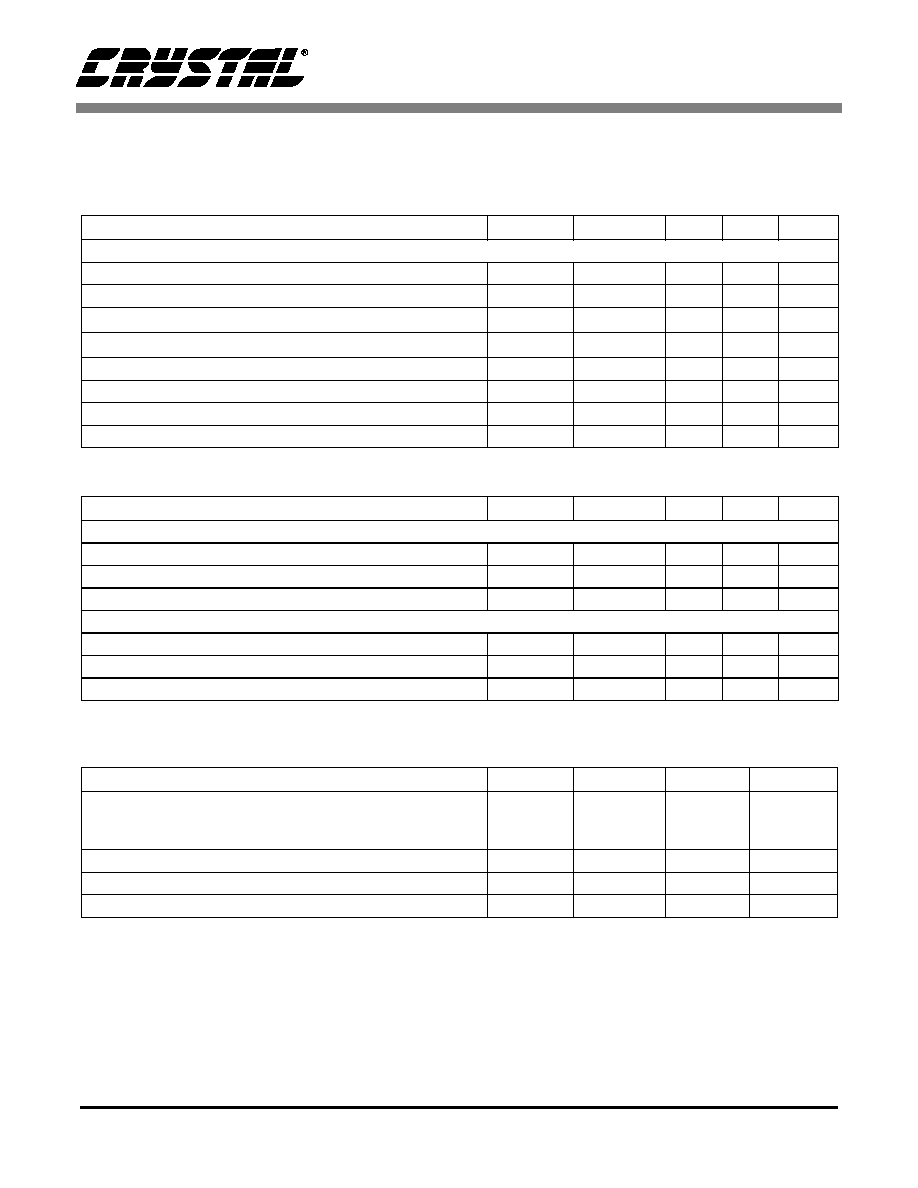

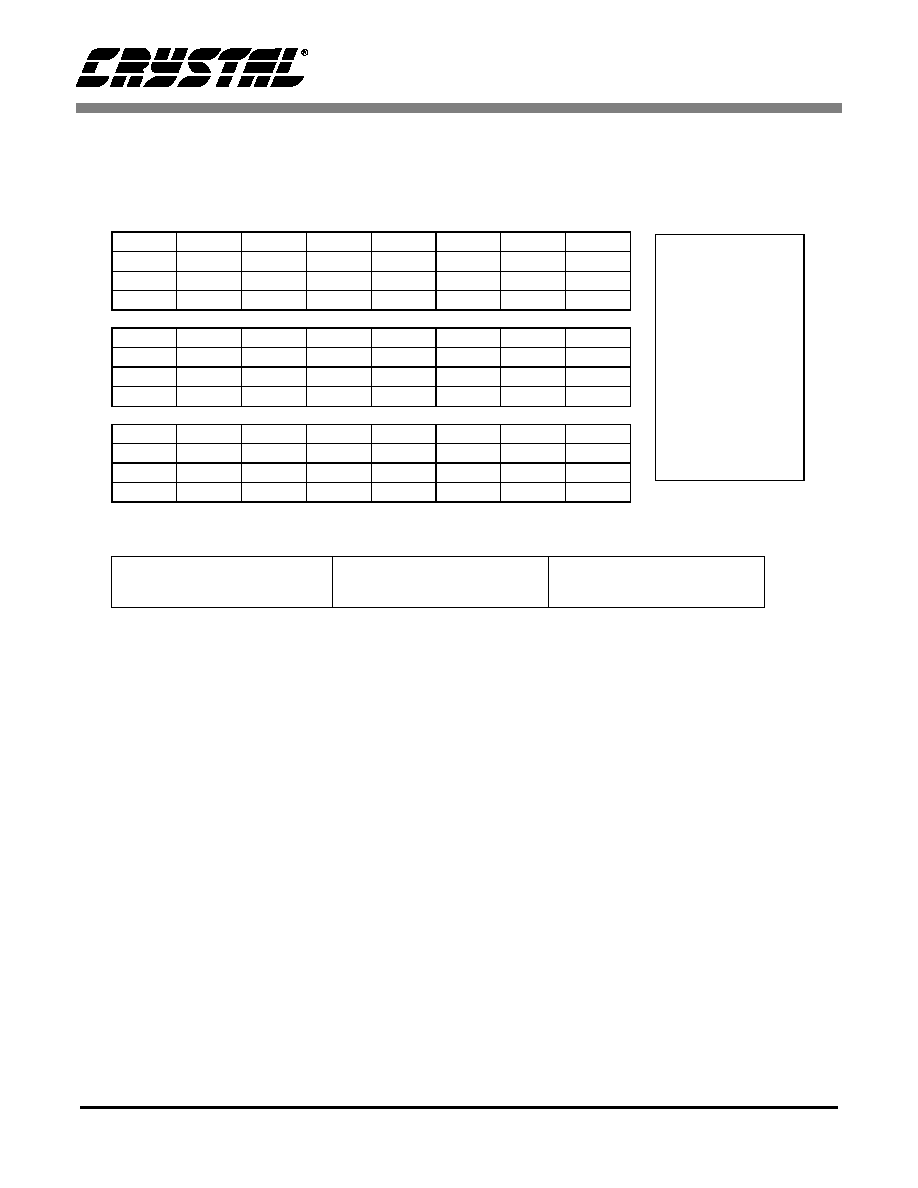

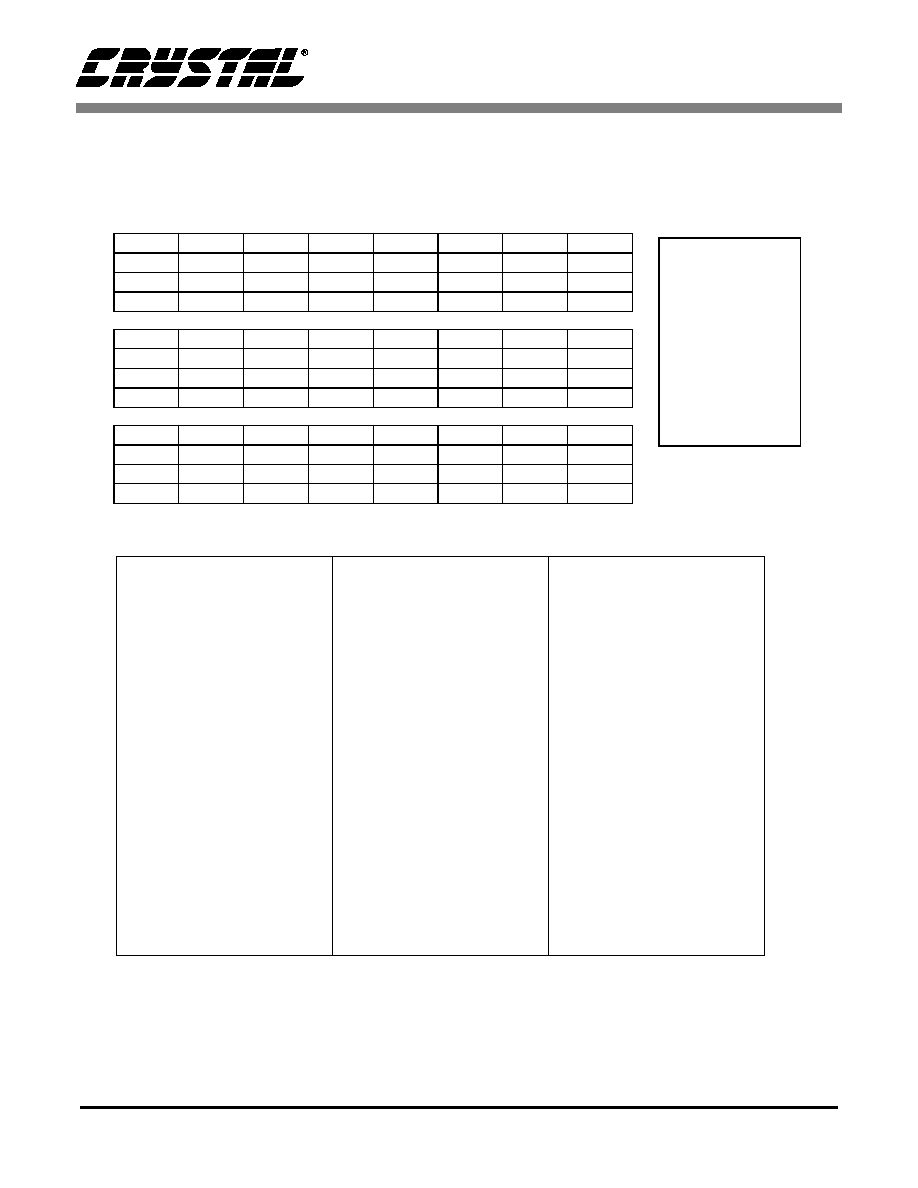

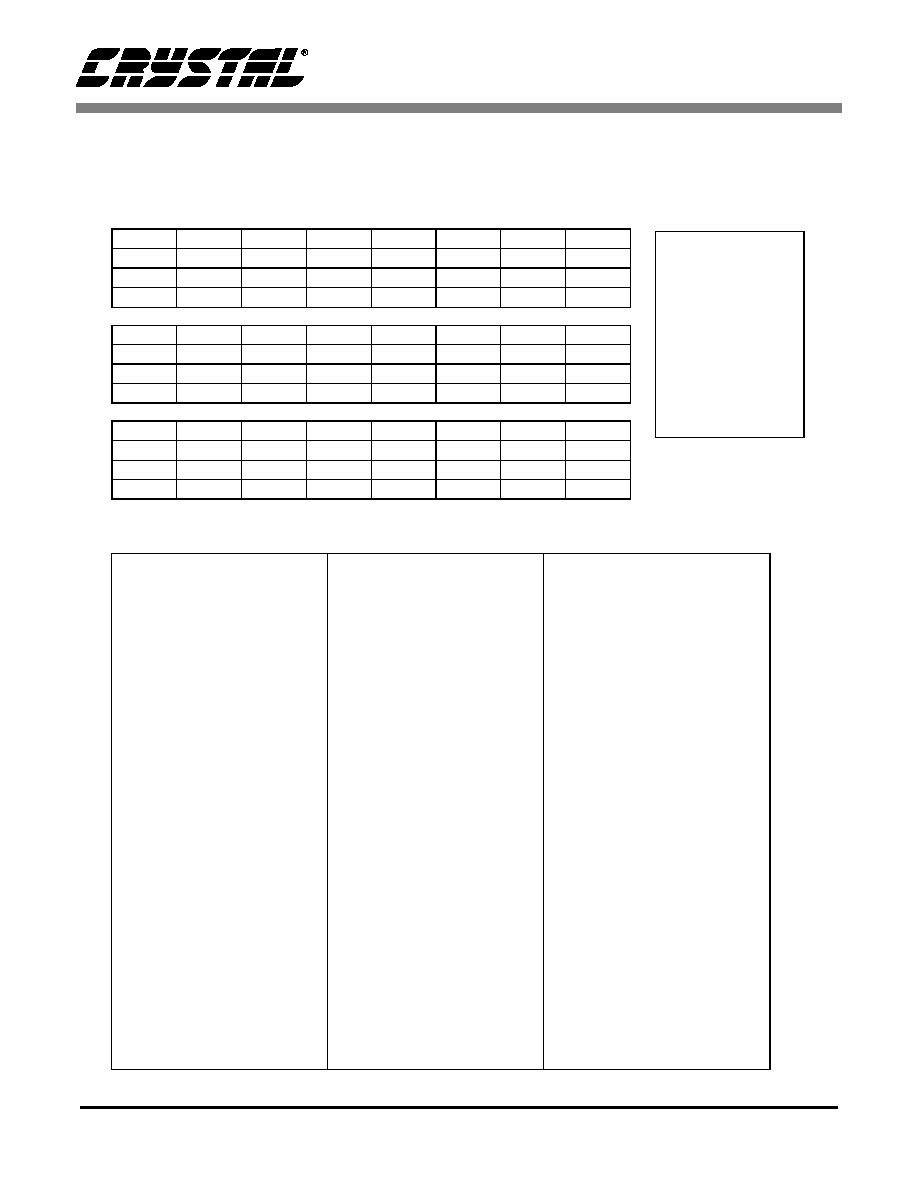

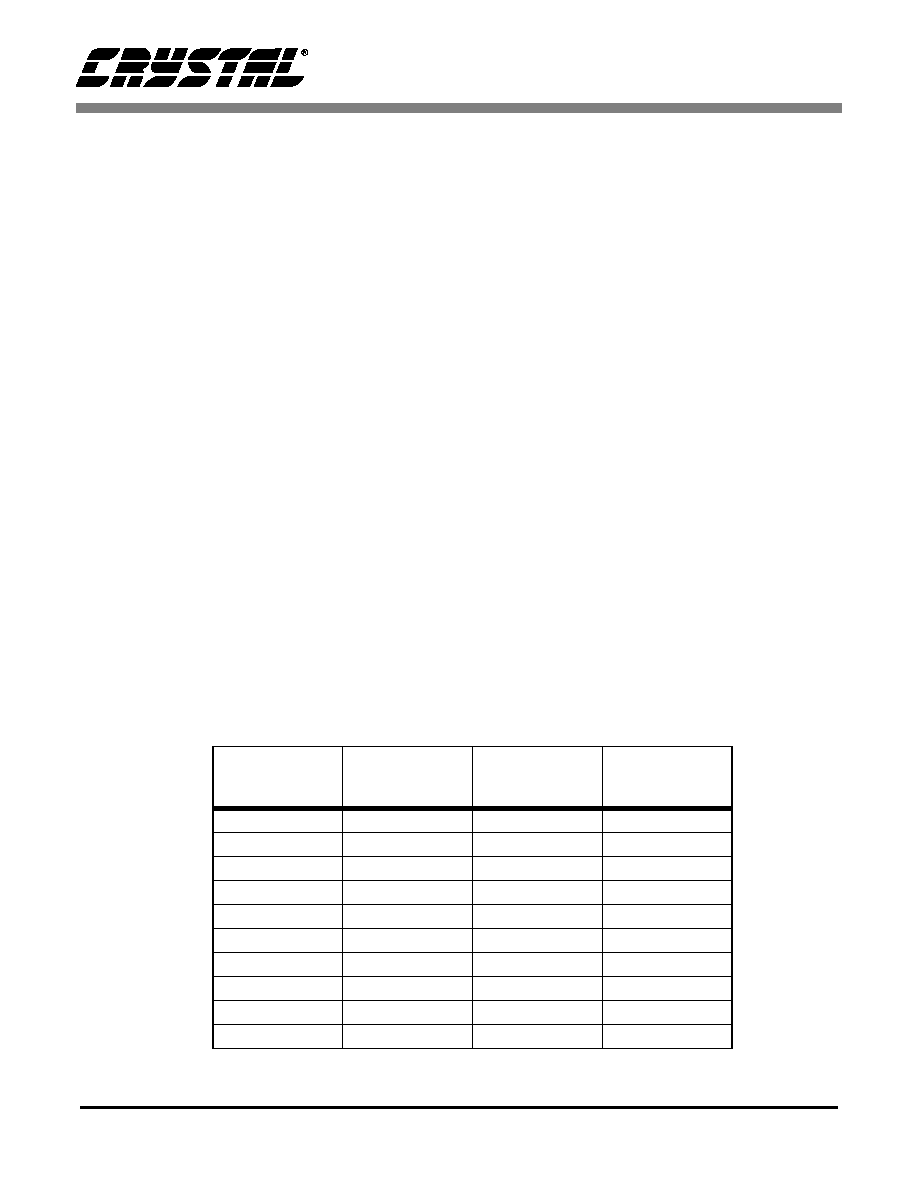

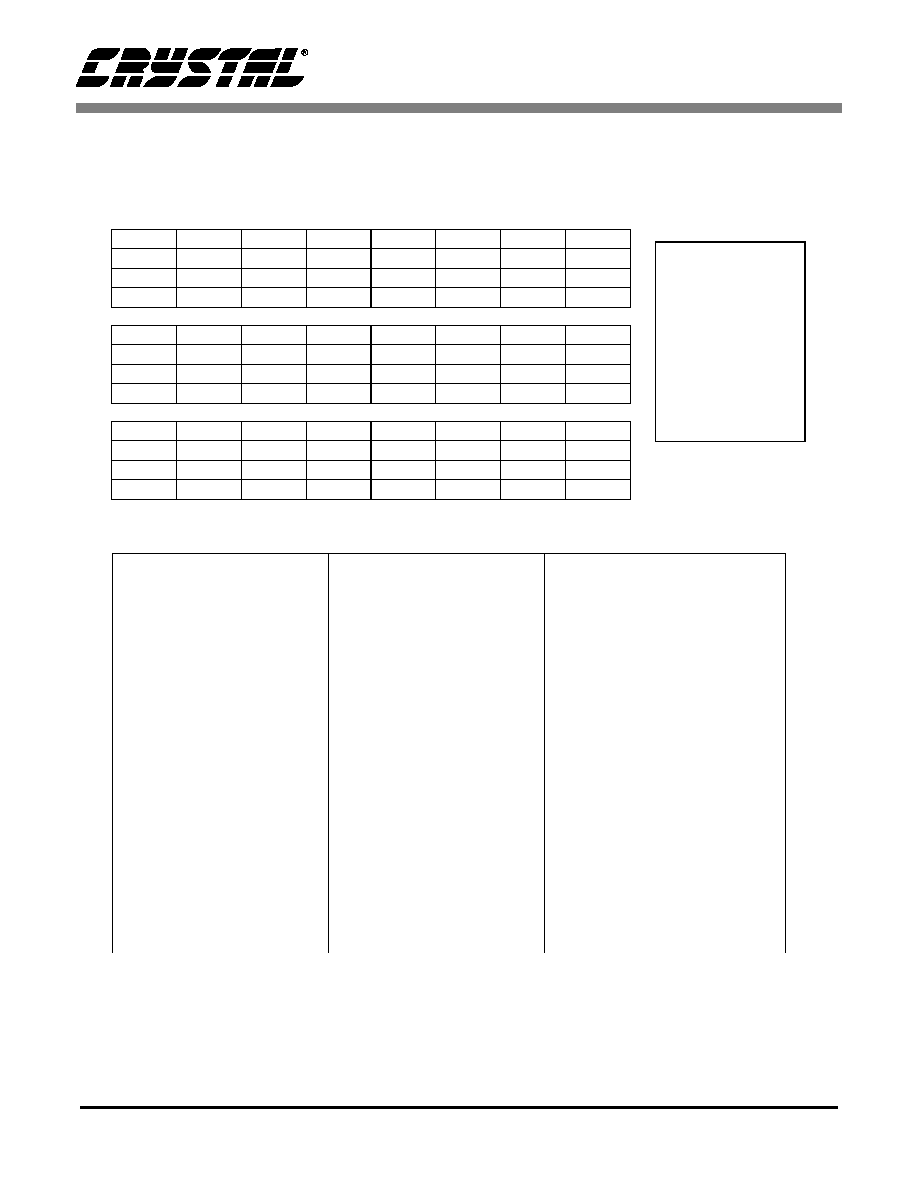

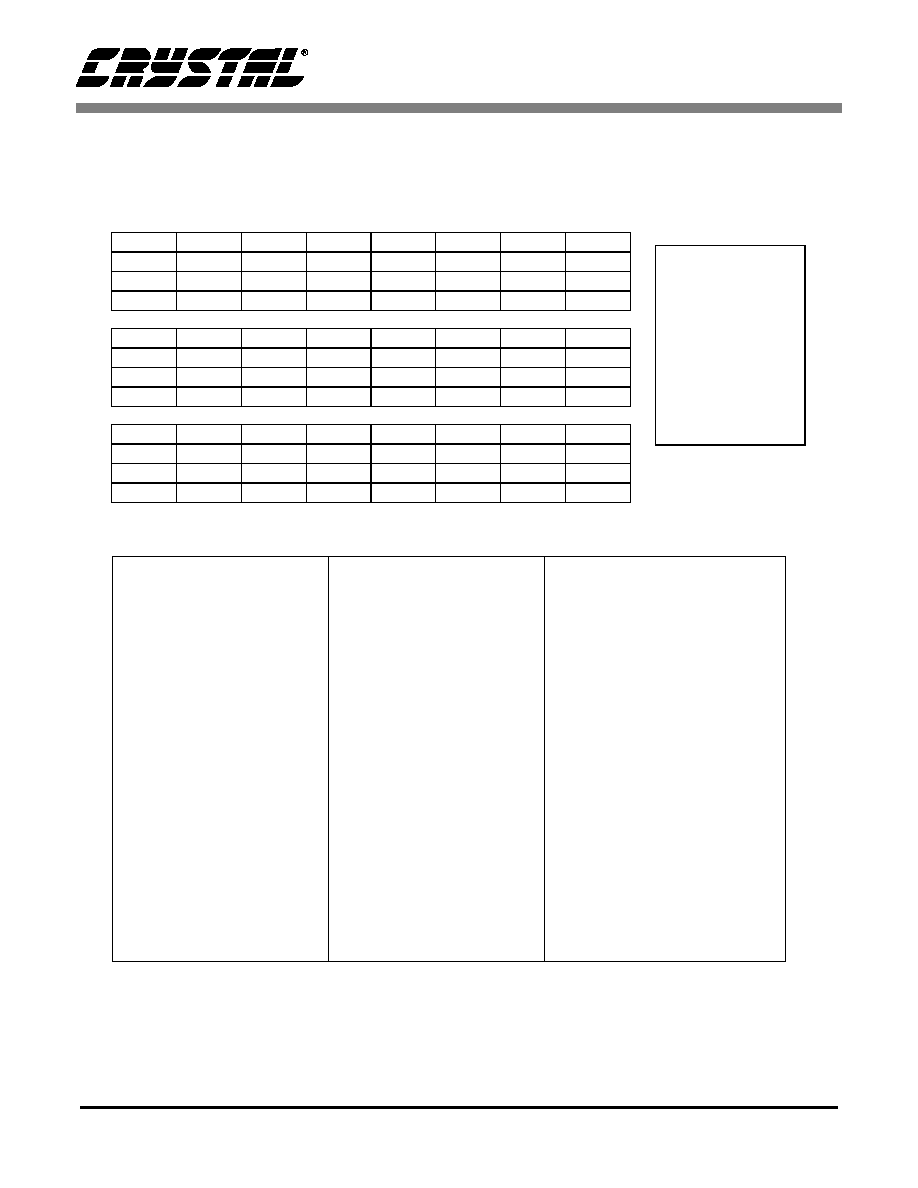

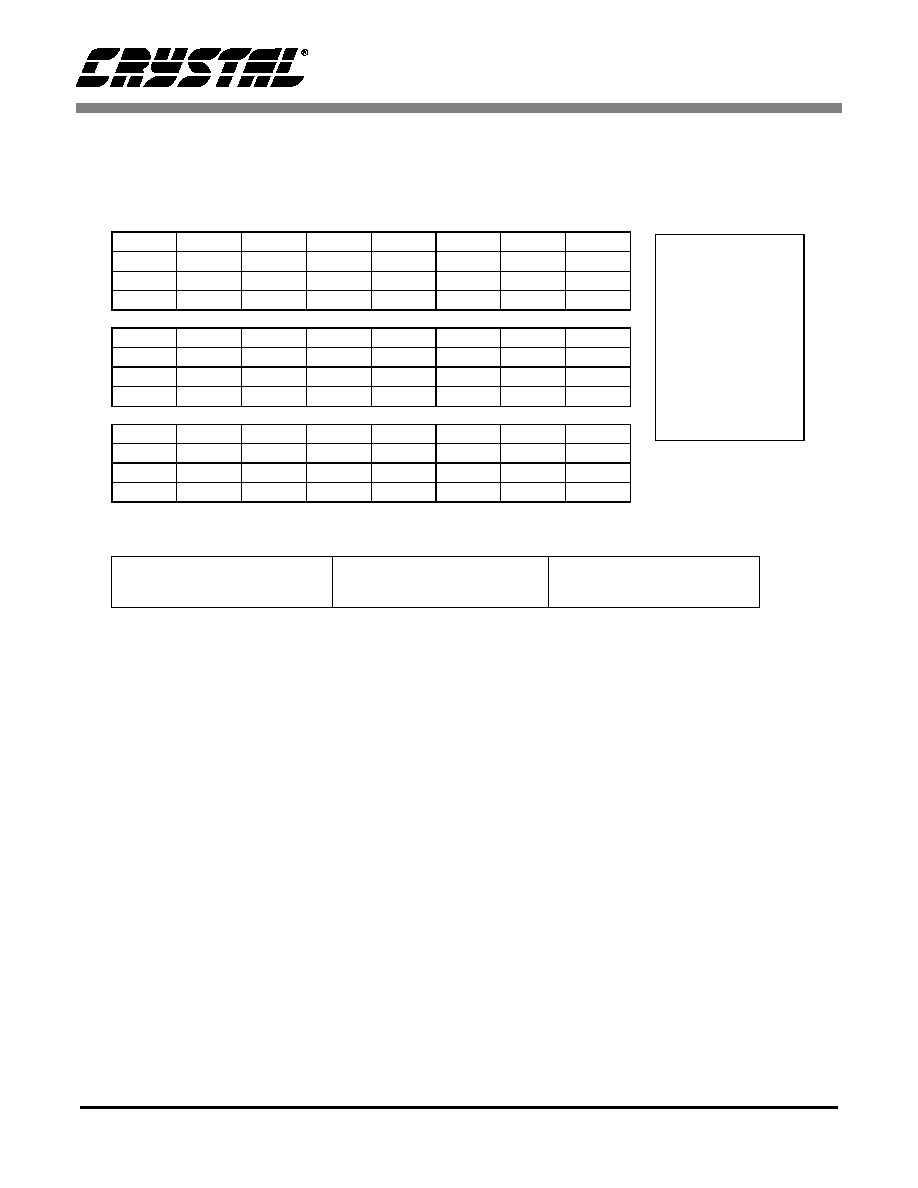

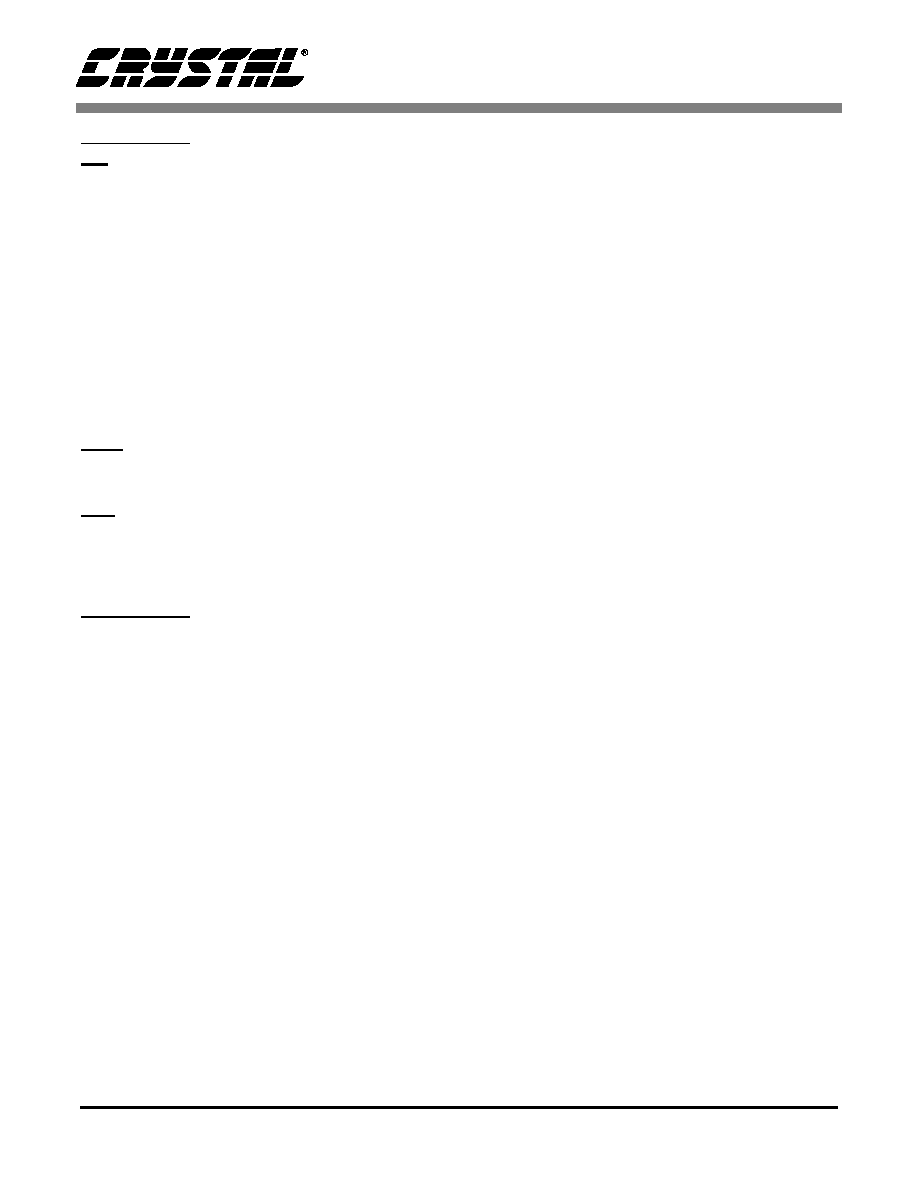

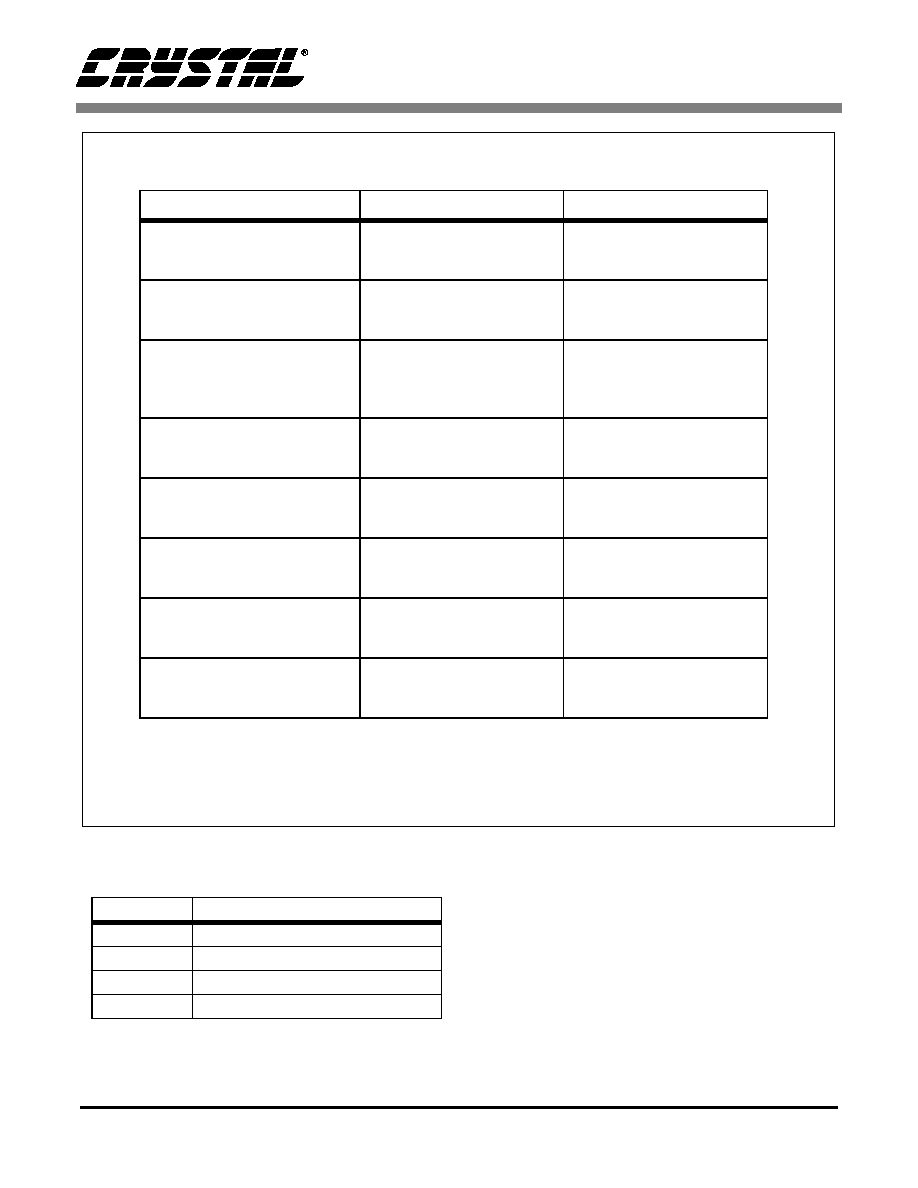

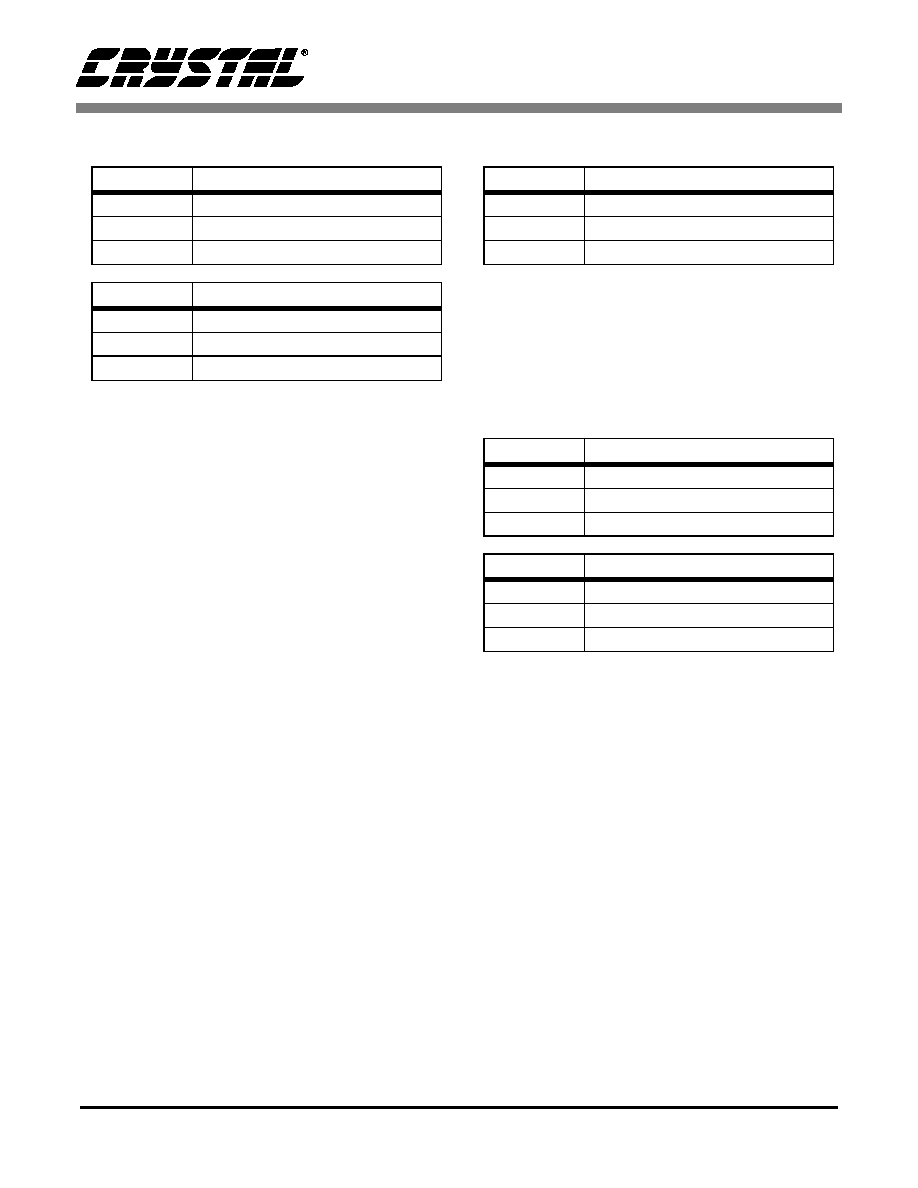

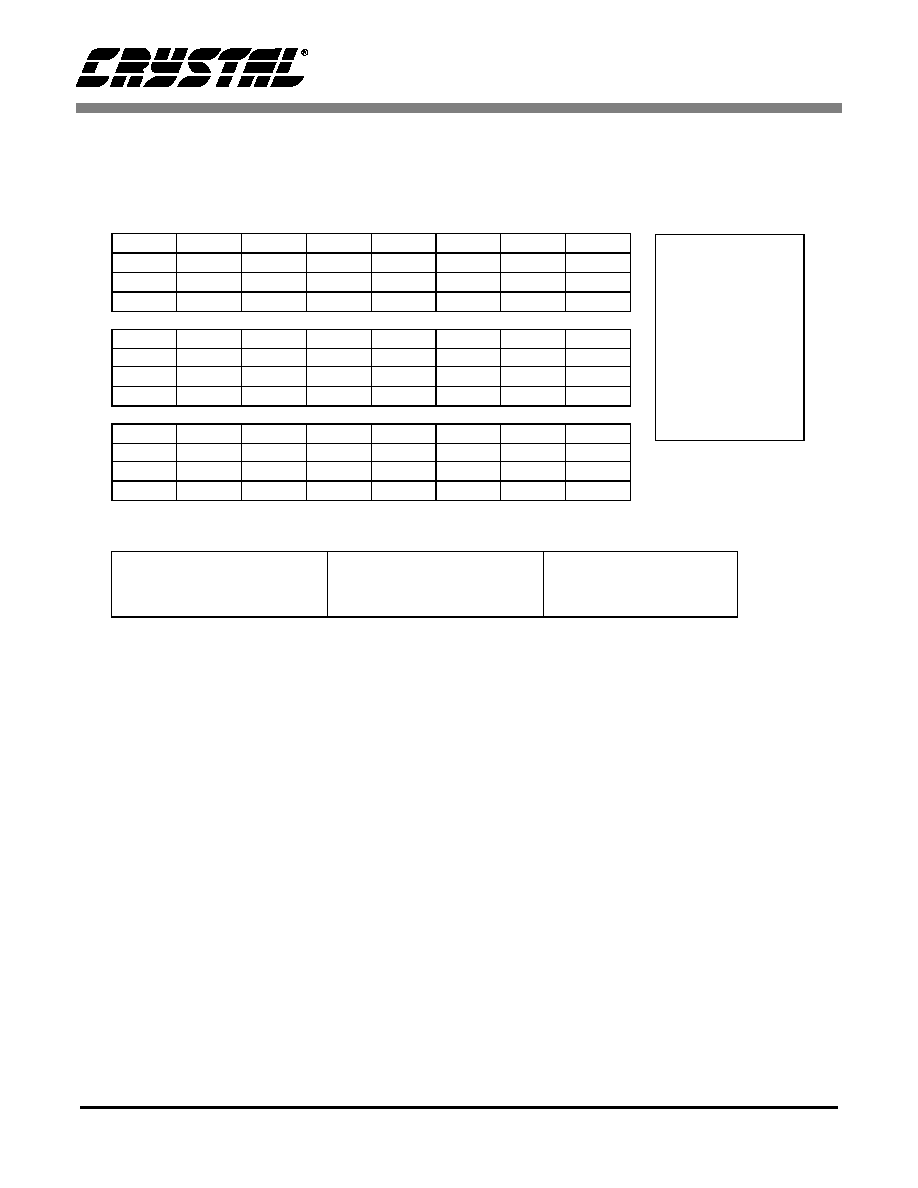

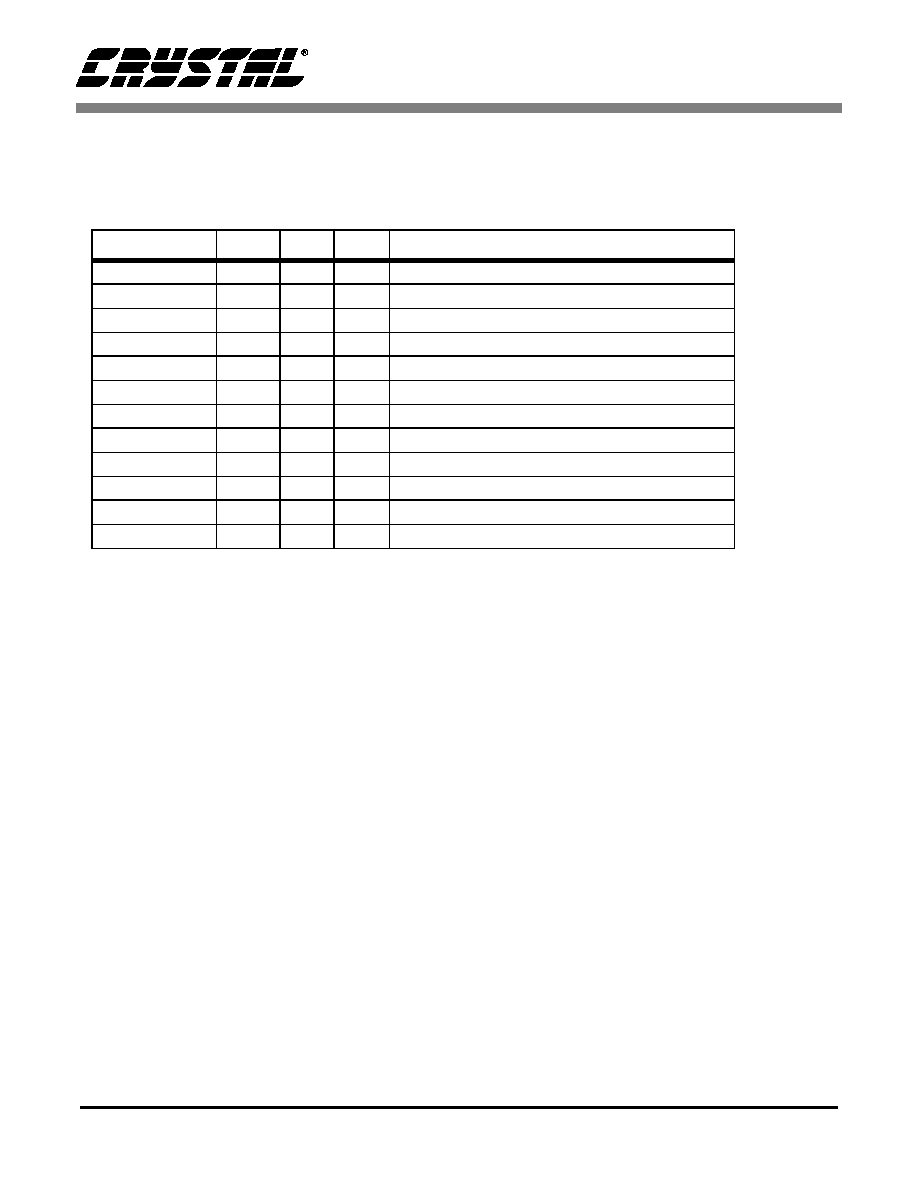

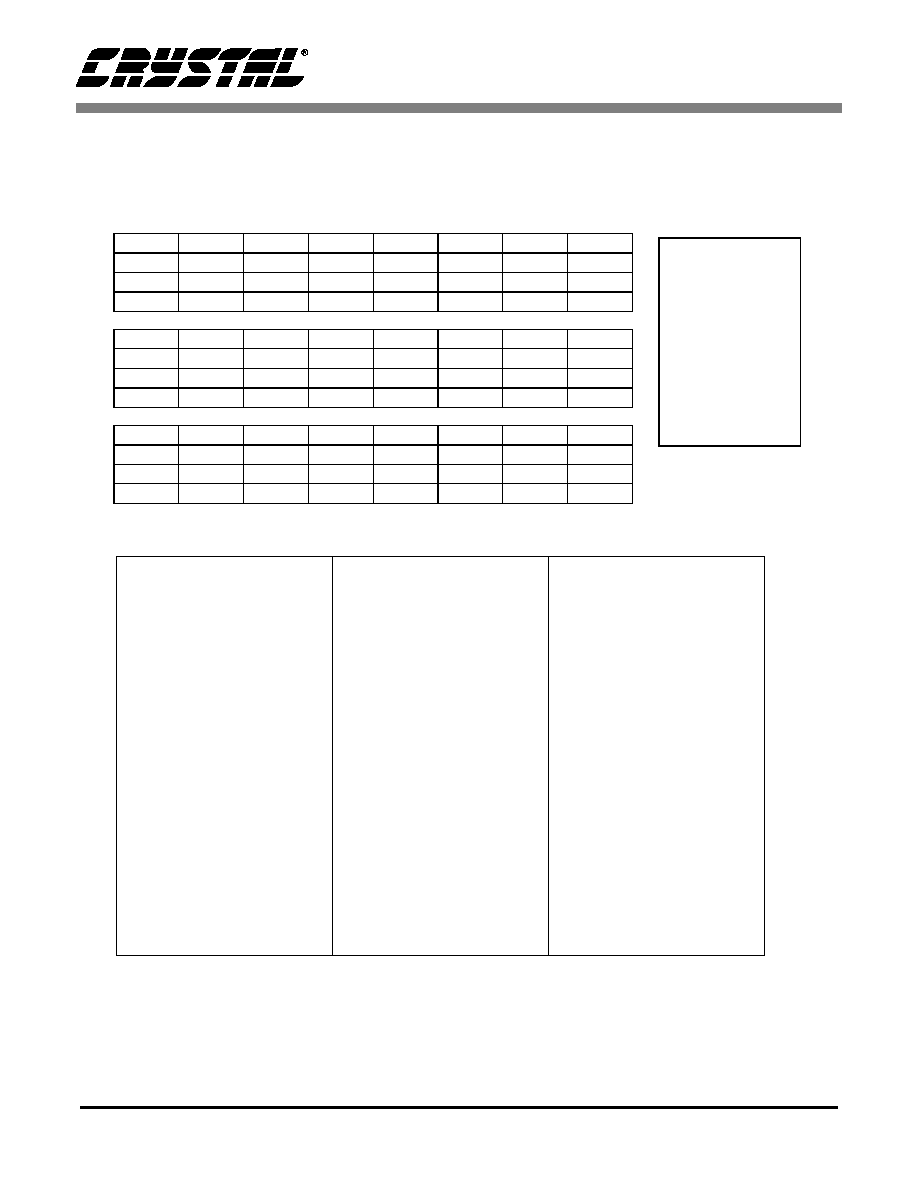

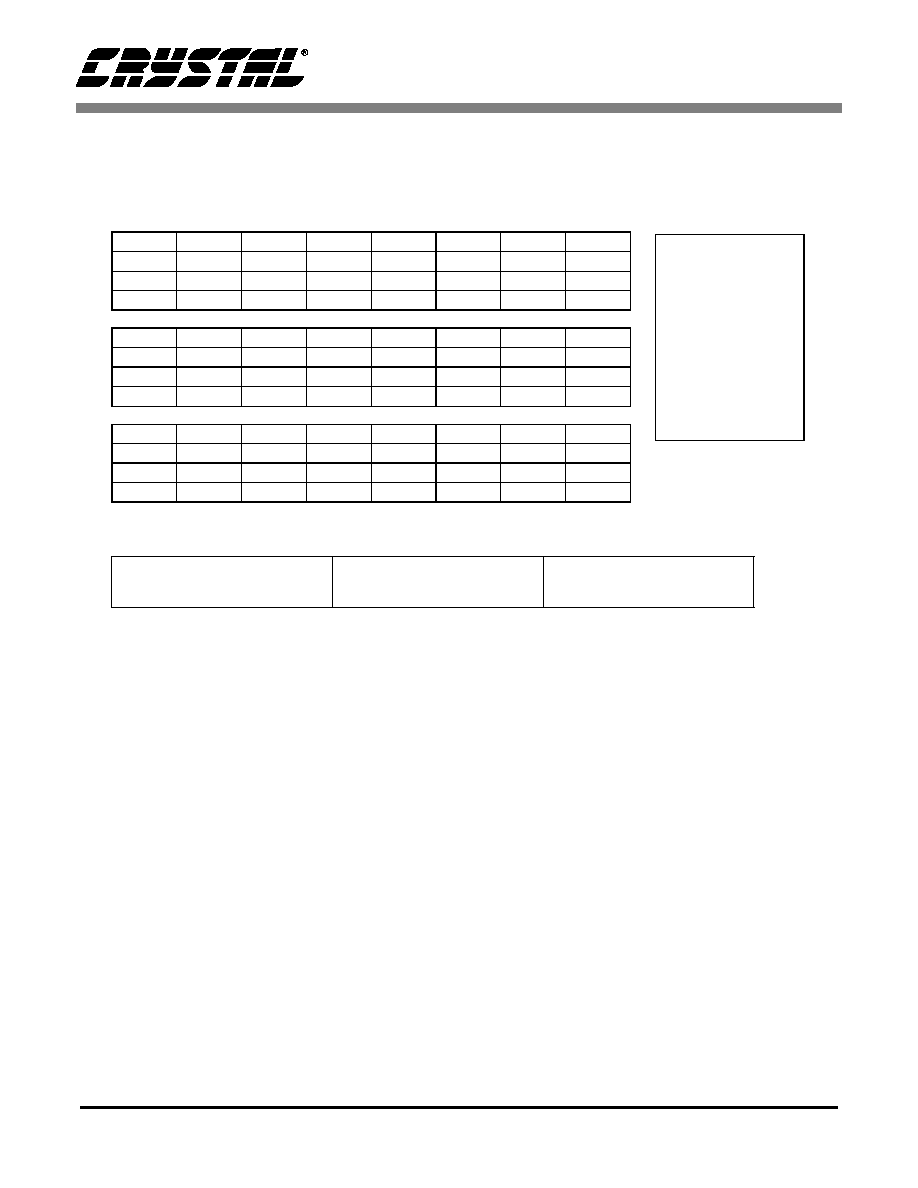

1. CHARACTERISTICS/SPECIFICATIONS

5.0 V AND 3.0 V DIGITAL CHARACTERISTICS

Notes:T

A

= 25 °C; VDD = 5.0 V ± 5% or 3.0 V

± 5%; GND = 0 V

POWER SUPPLY CHARACTERISTICS

Notes:T

A

= 25 °C; GND, GND1, GND2 = 0 V

ABSOLUTE MAXIMUM RATINGS

Notes:T

A

= 25 °C; GND, GND1, GND2 = 0 V; All voltages refer-

enced to ground

Parameter

Symbol Min Typ

Max

Unit

Digital Characteristics

High-Level Input Drive Voltage

V

IH

VDD - 0.6

-

-

V

Low-Level Input Drive Voltage

V

IL

-

-

1.0

V

High-Level Output Drive Voltage

I

out

= -40 µA

V

OH

VDD - 0.3

-

-

V

Low-Level Output Drive Voltage

I

out

= +40 µA

V

OL

-

-

0.3

V

Input Leakage Current

I

in

-

± 1

± 10

µA

3-State Leakage Current

I

OZ

-

-

± 10

µA

Digital Input Capacitance

C

IN

-

9

-

pF

Digital Output Pin Capacitance

C

out

-

9

-

pF

Parameter

Symbol Min Typ

Max

Unit

DC Supply

Digital Supply Pins

VD

2.5

3.0

5.25

V

I/O Interface Pins

VDD1

2.5

-

5.25

V

Modulator Interface Pins

VDD2

2.5

-

5.25

V

Power

One Channel

P1CH

-

6.0

-

mW

Four Channel

P4CH

-

22.0

-

mW

Standby

PSBY

-

100

-

µW

Parameter

Symbol Min Max

Unit

DC power supplies:

Digital Supply

I/O Interface

Modulator Interface

VD

VDD1

VDD2

-0.3

-0.3

-0.3

5.25

5.25

5.25

V

V

V

Input current, any pin except supplies

± 10

mA

Operating temperature (power applied)

Tmax

-55

+85

o

C

Storage temperature

Tstg

-65

+150

o

C

CS5376

DS256PP1

6

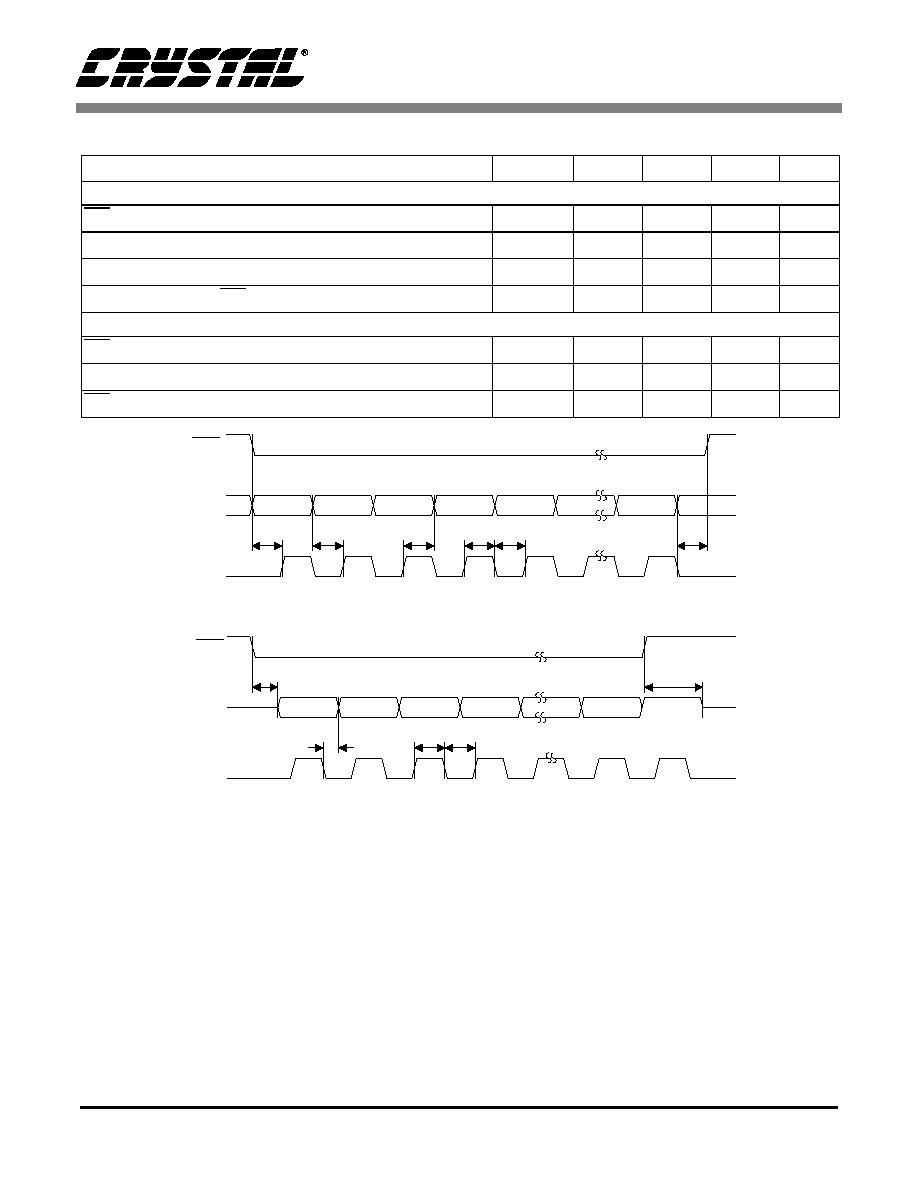

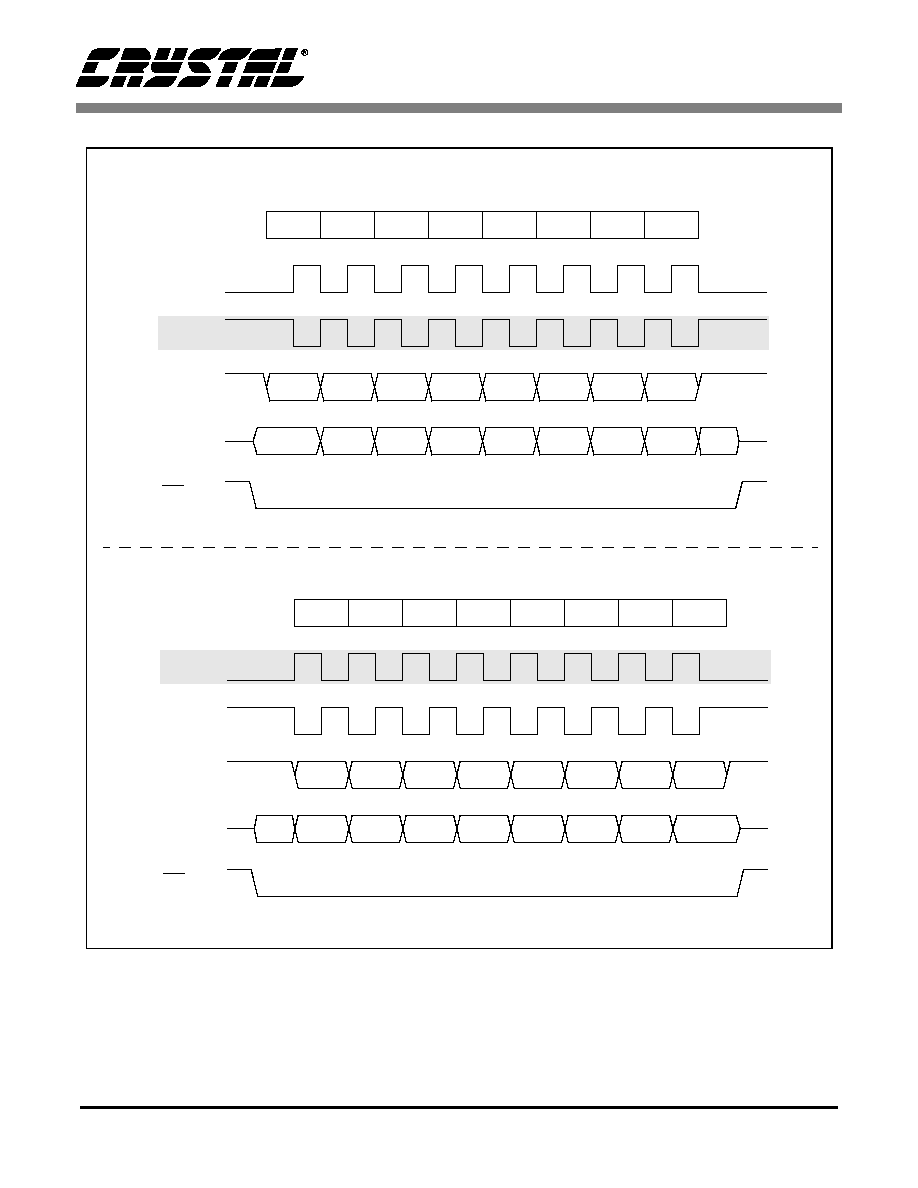

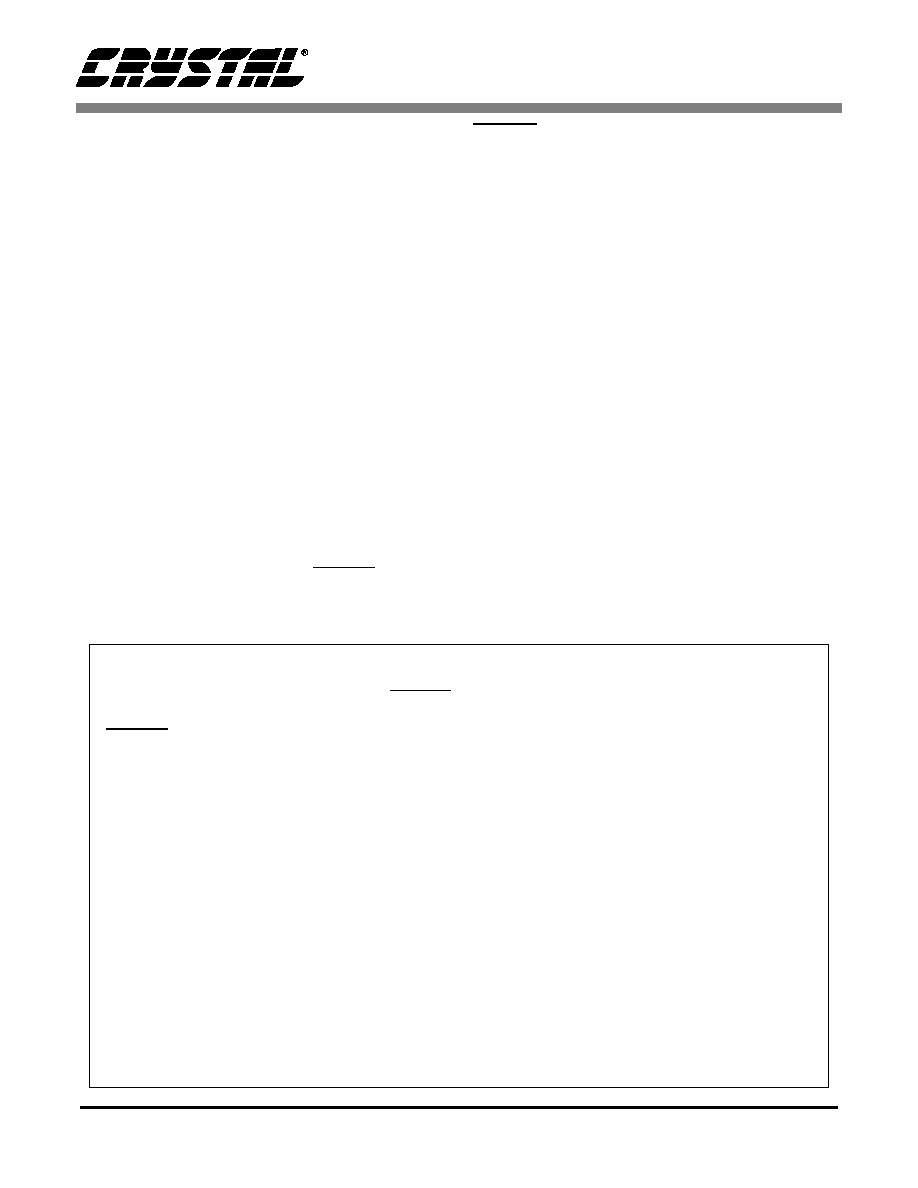

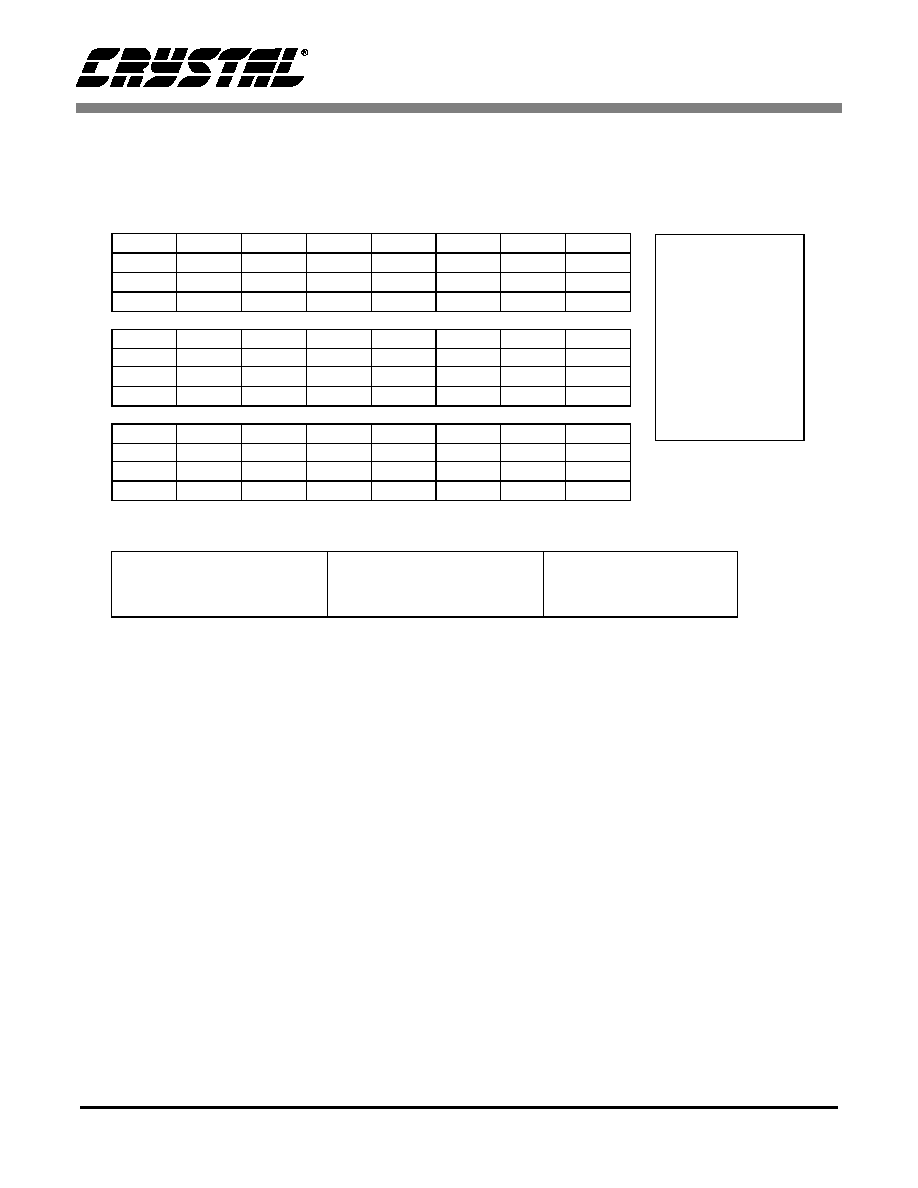

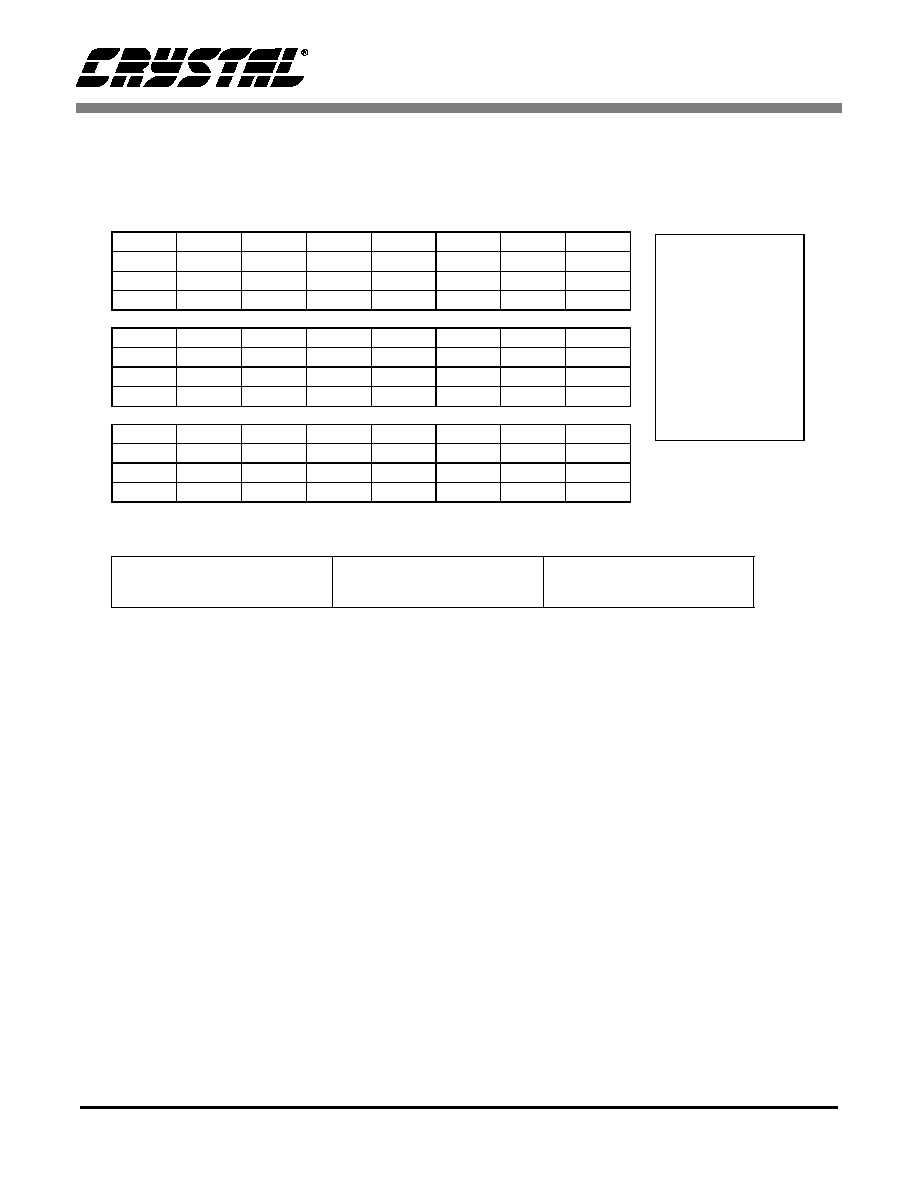

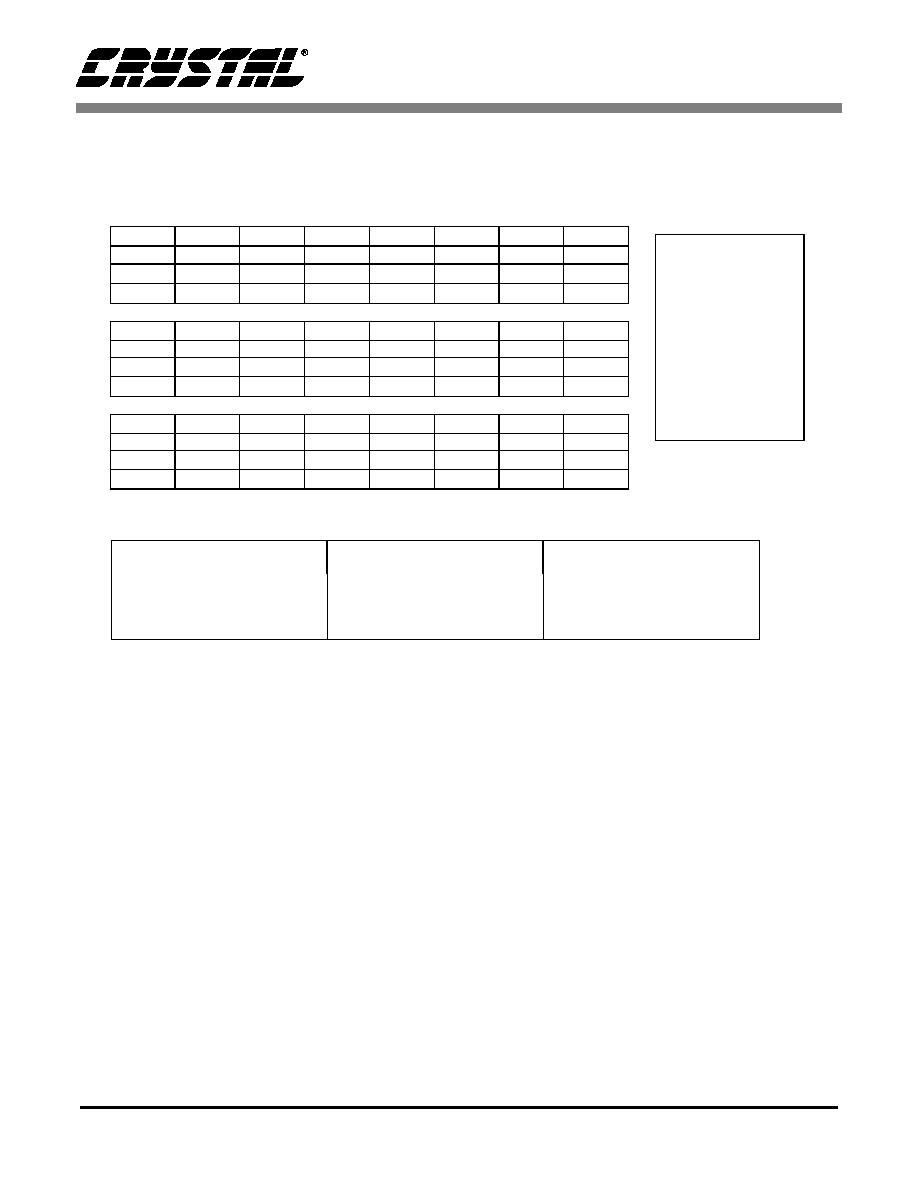

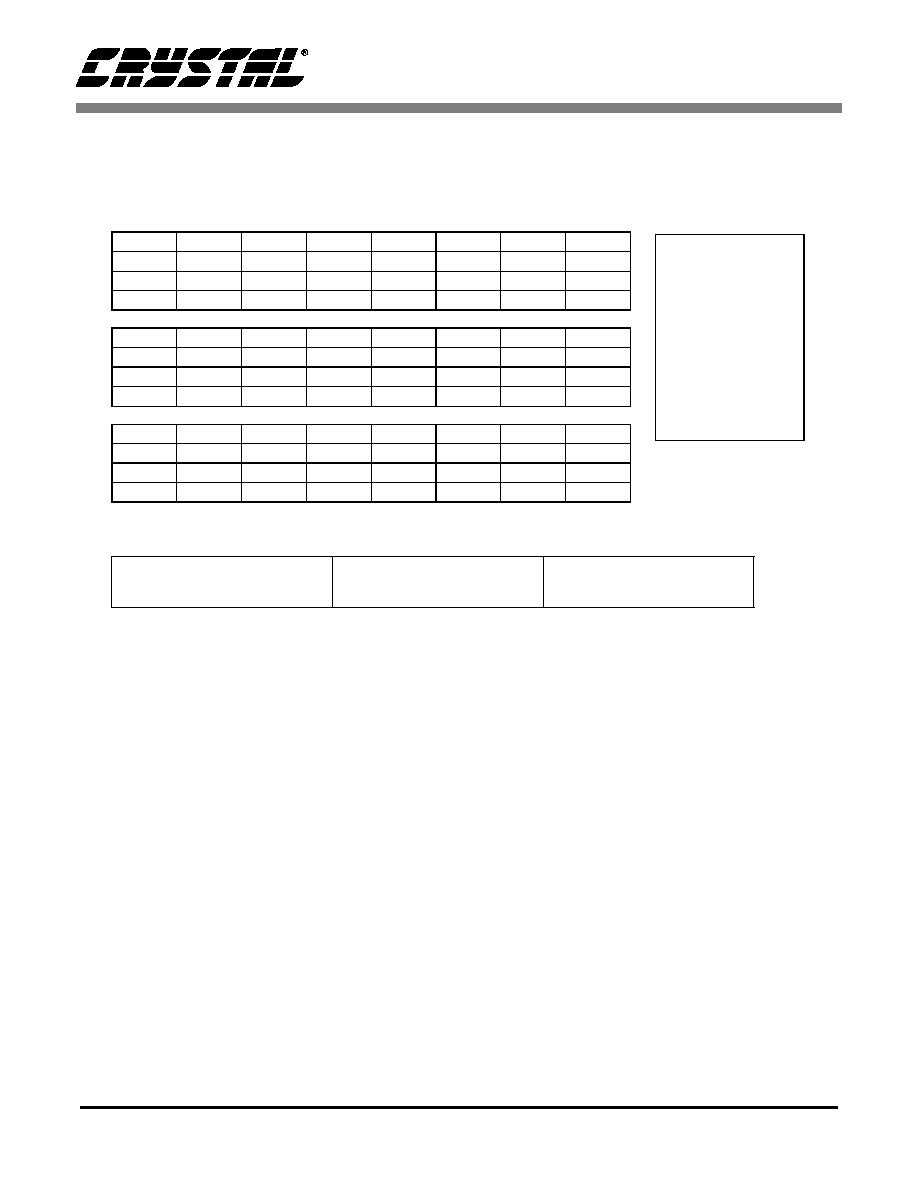

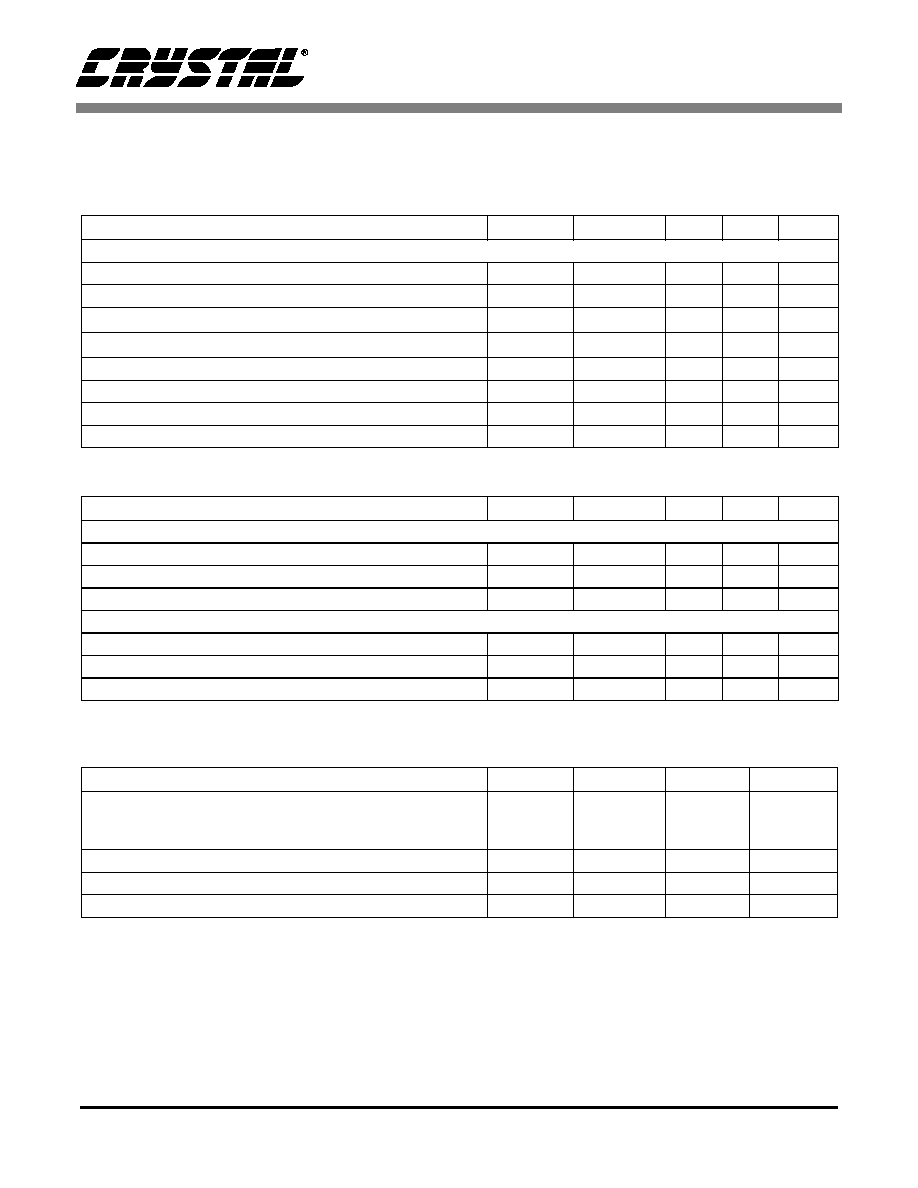

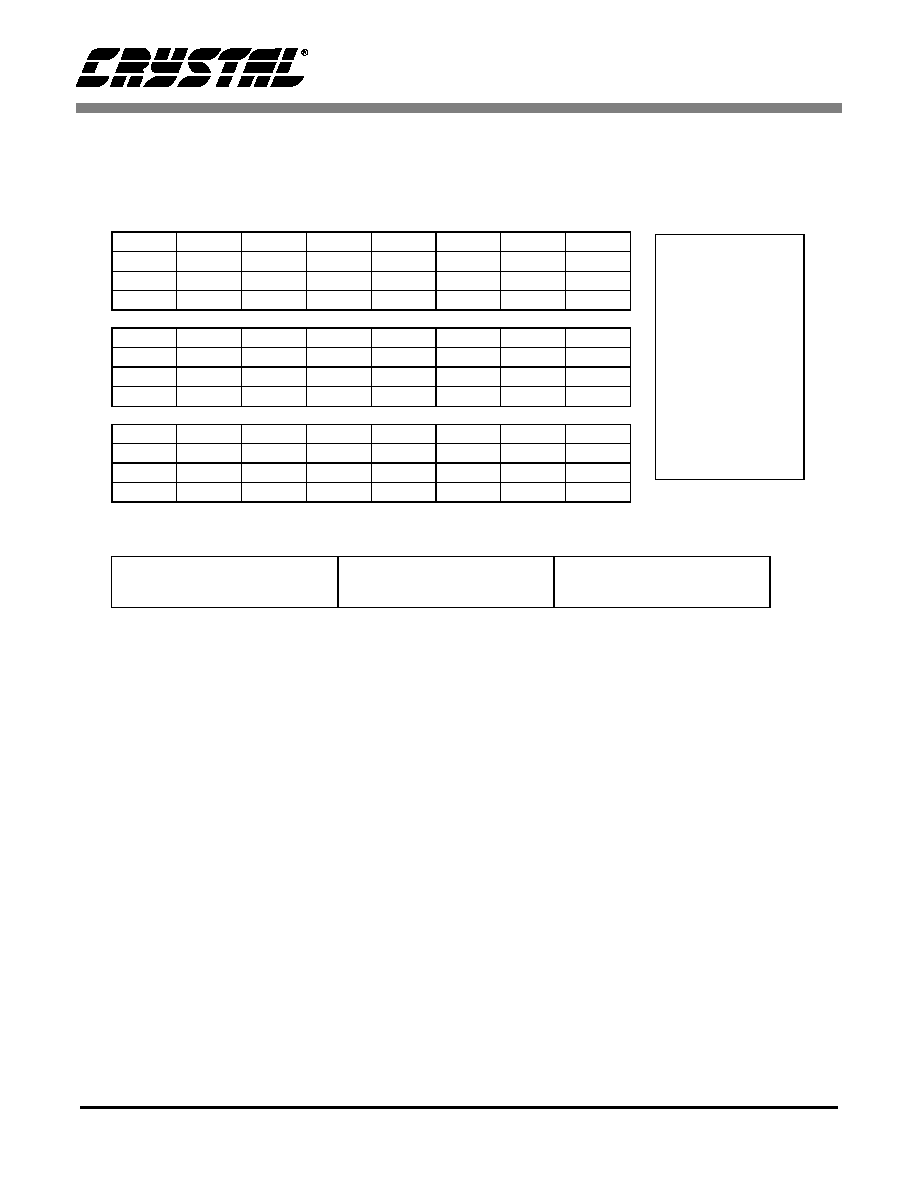

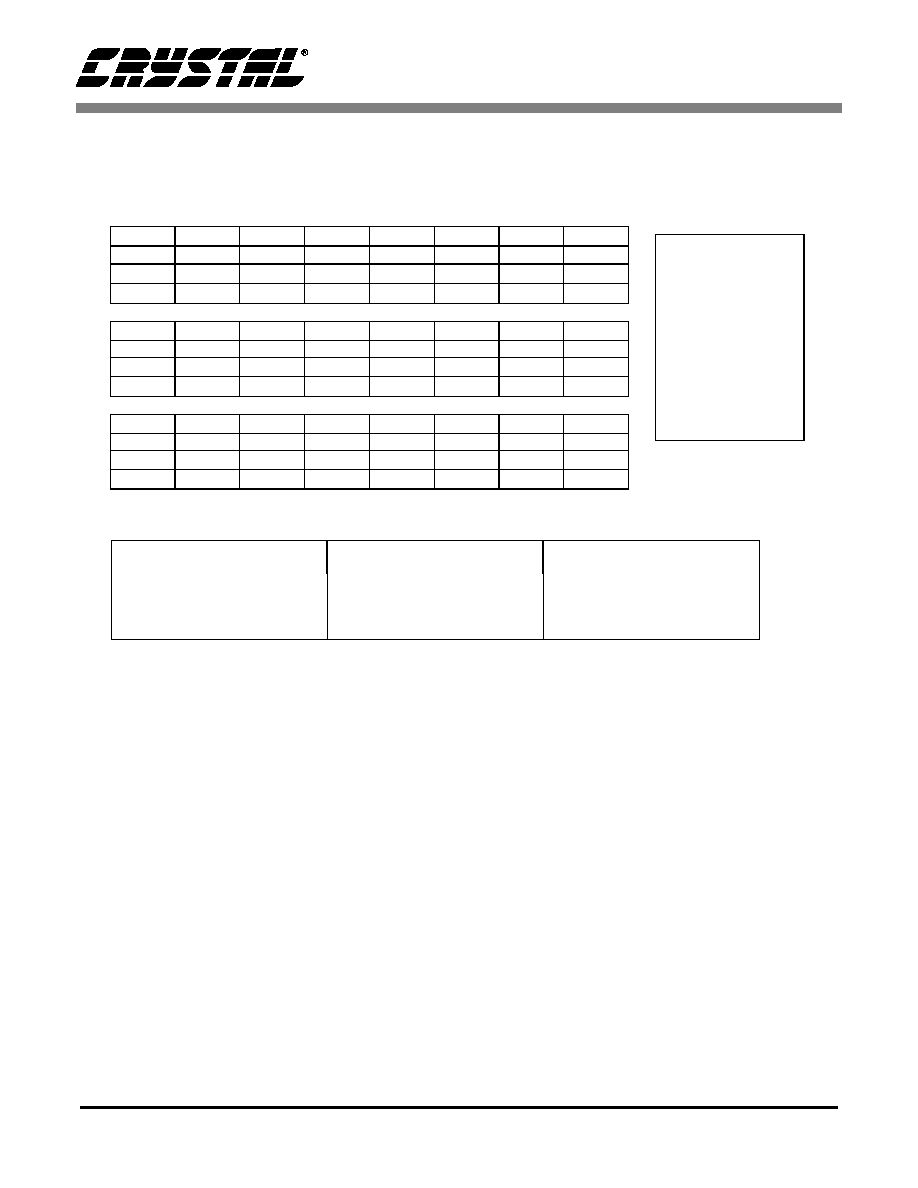

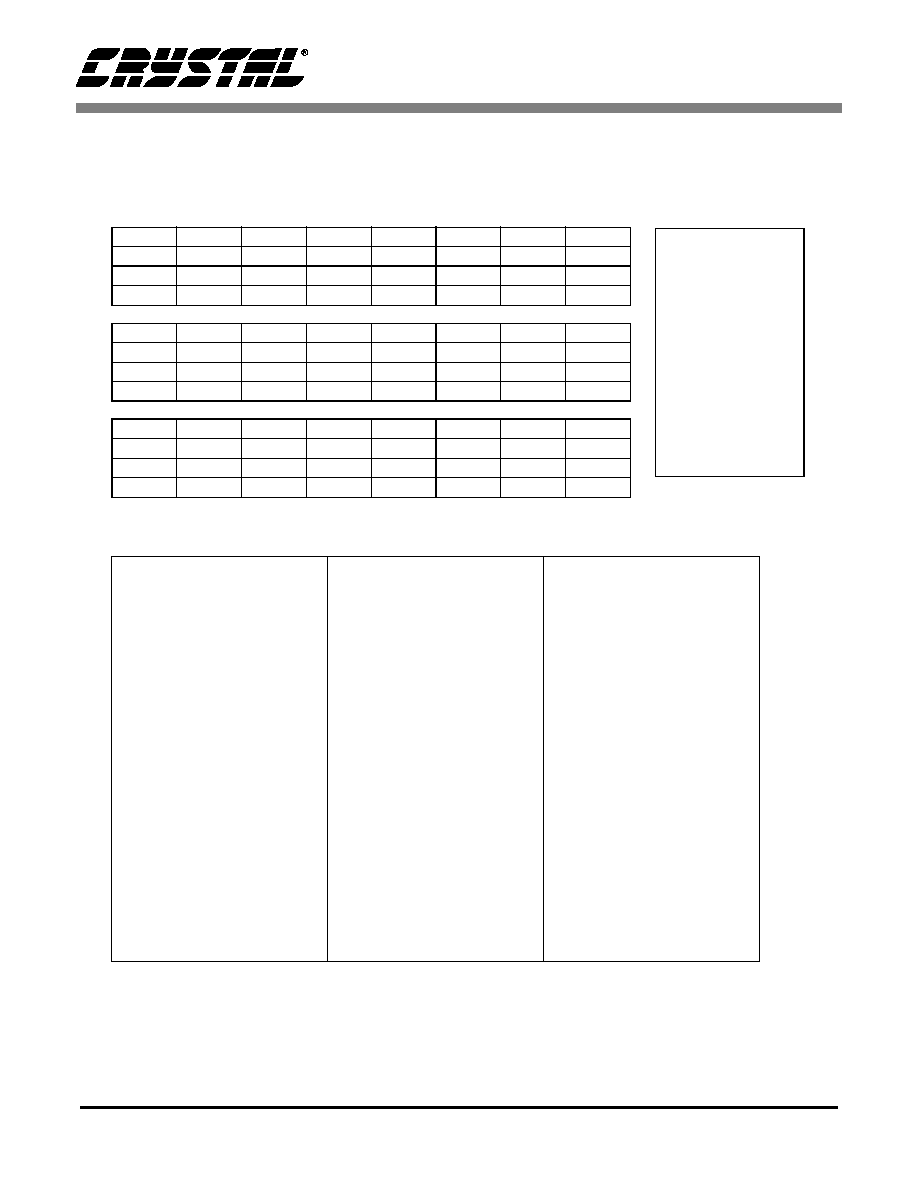

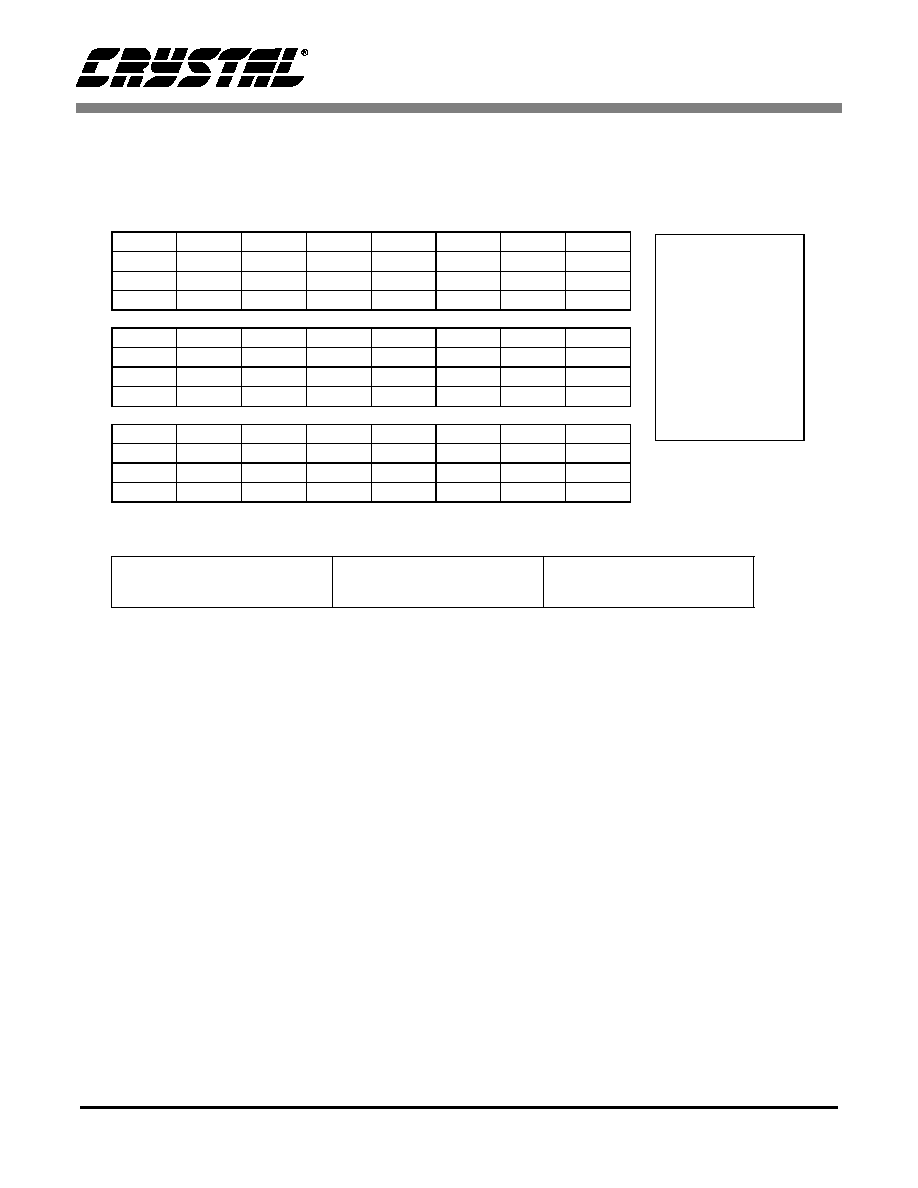

SWITCHING CHARACTERISTICS

Notes:T

A

= -40 °C to +85 °C; VD = 3.0 V ± 5% or 5.0 V ± 5%;

VDD1 = 3.3 V ± 5% or 5.0 V ± 5%; VDD2 = 3.3 V ± 5% or 5.0 V ± 5%; GND = GND1 = GND2 = 0 V; Logic Levels:

Logic 0 = 0 V, Logic 1 = VD, VDD1, VDD2; CL = 50pF

Notes: 1. Master clock frequencies below 32.768 MHz will affect generated clock frequencies.

2. Specified using 10% and 90% points on waveform of interest. Output loaded with 50 pF.

Parameter

Symbol Min Typ

Max

Unit

Master Clock Frequency

(Note 1)

CLK

0.1

32.768

33

MHz

Master Clock Duty Cycle

40

-

60

%

Rise Times

Any Digital Input Except SCK (Note 2)

SCK

Any Digital Output

t

rise

-

-

-

-

-

50

1.0

100

-

µs

µs

ns

Fall Times

Any Digital Input Except SCK (Note 2)

SCK

Any Digital Output

t

fall

-

-

-

-

-

50

1.0

100

-

µs

µs

ns

Modulator Data Interface

MSYNC Setup Time to MCLK rising

t

mss

-20

-

-

ns

MCLK rising to Valid MDATA

t

mdv

-

-40

75

ns

MSYNC falling to MCLK rising

t

msf

-20

-

-

ns

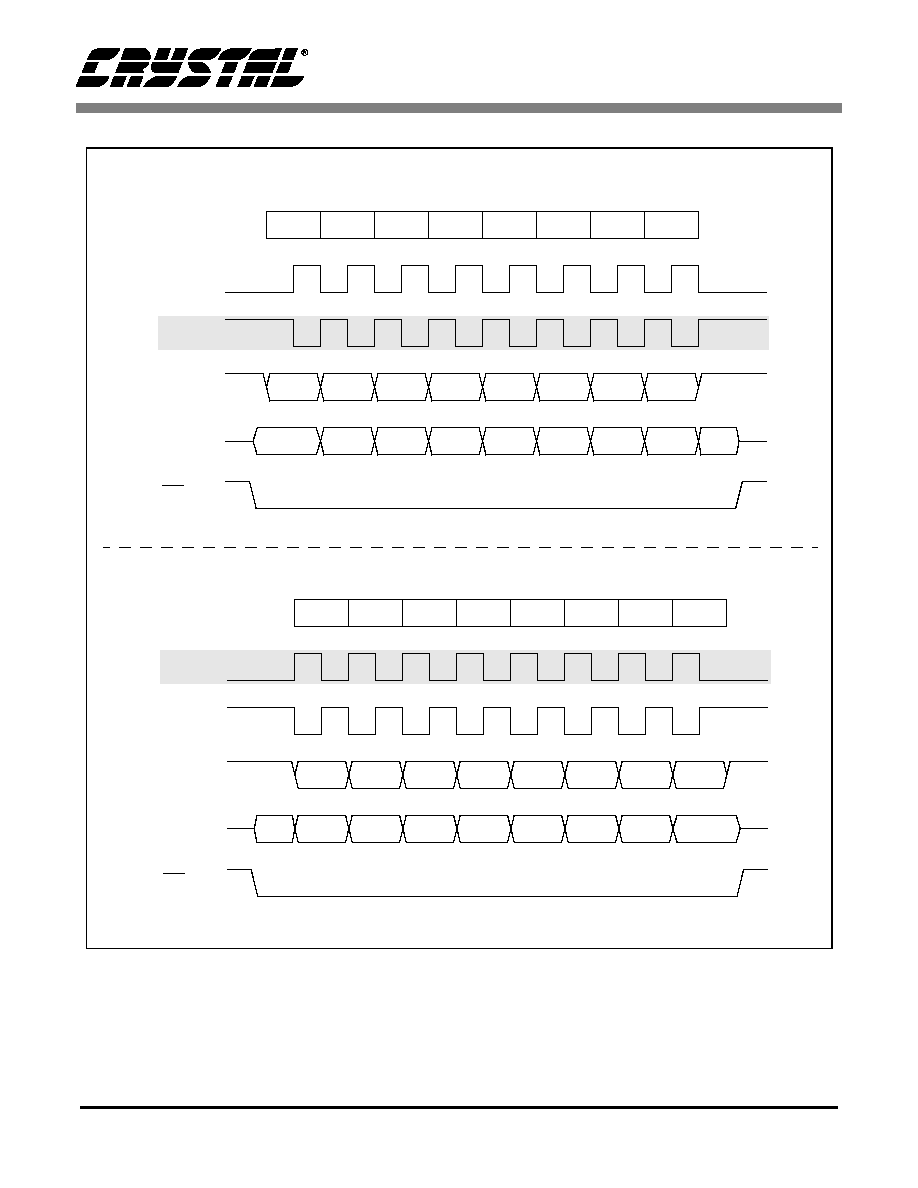

Serial Port Timing in SPI Slave Mode

Serial Clock Frequency

SCK

-

-

4.096

MHz

Serial Clock

Pulse Width High

Pulse Width Low

t

1

t

2

100

100

-

-

-

-

ns

ns

CS5376

DS256PP1

7

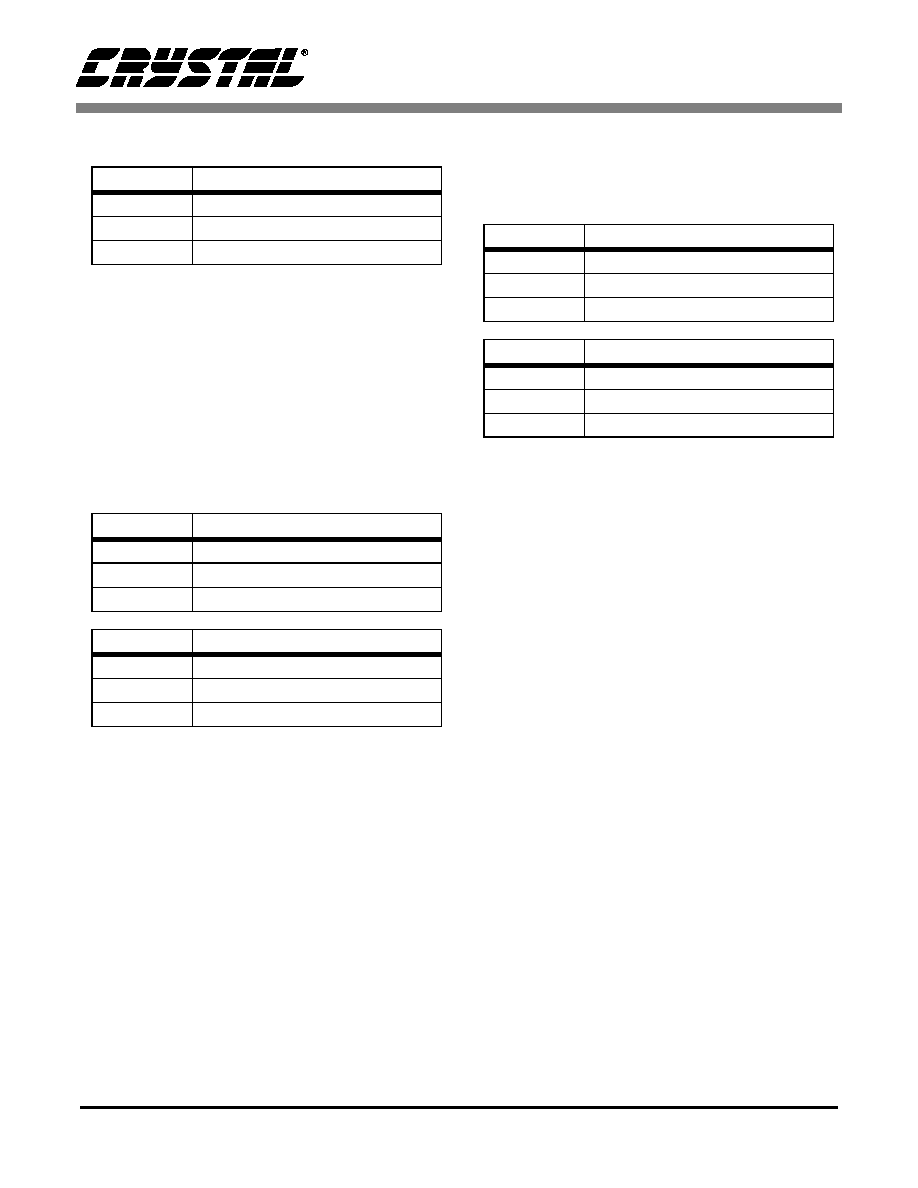

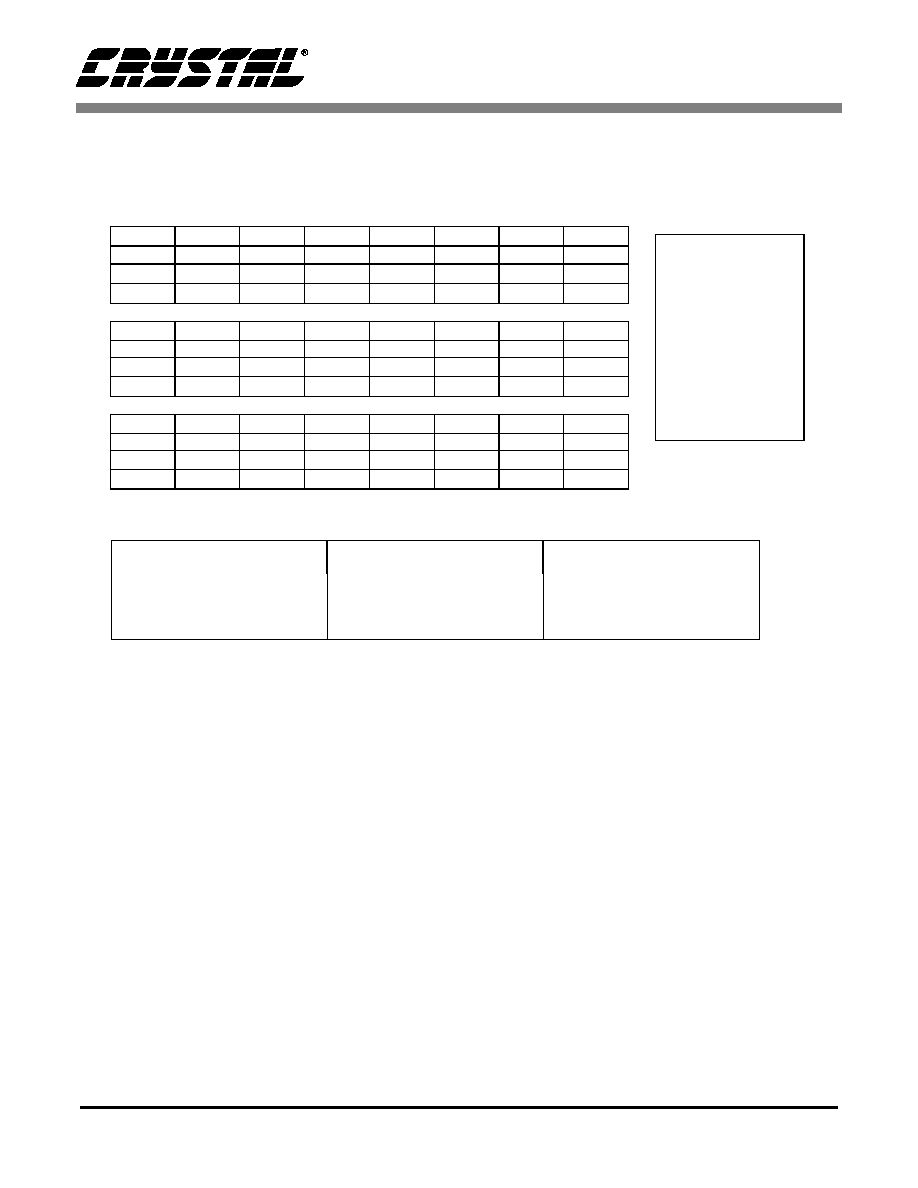

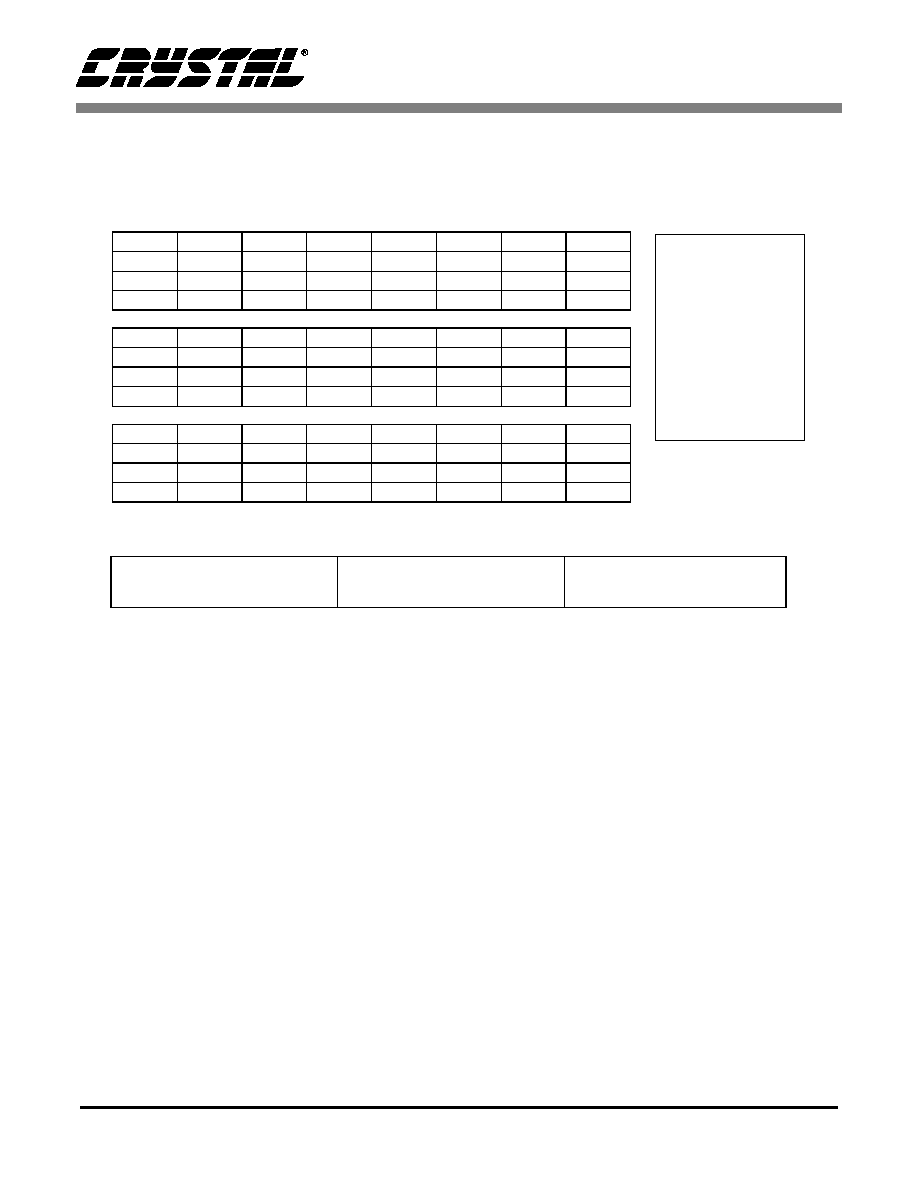

SWITCHING CHARACTERISTICS

(Continued)

Parameter

Symbol Min Typ

Max

Unit

MOSI Write Timing

SSI

Enable to Valid Latch Clock

t

3

50

-

-

ns

Data Set-up Time Prior to SCK Rising

t

4

50

-

-

ns

Data Hold Time After SCK Rising

t

5

100

-

-

ns

SCK Falling Prior to

SSI

Disable

t

6

100

-

-

ns

MISO Read Timing

SSI

Enable to Valid Latch Clock

t

7

-

-

150

ns

SCK Falling to New Data Bit

t

8

-

-

150

ns

SSI

Rising to MISO Hi-Z

t

9

-

-

150

ns

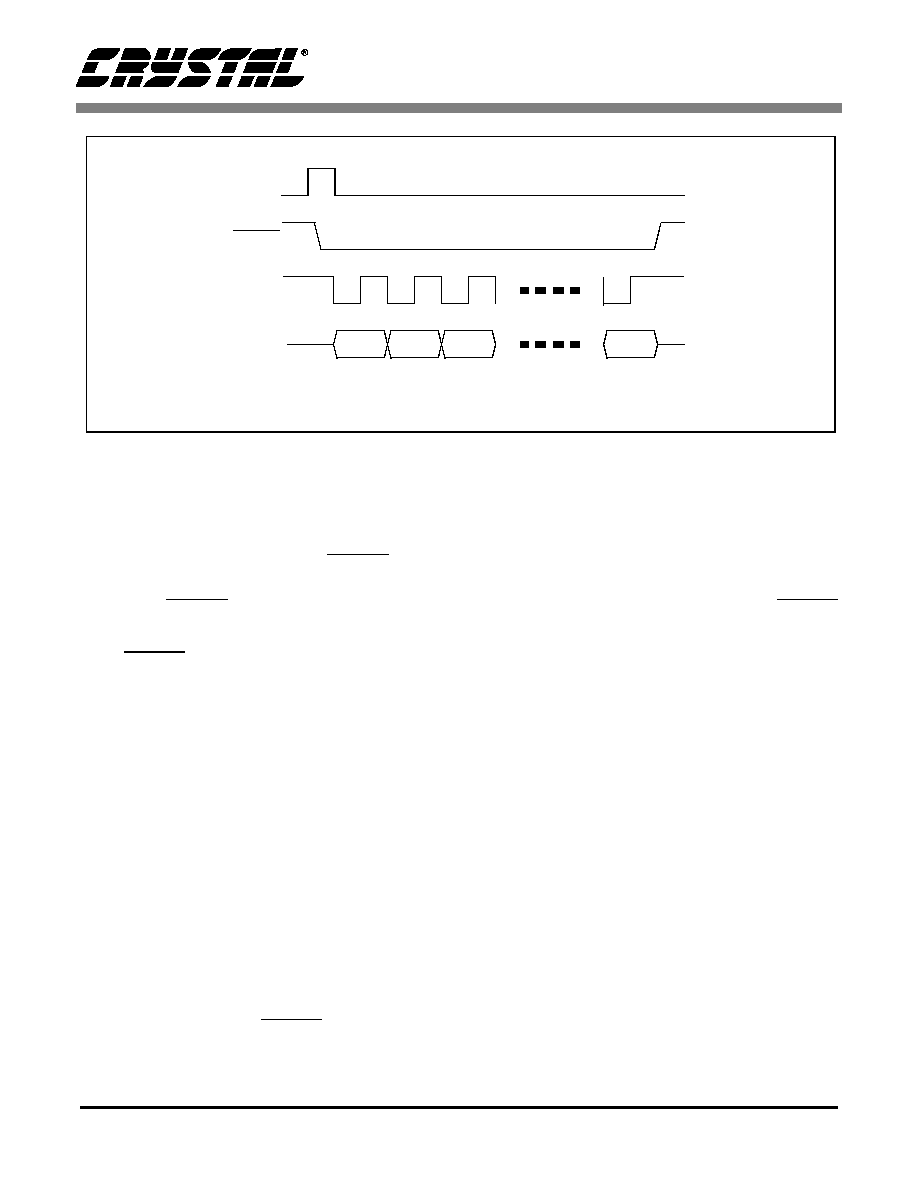

SSI

MOSI

SCLK

MSB

MSB - 1

LSB

t

6

t

2

t

1

t

5

t

4

t

3

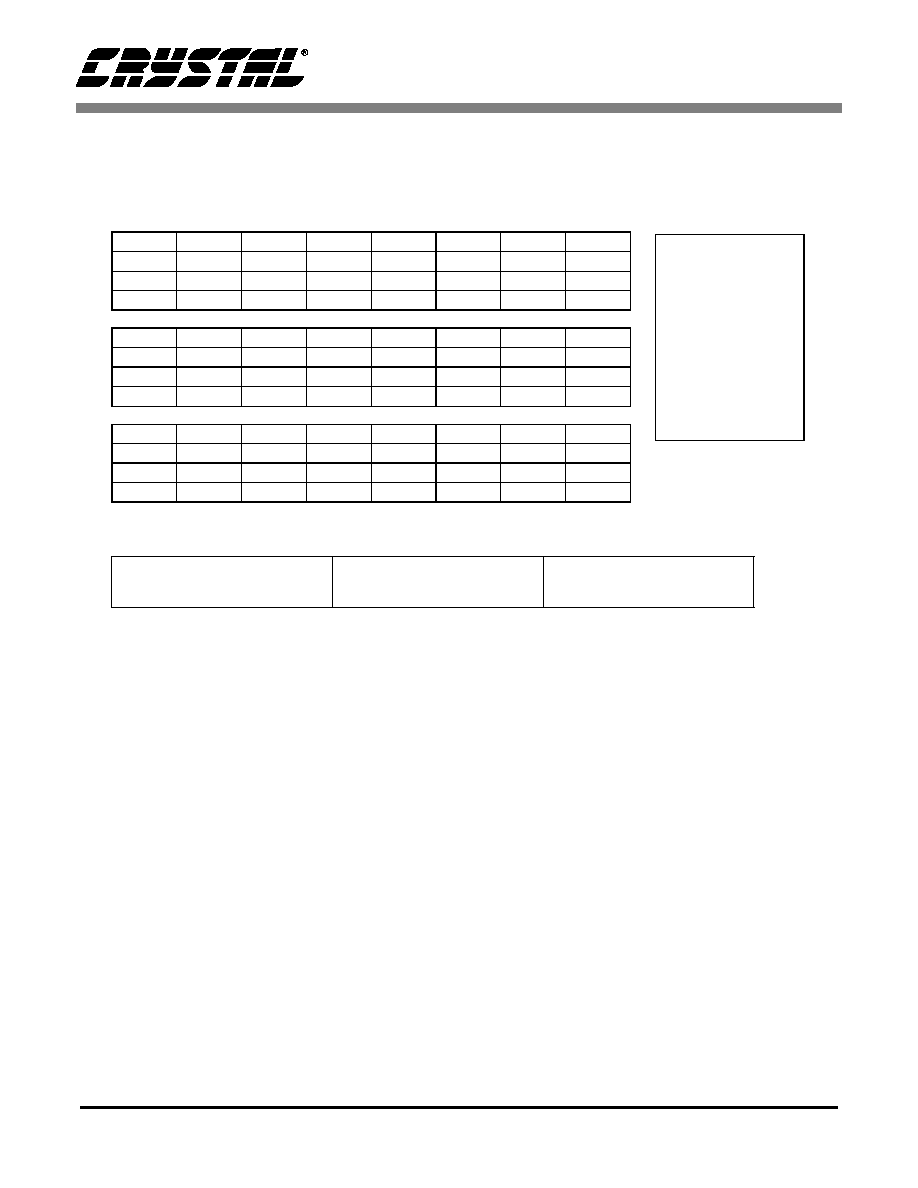

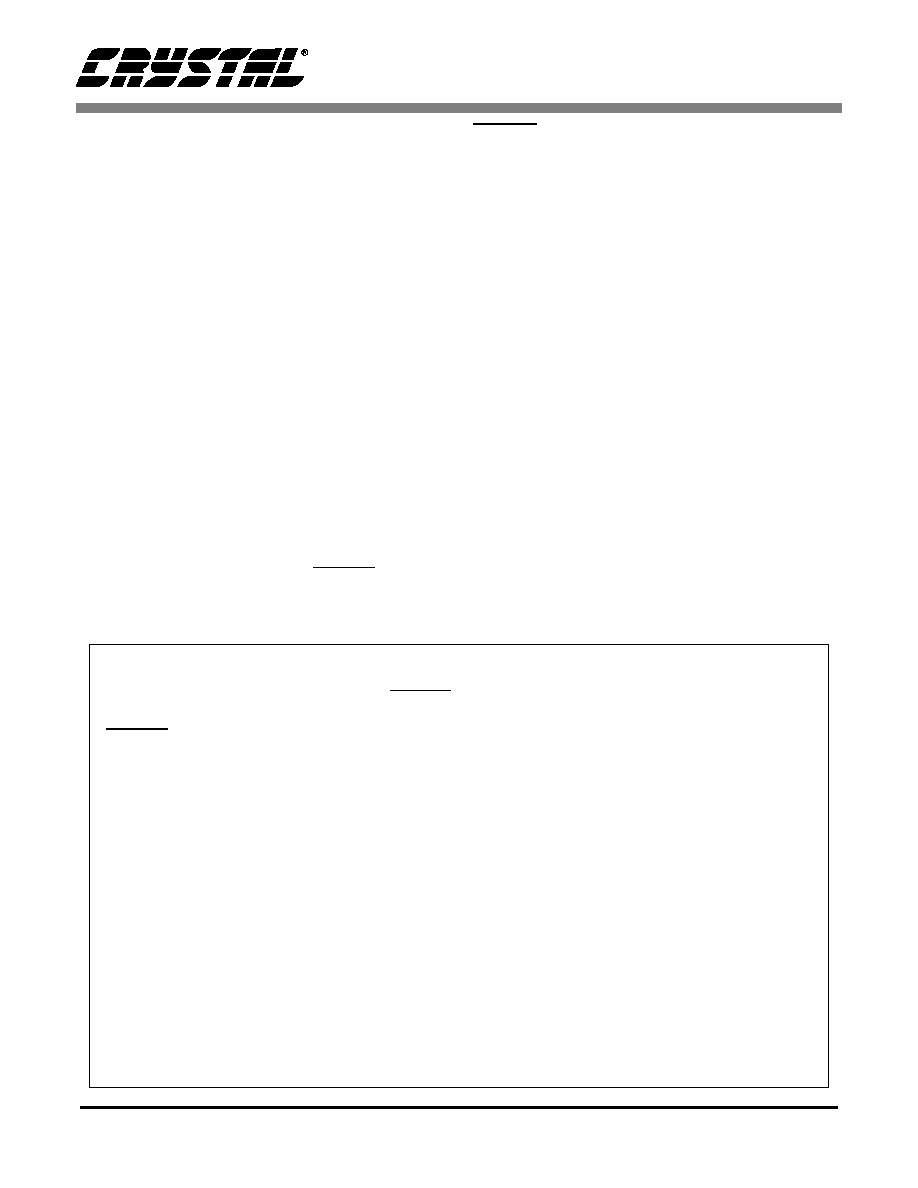

Figure 1. MOSI Write Timing in SPI Slave Mode (Not to Scale)

MISO

SCLK

MSB

MSB - 1

LSB

t

9

t

2

t

1

t

8

t

7

SSI

Figure 2. MISO Read Timing in SPI Slave Mode (Not to Scale)

CS5376

DS256PP1

8

2. GENERAL DESCRIPTION

The CS5376 is a multi-channel digital filter with

integrated system peripherals. The digital decima-

tion filter uses a coefficient programmable signal

processing architecture to filter up to four

-

modulator bit streams. An on-chip reference coef-

ficient set is included to provide an easy set up for

applications that do not require custom digital filter

coefficients.

The CS5376 integrated peripherals simplify system

design by providing a buffered high speed serial

data output port, a test bit stream generator suitable

for driving a test DAC, general purpose I/O pins for

local hardware control, a secondary master mode

SPI port for serial peripherals, and a JTAG port for

boundary scan testing. In addition, a clock and syn-

chronization block synchronizes the CS5376 to the

host system, and a time break controller generates

timing reference information in the output data

stream.

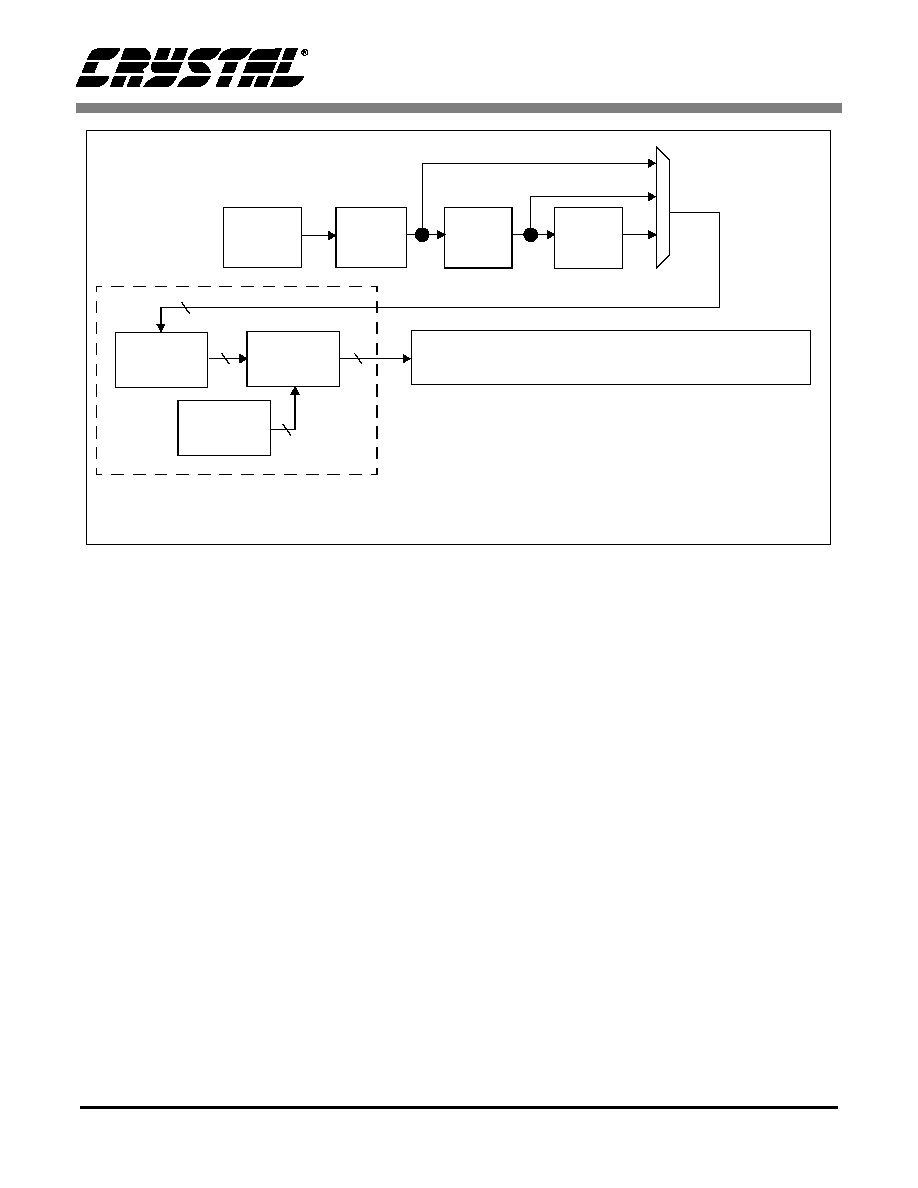

2.1 System Configurations

Coprocessor or Stand-Alone Configurations

Figure 3 illustrates a simplified block diagram of

the CS5376 in a multi-channel system architecture.

This diagram shows the CS5376 in coprocessor

mode, where an external microcontroller operates

as the local host. The microcontroller writes con-

figuration commands and filter coefficients into the

CS5376 from non-volatile memory or from the

communications channel. This system configura-

tion allows the microcontroller to change the filter-

ing function of the CS5376 when instructed to do

so by the system controller.

- Modulators

2

CS5376

Communications

Interface

To

System

Master

CS5372

2

2

2

CS5372

SYNC

CLK

SPI

SD

µC

GPIO

GPIO

GPIO

Modulator

-

Input

Input

Input

Input

Amp

Amp

Amp

Amp

TSBCLK

TSBDATA

MCLK

MSYNC

Figure 3. CS5376 System Level Block Diagram

CS5376

DS256PP1

9

Alternately, the CS5376 can be used in stand-alone

mode, where a configuration EEPROM replaces

the microcontroller. The CS5376 reads configura-

tion commands and filter coefficients directly from

EEPROM, and then enters a fixed operational state.

The stand-alone configuration simplifies system

design by eliminating the CS5376 to microcontrol-

ler interface.

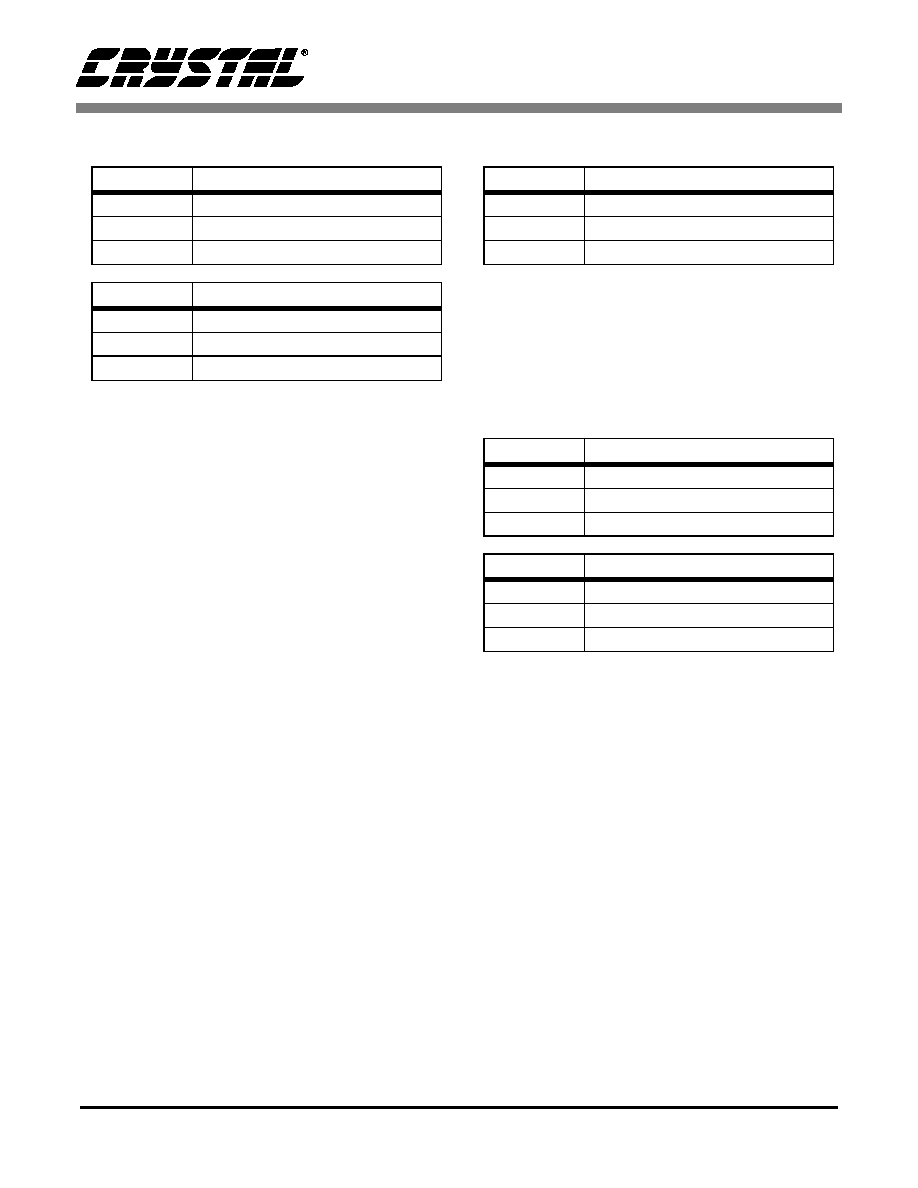

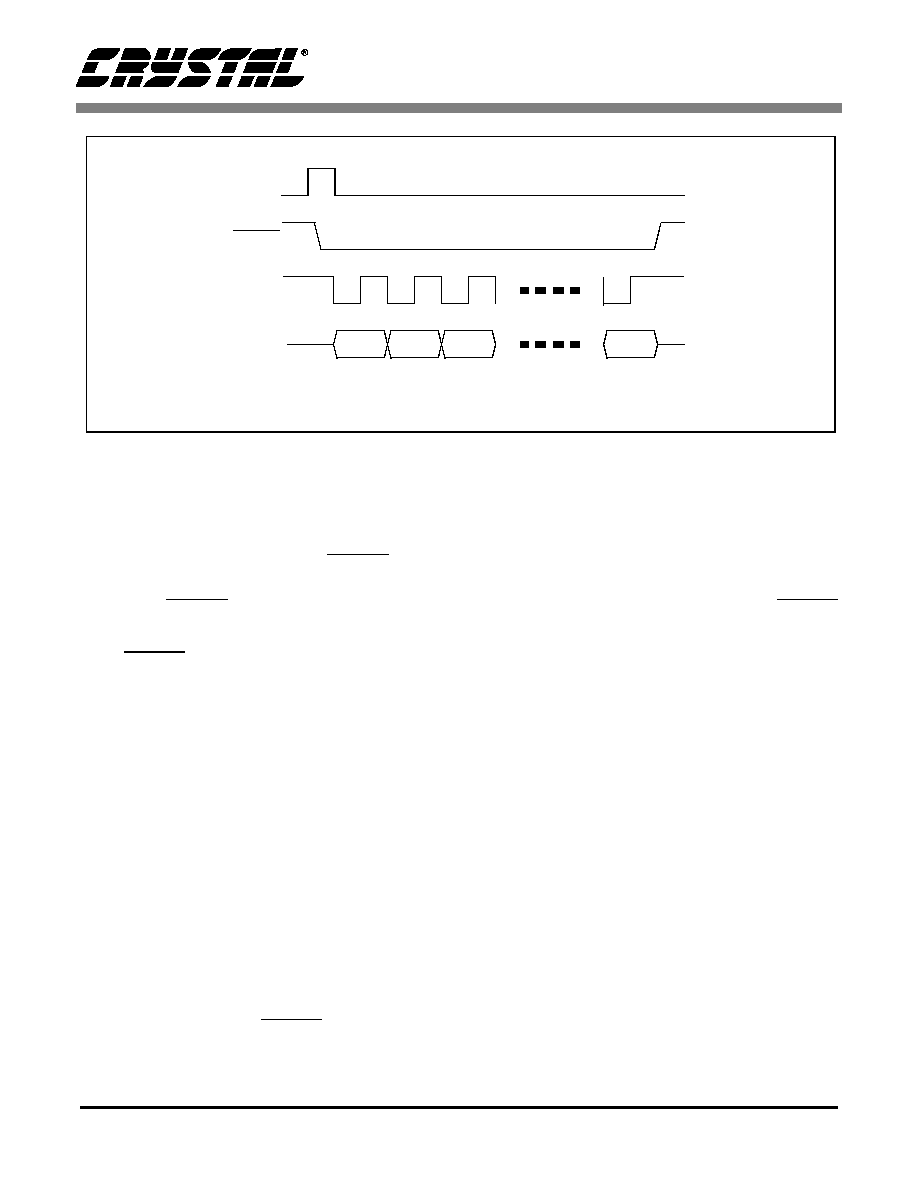

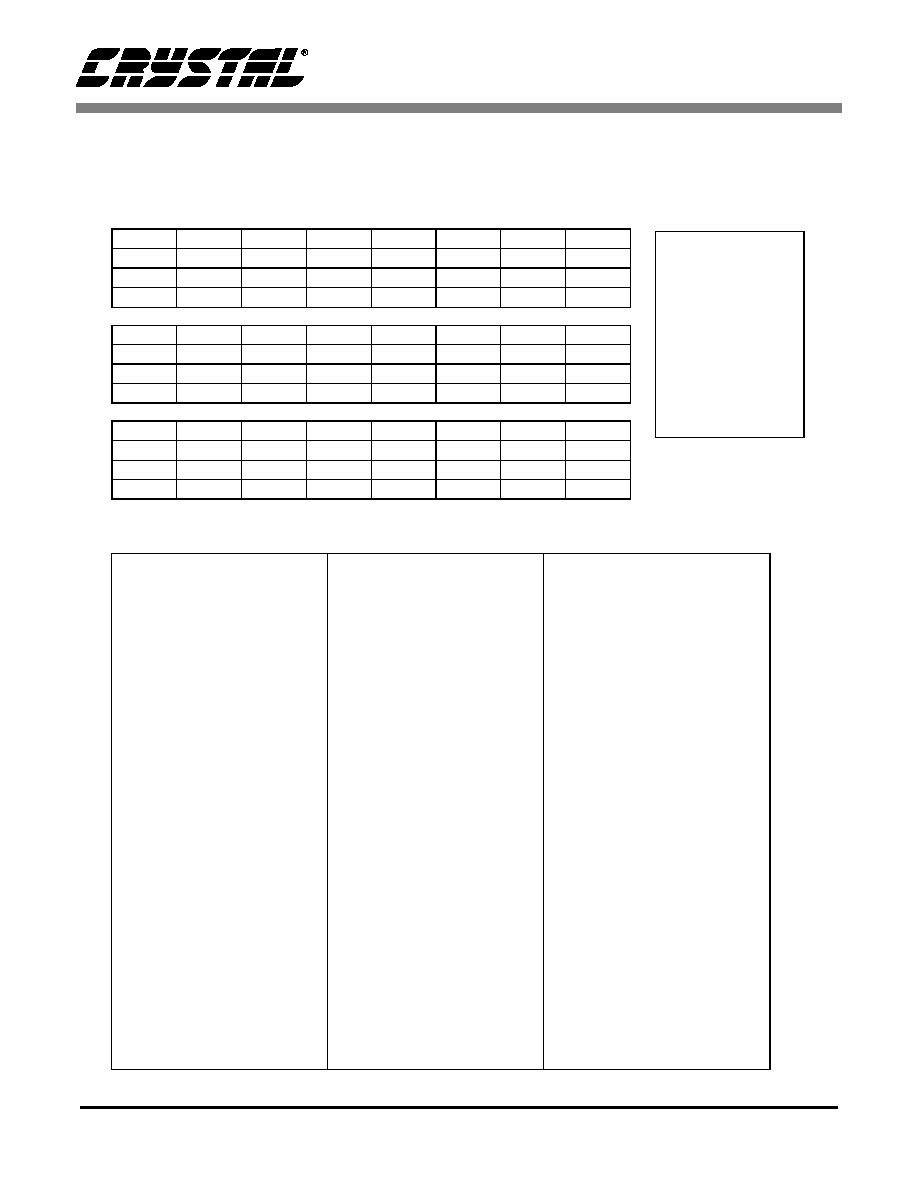

2.2 Digital Filter Description

Multi-Stage Signal Processing Architecture

The CS5376 has a multi-stage signal processing ar-

chitecture consisting of a hardware sinc filter, two

FIR filters, and a selectable 1st, 2nd, or 3rd order

IIR filter. The filter architecture is flexible, with the

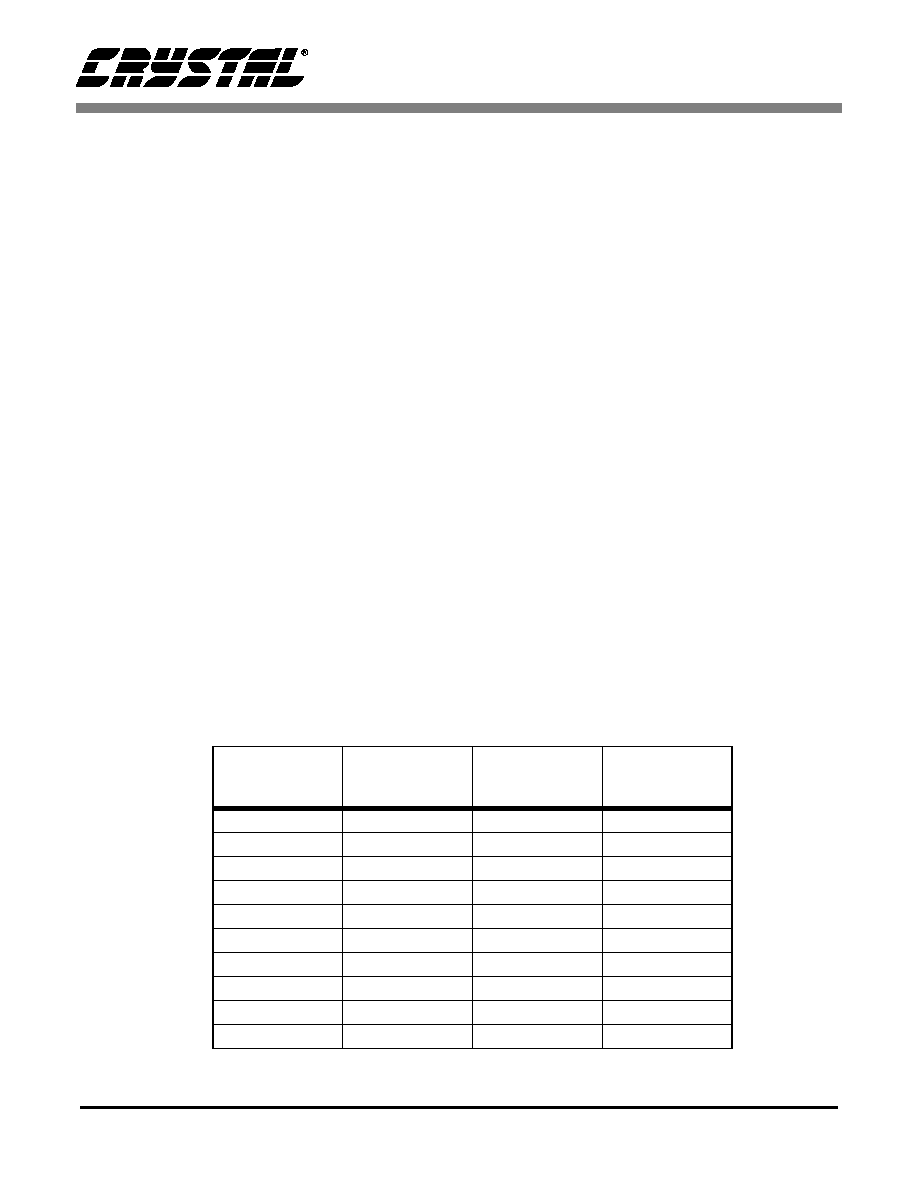

capability to bypass later filter stages and output

data immediately following any filter. Figure 4 il-

lustrates the digital filter stages of the CS5376.

The digital filters have decimation ratios that can

achieve data output word rates (OWRs) between

62.5 sps and 4000 sps. Figure 5 lists the standard

OWRs and their associated output periods. Slower

output word rates can be achieved by scaling down

the master clock input.

Programmable or Fixed Coefficients

The CS5376 is designed to load custom filter coef-

ficients and other configuration information via the

SPI 1 serial port from either a microcontroller or a

configuration EEPROM.

The programmed FIR filter coefficients can imple-

ment any type of finite impulse response filter. Lin-

ear phase, minimum phase, phase compensation, or

other complex filter types can be used depending

on the application requirements. The programmed

IIR filter coefficients can implement a 1st, 2nd, or

Figure 4. Digital Filtering Stages

Sinc Filter

16-128

FIR1

4,16

FIR2

2,4

IIR1

IIR2

1st Order

2nd Order

Output to High Speed Serial Data Port (SD Port)

DC Offset

Correction

Output Rate 62.5 Hz ~ 4 kHz

& Gain

Modulator

512 kHz

Input

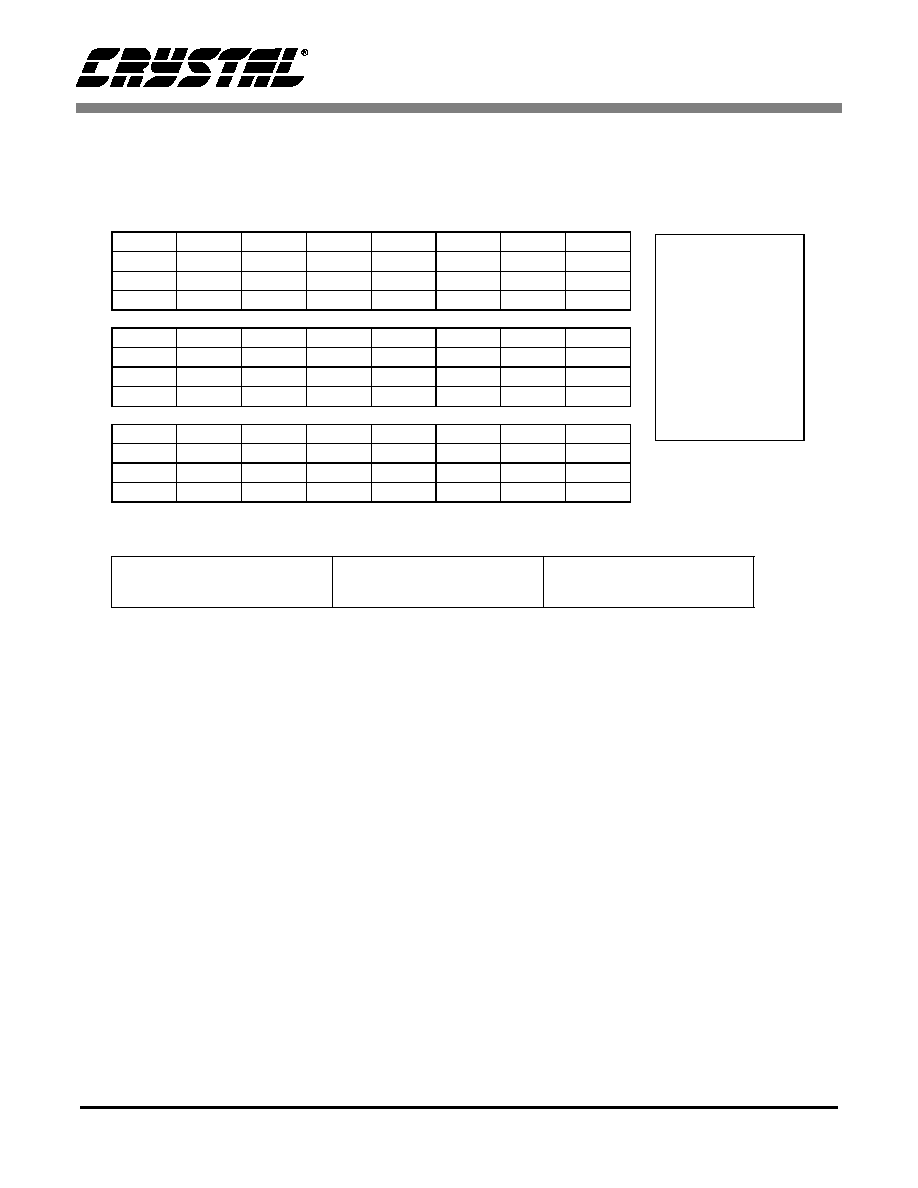

Figure 5. Digital Filter OWRs

Output Word Rate

Output Period

(OWR)

4000 sps

0.25 ms

2000 sps

0.5 ms

1000 sps

1.0 ms

500 sps

2.0 ms

333.3 sps

3.0 ms

250 sps

4.0 ms

125 sps

8.0 ms

62.5 sps

16.0 ms

CS5376

DS256PP1

10

3rd order infinite impulse response filter with any

corner frequency in the measurement bandwidth.

A set of on-chip FIR and IIR coefficients are in-

cluded in the CS5376 to provide an easy set up for

applications that do not require custom filter coef-

ficients. These coefficients have excellent filtering

characteristics, with the low-pass FIR filters having

a corner frequency at 40% f

s

, in-band ripple less

than ±0.01 dB, and stop-band attenuation greater

than 130 dB. The high-pass IIR filter provides a 3rd

order Butterworth response with a corner frequen-

cy at 2% f

s

.

Programmable Gain and Offset Correction

The final operation of the digital filter is to apply a

user defined gain and offset correction to the output

data. The gain correction value is independently

programmable for each channel and is used to nor-

malize sensor gain across a network. Similarly, the

offset correction is independently programmable

for each channel and is used to correct for DC off-

set in a sensor. The CS5376 also includes a built in

offset calibration routine that will calculate offset

correction values automatically.

2.3 Integrated Hardware Peripherals

High Speed Serial Data Output Port

After filtering is completed, each 24-bit output

sample is combined with an 8-bit status word that

encodes the channel number, a time break flag, and

any error conditions. This 32-bit data word is writ-

ten to an 8-deep FIFO buffer and then transmitted

on request to the communications interface through

the high speed serial data output port. In a typical

system, the communication interface will be a pro-

prietary design.

Test Bit Stream Generator

The CS5376 includes a programmable test bit

stream (TBS) generator that produces a 1-bit

-

modulated bitstream with 24-bits of precision, suit-

able for driving a test DAC to verify the analog per-

formance of the conversion channel. The TBS

generator also includes an internal digital loopback

option so the digital filters and communication in-

terface can be tested independently of the analog

circuitry. The TBS generator can easily be pro-

grammed to produce a number of test signals using

the included 1024 point sine wave data table. By

writing a single configuration register many com-

mon test frequencies can be generated, including

31.25 Hz, 50.0 Hz, and 125.0 Hz. Custom test sig-

nal frequencies can be generated by writing a new

sine wave data table.

Secondary SPI Port

A secondary master mode SPI 2 port allows serial

peripherals to be controlled through the primary

SPI 1 port. The CS5376 acts as an arbiter to con-

duct transactions between the communications in-

terface connected to the primary SPI 1 port and

serial peripherals connected to the secondary SPI 2

port. This simplifies system design by requiring

only one SPI connection to the communication in-

terface to control the CS5376 and multiple serial

peripherals.

General Purpose I/O Pins

Twelve general purpose I/O pins on the CS5376

can be used for local hardware control or as chip se-

lects for the SPI ports. These pins are independent-

ly programmable as inputs or outputs, with or

without an internal pull-up resistor.

JTAG Test Port

The CS5376 includes a standard IEEE 1149.1

JTAG test port for system level testing via bound-

ary scan.

Clock and Synchronization Block

A clock and synchronization block in the CS5376

establishes synchronous timing when used in a dis-

tributed measurement network. An input SYNC

signal from the host system resets the modulator

CS5376

DS256PP1

11

sampling instant, digital filter phase, and test bit-

stream phase to ensure measurement timing is con-

sistent across the network.

Time Break Controller

The CS5376 time break controller places a timing

reference flag in the status bits of the digital filter

output word. This timing reference flag is used to

mark measurement events in the digital data, or as

a digital sync to align multiple data streams during

post-processing. An externally generated TIMEB

signal starts a programmable sample counter (used

to correct for digital filter group delay), and when

it expires the time break flag is set in the next out-

put data word.

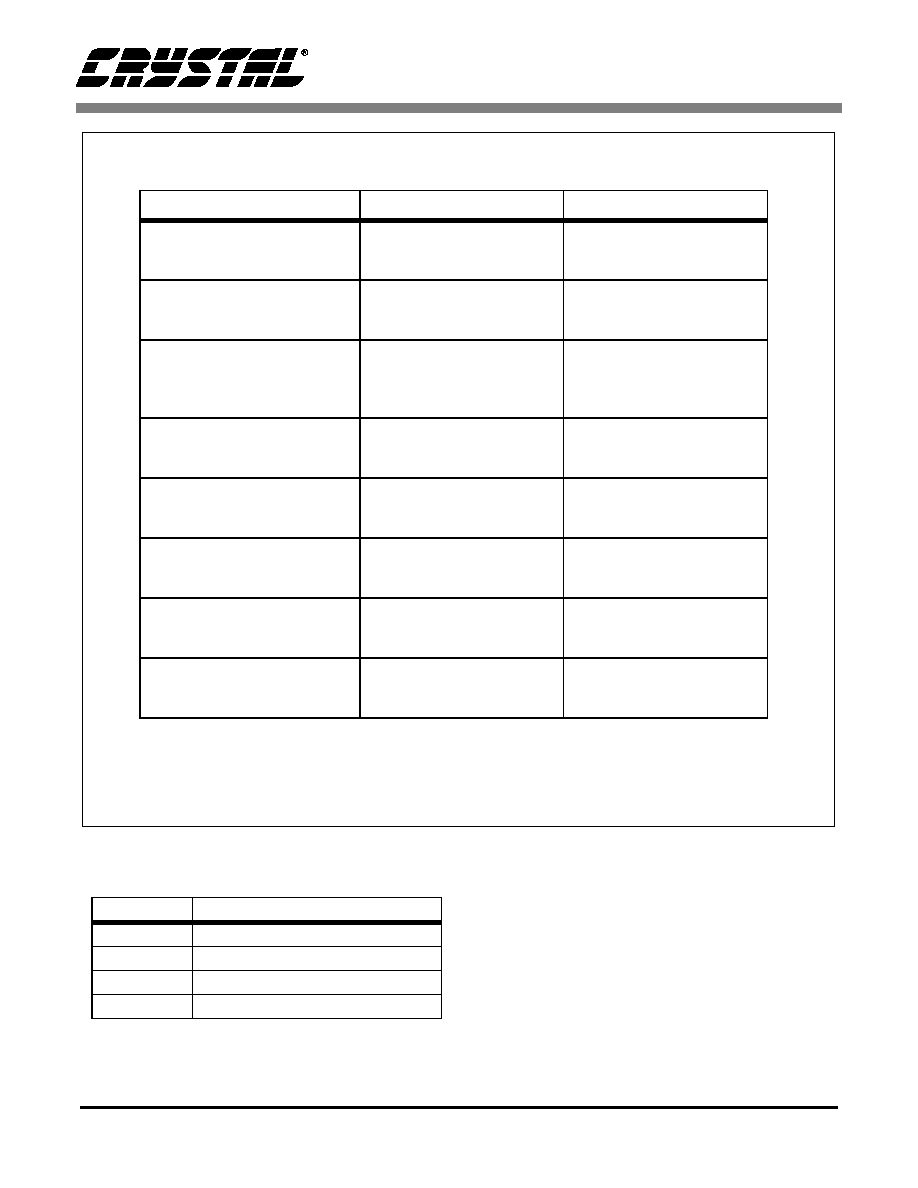

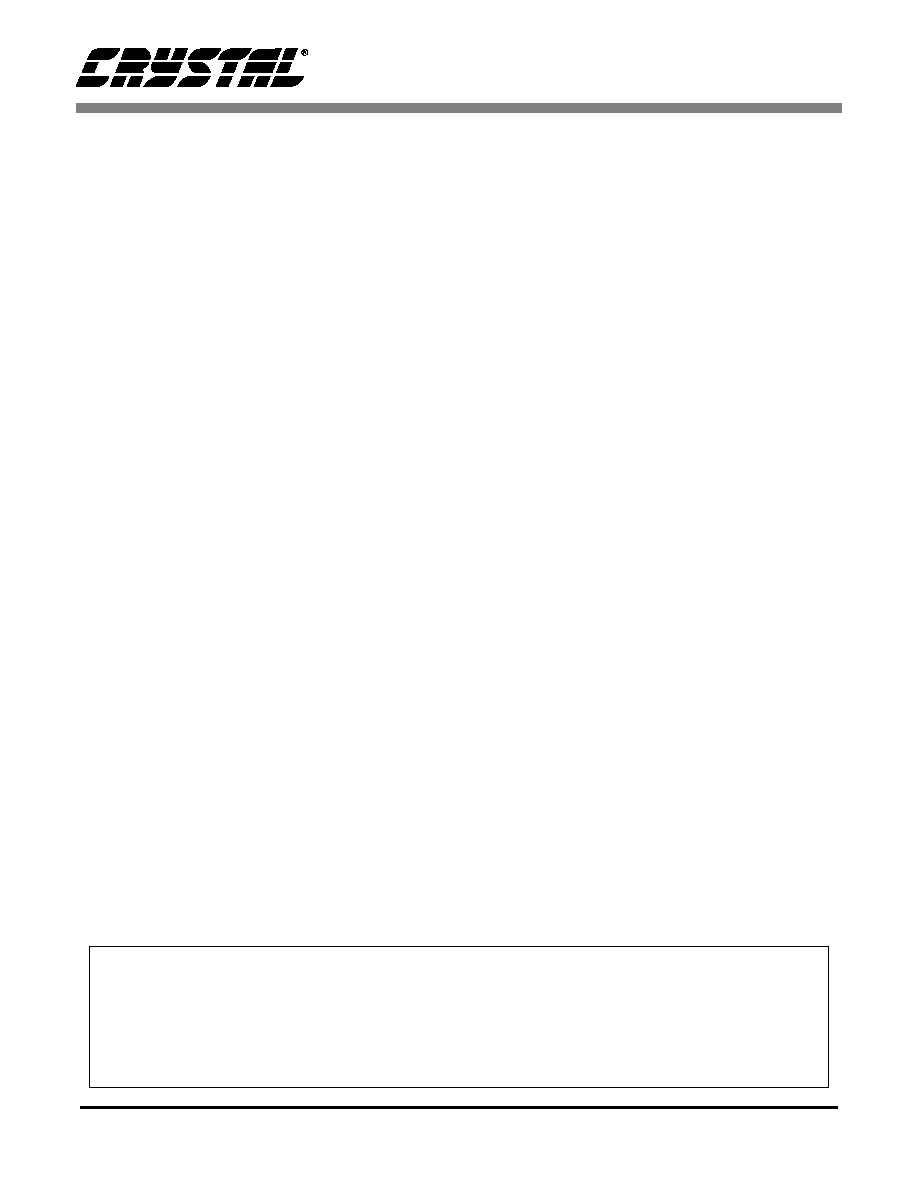

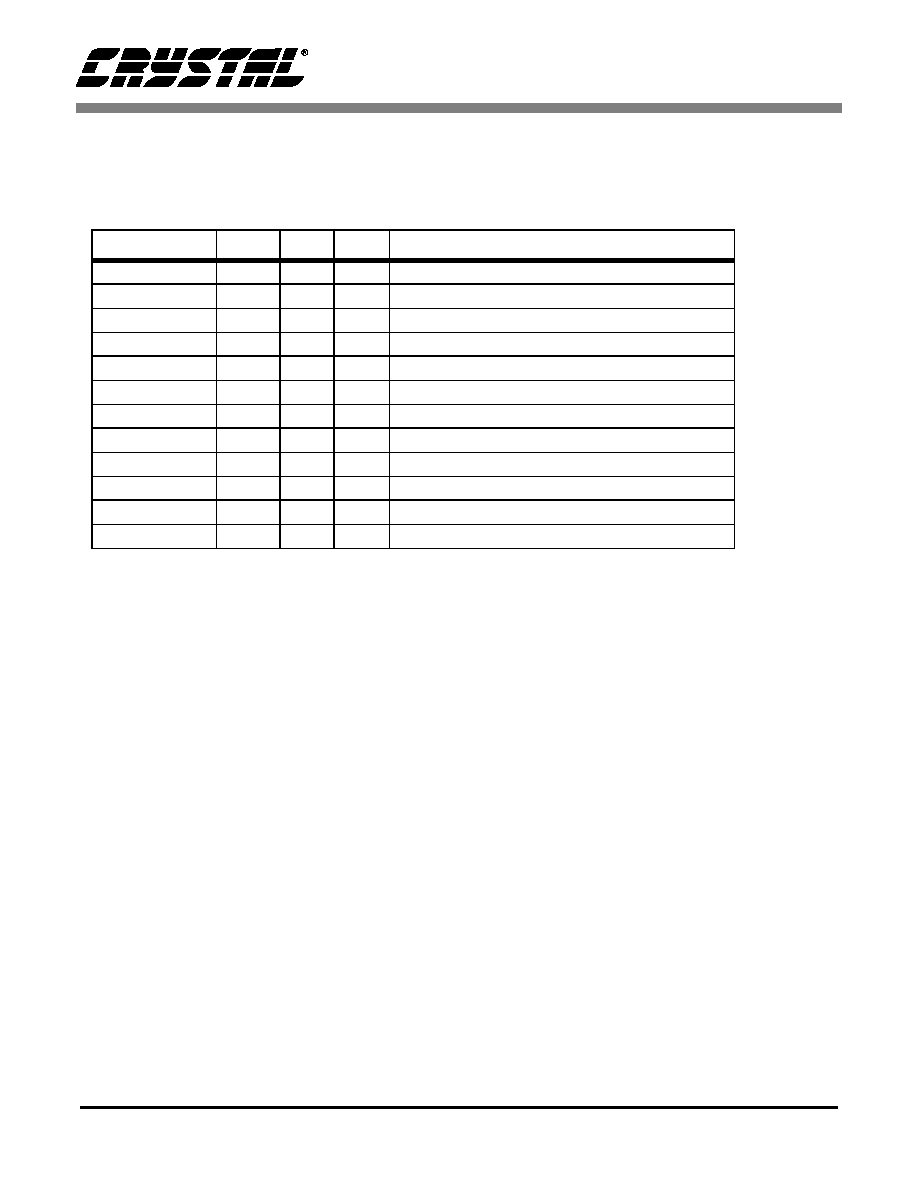

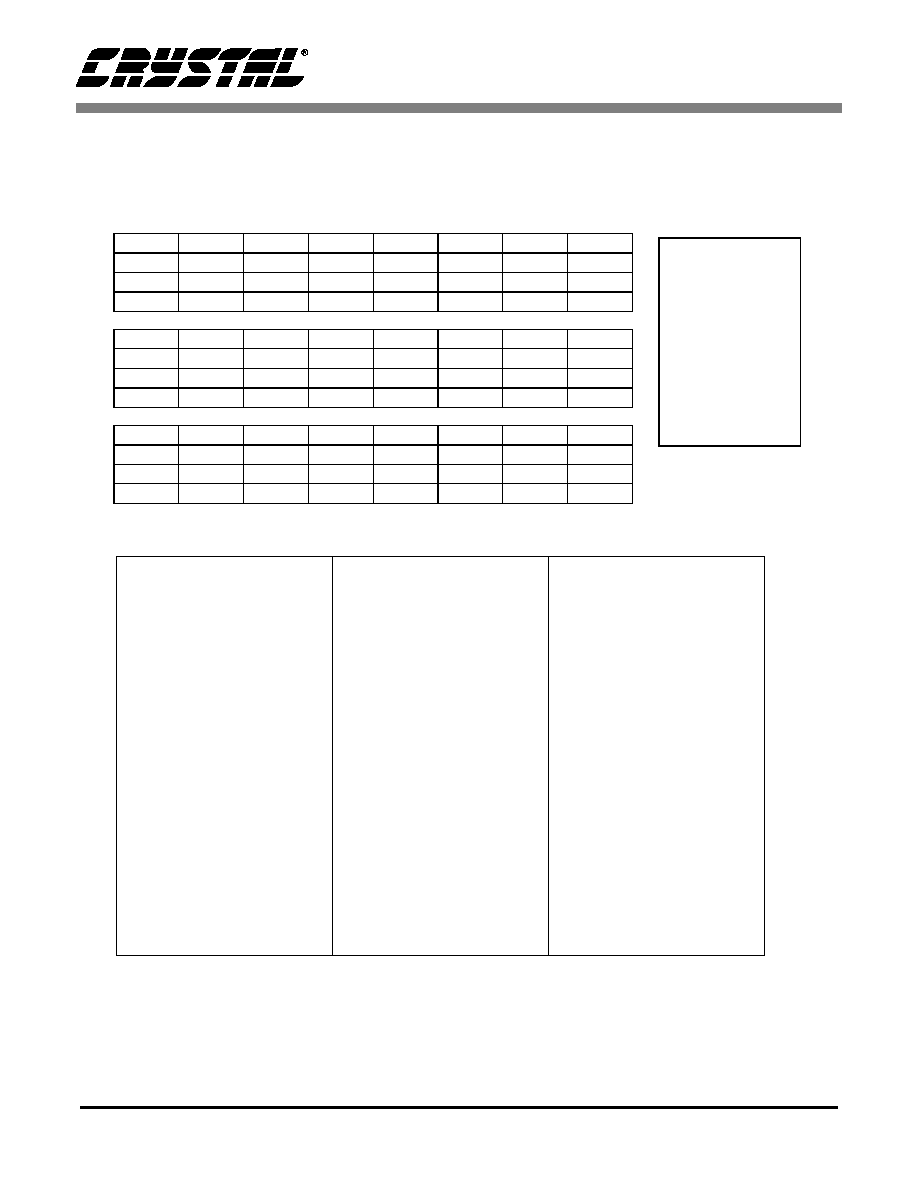

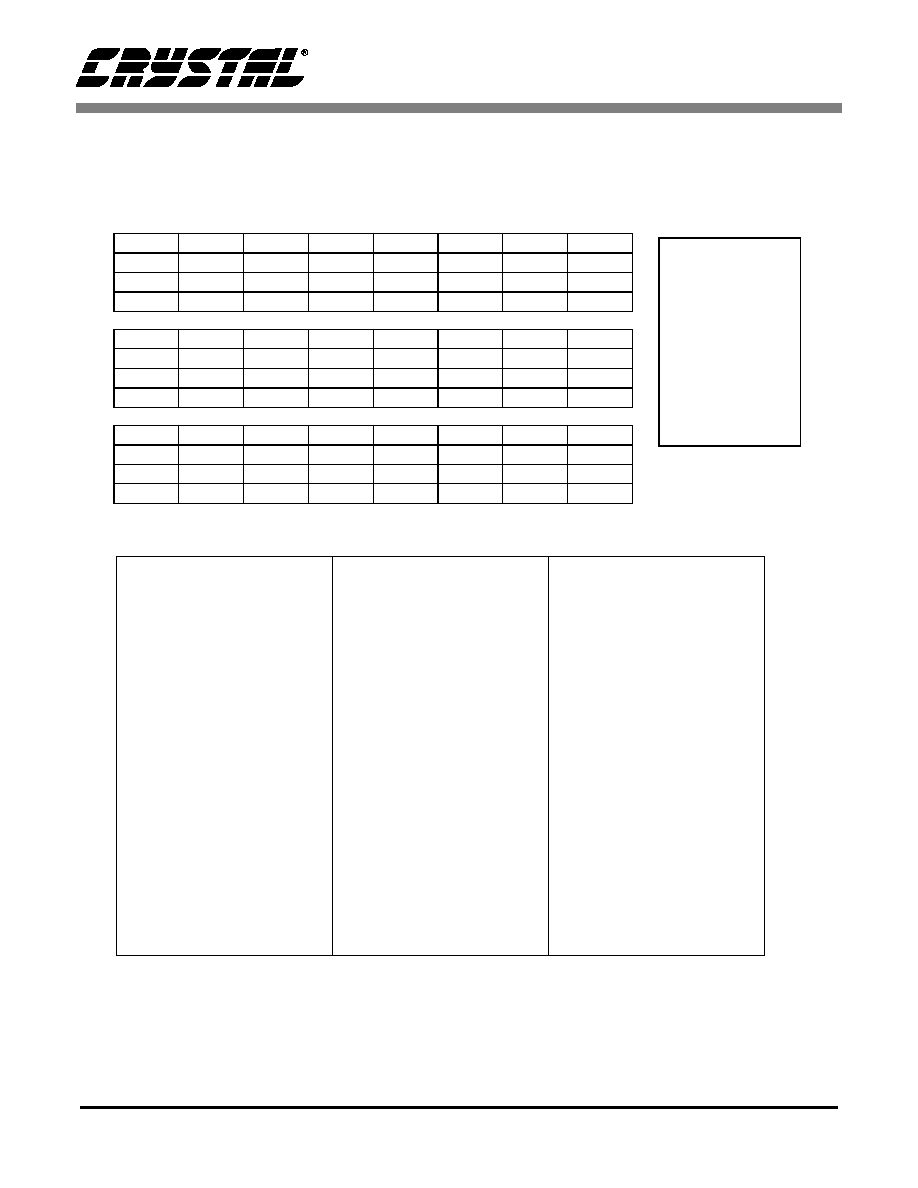

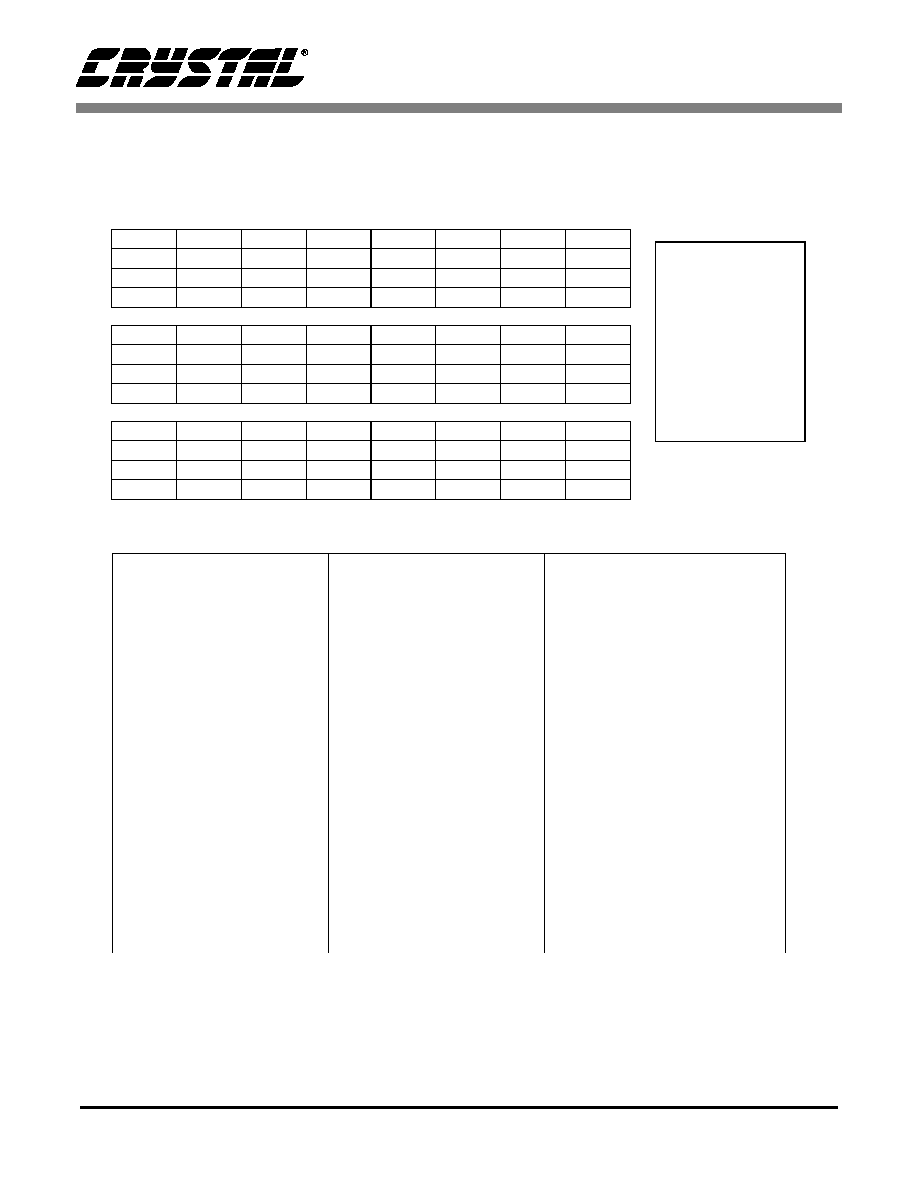

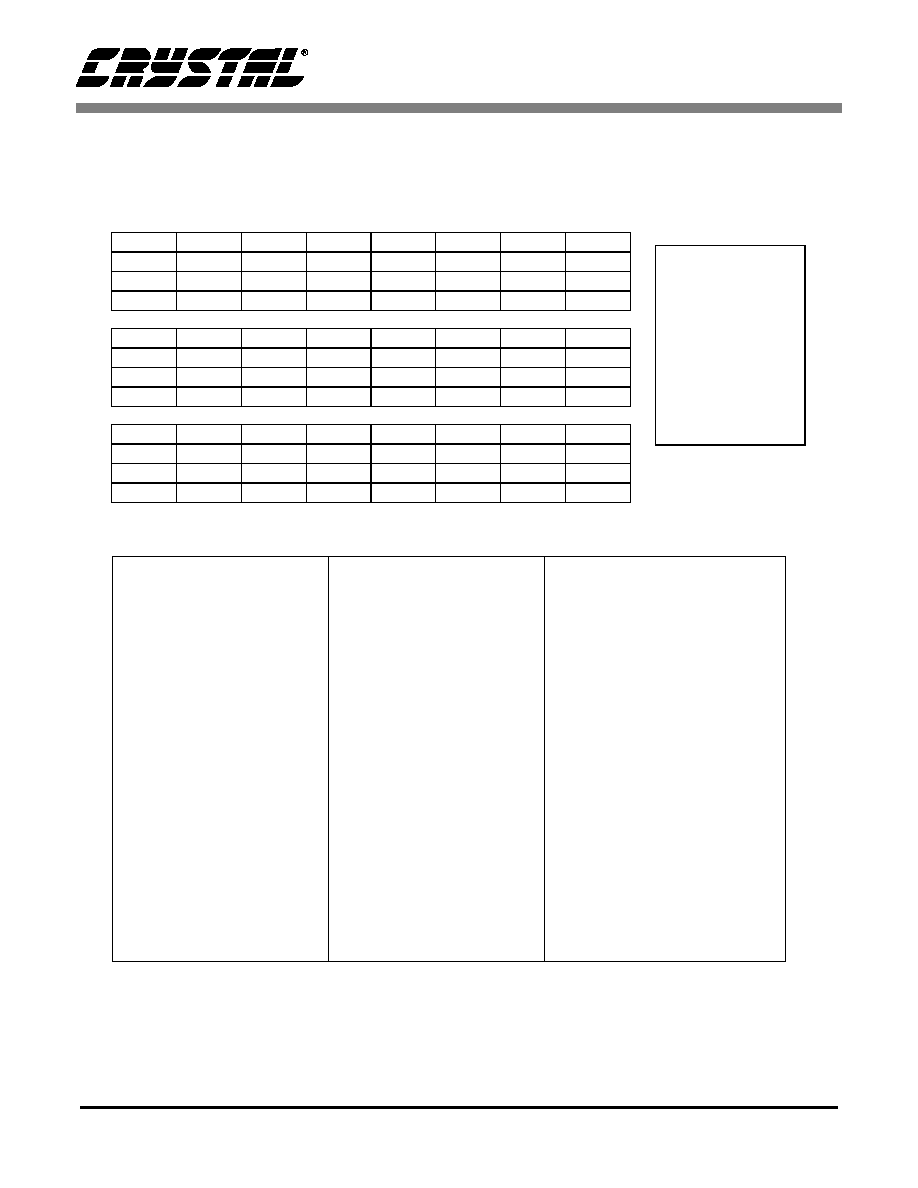

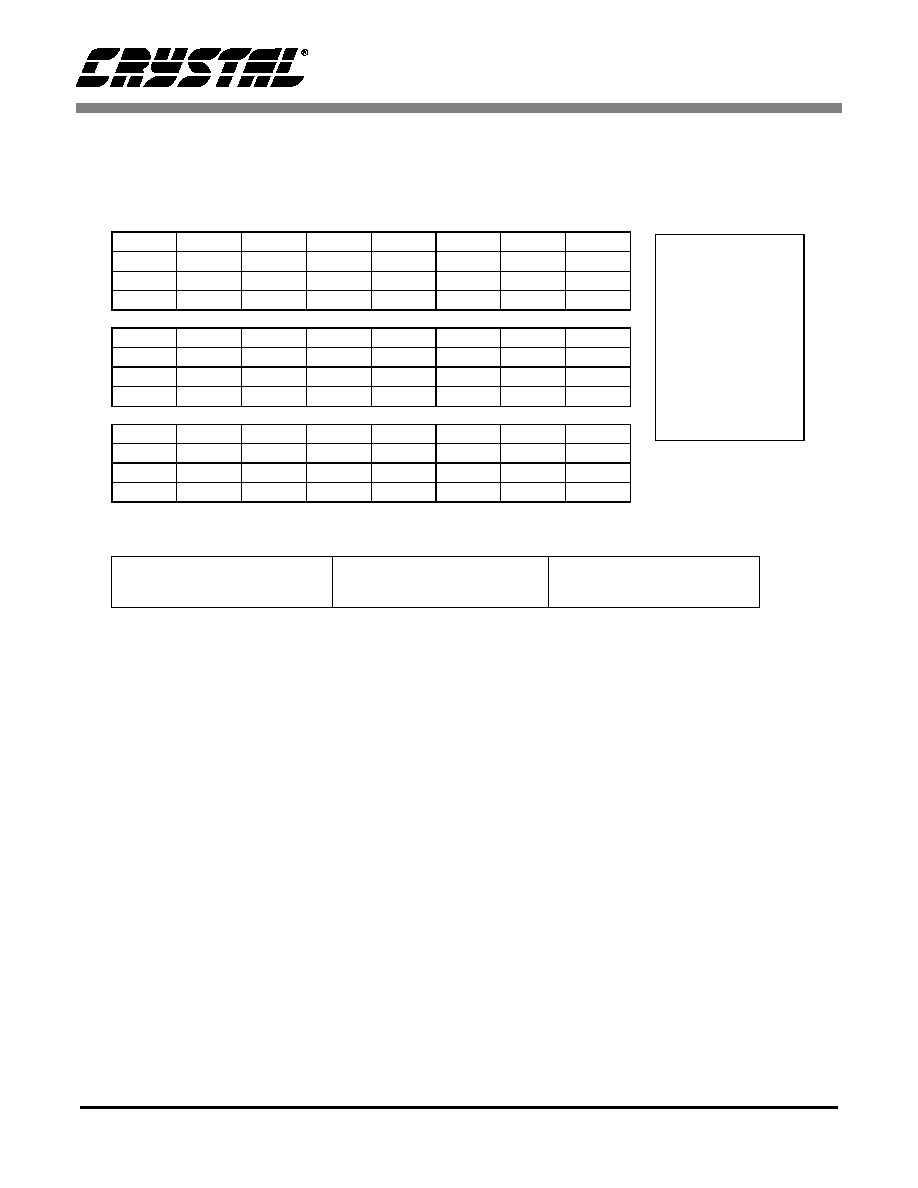

2.4 Register Descriptions

Decimation Engine Registers

Hardware functions and digital filter settings in the

CS5376 are controlled by registers in the decima-

tion engine. A summary of decimation engine reg-

isters is shown in Figure 6 on page 12. See

"Decimation Engine Registers" on page 99 for a

detailed listing of all decimation engine register bit

settings.

SPI 1 Registers

Decimation engine registers are not directly acces-

sible to the communication interface. Instead, they

are indirectly read and written using SPI 1 regis-

ters. See "Serial Peripheral Interface 1" on page 21

for a description of how to use the SPI 1 port to ac-

cess decimation engine registers.

Each 24-bit SPI 1 register is divided into three 8-bit

registers consisting of a high, mid, and low byte. A

summary of SPI 1 registers is shown in Figure 6 on

page 12. See "SPI 1 Registers" on page 94 for a de-

tailed listing of all SPI 1 register bit settings.

CS5376

DS256PP1

12

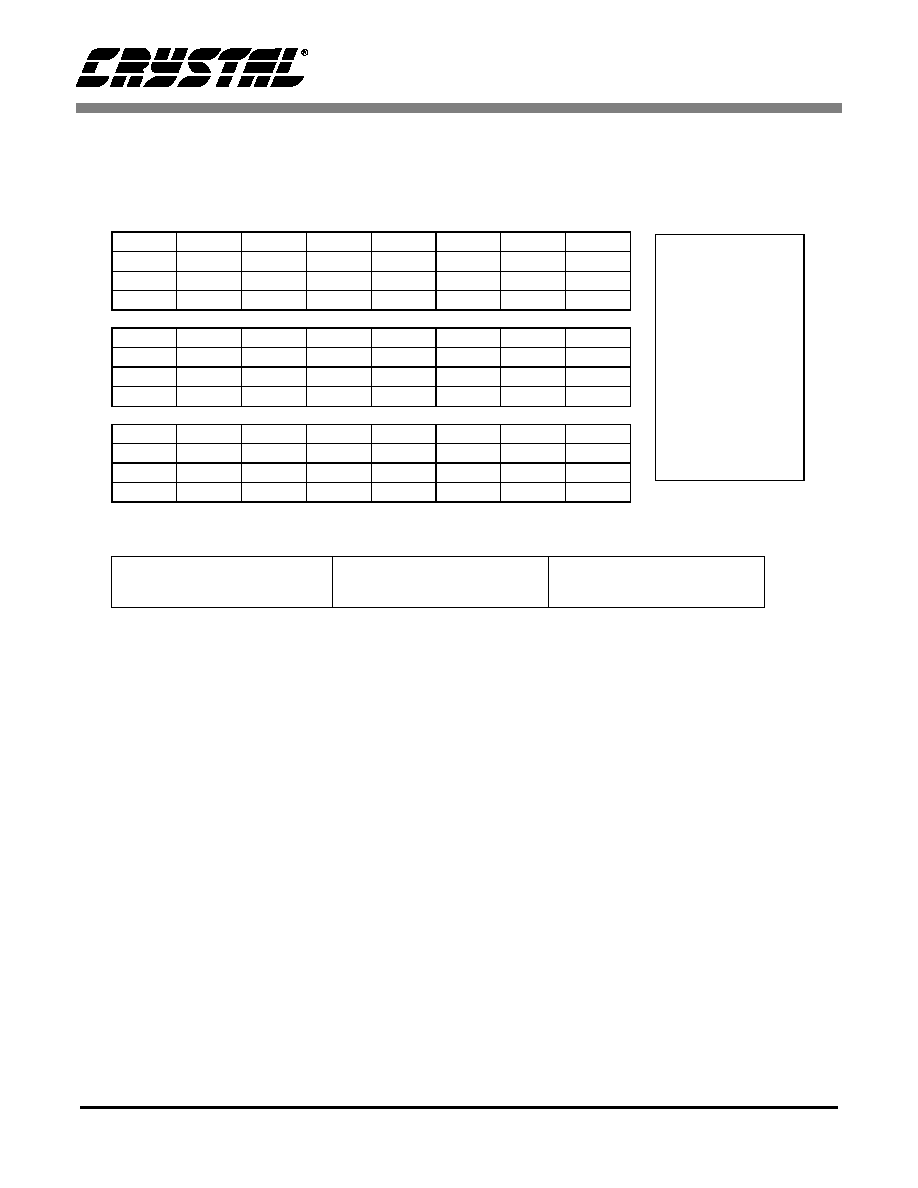

Decimation Engine Registers

SPI 1 Registers

Name

Addr.

Type

# Bits

Description

CONFIG

00

R/W

24

Decimation Engine Configuration

RESERVED

01-0D

R/W

24

Reserved

GPCFG0

0E

R/W

24

GPIO[7:0] Direction, Pullup Enable, and Data

GPCFG1

0F

R/W

24

GPIO[11:8] Direction, Pullup Enable, and Data

SPI2CTRL

10

R/W

24

SPI 2 Configuration

SPI2CMD

11

R/W

16

SPI 2 Command

SPI2DAT

12

R/W

24

SPI 2 Data

RESERVED

13-1F

R/W

24

Reserved

FILT_CFG

20

R/W

24

Filter Configuration

GAIN1

21

R/W

24

Gain Correction Channel 1

GAIN2

22

R/W

24

Gain Correction Channel 2

GAIN3

23

R/W

24

Gain Correction Channel 3

GAIN4

24

R/W

24

Gain Correction Channel 4

OFFSET1

25

R/W

24

Offset Correction Channel 1

OFFSET2

26

R/W

24

Offset Correction Channel 2

OFFSET3

27

R/W

24

Offset Correction Channel 3

OFFSET4

28

R/W

24

Offset Correction Channel 4

TIMEBRK

29

R/W

24

Time Break Counter Configuration

TBS_CFG

2A

R/W

24

Test Bit Stream Configuration

WD_CFG

2B

R/W

24

Watchdog Counter Configuration

SYSTEM1

2C

R/W

24

User Defined System Register 1

SYSTEM2

2D

R/W

24

User Defined System Register 2

VERSION

2E

R/W

24

Hardware Version ID

SELFTEST

2F

R/W

24

Self-Test Result Code

Name

Addr.

Type

# Bits

Description

SPI1CTRL

00 - 02

R/W

8, 8, 8

SPI 1 Control Register

SPI1CMD

03 - 05

R/W

8, 8, 8

DE <-> SPI 1 Command

SPI1DAT1

06 - 08

R/W

8, 8, 8

DE <-> SPI 1 Data 1

SPI1DAT2

09 - 0B

R/W

8, 8, 8

DE <-> SPI 1 Data 2

Figure 6. Decimation Engine and SPI 1 Registers

CS5376

DS256PP1

13

3. SYSTEM DESIGN

System issues to consider when designing with the

CS5376 include power supply voltages, distribu-

tion of clock and synchronization signals, connec-

tions for EEPROM reprogramming, connections

for boundary scan testing, and extra circuitry re-

quired for functional tests.

3.1 Power Supply Voltages

The CS5376 has three sets of power supply inputs.

Two sets supply power to the I/O pins of the chip

(VDD1, VDD2), and the third set supplies power to

the logic core (VD). The I/O pin power supplies de-

termine the maximum input and output voltages

when interfacing to peripherals, and the logic core

power supply determines the power consumption

of the CS5376.

The voltage choice for a specific power supply de-

pends on two considerations.

1) Available voltages.

It's simpler to drive all power supplies from a sin-

gle 5 V or 3.3 V supply if it's already available in

the design. This reduces system cost by eliminating

additional voltage regulators. Power sensitive ap-

plications, however, will require a 3 V supply into

the logic core to minimize power consumption.

2) Required interface voltages.

The two I/O pin power supplies are separated into

a `modulator side' and a `microcontroller side'. If

some elements in the design are specified to inter-

face at 5 V and other elements in the design are

specified to interface at another voltage, 3.3 V for

example, the I/O pin power supplies can be inde-

pendently driven to match.

VDD1, GND1 - Pins 54, 53

This I/O pin power supply sets the interface voltage

to the microcontroller, communications channel,

and related peripherals.

Pins driven by the VDD1 power supply are:

·

RESET, BOOT, CLK, SYNC, TIMEB

·

SSI, SCK1, MOSI, MISO, SINT, SSO

·

SDTKI, SDRDY, SDCLK, SDDAT, SDTKO

·

GPIO6 - GPIO11

·

TRST, TMS, TCK, TDI, TDO

VDD2, GND2 - Pins 11, 25, 24, 38

This I/O pin power supply sets the interface voltage

to the modulators, test DAC, and related peripher-

als.

Pins driven by the VDD2 power supply are:

·

MDATA1 - MDATA4, MFLAG1 - MFLAG4

·

MCLK, MCLK/2, MSYNC

·

SCK2, SI1 - SI4, SO

·

TBSCLK, TBSDATA

·

GPIO0 - GPIO5

VD, GND - Pins 7, 40, 6, 23, 39

This power supply sets the operational voltage for

the CS5376 logic core. Lowering this voltage to

3 V will minimize power consumption.

3.1.1

Bypass Capacitors

All power supply pins should be bypassed to pro-

vide noise immunity. The bypass capacitors should

be placed as close as possible to the pins of the

CS5376, between the power supply pin and its as-

sociated ground. Suggested values for bypass ca-

pacitors are two parallel caps of 1

µF and 0.01 µF,

or a single cap of 0.1

µF. Bypass capacitors can be

ceramic, tantalum, or any other dielectric type.

3.2 Clock and Synchronization Signals

Many applications of the CS5376 will use a multi-

channel distributed measurement network. To be

useful, data collection must occur with synchro-

nous timing between the measurement channels.

CS5376

DS256PP1

14

Careful design of a clock distribution and synchro-

nization network is crucial for keeping these timing

relationships consistent.

CLK - Pin 58

The CS5376 master clock pin, CLK, has a nominal

input frequency of 32.768 MHz. A slower master

clock can be used if the frequencies from the gen-

erated clocks (MCLK, MCLK/2, SCK1, SCK2,

and TBSCLK) are permitted to run slower. The

CS5376 is a fully static design and can have the

master clock gated off to place the system in a low-

power standby mode.

3.2.1

Master Clock Jitter and Skew

The clock distribution network should supply a

low-jitter, low-skew master clock signal. Clock jit-

ter on the master clock pin, CLK, will result in jitter

on all generated clocks. Jitter on the modulator

clocks (MCLK, MCLK/2) and the test bit stream

clock (TBSCLK) will cause inaccurate conversions

of analog-to-digital and digital-to-analog signals.

Great care should be taken to ensure recovered

clocks have as low jitter as possible.

Clock skew across a measurement network will

cause inaccurate results when reconstructing mea-

surement data during post-processing. By making

measurements at slightly different instants in time,

sensors with clock skew between them cause sig-

nals to appear slower or faster than reality. A good

measurement network design should minimize

clock skew.

3.2.2

Synchronization Jitter and Skew

Similar problems face the distribution of the SYNC

signal. The SYNC input on the CS5376 aligns the

internal clock edges and digital filter phase to the

external system, establishing a precise timing rela-

tionship across the measurement network. Jitter

and skew on the input SYNC signal will result in

phase errors in the CS5376 digital filter data.

The SYNC signal is also used to generate the

MSYNC signal to the modulators. The MSYNC

signal synchronizes the modulator sampling instant

and ensures all modulators are operating with iden-

tical timing across the network. Since the sampling

instant is defined by the MSYNC signal, errors

generating the SYNC signal will result in measure-

ment timing errors by the modulators.

See "System Synchronization" on page 77 for

more information on synchronizing the CS5376

measurement system.

3.3 EEPROM Programming

The CS5376 in stand-alone mode automatically

boots from EEPROM after reset. The configuration

EEPROM holds the commands and data needed to

initialize the system into a fixed operational state.

If stand-alone boot mode is used, the system should

include a way to address the configuration EE-

PROM for in-circuit reprogramming. This can be

performed locally by a technician through a con-

nector, or remotely through the communications

channel.

See "Serial Peripheral Interface 1" on page 21 for

more information about booting the CS5376 using

an EEPROM.

3.4 Boundary Scan Testing

During system design and in the field, in-circuit

testing is a valuable diagnostic tool. The CS5376

JTAG test port enables boundary scan testing by

providing access to all pins via internal boundary

scan cells. To use the JTAG test port, a system de-

sign must provide in-circuit access to the CS5376

JTAG pins (TRST, TMS, TCK, TDI, and TDO).

They can be accessed locally by a technician

through a connector, or remotely through the com-

munications channel.

See "JTAG Test Port (IEEE 1149.1)" on page 89

for more information on the JTAG test port.

CS5376

DS256PP1

15

3.4.1

TRST and RESET Pins

As required by the IEEE 1149.1 specification, the

JTAG reset signal, TRST, is independent of the

CS5376 reset signal, RESET. The status of the

TRST pin should be considered during system de-

sign since the TAP controller must be reset before

using the JTAG port.

In systems not using the JTAG test port, the TRST

pin can be connected directly to the RESET pin, or

can be connected to ground. In systems using the

JTAG test port, the TRST and RESET pins should

be independently driven to provide reset capability

during boundry scan.

3.5 Functional Testing

While boundary scan testing gives the ability to

check connections between circuit elements, test-

ing the functionality of the circuit elements them-

selves requires operation of the measurement

channel.

3.5.1

Analog Test DAC

To test the full signal path of a CS5376 system, an

analog test signal should be applied to the modula-

tor inputs. The CS5376 provides a test bit stream

generator that produces a

- bit stream suitable

for driving an external test DAC. The analog output

signal from the DAC can be multiplexed to the in-

puts of the measurement channel through relays or

analog multiplexers. Switching the analog test sig-

nal into the measurement channel is typically per-

formed on command from the communication

channel, and requires appropriate control signals to

be defined during system design.

Included as part of the CS5376 test bit stream gen-

erator is an internal feedback path into the digital

filters. This loopback mode provides a fully digital

signal path to test the digital filters and communi-

cations interface. If this is the only test mode used,

no external circuitry is required.

See "Test Bit Stream Generator" on page 81 for

more information about using the test bit stream

generator.

3.5.2

Step Input and Group Delay

Characterizing the step response of a combination

analog and digital measurement channel can be dif-

ficult. A simple method to empirically measure the

step response and group delay through the analog

and digital portions of a CS5376 measurement

channel is to use the time break signal as both a tim-

ing reference and an analog step input. This test re-

quires the system design to include relays or analog

multiplexers to connect the time break signal to the

analog inputs.

See "Time Break Function" on page 75 for more

information about the time break signal.

3.6 System Registers

Several registers are included in the CS5376 for

system information.

The VERSION register (0x2E) in the decimation

engine holds hardware version ID information.

Two registers in the decimation engine, SYSTEM1

and SYSTEM2 (0x2C, 0x2D), are provided for

user defined system information. These are general

purpose registers and will hold any 24-bit data val-

ues written to them.

CS5376

DS256PP1

16

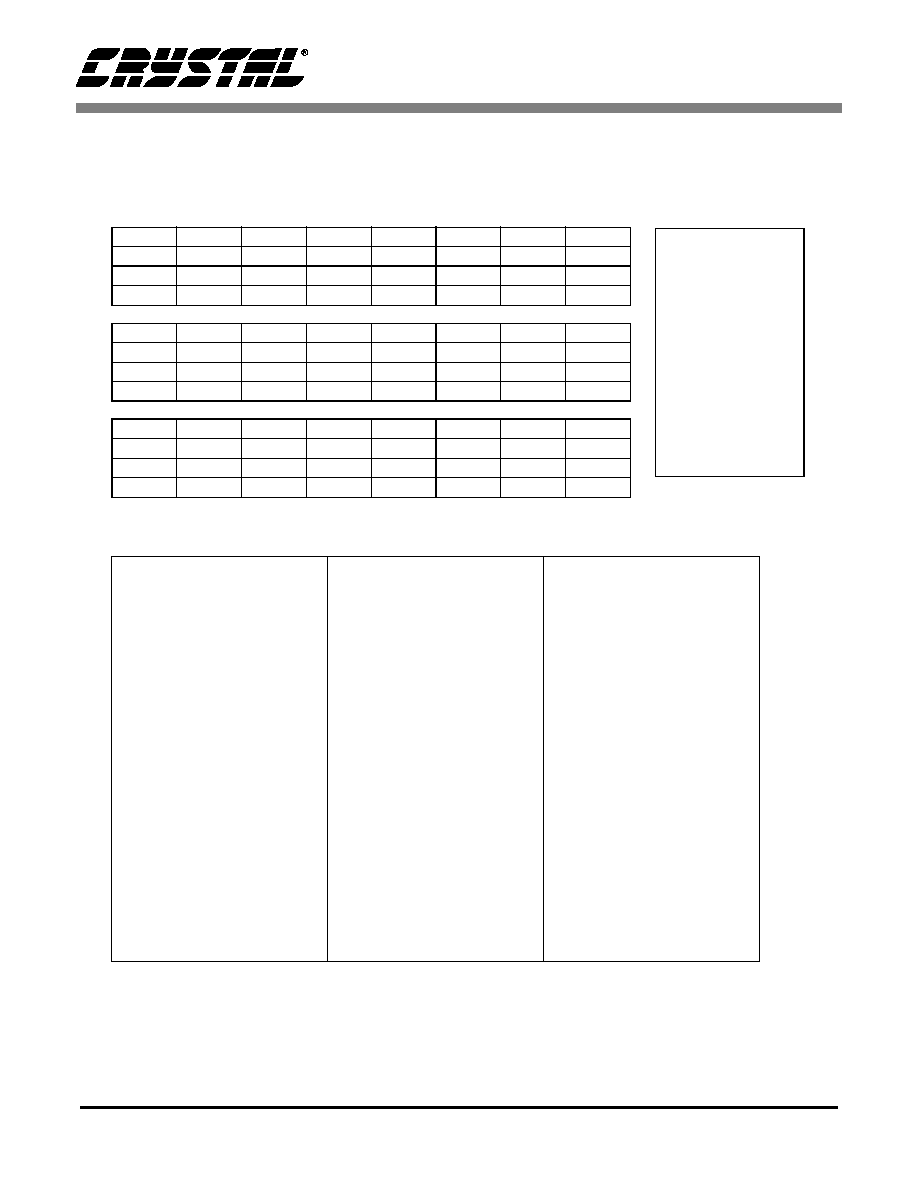

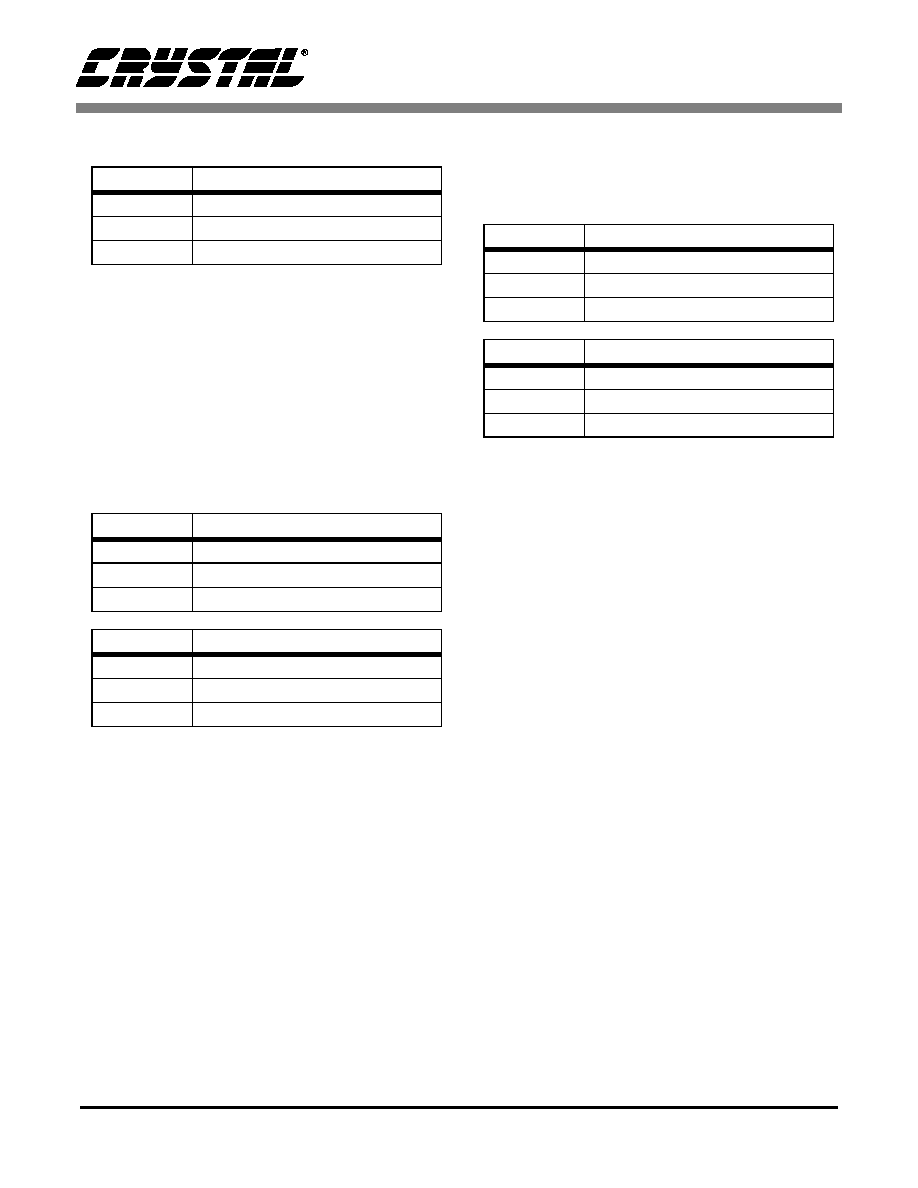

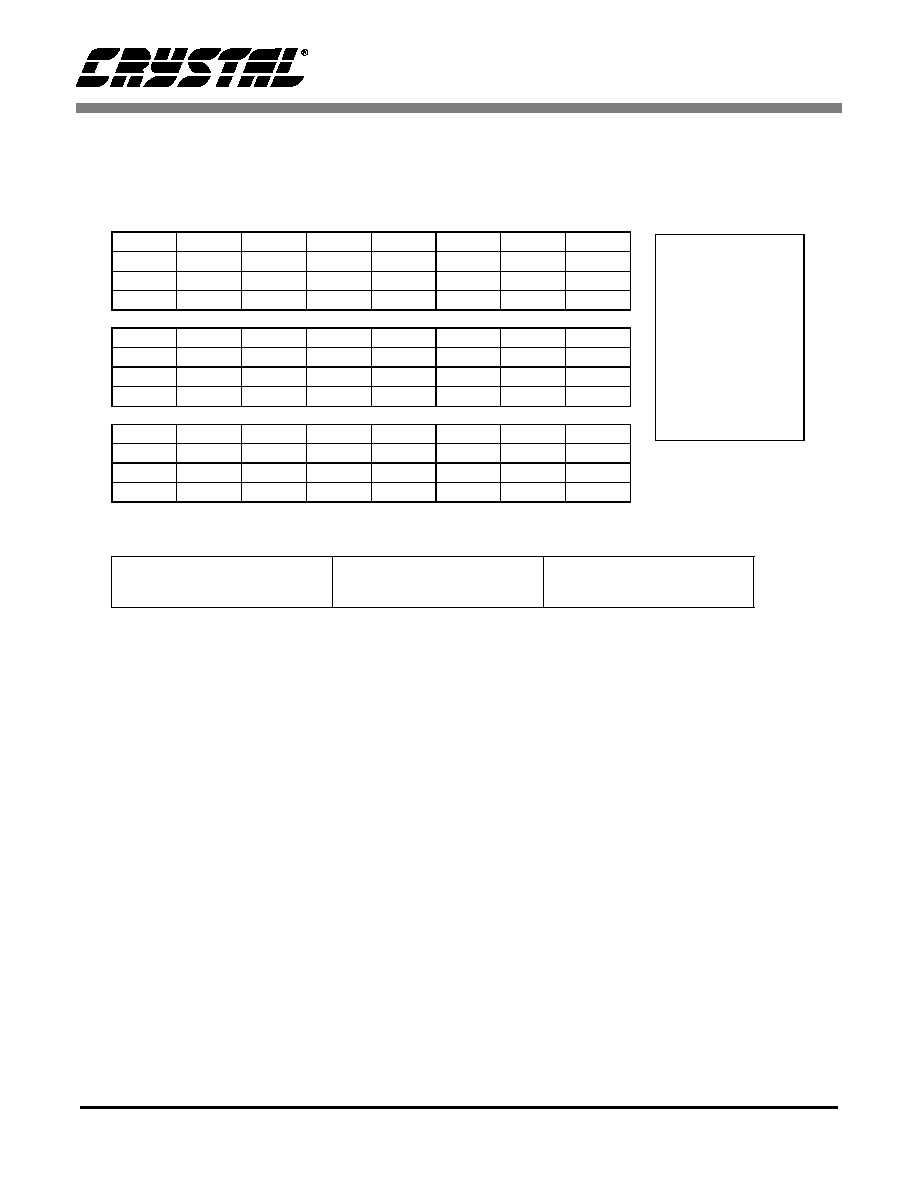

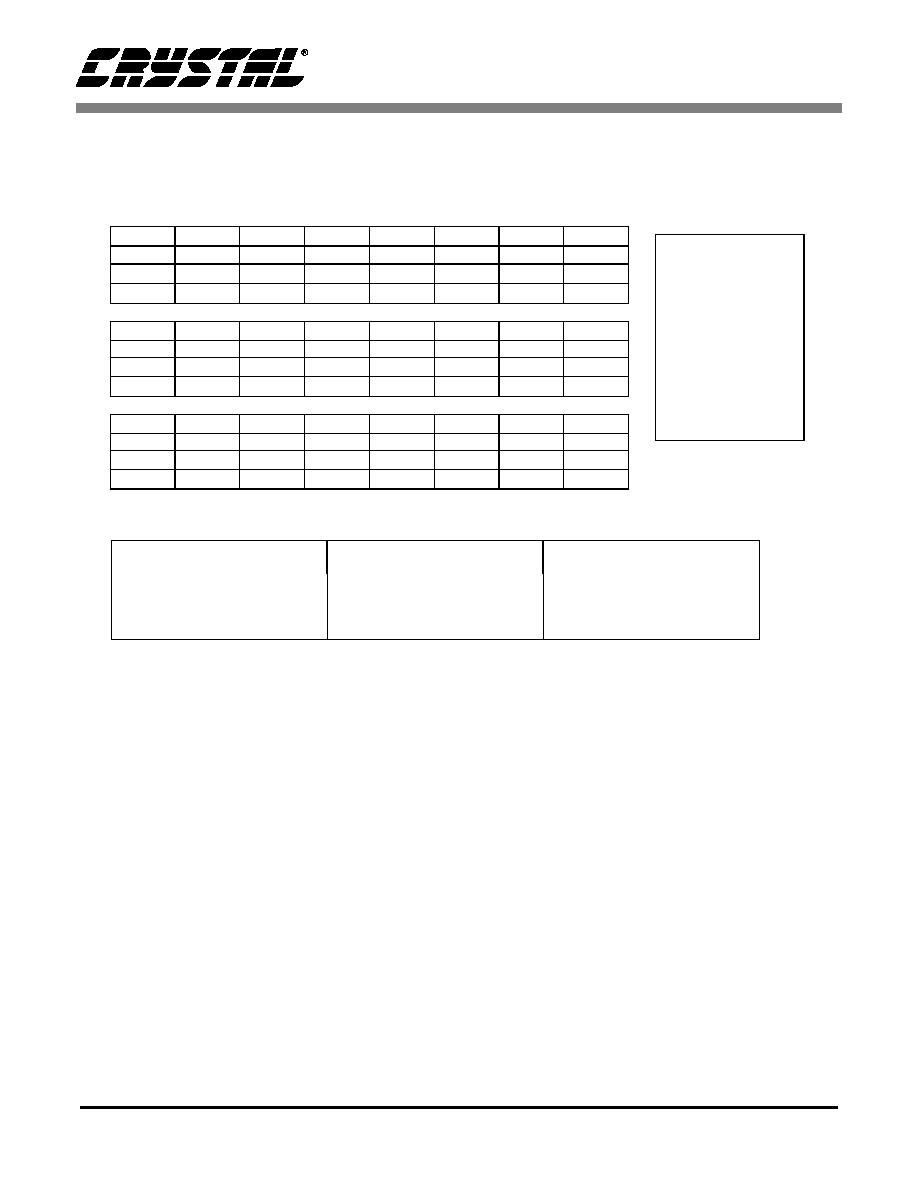

3.6.1

VERSION Register - 0x2E

(MSB) 23

22

21

20

19

18

17

16

TYPE7

TYPE6

TYPE5

TYPE4

TYPE3

TYPE2

TYPE1

TYPE0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

1

1

1

0

1

1

0

15

14

13

12

11

10

9

8

HW7

HW6

HW5

HW4

HW3

HW2

HW1

HW0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

1

7

6

5

4

3

2

1

(LSB) 0

ROM7

ROM6

ROM5

ROM4

ROM3

ROM2

ROM1

ROM0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

1

I/O Address: 0x2E

--

Not defined;

read as 0

R

Readable

W

Writable

R/W

Readable and

Writable

Bits in bottom rows

are reset condition

Figure 7. Hardware Version ID Register VERSION

Bit definitions:

23:16 TYPE

[7:0]

Chip Type

76 - CS5376

15:8

HW

[7:0]

Hardware Revision

01 - Rev A

7:4

ROM

[7:0]

ROM Version

01 - Ver 1.0

CS5376

DS256PP1

17

3.6.2

SYSTEM1, SYSTEM2 Registers - 0x2C, 0x2D

(MSB) 23

22

21

20

19

18

17

16

SYS23

SYS22

SYS21

SYS20

SYS19

SYS18

SYS17

SYS16

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

0

15

14

13

12

11

10

9

8

SYS15

SYS14

SYS13

SYS12

SYS11

SYS10

SYS9

SYS8

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

0

7

6

5

4

3

2

1

(LSB) 0

SYS7

SYS6

SYS5

SYS4

SYS3

SYS2

SYS1

SYS0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

0

0

0

0

I/O Address: 0x2C

--

Not defined;

read as 0

R

Readable

W

Writable

R/W

Readable and

Writable

Bits in bottom rows

are reset condition

Figure 8. User Defined System Register SYSTEM1

Bit definitions:

23:16 SYS[23:16]

System Register

Upper Byte

15:8

SYS[15:8]

System Register

Middle Byte

15:8

SYS[7:0]

System Register

Lower Byte

CS5376

DS256PP1

18

4. RESET CONTROL

When the RESET signal is released, the CS5376

automatically performs a series of self-tests. De-

pending on the state of the BOOT pin, it then either

actively boots from EEPROM or waits for config-

uration information to be written by a microcon-

troller.

4.1 Reset Pin Descriptions

RESET - Pin 55

RESET is an active low signal that places the

CS5376 into a reset state when asserted.

BOOT - Pin 56

The BOOT signal selects how the CS5376 loads

configuration information. The logic state of this

pin is latched 1

µs after RESET is released to select

between coprocessor or stand-alone boot modes. A

logical low selects coprocessor boot mode, a logi-

cal high selects stand-alone boot mode.

4.2 Boot Configurations

When booting in coprocessor mode, a microcon-

troller or other SPI bus master is required to write

configuration information. When booting in stand-

alone mode, the CS5376 reads configuration infor-

mation from EEPROM and no microcontroller is

required. A hybrid mode can also be used which

reads an initial configuration from EEPROM and

then writes changes using a microcontroller.

Coprocessor Mode

Coprocessor mode is designed for systems required

to run multiple configurations from a common set

of hardware. The ability to change configurations

in real time gives maximum flexibility in the field.

This mode requires a microcontroller or other SPI

bus master to be connected to the CS5376 SPI 1

port. The microcontroller can rewrite the filter co-

efficients, change the filter output stage, enable and

disable the test bit stream, and manually update the

gain and offset correction values during operation.

To set the CS5376 configuration, the microcontrol-

ler writes a series of command and data values to

the decimation engine through the SPI 1 port. See

"Serial Peripheral Interface 1" on page 21 for more

information on connecting a microcontroller to the

SPI 1 port.

Stand-Alone Mode

If the CS5376 is designed into a system with a fixed

configuration, no microcontroller is required.

Stand-alone mode boots from EEPROM to a fixed

configuration and immediately begins operation.

The EEPROM contains all configuration informa-

tion including filter coefficients, register settings,

and test bit stream data.

It might not be possible to know the gain and offset

correction values in advance of deploying a system.

If the configuration EEPROM is in-circuit repro-

grammable, the system can be booted with offset

and gain correction disabled and the appropriate

correction values calculated. The new correction

values can then be programmed into the EEPROM

and the CS5376 re-booted with gain and offset cor-

rection enabled.

See "Serial Peripheral Interface 1" on page 21 for

more information on booting from a configuration

EEPROM, and the format required for EEPROM

data.

Hybrid Mode

A boot configuration that requires more engineer-

ing effort to implement is a hybrid

coprocessor / stand-alone boot mode. In hybrid

mode the CS5376 initially boots in stand-alone

mode from a configuration EEPROM. After boot-

ing, a microcontroller updates the configuration in-

formation in coprocessor mode by writing

commands to the decimation engine through the

SPI 1 port.

Hybrid mode is more complex at the system level

because it requires the ability to tri-state the micro-

CS5376

DS256PP1

19

controller to SPI 1 connection during the initial EE-

PROM boot. After the initial configuration is

loaded, the microcontroller seizes control of the

SPI 1 port and updates the configuration as re-

quired. The EEPROM will not interfere with mi-

crocontroller to SPI 1 transactions provided the

initial stand-alone boot was completed.

Updated configuration information from the micro-

controller can not be written until the EEPROM

boot loader has relinquished control of the SPI 1

port. To guarantee this, the microcontroller should

monitor the CS5376 CS11 / GPIO11 pin into the

EEPROM for inactivity, or simply wait the maxi-

mum time required to boot from EEPROM. The re-

quired boot time from EEPROM depends on the

number of coefficients written, the number of reg-

isters written, and if test bit stream data is written.

A final requirement for hybrid boot mode is the

ability to address both the CS5376 and the config-

uration EEPROM. When writing to the CS5376

SPI 1 port, serial transactions use an 8-bit address.

Supported serial EEPROMs, however, require seri-

al transactions to use 16-bit addressing. If a micro-

controller is to interface with the CS5376 and also

be able to in-circuit reprogram the configuration

EEPROM, the serial port connection must support

both addressing modes.

See "Serial Peripheral Interface 1" on page 21 for

information about connections to the SPI 1 port,

the format required for EEPROM data, and the

SPI 1 commands available for updating the config-

uration.

4.3 Reset Self-Tests

After the reset signal is de-asserted but before the

CS5376 starts the boot operation, a series of self

test are run. These tests check the operation of the

decimation engine and report pass/fail codes in the

SELFTEST register (0x2F). The full suite of self

tests require approximately 60ms to complete.

Program ROM Test

This self-test calculates a checksum from the con-

tents of program ROM and compares against an ex-

pected value. The result of this test is 0x00000A if

passed or 0x00000F if failed.

Data ROM Test

This self-test calculates a checksum from the con-

tents of data ROM and compares against an expect-

ed value. The result of this test is 0x0000A0 if

passed or 0x0000F0 if failed.

Program RAM Test

This self-test writes a series of patterns into the pro-

gram RAM and compares against expected read

values. The result of this test is 0x000A00 if passed

or 0x000F00 if failed.

Data RAM Test

This self-test writes a series of patterns into the data

RAM and compares against expected read values.

The result of this test is 0x00A000 if passed or

0x00F000 if failed.

Execution Unit Test

This self-test exercises the execution unit with a se-

quence of calculations, comparing against expect-

ed values. The result of this test is 0x0A0000 if

passed or 0x0F0000 if failed.

CS5376

DS256PP1

20

4.3.1

SELFTEST Register - 0x2F

(MSB) 23

22

21

20

19

18

17

16

--

--

--

--

EU3

EU2

EU1

EU0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

0

0

0

0

1

0

1

0

15

14

13

12

11

10

9

8

DRAM3

DRAM2

DRAM1

DRAM0

PRAM3

PRAM2

PRAM1

PRAM0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

1

0

1

0

1

0

1

0

7

6

5

4

3

2

1

(LSB) 0

DROM3

DROM2

DROM1

DROM0

PROM3

PROM2

PROM1

PROM0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

1

0

1

0

1

0

1

0

I/O Address: 0x2F

--

Not defined;

read as 0

R

Readable

W

Writable

R/W

Readable and

Writable

Bits in bottom rows

are reset condition

Figure 9. Self Test Result Register SELFTEST

Bit definitions:

23:20 --

reserved

15:12 DRAM

[3:0]

Data RAM Test

`A': Pass

`F': Fail

7:4

DROM

[3:0]

Data ROM Test

`A': Pass

`F': Fail

19:16 EU

[3:0]

Execution Unit Test

`A': Pass

`F': Fail

11:8

PRAM

[3:0]

Program RAM Test

`A': Pass

`F': Fail

3:0

PROM

[3:0]

Program ROM Test

`A': Pass

`F': Fail

CS5376

DS256PP1

21

5. SERIAL PERIPHERAL INTERFACE 1

The Serial Peripheral Interface 1 (SPI 1) port is an

industry standard master / slave SPI interface, and

is the primary interface to the CS5376 decimation

engine. The port operates as an SPI bus master

when booting from a configuration EEPROM in

stand-alone mode, and as an SPI slave when com-

municating with a microcontroller in coprocessor

mode.

Master Mode

The SPI 1 port operates in master mode only while

loading configuration information from EEPROM

during stand-alone boot mode. In this mode the

CS5376 actively initiates serial transactions to read

configuration register values, digital filter coeffi-

cients, and test bit stream data from EEPROM

memory. After booting from EEPROM, the SPI 1

port reverts to slave mode to interface with a micro-

controller, if present.

Master mode serial transactions in the CS5376 gen-

erate a chip select output on the CS11 / GPIO11

pin, and a serial clock output on the SCK1 pin. Se-

rial data is output from the CS5376 on the MOSI

pin, and input from the EEPROM on the MISO pin.

To be compatible with many serial EEPROMs,

transactions in master mode use 16-bit addresses,

different from the 8-bit addresses required when

accessing the CS5376 in slave mode.

Slave Mode

When booting from a microcontroller in coproces-

sor mode, or after booting from EEPROM in stand-

alone mode has completed, the SPI 1 port operates

in slave mode. In slave mode the CS5376 is pas-

sive, with serial transactions initiated by a micro-

controller or other SPI bus master. The

microcontroller uses SPI 1 commands to write con-

figuration register values, digital filter coefficients,

and test bit stream data from a local memory or

from the communications channel.

Slave mode serial transactions require the micro-

controller to use the SSI pin as the CS5376 chip se-

lect, and to generate a serial clock input on the

SCK1 pin. Serial data is received from the micro-

controller on the MOSI pin, and output from the

CS5376 on the MISO pin.

When pulled low the SSI pin (Slave Select Input)

places the SPI 1 port into a default configuration

that requires 8-bit addresses, different from the 16-

SCK1

MISO

MOSI

Pin Logic

SPI 1

Figure 10. Serial Peripheral Interface 1 (SPI 1) Block Diagram

SINT

To

8-bit Shift Register

SSI

SSO

Chip

Select

Logic

Control Logic

CS8

CS10

CS9

CS11

Registers

Engine

Decimation

SPI 1

CS5376

DS256PP1

22

bit addresses generated when accessing an EE-

PROM in master mode.

5.1 SPI 1 Pin Descriptions

The Serial Peripheral Interface 1 port is a standard

3-wire, bidirectional, synchronous serial interface.

The SCK1, MISO, and MOSI pins, along with ei-

ther the CS11 or SSI chip select pins, are used to in-

terface the decimation engine of the CS5376 to

external serial devices. Several miscellaneous pins,

SINT, SSO, and CS8 - CS10 are not used but are

defined to make the SPI 1 port extensible in the fu-

ture.

CS11 - Pin 46

Master mode chip select output pin, active low. EE-

PROM chip select signal automatically generated

when booting in stand-alone mode.

SSI - Pin 49

Slave mode chip select input pin, active low. Chip

select signal that places the SPI 1 port into slave

mode to receive commands from a microcontroller.

SCK1 - Pin 48

Master mode serial clock output, slave mode serial

clock input. In both modes a serial clock rising

edge indicates valid data, a falling edge indicates a

data transition.

In master mode the SCK1 pin is an output that gen-

erates a serial clock to read data from the configu-

ration EEPROM. The serial clock output rate in

master mode defaults to 1.024 MHz.

In slave mode the SCK1 pin is an input that re-

ceives a serial clock from a microcontroller. The

serial clock input rate in slave mode can be any rate

up to a maximum of 4.096 MHz.

MOSI - Pin 51

Master Out, Slave In data pin. Data output in mas-

ter mode, data input in slave mode. Data is valid on

the rising edge of SCK1, and transitions on the fall-

ing edge.

MISO - Pin 50

Master In, Slave Out data pin. Data input in master

mode, data output in slave mode. Data is valid on

the rising edge of SCK1, and transitions on the fall-

ing edge.

SINT - Pin 52

SPI 1 interrupt output pin, active low. A pulsed

output indicates data was written to the SPI 1 reg-

isters by the decimation engine. Not used by

CS5376 rev A, reserved for future revisions.

SSO - Pin 47

Slave select output pin, active low. Chip select out-

put that mirrors the SSI pin. Not used by CS5376

rev A, reserved for future revisions.

CS8 - CS10 - Pins 43 - 46

Additional chip selects for SPI 1 master mode. Not

used by CS5376 rev A, reserved for future revi-

sions.

5.2 SPI 1 Stand-Alone Mode

In stand-alone mode, the SPI 1 port operates as an

SPI bus master to load configuration information

from an EEPROM. Commands to write configura-

tion registers, filter coefficients, and test bit stream

data are programmed into the EEPROM along with

the required data words.

The CS5376 automatically reads 1-byte command

and 3-byte data words from EEPROM memory un-

til the `Filter Start' command is received. The `Fil-

ter Start' command initializes the CS5376 digital

filters and places the SPI 1 port into slave mode.

See "SPI 1 Coprocessor Mode" on page 27 for

more information about SPI 1 slave mode.

CS5376

DS256PP1

23

5.2.1

EEPROM Organization

The configuration EEPROM is programmed with a

series of command and data values. Commands are

one byte (8-bit) values that select the type of EE-

PROM loader operation. Data words are three byte

(24-bit) values used by the EEPROM loader.

The CS5376 expects EEPROM programming to

start at memory location 0x10, with the bytes from

0x00 to 0x0F defined for manufacturing header in-

formation. The first CS5376 to EEPROM transac-

tion reads a 1-byte command from memory

location 0x10. Depending on the command type,

multiple 3-byte data words are read to complete the

command. The CS5376 continues reading com-

mand and data values until the `Filter Start' com-

mand is recognized. Figure 11 illustrates the

organization of an 8 Kbyte (64 Kbit) configuration

EEPROM.

The maximum data that can be written for a single

configuration is approximately 5 Kbyte (40 Kbit),

which includes command overhead:

-

22 Configuration Registers, 154 bytes

-

255 + 255 FIR Coefficients, 1537 bytes

-

3 + 5 IIR Coefficients, 25 bytes

-

1024 Test Bit Stream Data, 3076 bytes

-

Filter Start Command, 1 byte

Supported serial configuration EEPROMs are

SPI mode 0 (0,0) compatible, 16-bit addresses, 8-

bit data, and larger than 5 Kbyte. ATMEL

AT25640, AT25128, or similar serial EEPROMs

are recommended.

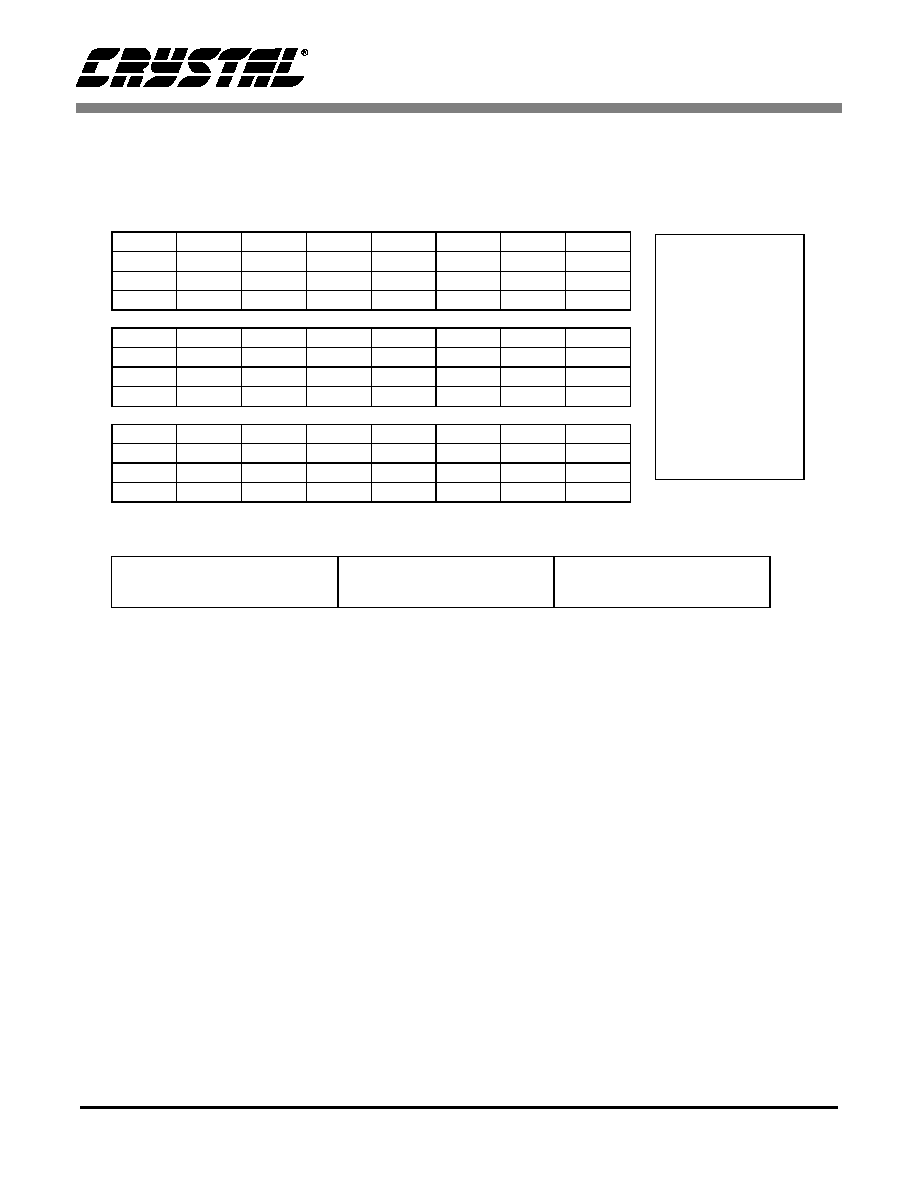

5.2.2

EEPROM Commands

The configuration EEPROM contains a series of 1-

byte command and 3-byte data words. After an EE-

PROM command is read, multiple data words are

read to complete the programmed operation. Not

all EEPROM commands require additional data

words.

EEPROM commands can write decimation engine

registers, write FIR filter coefficients, write IIR fil-

ter coefficients, write test bitstream data, and start

the digital filters. A summary of available EE-

PROM commands is shown in Figure 12 on

page 24.

Write Register - 0x01

This EEPROM command writes a data value to the

specified decimation engine register. Decimation

engine registers control hardware and filtering

functions. See "Decimation Engine Registers" on

page 99 for information about the bit definitions of

the decimation engine registers.

Figure 11. EEPROM Memory Organization

0000h

1FFFh

EEPROM

Manufacturing

Information

EEPROM

Command and

Data Values

Mfg Header

8 bit Command

0010h

N x 24 bit Data

8 bit Command

N x 24 bit Data

8 bit Command

N x 24 bit Data

. . .

Type

Description

CMD

0x01 - Register Write Command

DATA

Register Address

DATA

Register Write Data

CS5376

DS256PP1

24

Write FIR Coefficients - 0x02

This EEPROM command writes custom coeffi-

cients for the FIR1 and FIR2 filters. The first two

data words set the number of FIR1 and FIR2 coef-

ficients to be written. The remaining data words are

the concatenated FIR1 and FIR2 coefficients.

A maximum of 255 coefficients can be written for

each FIR filter, though the available decimation en-

gine computation cycles will limit their practical

size. See "FIR Filters" on page 60 for more infor-

mation about the FIR filters and the cycle limita-

tions of the decimation engine.

Type

Description

CMD

0x02 - FIR Coefficient Write Cmd

DATA

Number of FIR1 Coefficients

DATA

Number of FIR2 Coefficients

DATA

(FIR Coefficients)

EEPROM Command

Command Opcode

Data Format

1

Nop

0x00

--

Write I/O Register

0x01

Address

Write Data

Write FIR Coefficients

0x02

Num FIR1 Coeff

Num FIR2 Coeff

(FIR Coeff)

Write IIR Coefficients

0x03

(IIR Coeff)

Write ROM Coefficients

0x04

--

Write TBS Data

0x05

Num TBS Data

(TBS Data)

Write ROM TBS Data

0x06

--

Filter Start

0x07

--

Figure 12. EEPROM Boot Loader Commands

1

(data) indicates multiple data words of this type to be written.

CS5376

DS256PP1

25

Write IIR Coefficients - 0x03

This EEPROM command uploads custom coeffi-

cients for the two stage IIR filter. The IIR architec-

ture and number of coefficients is fixed, so eight

data words containing coefficient values immedi-

ately follow the command byte. The IIR coefficient

write order is: a11, b10, b11, a21, a22, b20, b21,

and b22.

The IIR filter consists of a 1st order filter requiring

three coefficients (a11, b10, b11) and a 2nd order

filter requiring five coefficients (a21, a22, b20,

b21, b22). A 3rd order filter is implemented by run-

ning both the 1st and 2nd order filters. See "IIR Fil-

ter" on page 61 for more information about the IIR

filter.

Write ROM Coefficients - 0x04

This EEPROM command writes the on-chip refer-

ence coefficients for FIR1, FIR2, IIR 1st order, and

IIR 2nd order filters for use by the decimation en-

gine. No data words are required for this EEPROM

command. See "Reference Coefficients" on

page 63 for more information about the reference

FIR and IIR coefficient sets.

Write TBS Data - 0x05

This EEPROM command uploads a custom data

set for the test bit stream (TBS) generator. The first

data word sets the number of TBS data to be written

and the remaining data words are the TBS data val-

ues.

This command, along with the ability to program

the test bit stream generator interpolation and clock

rate, allows the creation of custom frequency test

signals. See "Test Bit Stream Generator" on

page 81 for information on generating specific test

frequencies using custom test bit stream data sets.

Write ROM TBS Data - 0x06

This EEPROM command writes the on-chip test bit

stream (TBS) data for use by the TBS generator.

No data words are required for this EEPROM com-

mand. See "Test Bit Stream Generator" on page 81

for information on generating test frequencies us-

ing the on-chip test bit stream data set.

Filter Start - 0x07

This EEPROM command initializes the decimation

engine and starts the digital filters. It also ends the

EEPROM boot loader operation and places the

SPI 1 port into slave mode. No data words are re-

quired for this EEPROM command.

After receiving the Filter Start command, the deci-

mation engine uses the filter configuration speci-

fied in the FILT_CFG register (0x20) and filter

Type

Description

CMD

0x03 - IIR Coefficient Write Cmd

DATA

IIR Coefficient a11

DATA

IIR Coefficient b10

DATA

IIR Coefficients b11

DATA

IIR Coefficients a21

DATA

IIR Coefficients a22

DATA

IIR Coefficients b20

DATA

IIR Coefficients b21

DATA

IIR Coefficients b22

Type

Description

CMD

0x04 - ROM Coefficient Write Cmd

Type

Description

CMD

0x05 - TBS Data Write Cmd

DATA

Number of TBS Data

DATA

(TBS Data)

Type

Description

CMD

0x06 - TBS ROM Data Write Cmd

Type

Description

CMD

0x07 - Filter Start Command

CS5376

DS256PP1

26

coefficients specified by prior EEPROM com-

mands.

5.2.3

CS5376 to EEPROM Transactions

When reading data from EEPROM in stand-alone

boot mode, the SPI 1 port operates as a bus master.

Two types of serial transactions are generated by

the CS5376, command reads and data reads. Com-

mand reads are 4-byte serial transactions to read a

command byte, and data reads are 6-byte serial