APEX MICROTECHNOLOGY CORPORATION · TELEPHONE (520) 690-8600 · FAX (520) 888-3329 · ORDERS (520) 690-8601 · EMAIL prodlit@apexmicrotech.com

1

PRELIMINARY

INTRODUCTION

The EK60 evaluation kit is designed to provide a convenient

way to breadboard design ideas for the PA78EU power opera-

tional amplifiers. The EVAL60 evaluation board is pre-wired for

all required and recommended external components including

the ones for power supply bypassing, compensation and cur-

rent limiting. The EVAL60 also includes a breadboard area for

constructing your application circuit with provisions for a pre-

amplifier to drive the PA78 inputs.

PARTS LIST

Apex Part #

Description

Quantity

HS27

Heatsink, Apex

1

EVAL60

PC Board, Apex

1

TW12

Thermal Washer, Apex

1 Box

OX7R105KWN 1 uF Cap 3530B105K501N

2

Novacap,

200V Breakdown

140-500N5-330J 33pF Cap CDR-500N5-330KS

1

XICON

146510CJ

BNC Connector

3

MS02

Socket Strip

1 bag

MS11

Socket Strip

1 bag

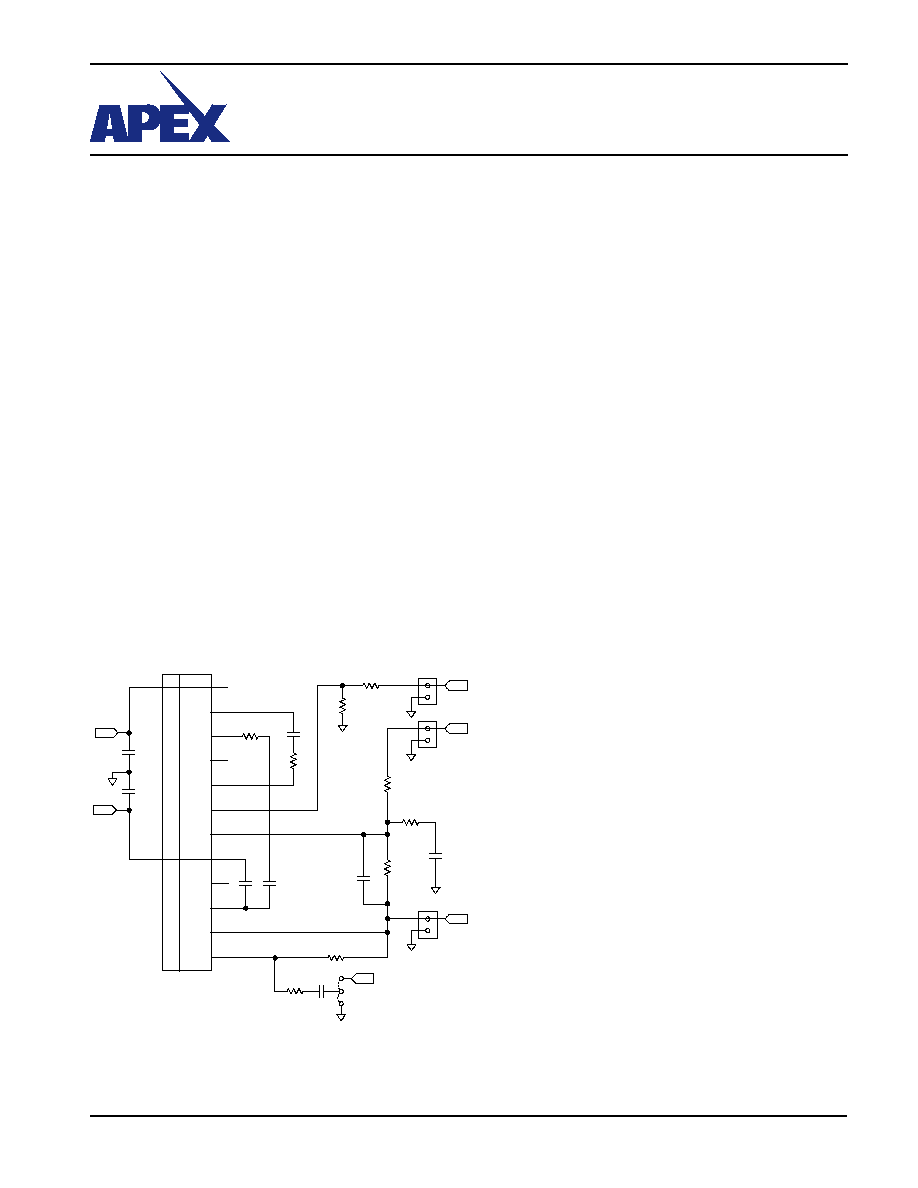

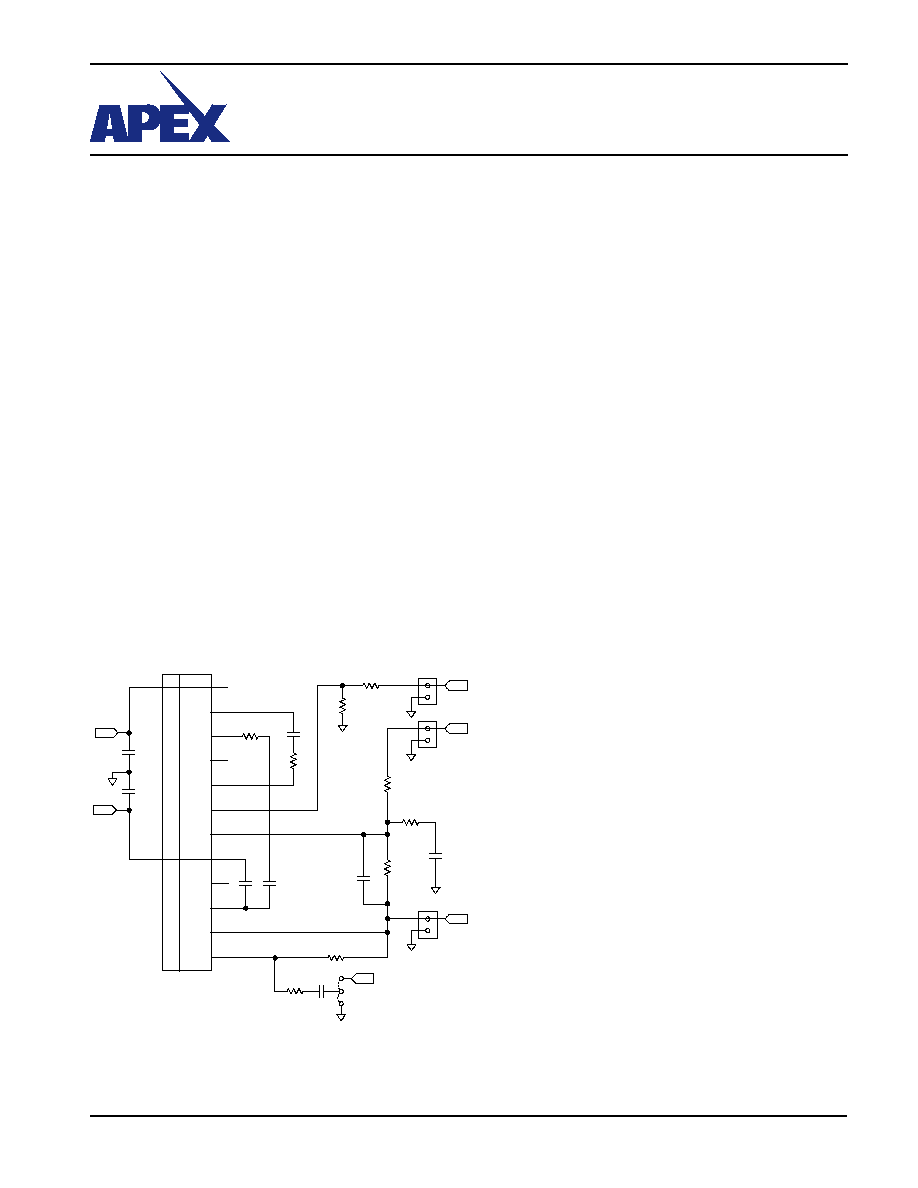

EK60 SCHEMATIC

ASSEMBLY

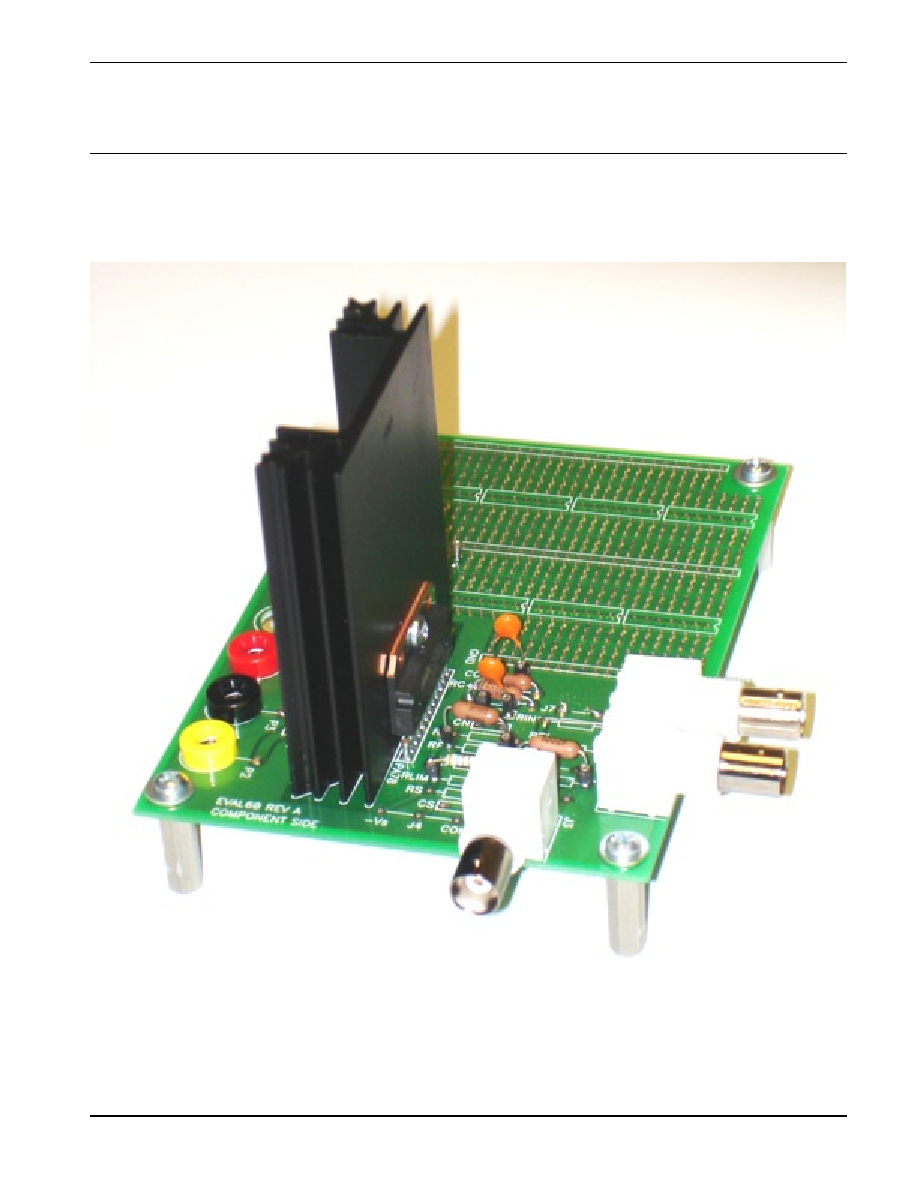

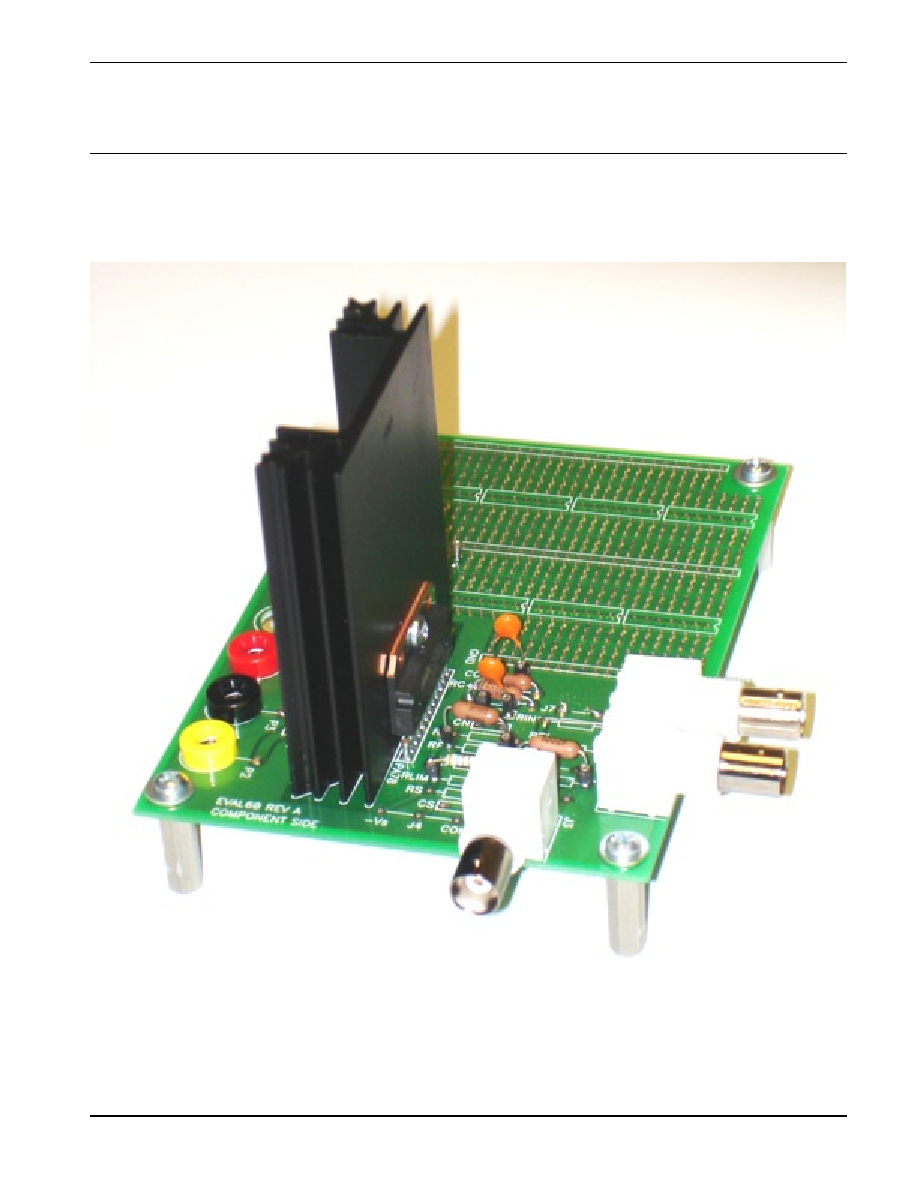

During assembly refer to Figure 1 and Figure 2.

1. Solder surface mount ceramic capacitors C4 and C5 on the

DUT side of the board.

2. Add components for compensation (CC-, CC+, RC- and RC+)

based on the closed loop gain and capacitive load. Add the

current limit resistor (RLIM) based on load requirements (a

minimum value of 4.5 ohms should be used to protect the

PA78 internal output devices). It is recommended to use

MSO2 sockets for the components for quick component

changes on the board. Add 33pF capacitor (CT) between

DUT pins 3 and 5.

3. While developing your application circuit you will probably

want to use the mating socket strip. Use the MS11 socket

strip for mounting the PA78 EU. Clip off the strip after the

12th position. Insert the strip into the circuit board on the

DUT side and solder one pin on the reverse side. Check

whether the mating socket strip is fully seated against the

circuit board and then solder the remaining pins. Insert the

amplifier fully into the socket strip, noting the pin 1 location

on the amplifier and the circuit board.

4. For high power applications (see PA78EU datasheet for

SOA considerations) mount the heat sink (HS27) in the

outlined area on the circuit board.

5. If a heat sink is used, position the thermal washer behind

the amplifier in such a way that the hole on the washer

coincides with the hole on the tab and the heat sink.

6.

For high slew rate performance connect the heat tab to

a stable reference (see PA78U datasheet for details).

7. Install the banana jacks for P1 (+Vs), P2 (-Vs) and P3 (GND)

as shown in figure 1 and 2. There are provisions for two

extra banana jacks (P4 and P5) and can be used if desired

for external connections.

APEX MICROTECHNOLOGY CORPORATION · TELEPHONE (520) 690-8600 · FAX (520) 888-3329 · ORDERS (520) 690-8601 · EMAIL prodlit@apexmicrotech.com

3

PRELIMINARY

EVALUATION KIT

FOR PA78 PIN-OUT

EK60

This data sheet has been carefully checked and is believed to be reliable, however, no responsibility is assumed for possible inaccuracies or omissions. All specifications are subject to change without notice.

EK60U REV 3 JANUARY 2006 © 2006 Apex Microtechnology Corp.

Figure 2: Assembled PCB