Data Sheet

February 1999

LG1626DXC Modulator Driver

Features

s

High data-rate optical modulator driver

s

Adjustable output voltage up to 3 Vp-p (R

L

= 50

)

s

Adjustable modulator dc offset

s

Operation up to 3 Gbits/s

s

Single ended or differential inputs

s

Single 5.2 V power supply

s

90 ps rise and fall times

s

Enable control

Applications

s

SONET/SDM transmission systems

s

SONET/SDM test equipment

s

Optical transmitters

Functional Description

The LG1626DXC is a gallium-arsenide (GaAs) inter-

grated circuit used to provide voltages to drive optical

modulators in high-speed non-return-to-zero (NRZ)

transmission systems. The device is made in a high-

performance 0.9

µ

m gate GaAs hetero-junction FET

technology that utilizes high-density MIM capacitors,

airbridge interconnect, and NiCr film precision resis-

tors. The device contains four cascaded stages,

operates with a single 5.2 V power supply, and

accepts ECL 100K level inputs. The output is an

open drain designed to drive 50

loads. Voltages

control the output modulation amplitude and modula-

tor dc offset. A 2.5 V band-gap reference is required

for stable operation over temperature and varying

power supply voltage. The LG1626DXC is available

in a 24-lead hermetic, gull-wing package.

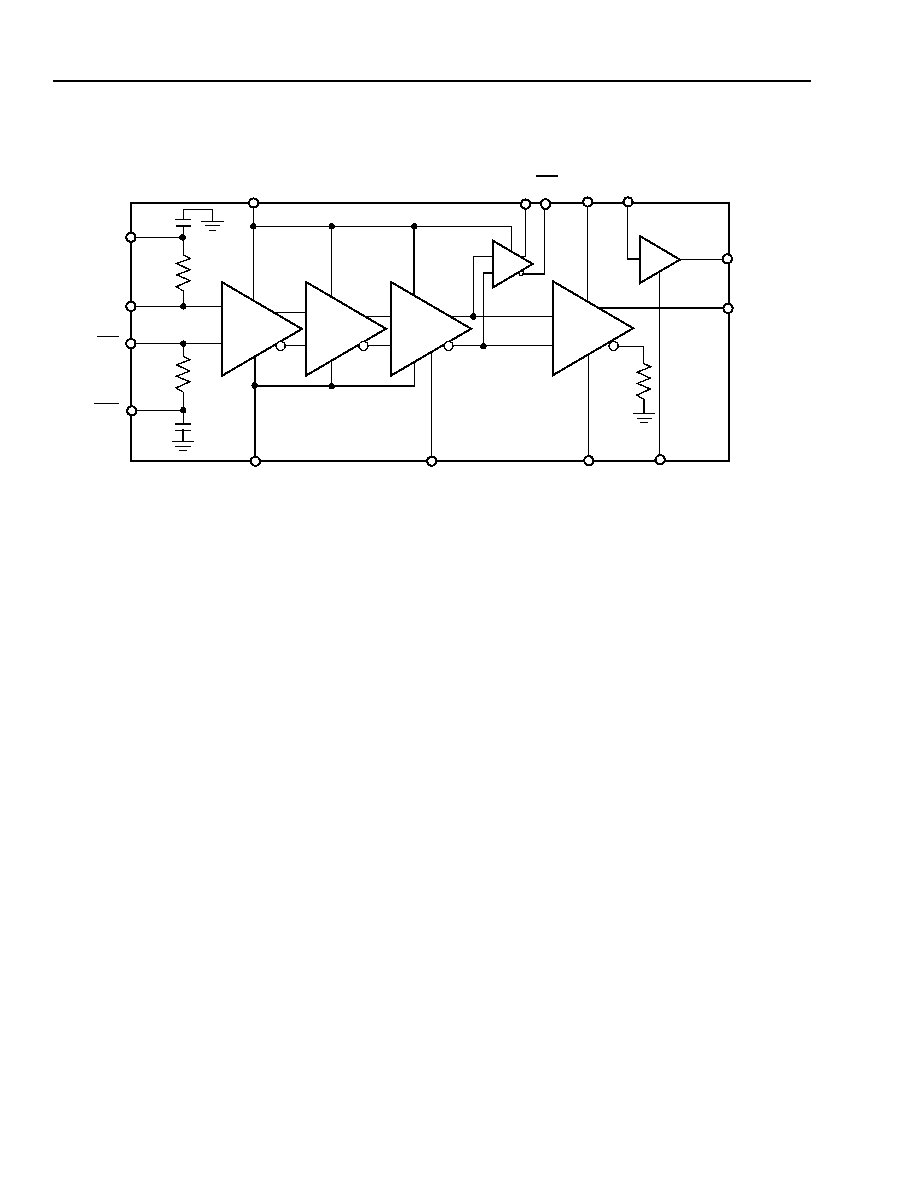

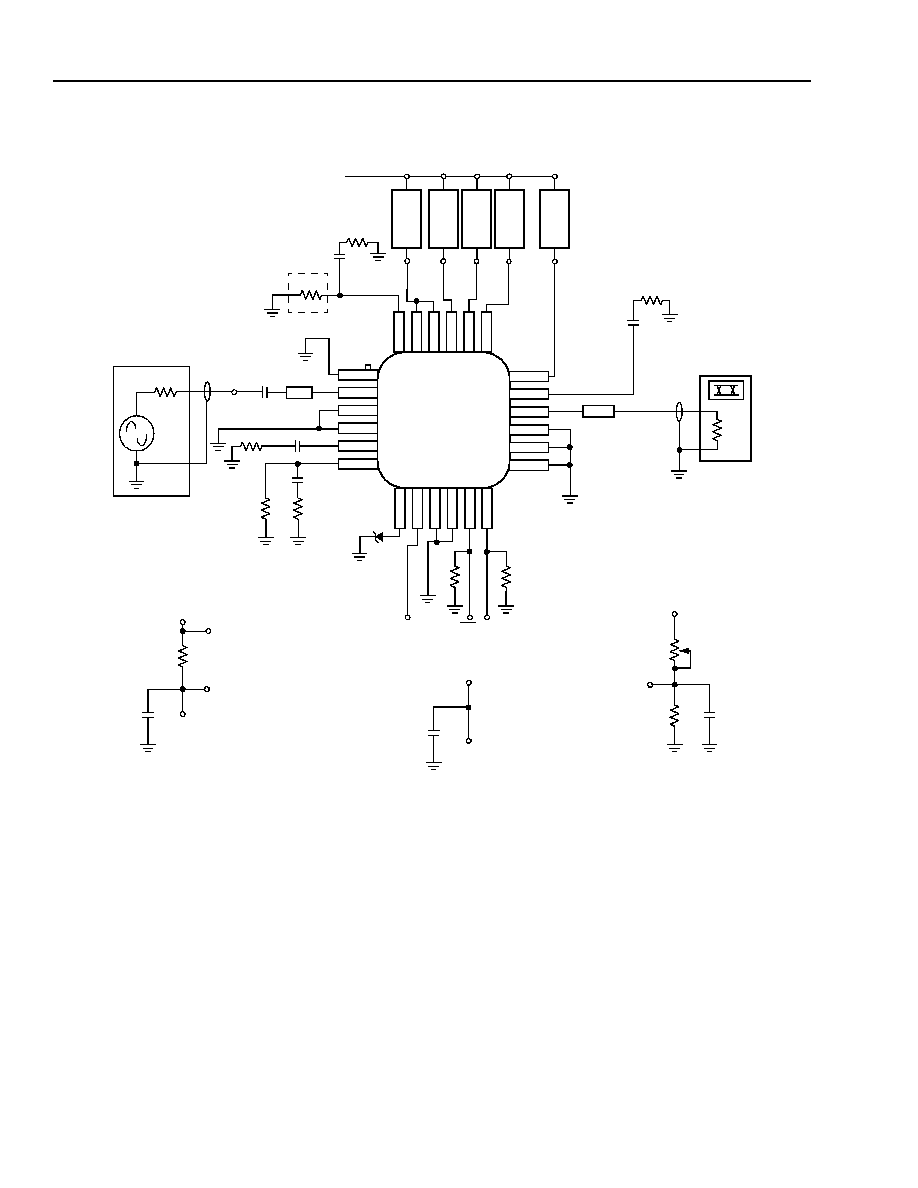

5-6549(F)

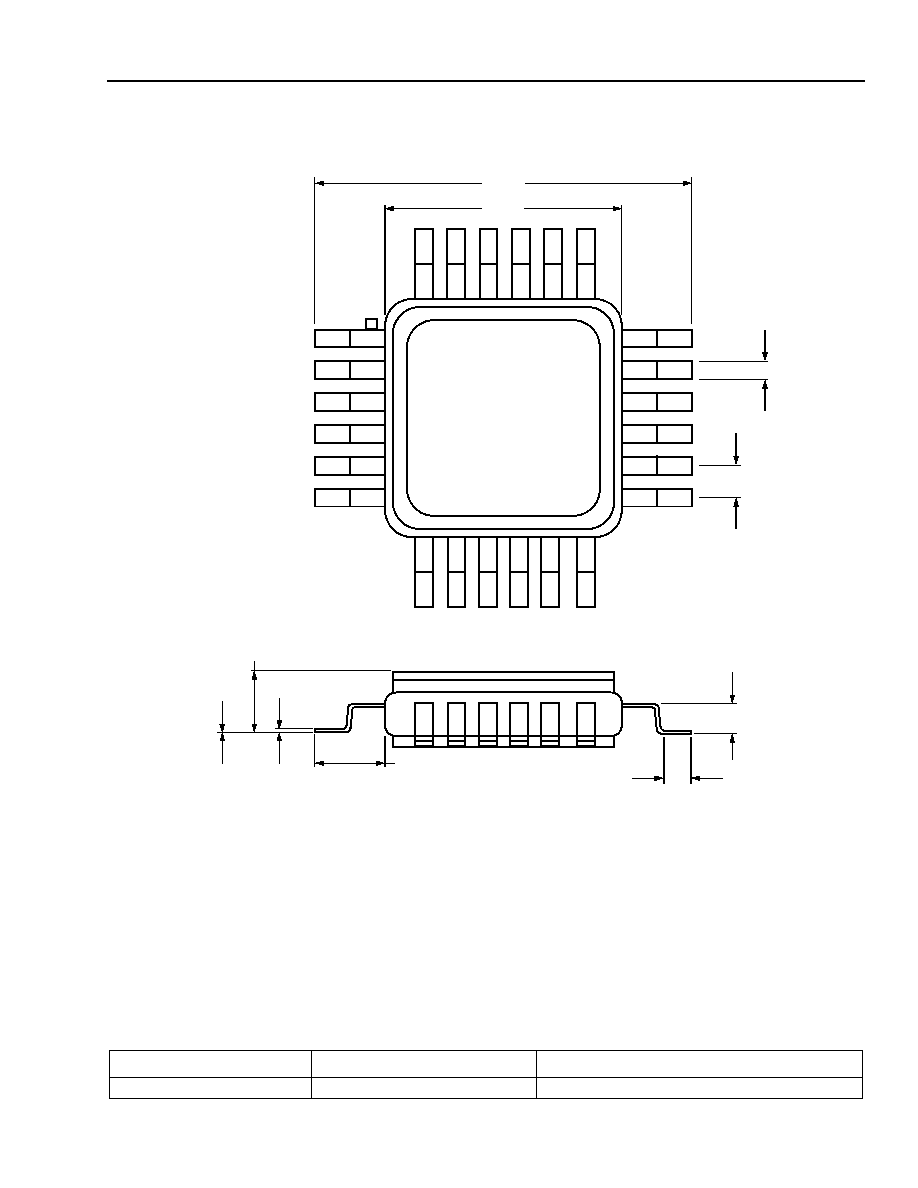

Figure 1. Functional Diagram

V

IN

BG2P5

V

SS1

V

TH

V

SS2

GND

V

OUT

MK

MK

V

SS3

V

MOD

V

OUT-DC

MOD_E

V

IN

V

TH

V

DC-ADJ

2

Lucent Technologies Inc.

Data Sheet

February 1999

LG1626DXC Modulator Driver

Pin Information

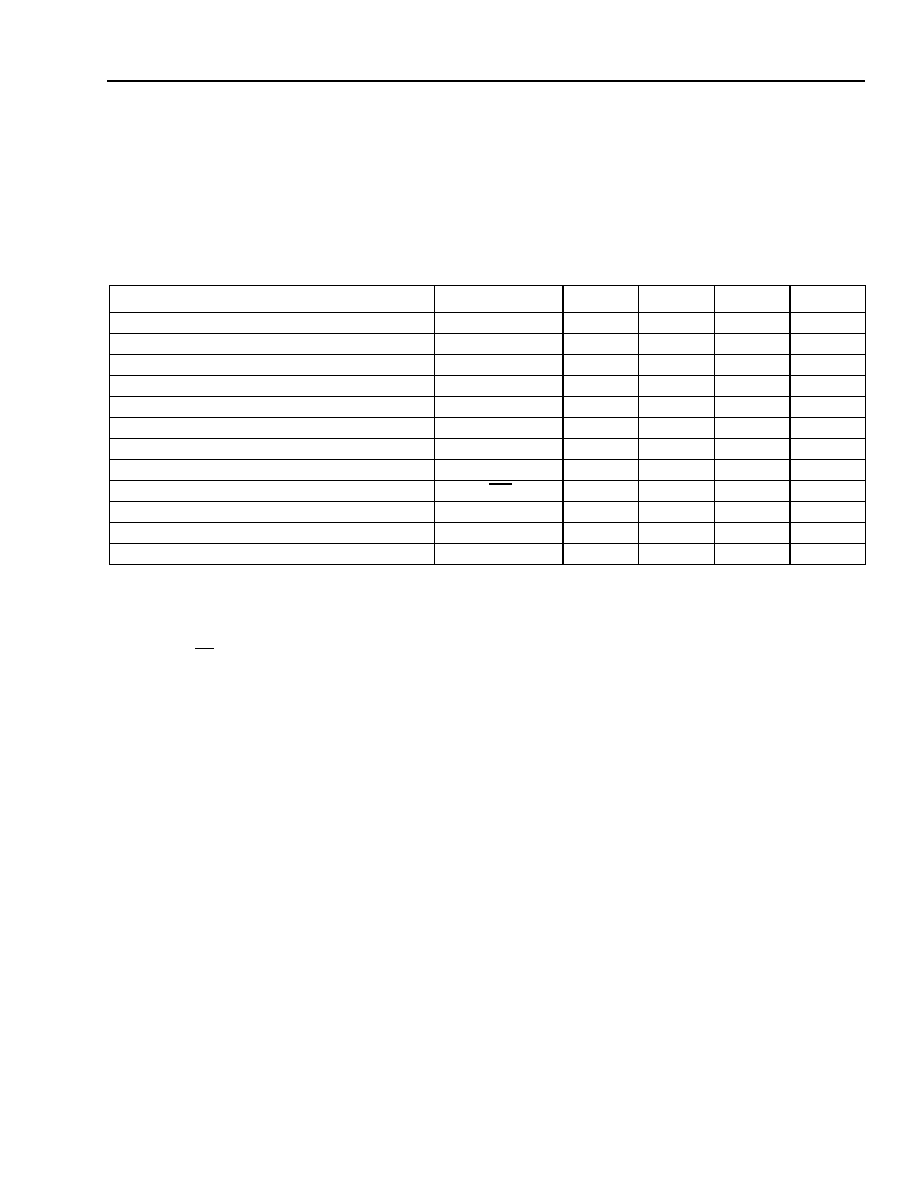

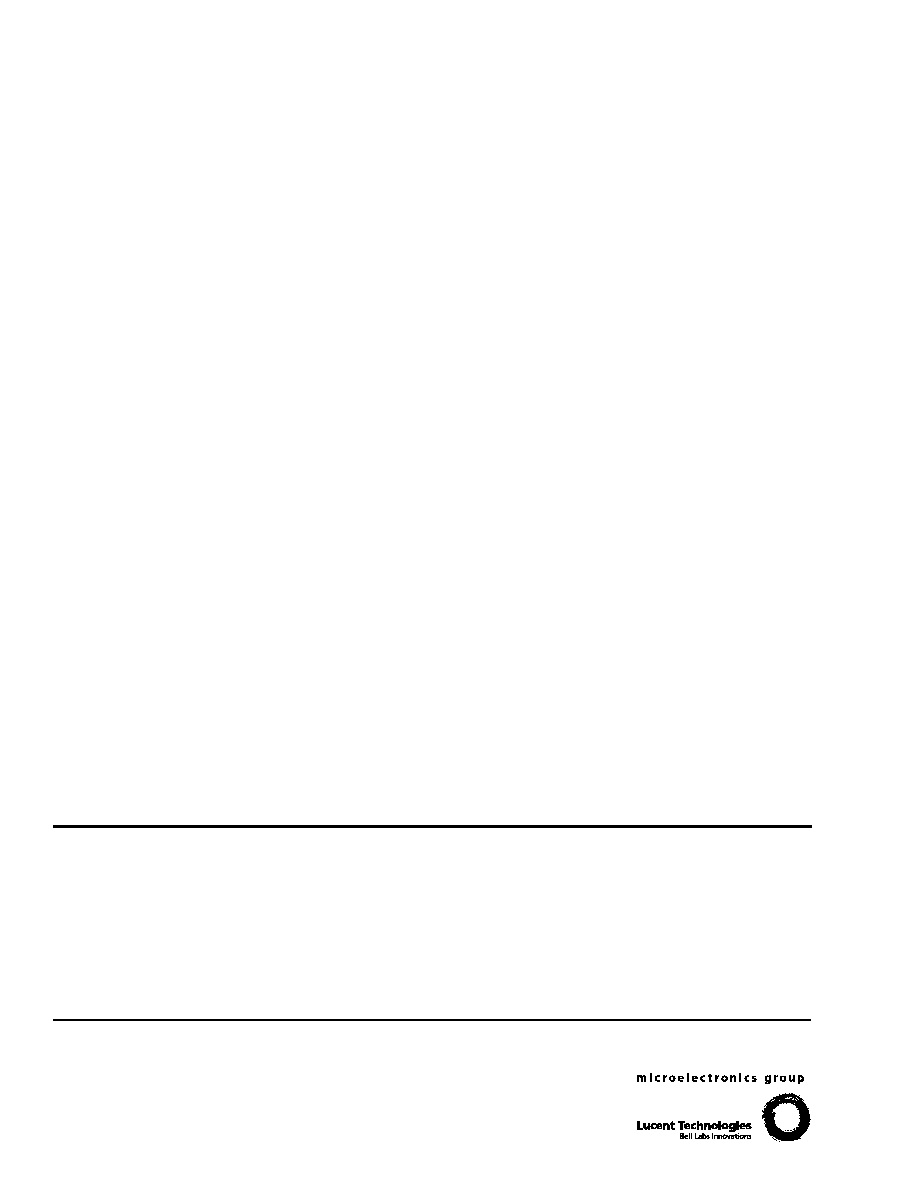

5-6550(F)

Figure 2. LG1626DXC Die Block Diagram

V

TH

V

IN

V

OUT

V

SS3

V

MOD

V

SS1

50

GND

MK

MK

V

SS2

V

DC-ADJ

50

+

+

V

IN

V

TH

50

MOD_E

Lucent Technologies Inc.

3

Data Sheet

February 1999

LG1626DXC Modulator Driver

Pin Information

(continued)

5-6551(F)

Note: Figure is not to scale.

Figure 3. LG1626DXC Package Pinout

Table 1. LG1626DXC Pin Description

*

National

Semiconductor

is a registered trademark of National Semiconductor Corporation.

Symbol

Pin

Description

GND

1, 3, 4, 9, 10, 13, 14, 15,

Package Bottom

Ground. For optimum performance, the package bottom must be

soldered to the ground plane.

V

IN

2

Data input.

5

Complementary data input.

6

Complementary threshold control (eye crossing) input.

BG2P5

7

2.5 V band-gap reference (

National

Semiconductor

* LM4040).

MOD_E

8

Modulation enable (connect to V

SS1

to enable, float to disable).

MK

11

Complementary mark density output.

MK

12

Mark density output.

V

OUT

16

Output, ac couple to 50

modulator.

V

OUT-DC

17

Output, modulator dc offset.

V

DC-ADJ

18

Modulator dc offset control input.

V

SS2

19

V

SS2

supply 5.2 V for output prebias.

V

SS3

20

V

SS3

supply 5.2 V for output modulation.

V

MOD

21

Output modulation control input.

V

SS1

22, 23

V

SS1

supply 5.2 V.

V

TH

24

Threshold control (eye crossing) input.

GND

GND

GND

V

OUT

V

OUT-DC

V

DC-ADJ

V

SS2

V

SS3

V

MOD

V

SS1

V

SS1

V

TH

1

2

3

4

5

6

13

14

15

16

17

18

24

BG

2

P

5

MO

D

_

E

GN

D

GN

D

MK

MK

GND

V

IN

GND

GND

V

IN

V

TH

23

22

21

20

19

7

8

9

10

11

12

LG1626DXC

MODULATOR

DRIVER

V

IN

----------

V

TH

-----------

4

Lucent Technologies Inc.

Data Sheet

February 1999

LG1626DXC Modulator Driver

Absolute Maximum Ratings

(at T

A

= 25

°

C unless otherwise specified)

Table 2. Absolute Maximum Ratings

Handling Precautions

Although protection circuitry has been designed into this device, proper precautions should be taken to avoid expo-

sure to electrostatic discharge (ESD) during handling and mounting. Lucent employs a human-body model (HBM)

and a charged-device model (CDM) for ESD-susceptibility testing and protection design evaluation. ESD voltage

threshold are dependent on the circuit parameters used to define the model. No industry-wide standard has been

adopted for the CDM. However, a standard HBM (resistance = 1500

,

capacitance = 100 pF) is widely used and

therefore, can be used for comparision. The HBM ESD threshold presented here was obtained by using these cir-

cuit parameters.

Table 3. ESD Threshold Voltage

Mounting and Connections

Cetain precautions must be taken when using solder. For installation using a constant temperature solder, temper-

atures of under 300

°

C may be employed for periods of time up to 5 seconds, maximum. For installation with a sol-

dering iron (battery operated or nonswitching only), the soldering tip temperature should not be greater than

300

°

C and the soldering time for each lead must not exceed 5 seconds. This device is supplied with solder on the

back of the package. For optimum performance, it is recommended to solder the back of the package to the

ground.

Parameter

Symbol

Min

Max

Unit

Supply Voltage

V

SS

--

5.75

V

Input Voltage

V

I

GND

V

SS

V

Power Dissipation

P

D

--

1

W

Storage Temperature Range

Tstg

40

125

°

C

Operating Temperature Range

T

C

0

100

°

C

Human-Body Model ESD Threshold

Device

Voltage

LG1626DXC

>200 V

Lucent Technologies Inc.

5

Data Sheet

February 1999

LG1626DXC Modulator Driver

Electrical Characteristics

T

A

= 25

°

C, V

SS1

= V

SS2

= V

SS3

= 5.2 V, V

TH

= 1.3 V, V

MOD

= 3.8 V, R

L

= 50

.

Minimum and maximum values are testing requirements. Typical values are characteristics of the device and are

the result of engineering evaluations. Typical values are for information purposes only and are not part of the test-

ing requirements. Stresses in excess of the absolute maximum ratings can cause permanent damage to the

device.

Table 4. LG1626DXC Minimum and Maximum Values

1. Maximum output modulation at maximum V

MOD

(R

L

= 50

).

2. Minimum output modulation when MOD_E is floating and V

MOD

= V

SS3.

3. Excludes I

PRE

and average I

MOD:

Power suppy current I

SS2

(relating to prebias) is dependent on V

PRE.

Power suppy current I

SS3

(relating to modulation) is dependent on V

MOD.

4. Both MK and MK are open drains, the typical value is obtained by driving a 1k

load.

5. Maximum modulator dc offset voltage (R

L

= 50

) at maximum V

DC-ADJ.

6. Minimum modulator dc offset voltage (R

L

= 50

) at V

DC-ADJ

= V

SS2.

Note: All parameters measured at 25

°

C ambient.

Parameter

Symbol

Min

Typ

Max

Unit

Data Input Voltage (peak to peak) Single Ended

V

IN

300

600

1000

mV

Voltage Control for Output Modulation Current

V

MOD

5.5

--

4

V

Maximum Modulated Output Voltage

1

V

OUT

2.70

--

3.00

V

Minimum Modulated Output Voltage

2

V

OUT

0

--

0.2

V

Output Rise and Fall Times (20%--80%)

t

R

, t

F

--

90

--

ps

Power Supply Voltage

V

SS1

, V

SS2

, V

SS3

5.5

5.2

4.9

V

Power Supply Current

3

I

SS1

100

140

180

mA

Mark Density

4

MK

--

0.5

--

V

Complementary Mark Density

4

MK

--

0.5

--

V

Voltage Control for Modulator dc Offset

V

DC-ADJ

5.5

--

3

V

Maximum Output, Modulator dc Offset

5

V

OUT-DC

1.2

--

1.5

V

Minimum Output, Modulator dc Offset

6

V

OUT-DC

0

--

0.1

V

6

Lucent Technologies Inc.

Data Sheet

February 1999

LG1626DXC Modulator Driver

Electrical Characteristics

(continued)

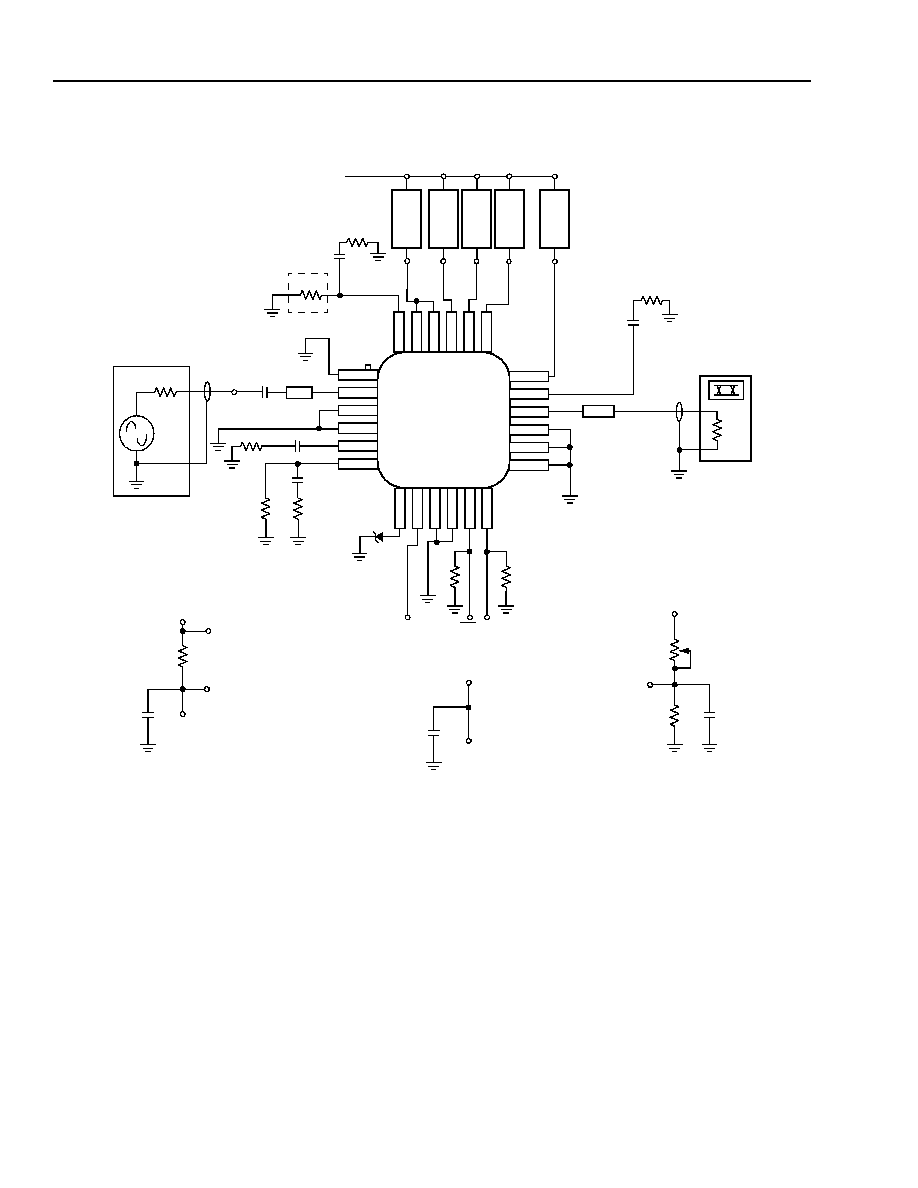

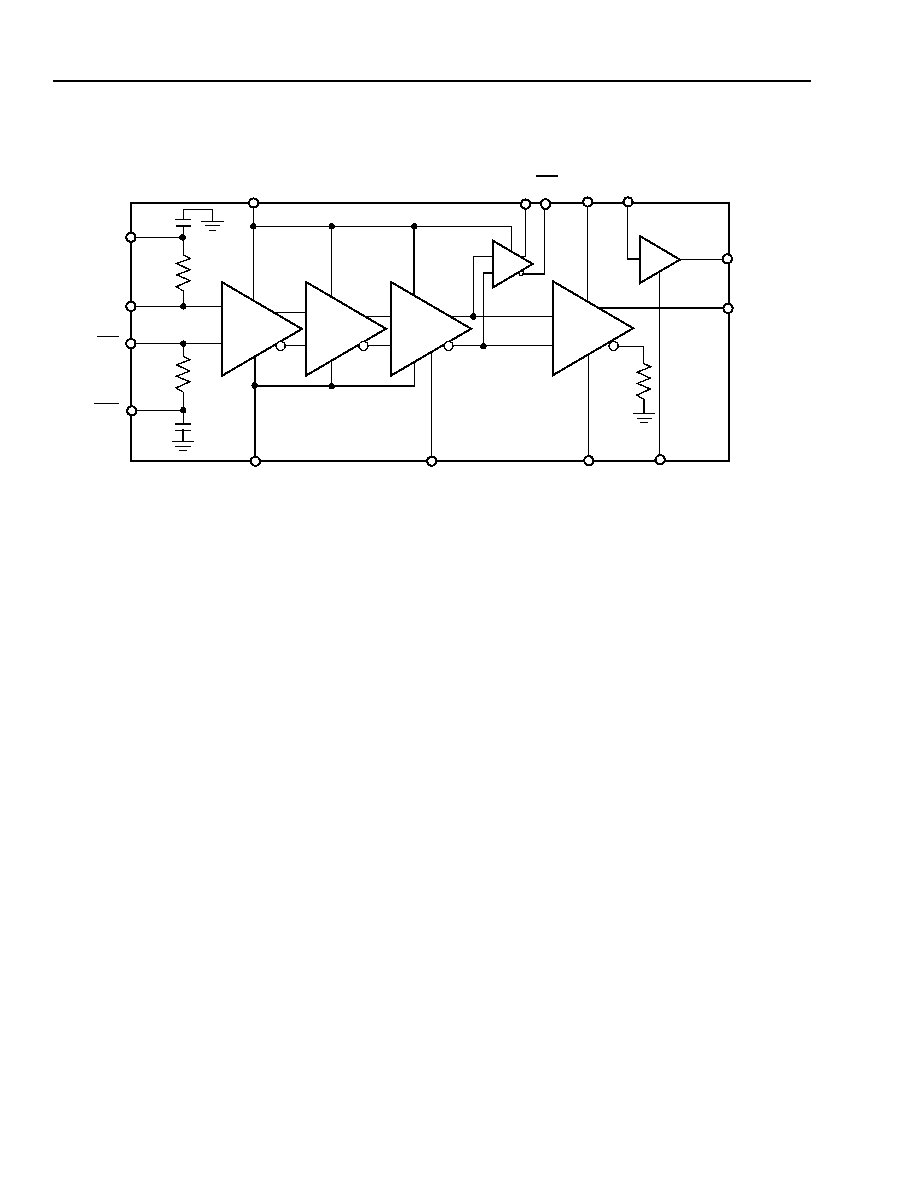

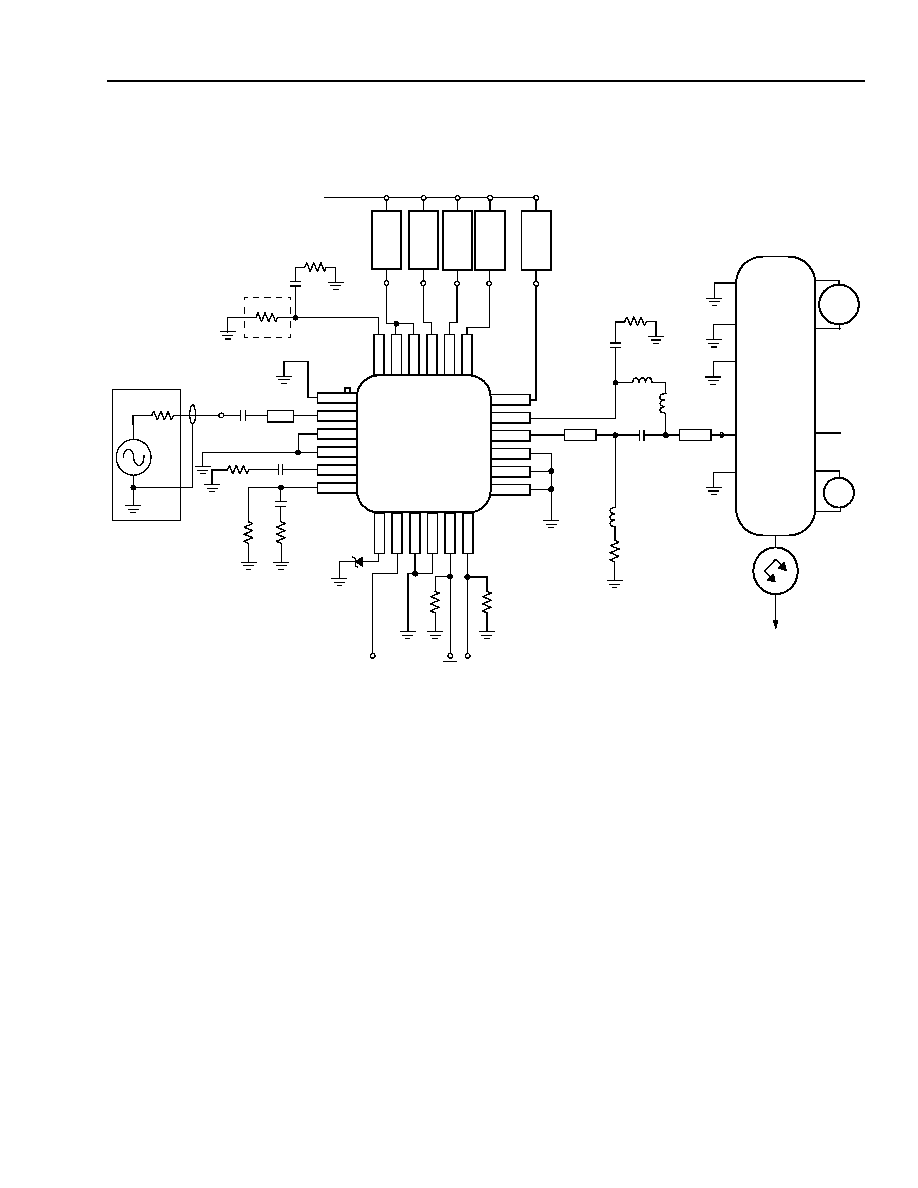

5-6553(F).b

*A 2.5 k

resistor will set the eye crossing at 50%. A 5 k

potentiometer will allow the eye crossing to be varied.

Notes:

All bypass caps should be mounted close to the package.

I

SS3

can be measured and used to control V

MOD

.

I

SS2

can be measured and used to control V

OUT-DC

.

For optimal performance, the proximity of the two components should be minimized and the package bottom must be soldered to the circuit

board (GND).

For proper impedance matching, high-speed transmission lines should be 50

controlled impedance lines.

Figure 4. LG1626DXC Typical Electrical Evaluation (ac Coupled to Scope)

VO

L

T

A

G

E

DI

VI

DER

CURR

ENT

SENSE

V

SS1

BYPASS

1

2

3

4

5

6

7

8

9 10 11 12

13

14

15

16

17

18

19

20

21

22

23

24

LG1626DXC

MODULATOR

DRIVER

50

50

+

DATA

GENERATOR

SCOPE

Zo = 50

DATA IN

V

SS

1

V

SS

3

V

MO

D

2.5 k

*

V

SS

= 5.2 V

0.047

µ

F

1 k

1 k

MK MK

1

3 k

2 k

V

SS

0.1

µ

F

REQUIRED TO SET

V

MOD

AND V

DC-ADJ

TO ACHIEVE DESIRED

MODULATION, ONE EACH.

VOLTAGE

DIVIDER

V

SS

0.1

µ

F

TO USER-SUPPLIED

VOLTAGE MONITOR

TO NODE

V

SS2

AND V

SS3

(DVM).

CURRENT

SENSE

ONE EACH.

0.1

µ

F

V

SS

BYPASS

FOR V

SS1

V

SS1

V

TH

V

IN

V

OUT

V

SS

2

V

OUT-DC

V

DC-

A

D

J

VO

L

T

A

G

E

DI

VI

DER

CURR

ENT

SENSE

Zo = 50

0.1

µ

F

10

0.1

µ

F

BG2P5

LM4040

MOD_5

V

SS

= 5.2 V

10

0.047

µ

F

2.5 k

10

0.1

µ

F

50

Lucent Technologies Inc.

7

Data Sheet

February 1999

LG1626DXC Modulator Driver

Electrical Characteristics

(continued)

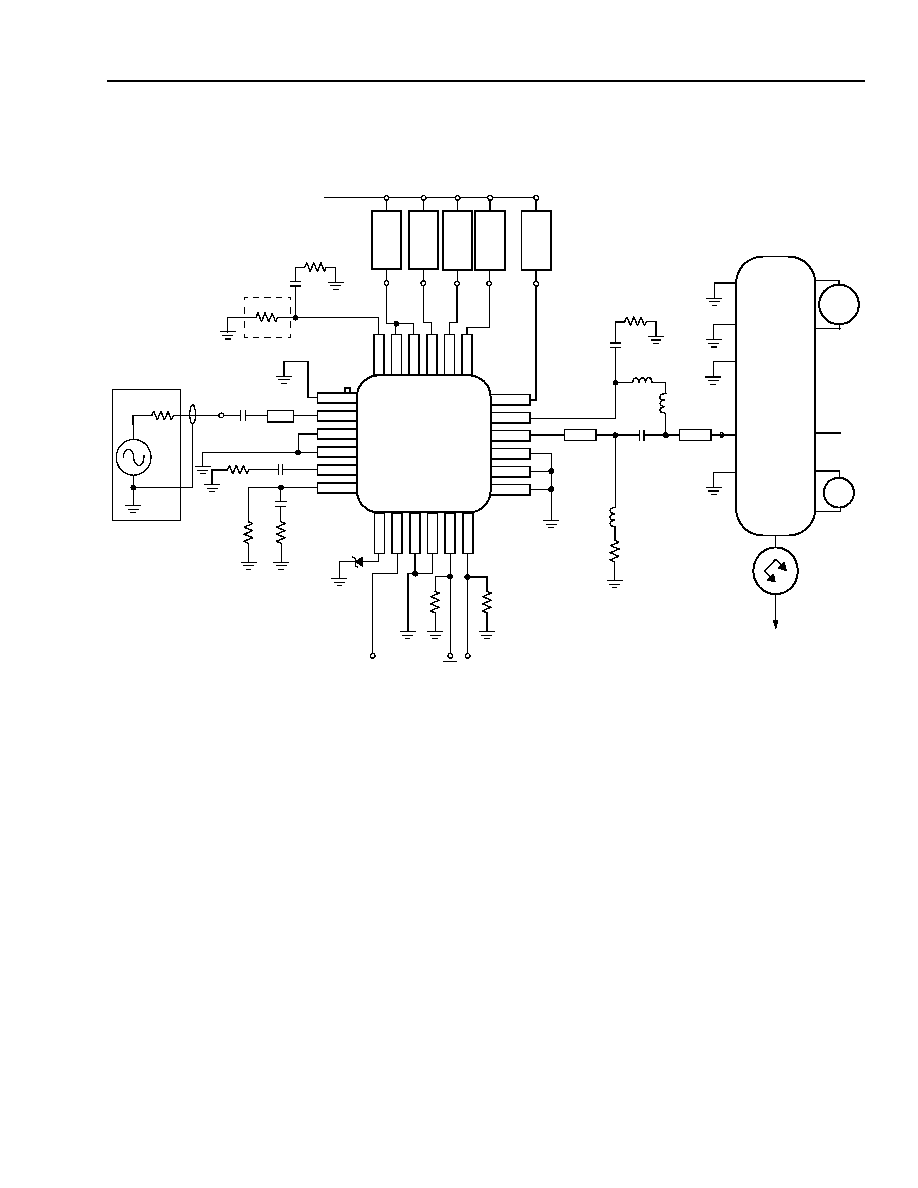

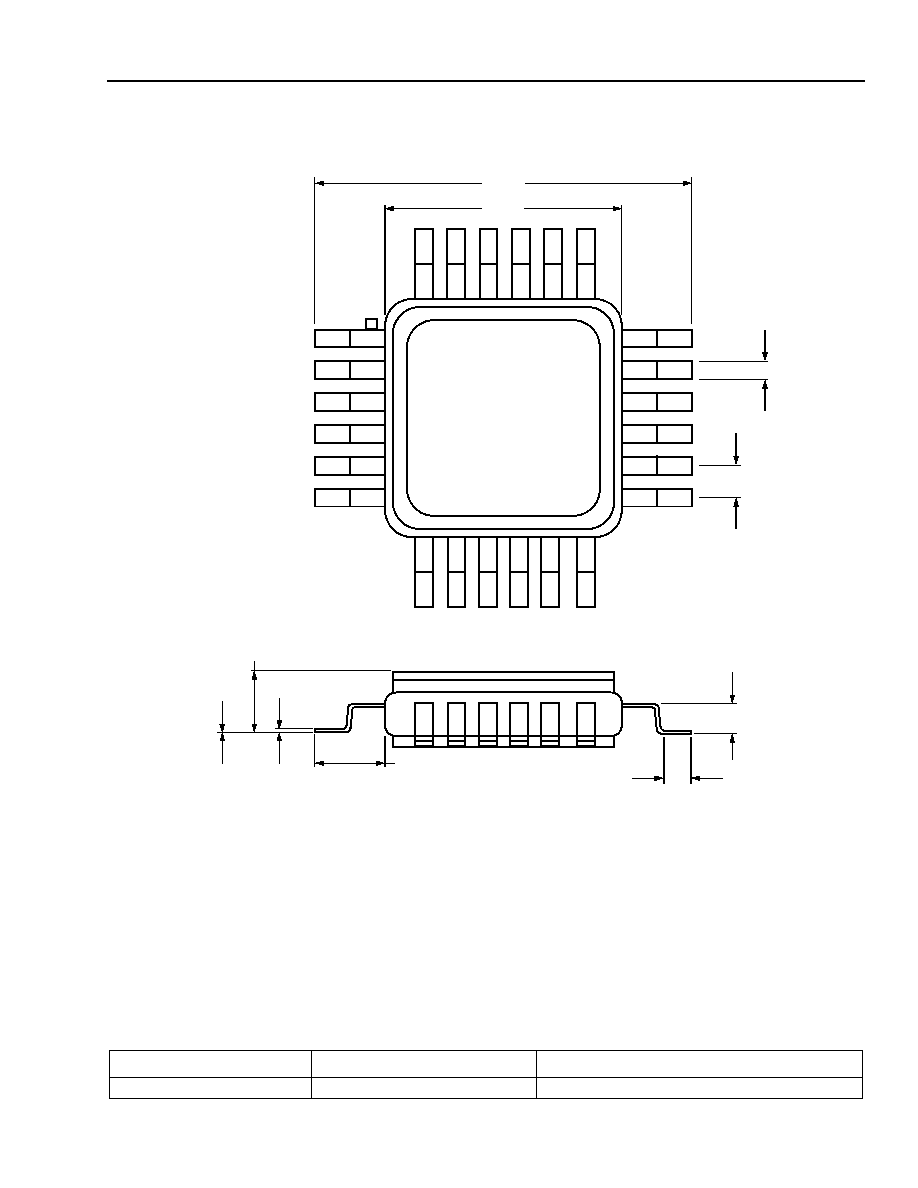

5-6554(F).b

*A 2.5 k

resistor will set the eye crossing at 50%. A 5 k

potentiometer will allow the eye crossing to be varied.

Notes:

All bypass caps should be mounted close to the package.

I

SS3

can be measured and used to control V

MOD

.

I

SS2

can be measured and used to control V

OUT-DC

.

For optimal performance, the proximity of the two components should be minimized and the package bottom must be soldered to the circuit

board (GND).

For proper impedance matching, high-speed transmission lines should be 50

controlled impedance lines.

Figure 5. Typical Optical Evaluation of the LG1626DXC and EM2500 EM-ILM

VO

L

T

AG

E

DIVI

DER

CU

RRENT

SENSE

VSS1

BYPASS

VSS1

VSS3

VM

O

D

VTH

VS

S2

CU

RRE

NT

SENSE

1

2

3

4

5

6

7

8

9

10 11 12

13

14

15

16

17

18

19

20

21

22

23

24

LG1626DXC

MODULATOR

DRIVER

Zo = 50

Zo = 50

DATA

2.5 k

*

0.1

µ

F

VSS = 5.2 V

0.047

µ

F

1 k

1 k

MK MK

VIN

VOUT

VOUT-DC

V

DC-

A

D

J

VO

L

T

AG

E

DIVI

DER

Zo = 50

1

2

3

4

5

6

7

14

13

12

11

10

9

8

E2500

EM-ILM

INPUT

+2 V

MAX

DMM

dc

SUPPLY

0.1

µ

F

IN

VSS = 5.2 V

MOD_E

BG2P5

LM4040

50

+

DATA

GENERATOR

0.047

µ

F

2.5 k

10

0.1

µ

F

10

10

50

50

0.047

µ

F

10

µ

H

10

µ

H

100

µ

H

8

Lucent Technologies Inc.

Data Sheet

February 1999

LG1626DXC Modulator Driver

Electrical Characteristics

(continued)

5-7341(F)

Figure 6. Typical Electrical Eye Diagram (ac Coupled to Scope)

5-7342(F)

Figure 7. Typical Optical Eye Diagram

Table 5. Pin Description of Lucent's E2500 EM-ILM Modulator

Pin

Description

1, 2

Thermistor

3

Laser Anode

4

Monitor Anode

5

Monitor Cathode

6

Thermoelectric Cooler (+)

7

Thermoelectric Cooler ()

8, 9

Case Ground

10, 14 No Connect

11, 13 Laser/Modulator Ground

12

Modulator Anode () 50

RF Input

750

mV

/

d

i

v

80 ps/div

500 m

W

/

div

60 ps/div

Lucent Technologies Inc.

9

Data Sheet

February 1999

LG1626DXC Modulator Driver

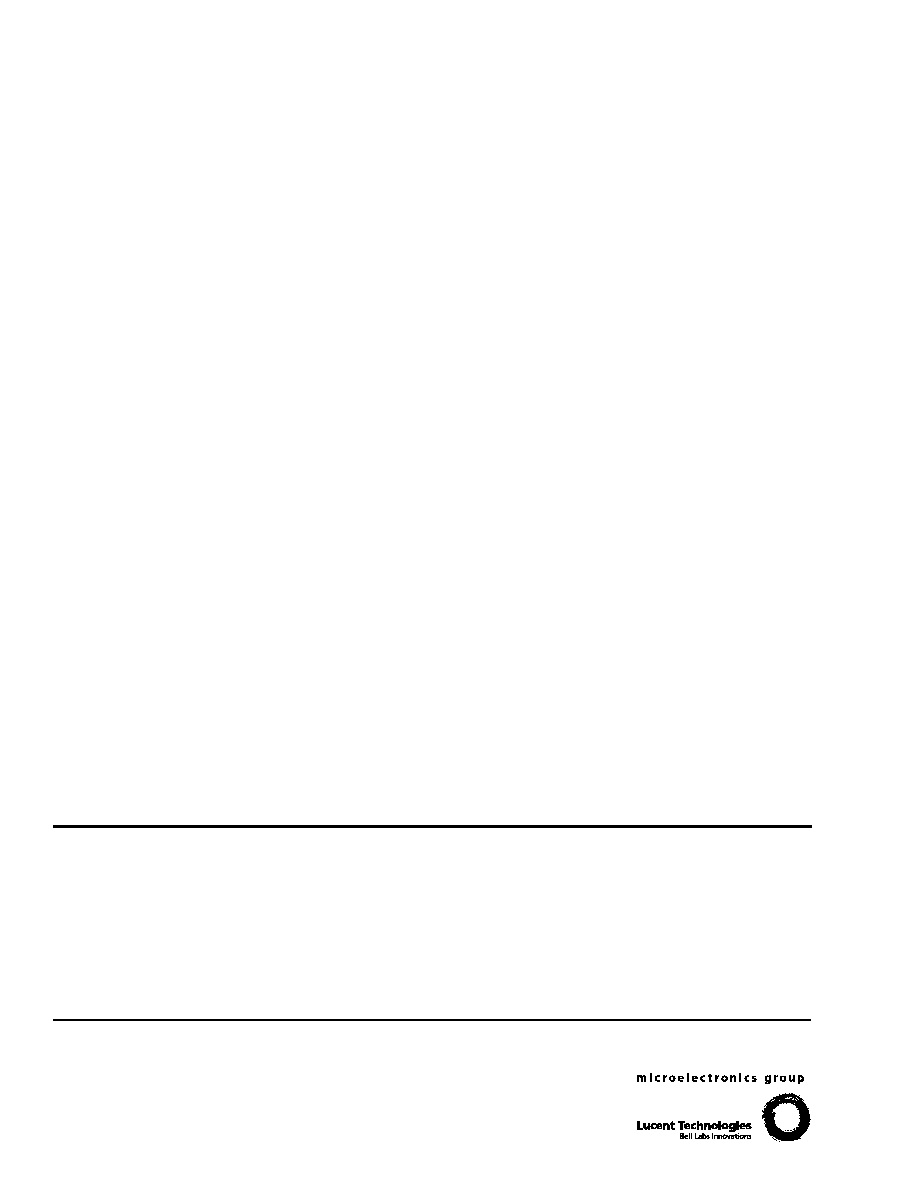

Outline Diagram

12-3224(F).a

Assembly Notes:

Standoff specifications applies to package prior to solder dipping of leads and package base.

During board assembly use back lighting to silhouette the package. This will eliminate reflection problems with the

solder on the bottom of the package.

Lead space tolerance should be set to

±

0.012 in.

Board solder pattern for the package base should not exceed 50% of the package base area.

Insertion pressure should not exceed 125 grams.

LG1626DXC Ordering Information

Device

Type

Comcode Number

LG1626DXC

24-Pin Package

108192865

1

1

0 -- 0.004

0.082

0.005

0.092

0.045

0.035

0.030

0.012

0.280

0.465

LUCENT

LG1626DXC

XXXXXXX

Lucent Technologies Inc. reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of their use or application. No

rights under any patent accompany the sale of any such product(s) or information.

Copyright © 1999 Lucent Technologies Inc.

All Rights Reserved

February 1999

DS99-145HSPL

For additional information, contact your Microelectronics Group Account Manager or the following:

INTERNET:

http://www.lucent.com/micro

E-MAIL:

docmaster@micro.lucent.com

N. AMERICA:

Microelectronics Group, Lucent Technologies Inc., 555 Union Boulevard, Room 30L-15P-BA, Allentown, PA 18103

1-800-372-2447, FAX 610-712-4106 (In CANADA: 1-800-553-2448, FAX 610-712-4106)

ASIA PACIFIC: Microelectronics Group, Lucent Technologies Singapore Pte. Ltd., 77 Science Park Drive, #03-18 Cintech III, Singapore 118256

Tel. (65) 778 8833, FAX (65) 777 7495

CHINA:

Microelectronics Group, Lucent Technologies (China) Co., Ltd., A-F2, 23/F, Zao Fong Universe Building, 1800 Zhong Shan Xi Road, Shanghai

200233 P. R. China Tel. (86) 21 6440 0468, ext. 316, FAX (86) 21 6440 0652

JAPAN:

Microelectronics Group, Lucent Technologies Japan Ltd., 7-18, Higashi-Gotanda 2-chome, Shinagawa-ku, Tokyo 141, Japan

Tel. (81) 3 5421 1600, FAX (81) 3 5421 1700

EUROPE:

Data Requests: MICROELECTRONICS GROUP DATALINE: Tel. (44) 1189 324 299, FAX (44) 1189 328 148

Technical Inquiries:GERMANY: (49) 89 95086 0 (Munich), UNITED KINGDOM: (44) 1344 865 900 (Ascot),

FRANCE: (33) 1 40 83 68 00 (Paris), SWEDEN: (46) 8 594 607 00 (Stockholm), FINLAND: (358) 9 4354 2800 (Helsinki),

ITALY: (39) 02 6608131 (Milan), SPAIN: (34) 1 807 1441 (Madrid)