Äîêóìåíòàöèÿ è îïèñàíèÿ www.docs.chipfind.ru

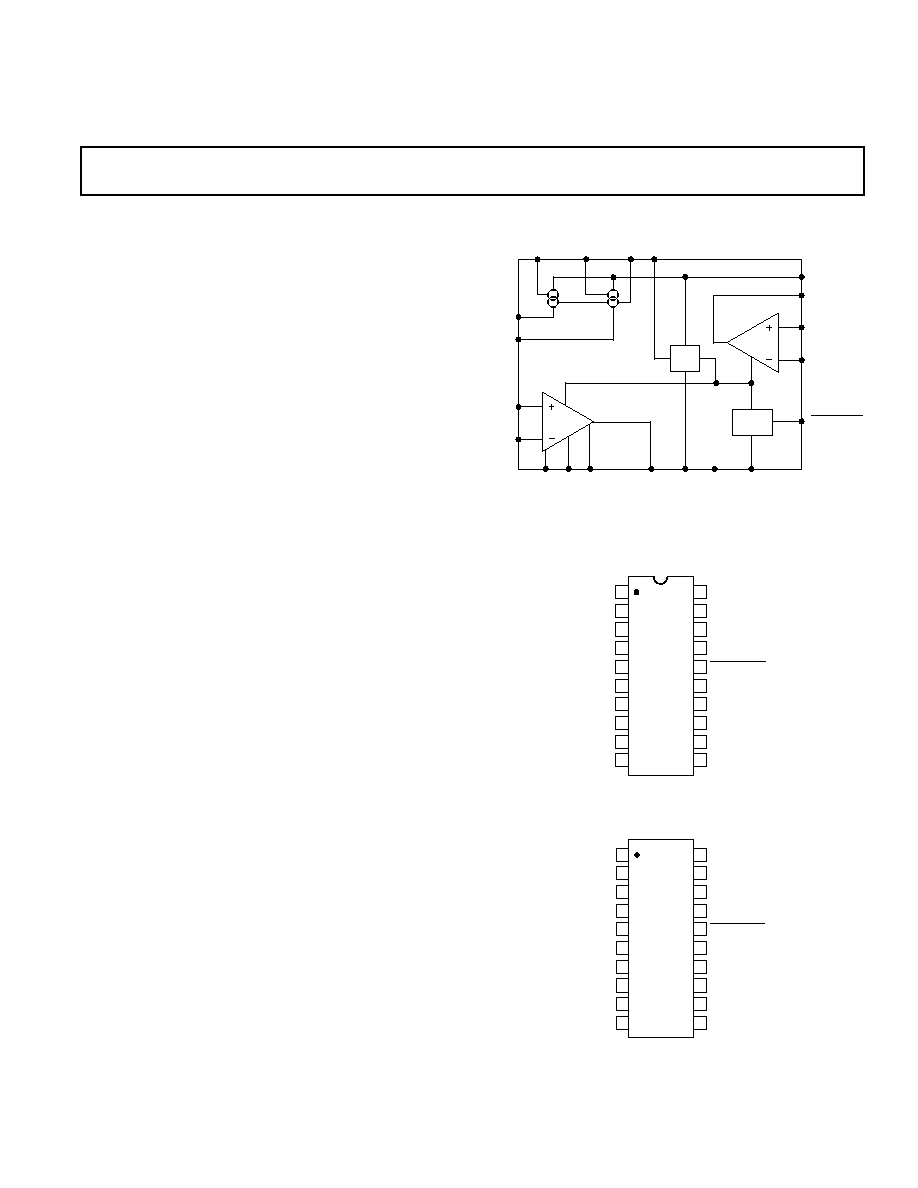

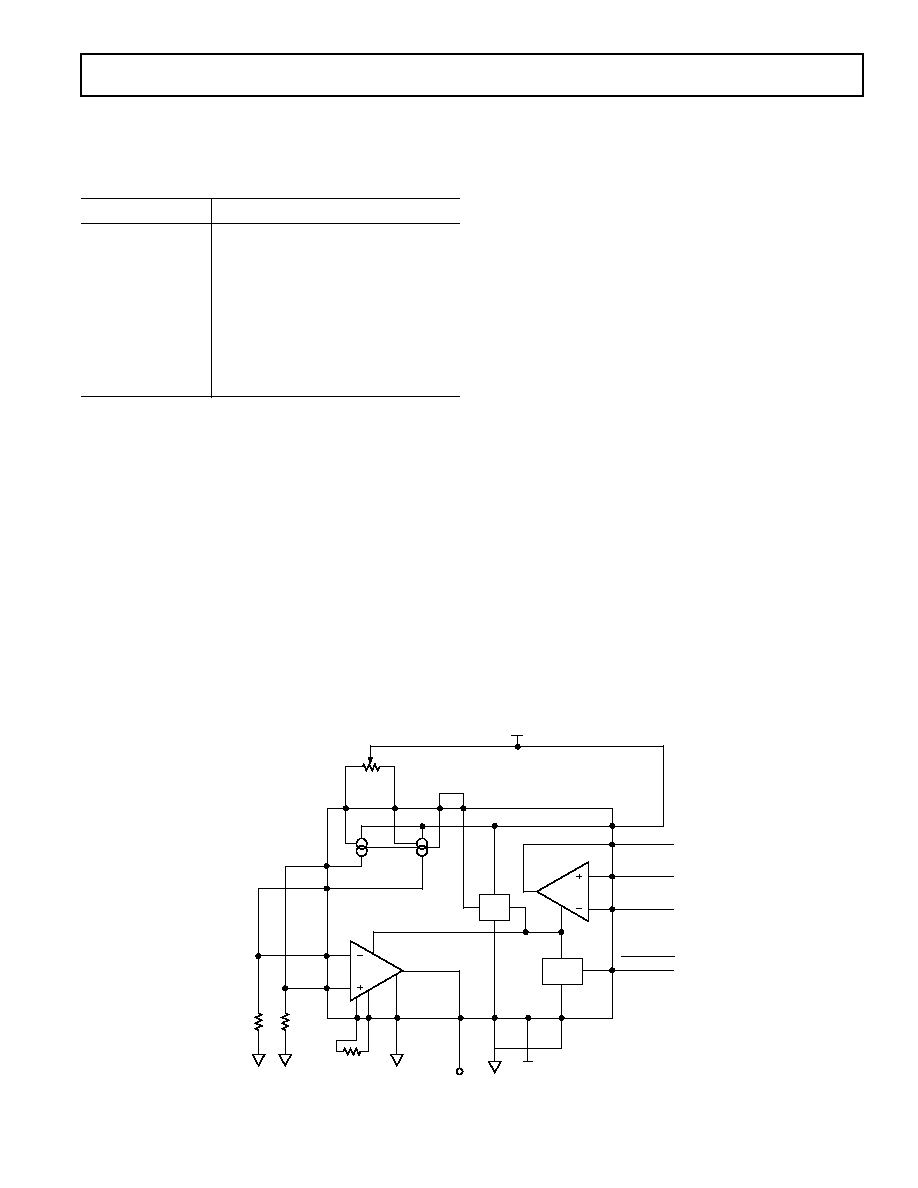

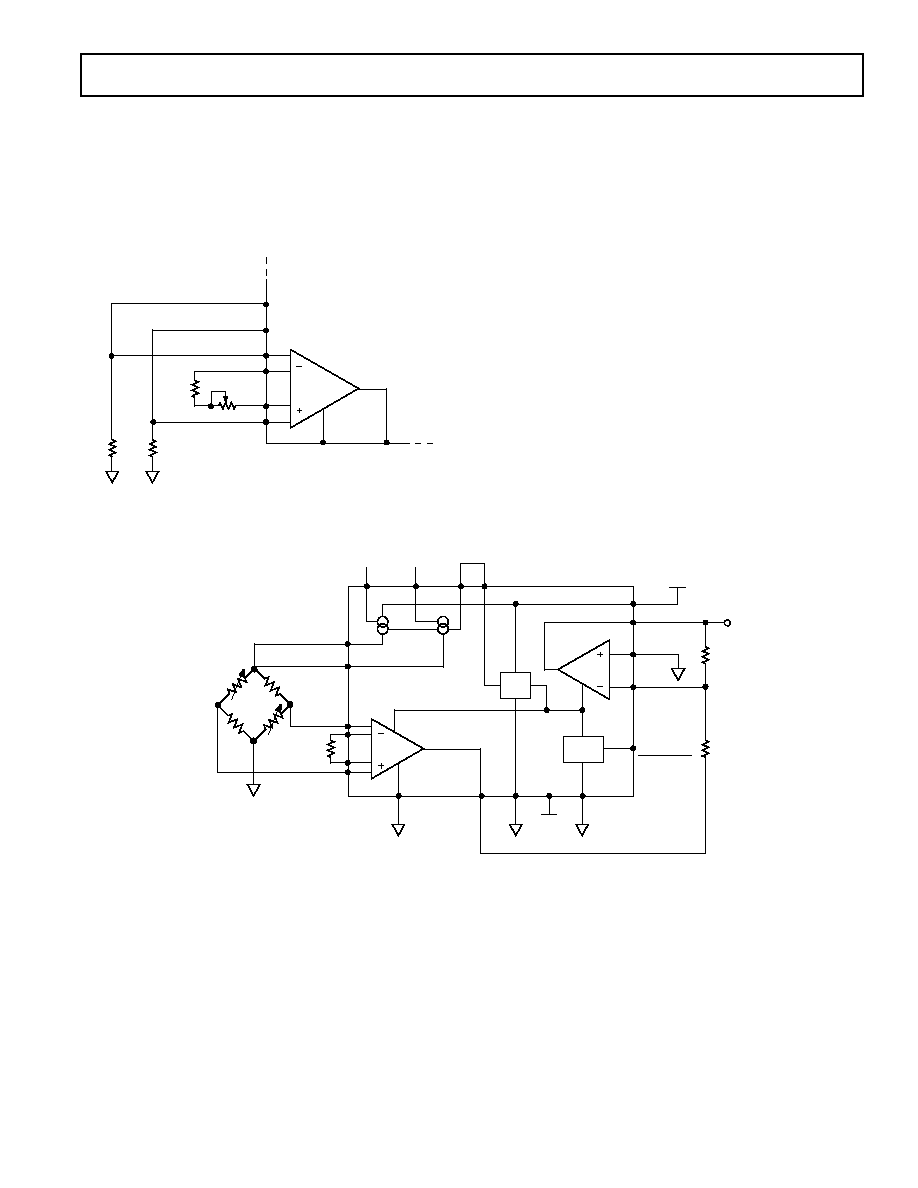

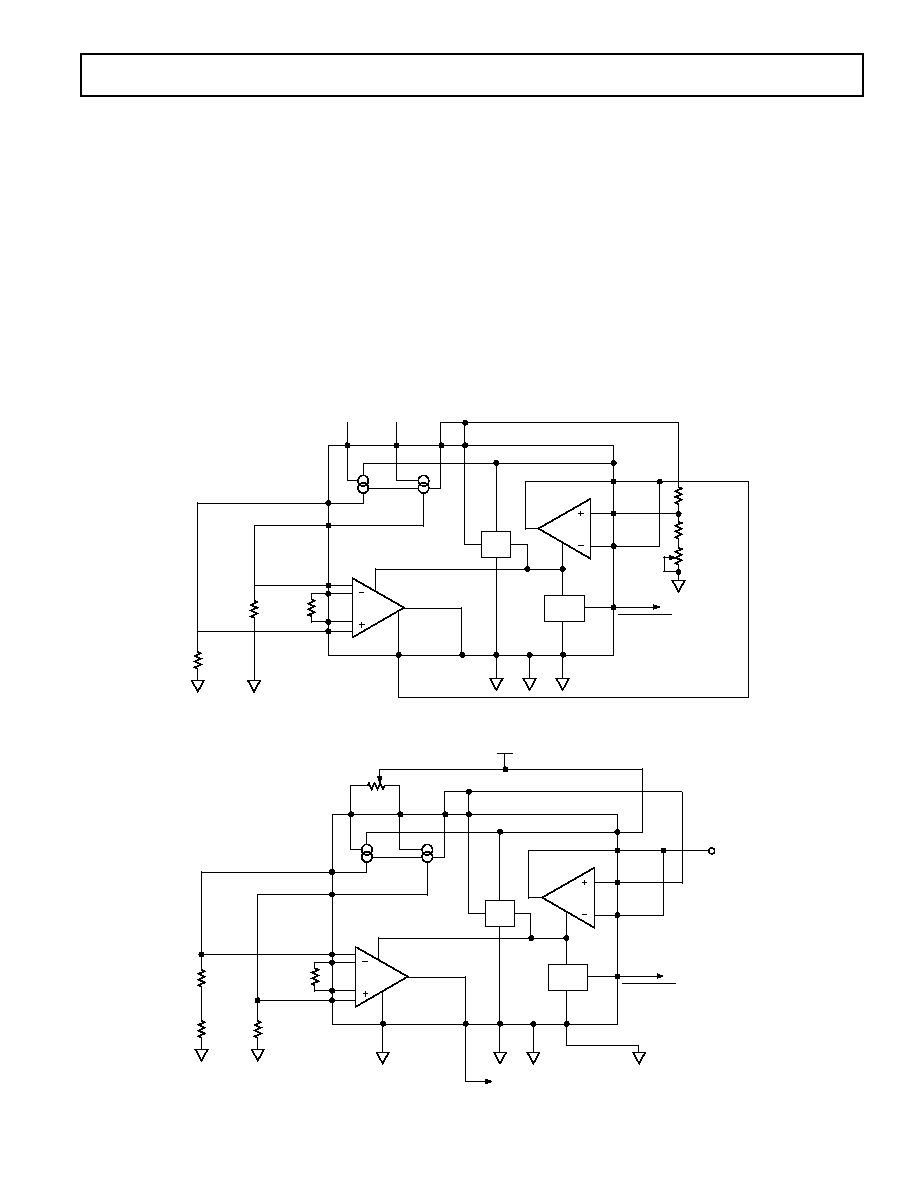

FUNCTIONAL BLOCK DIAGRAM

RGA RGB

IN

IA

+IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

OUT

IA

AGND

DGND

V

S

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS 2.5V

REFOUT

ADT70

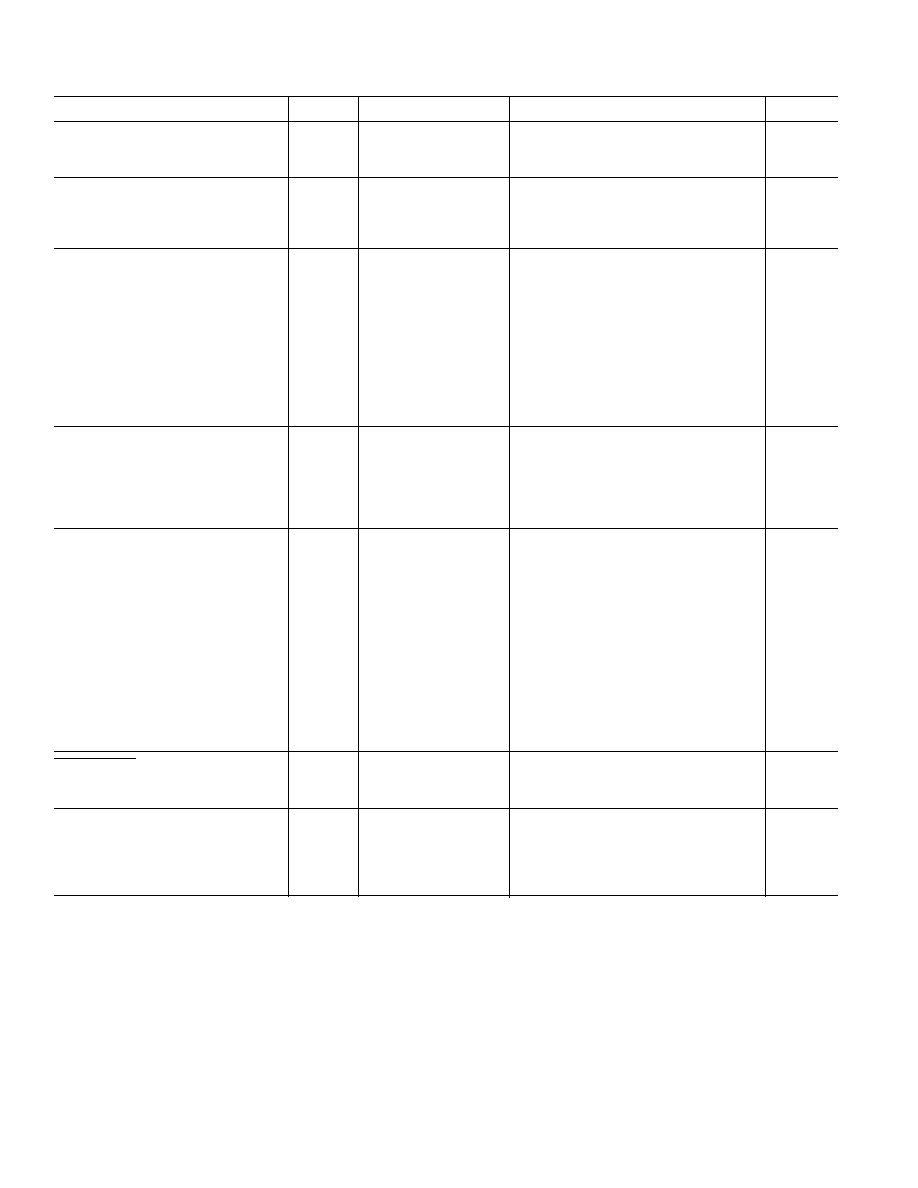

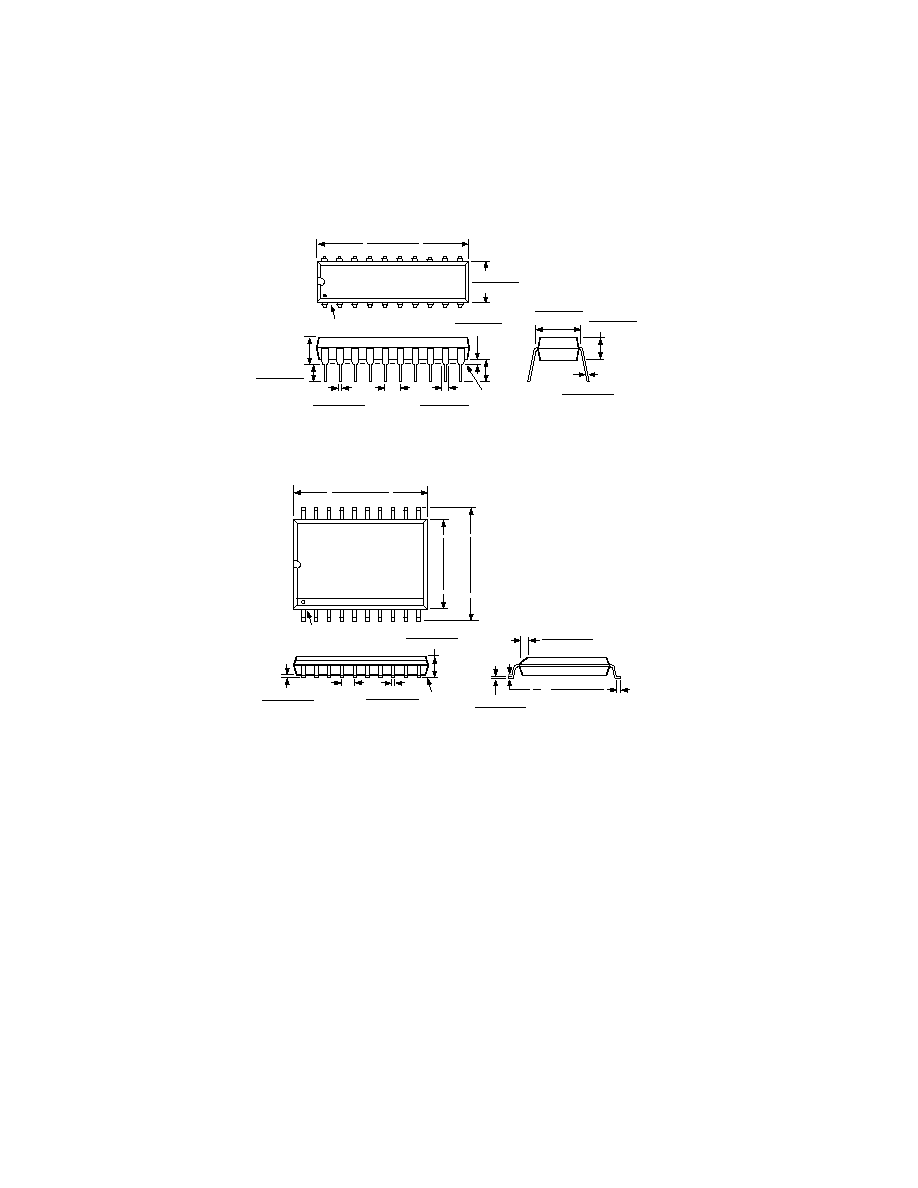

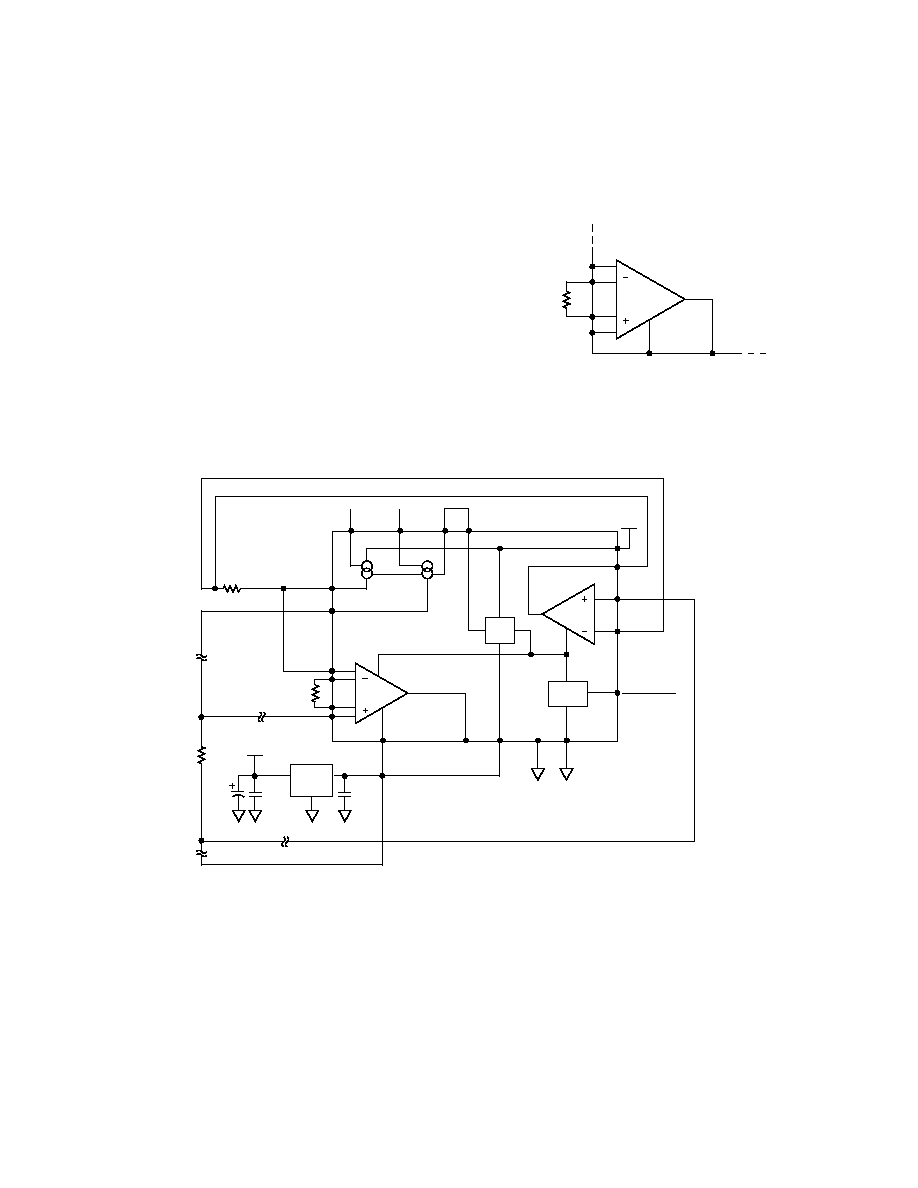

PIN CONFIGURATIONS

20-Lead P-DIP

(N Suffix)

SHUTDOWN

14

13

12

11

17

16

15

20

19

18

10

9

8

1

2

3

4

7

6

5

V

S

+IN

OA

IN

OA

V

OUT

OA

+V

S

AGND

V

REFOUT

BIAS

V

OUT

IA

DGND

NULLA

NULLB

I

OUTA

I

OUTB

IN

IA

+IN

IA

RGA

RGB

GND SENSE

a

ADT70

TOP VIEW

(Not to Scale)

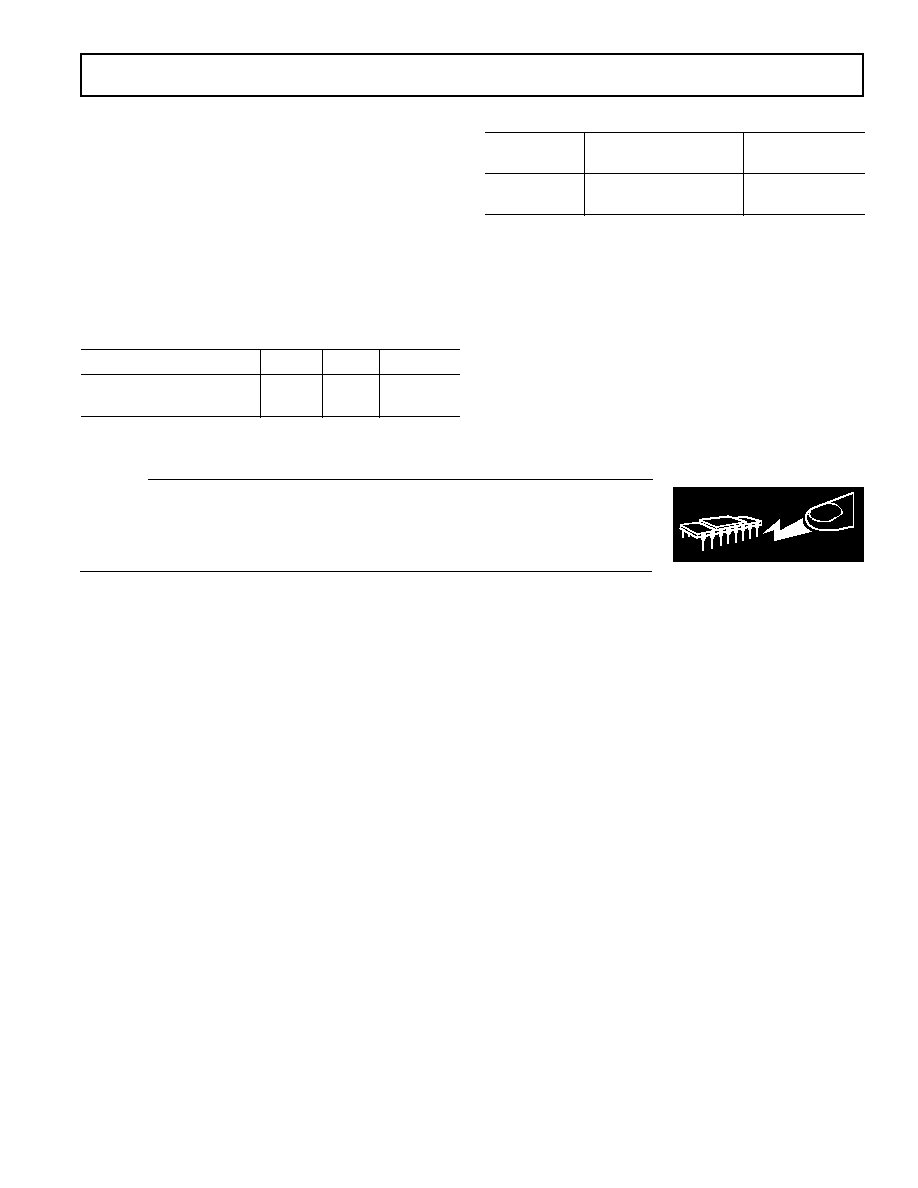

20-Lead SOIC

(R Suffix)

14

13

12

11

17

16

15

20

19

18

10

9

8

1

2

3

4

7

6

5

V

S

+IN

OA

IN

OA

V

OUT OA

+V

S

AGND

V

REFOUT

BIAS

V

OUT

IA

DGND

SHUTDOWN

NULLA

NULLB

I

OUTA

I

OUTB

IN

IA

IN

IA

RGA

RGB

GND SENSE

ADT70

TOP VIEW

(Not to Scale)

a

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

a

PRTD Conditioning Circuit

and Temperature Controller

ADT70*

FEATURES

PRTD Temperature Measurement Range

Typical IC Measurement Error 1 C

Includes Two Matched Current Sources

Rail-to-Rail Output Instrumentation Amp

Uncommitted, Rail-to-Rail Output Op Amp

On-Board 2.5 V Reference

Temperature Coefficient 25 ppm/ C

5 V or 5 V Operation

Supply Current 4 mA Max

10 A Max in Shutdown

APPLICATIONS

Temperature Controllers

Portable Instrumentation

Temperature Acquisition Cards

GENERAL DESCRIPTION

The ADT70 provides excitation and signal conditioning for

resistance-temperature devices (RTDs). It is ideally suited for

1 k

Platinum RTDs (PRTDs), allowing a very wide range of

temperature measurement. It can also easily interface to 100

PRTDs. Using a remote, low cost thin-film PRTD, the ADT70

can measure temperature in the range of 50

°

C to +500

°

C.

With high performance platinum elements, the temperature

change can be extended to 1000

°

C. Accuracy of the ADT70

and PRTD system over a 200

°

C to +1000

°

C temperature

range heavily depends on the quality of the PRTD. Typically

the ADT70 will introduce an error of only

±

1

°

C over the

transducer's temperature range, and the error may be trimmed

to zero at a single calibration point.

The ADT70 consists of two matched 1 mA (nominal) current

sources for transducer and reference resistor excitation, a preci-

sion rail-to-rail output instrumentation amplifier, a 2.5 V refer-

ence and an uncommitted rail-to-rail output op amp. The

ADT70 includes a shutdown function for battery powered

equipment, which reduces the quiescent current from 4 mA to

less than 10

µ

A. The ADT70 operates from either single +5 V

or

±

5 V supplies. Gain or full-scale range for the PRTD and

ADT70 system is set by a precision external resistor connected

to the instrumentation amplifier. The uncommitted op amp may

be used for scaling the internal voltage reference, providing a

"PRTD open" signal or "over-temperature" warning, a heater

switching signal, or other external conditioning determined by

the user.

The ADT70 is specified for operation from 40

°

C to 125

°

C

and is available in 20-lead DIP and SO packages.

*

Patent pending.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700

World Wide Web Site: http://www.analog.com

Fax: 781/326-8703

© Analog Devices, Inc., 1998

Parameter

Symbol

Conditions

Min

Typ

Max

Units

SYSTEM CONFIGURATION

Gain

R

L

= 1 k

1.234

1.295

1.364

mV/

Line Regulation

2.25

0.35

2.25

%/V

CURRENT SOURCES

Output Current

I

Q1

, I

Q2

R

L

= 1 k

0.9

mA

Output Current Mismatch

I

Q1

I

Q2

R

L

= 1 k

2

0.5

2

µ

A

Voltage Compliance

V

S

to +V

S

1.5

V

INSTRUMENTATION AMP

Input Offset Voltage

V

IOS

700

150

700

µ

V

T

A

= +25

°

C

500

100

500

µ

V

Output Offset Voltage

V

OOS

12

5

12

mV

T

A

= +25

°

C

7

3

7

mV

Input Bias Current

I

B

75

40

75

nA

T

A

= +25

°

C

60

30

60

nA

Input Offset Current

I

OS

3

1

3

nA

Common-Mode Rejection

CMR

V

CM

= 0.5 V to 3 V

65

85

dB

Output Voltage Swing

V

OUT

R

L

=

, V

S

= 5 V

V

S

+ 25

+V

S

25

mV

Power Supply Rejection Ratio

PSRR

+ 4.5 V

V

S

5.5 V

2.5

0.5

2.5

mV/V

VOLTAGE REFERENCE

Output Voltage

2.485

2.5

2.515

V

T

A

= +25

°

C

2.49

2.5

2.51

V

Load Regulation

I

L

= 0 mA to 1 mA

250

ppm/mA

Temperature Coefficient

10

ppm/

°

C

Line Regulation

+ 4.5 V

V

S

+5.5 V

75

ppm/V

OPERATIONAL AMPLIFIER

Input Offset Voltage

V

IOA

1,000

400

1,000

µ

V

T

A

= +25

°

C

800

200

800

µ

V

Input Offset Voltage Drift

T

C

V

IOA

1

µ

V/

°

C

Input Bias Current

I

B

75

40

75

nA

T

A

= +25

°

C

60

30

60

nA

Input Offset Current

I

OS

3

1

3

nA

Open-Loop Voltage Gain

A

VOL

R

L

=

2

V/

µ

V

Output Voltage Swing

V

OUTA

R

L

=

V

S

+ 10

+V

S

10

mV

Common-Mode Rejection Ratio

CMRR

V

CM

= 1 V to 4 V

85

105

dB

T

A

= +25

°

C

88

110

dB

Power Supply Rejection Ratio

PSRR

3 V

V

S

6 V

100

150

dB

Slew Rate

SR

T

A

= +25

°

C, A

V

= 1,

0.17

V/

µ

s

V

IN

= 0 V to 4 V

SHUTDOWN INPUT

Input Low Voltage

V

IL

0.8

V

Input High Voltage

V

IH

2.4

V

POWER SUPPLY

Supply Current

I

SY

R

L

= 1 k

3.5

5

mA

Shutdown Supply Current

I

SD

10

30

µ

A

Supply Voltage

V

S

+4.5

+5.5

V

Dual Supply Voltage

4.5

5.5

V

Specifications subject to change without notice.

ADT70SPECIFICATIONS

REV. 0

2

(V

S

= 5 V, 40 C

T

A

125 C unless otherwise noted)

ADT70

REV. 0

3

ORDERING GUIDE

Temperature

Model

Range

Package

ADT70GR

40

°

C to 125

°

C

20-Lead SOIC

ADT70GN

40

°

C to 125

°

C

20-Lead PDIP

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 V

Output Short-Circuit Duration . . . . . . . . . . . . . . . . . Indefinite

Storage Temperature Range

N, R Package . . . . . . . . . . . . . . . . . . . . . .

65

°

C to 150

°

C

Operating Temperature Range . . . . . . . . . .

40

°

C to 125

°

C

Junction Temperature Range

N, R Package . . . . . . . . . . . . . . . . . . . . . .

65

°

C to 125

°

C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . .

300

°

C

NOTE

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those listed in the operational sections

of this specification is not implied. Exposure to absolute maximum rating condi-

tions for extended periods may affect device reliability.

Package Type

JA

*

JC

Units

20-Lead SOIC (R)

74

24

°

C/W

20-Lead PDIP (N)

102

31

°

C/W

NOTE

*

JA

is specified for device in socket/soldered on circuit board (worst case conditions).

TRANSISTOR COUNT: 158

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADT70 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

ADT70

REV. 0

4

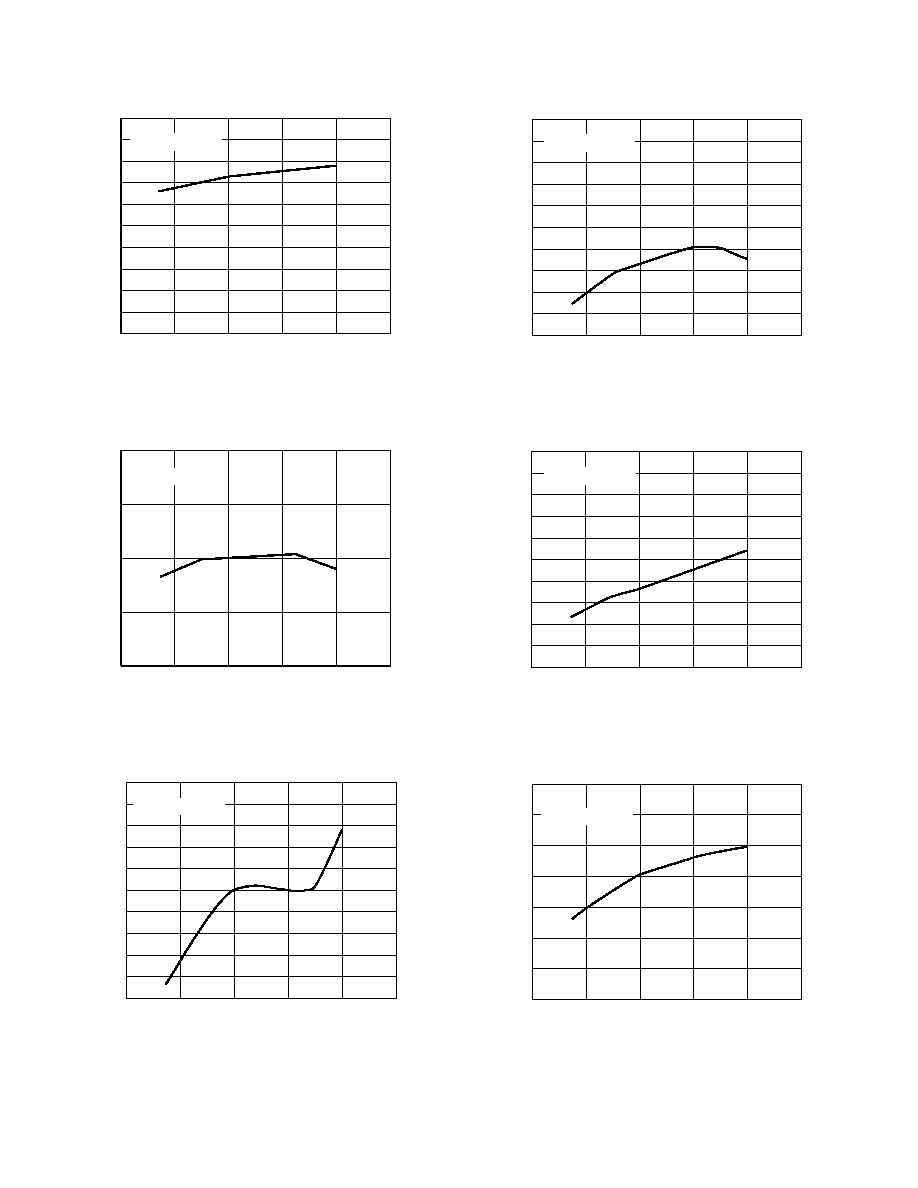

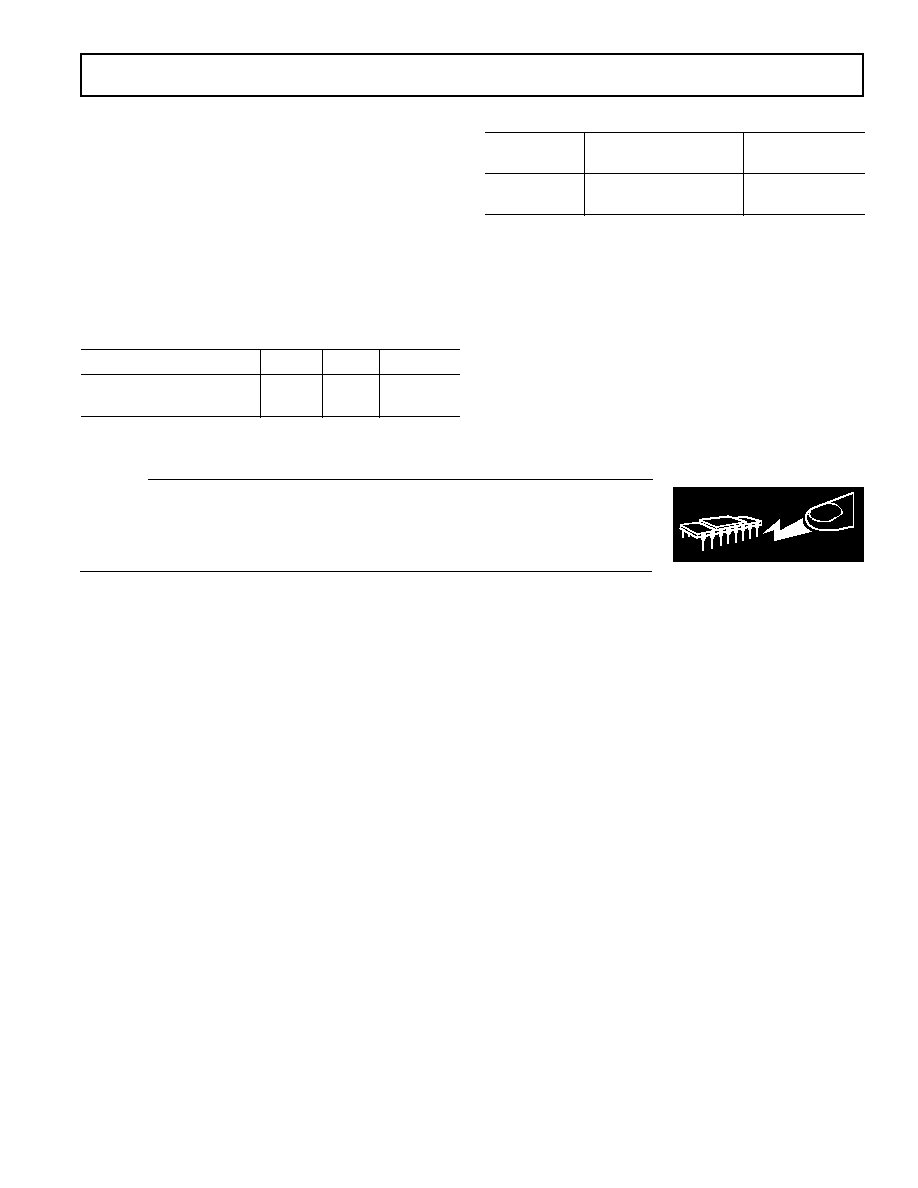

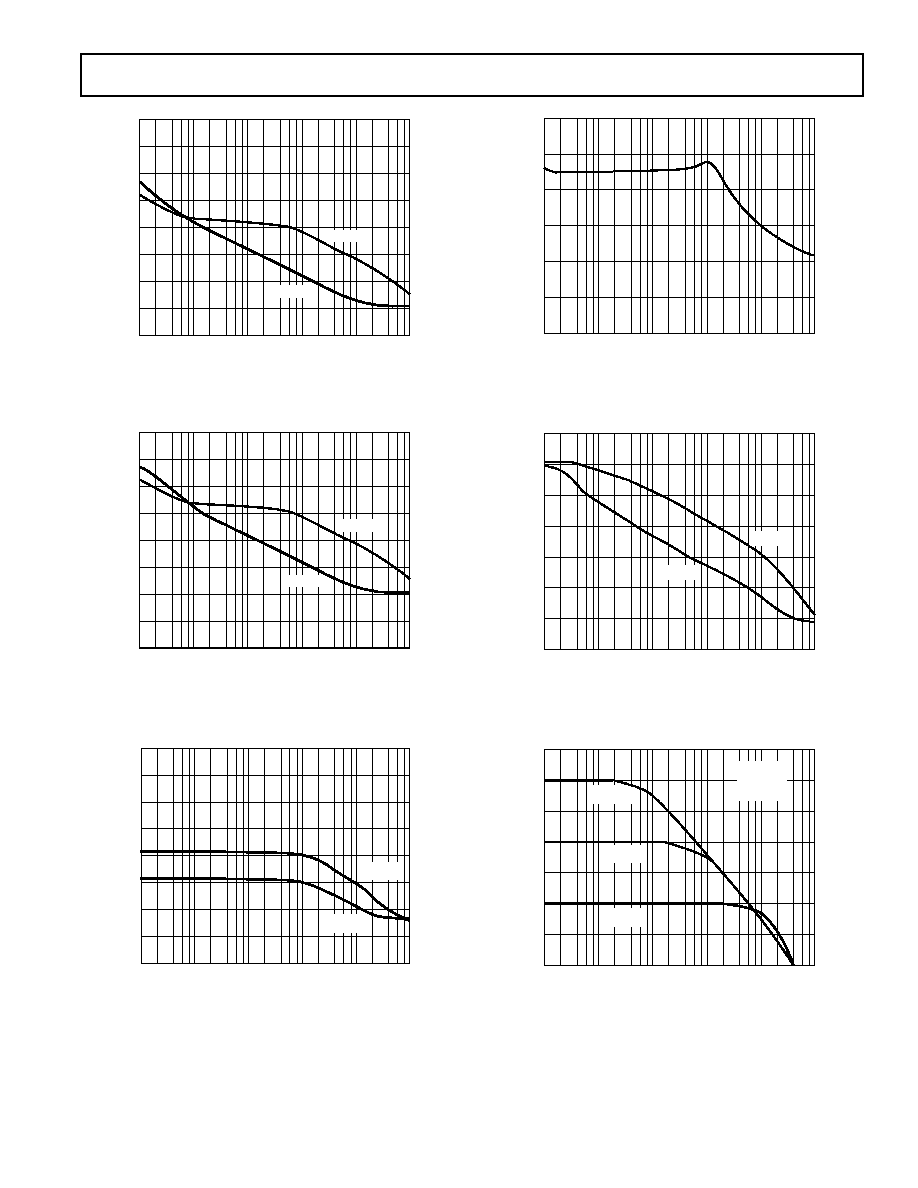

TEMPERATURE C

5

4

0

SUPPLY CURRENT mA

3

2

1

25

25

75

125

0.5

1.5

2.5

3.5

4.5

V

S

= +5V, NO LOAD

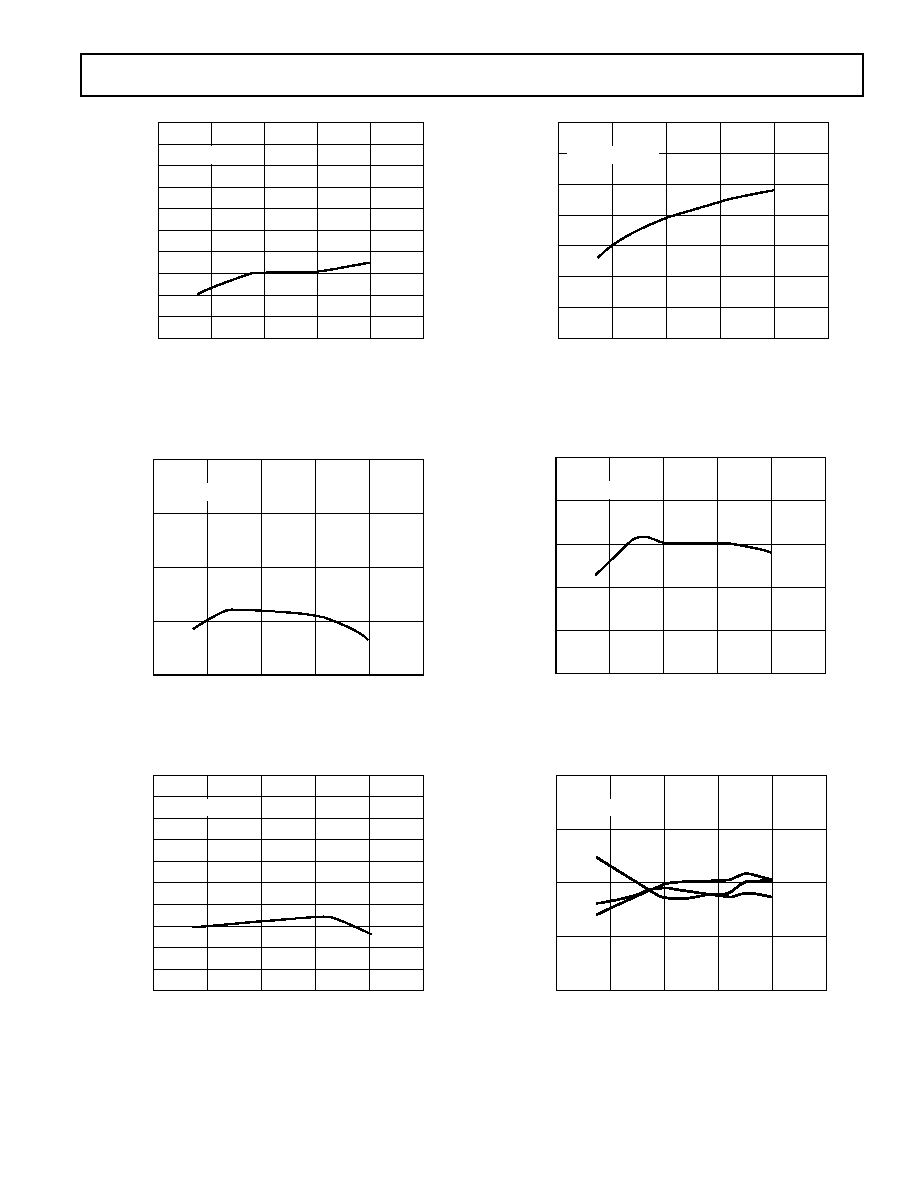

Figure 1. Supply Current vs. Temperature

TEMPERATURE C

SYSTEM GAIN mV/

25

25

75

125

1.2

1.25

1.3

V

S

= +5V, NO LOAD

1.4

1.35

Figure 2. System Gain vs. Temperature

TEMPERATURE C

SYSTEM GAIN PSRR %/V

25

25

75

125

0.06

V

S

= +5V, NO LOAD

0.08

0.1

0.04

0.02

0

0.02

0.04

0.06

0.08

0.1

Figure 3. Total System Gain PSRR vs. Temperature

TEMPERATURE C

INSTRUMENTATION AMPLIFIER INPUT

OFFSET VOLTAGE

V

25

25

75

125

60

V

S

= +5V, NO LOAD

80

100

40

20

0

20

40

60

80

100

Figure 4. Instrumentation Amplifier Input Offset Voltage

vs. Temperature

TEMPERATURE C

INSTRUMENTATION AMPLIFIER OUTPUT

OFFSET VOLTAGE mV

25

25

75

125

6

V

S

= +5V, NO LOAD

8

10

4

2

0

2

4

6

8

10

Figure 5. Instrumentation Amplifier Output Offset Voltage

vs. Temperature

TEMPERATURE C

INSTRUMENTATION AMPLIFIER INPUT

BIAS CURRENT nA

25

25

75

125

V

S

= +5V, NO LOAD

70

60

0

50

40

30

20

10

Figure 6. Instrumentation Amplifier Input Bias Current vs.

Temperature

ADT70

REV. 0

5

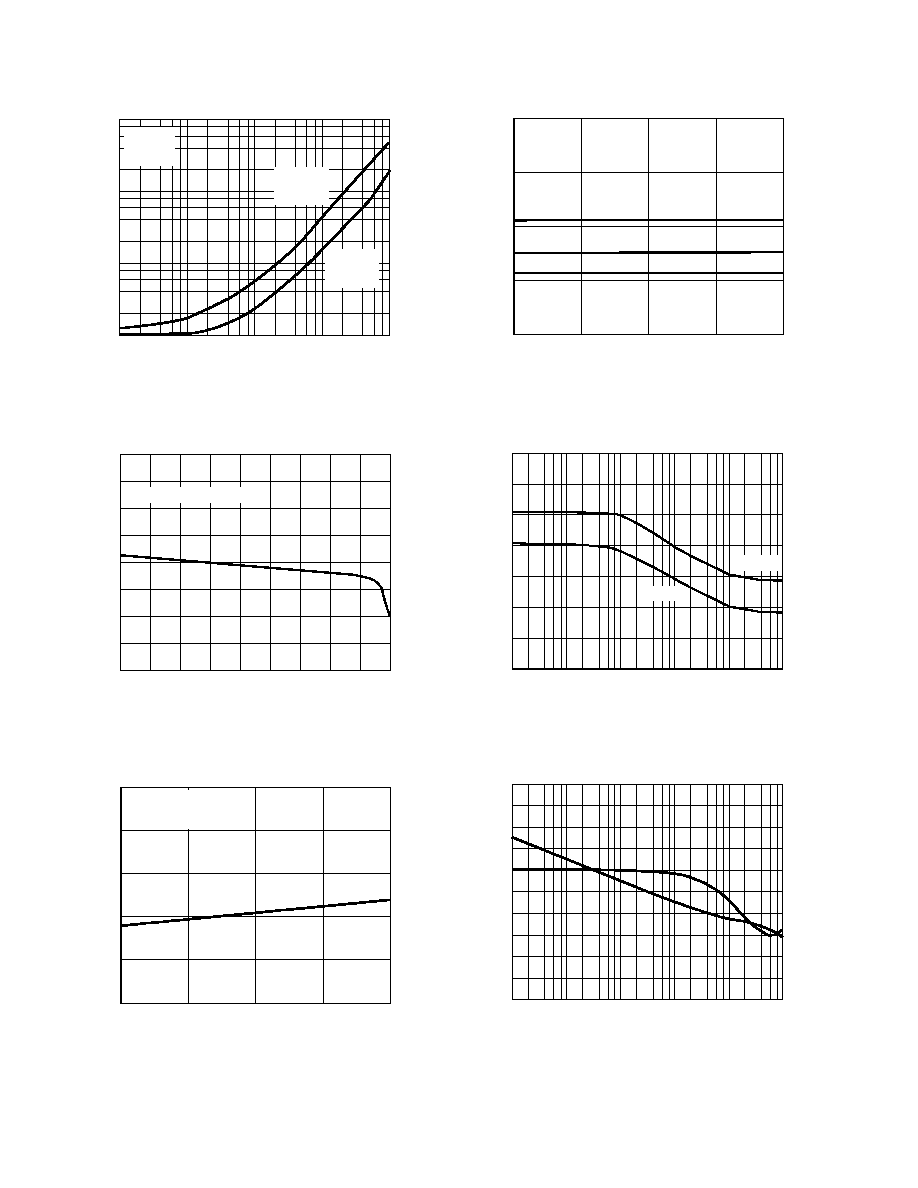

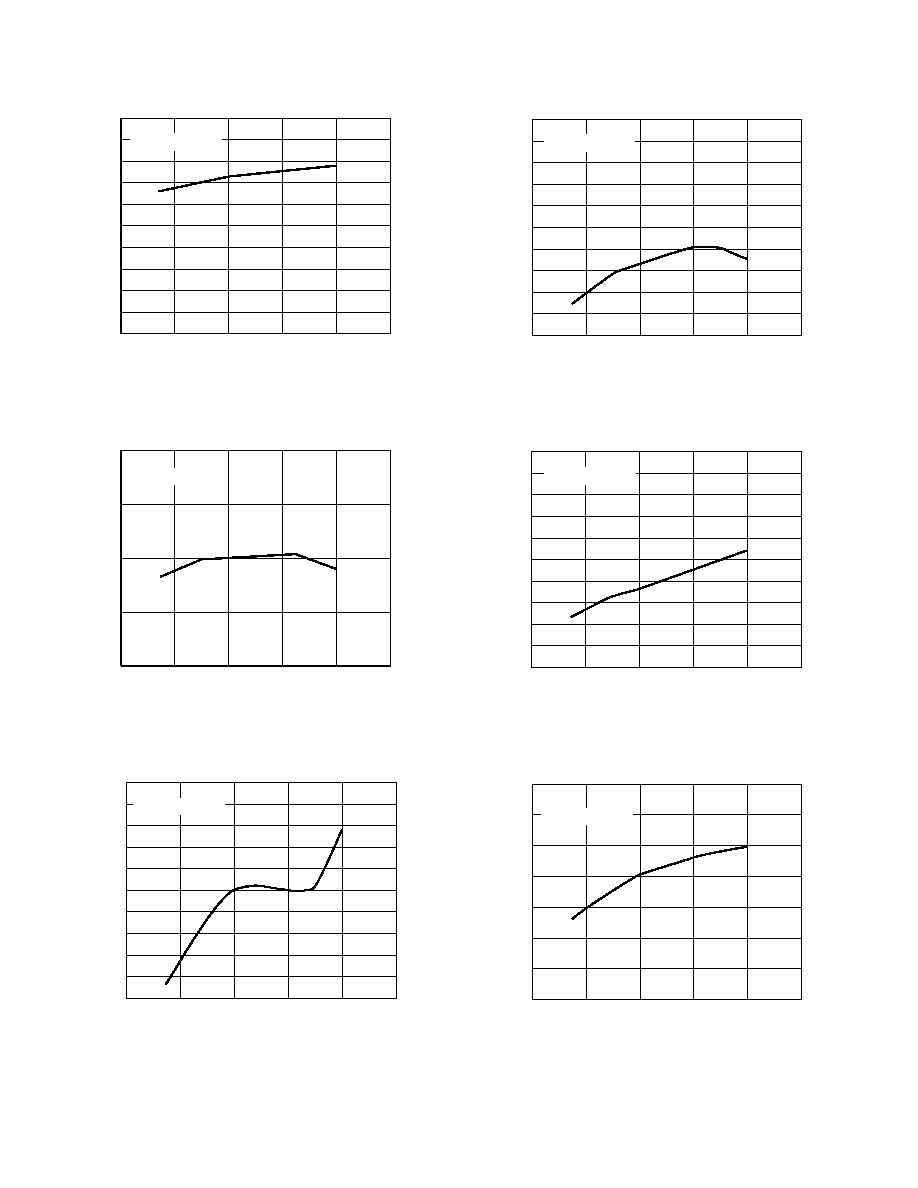

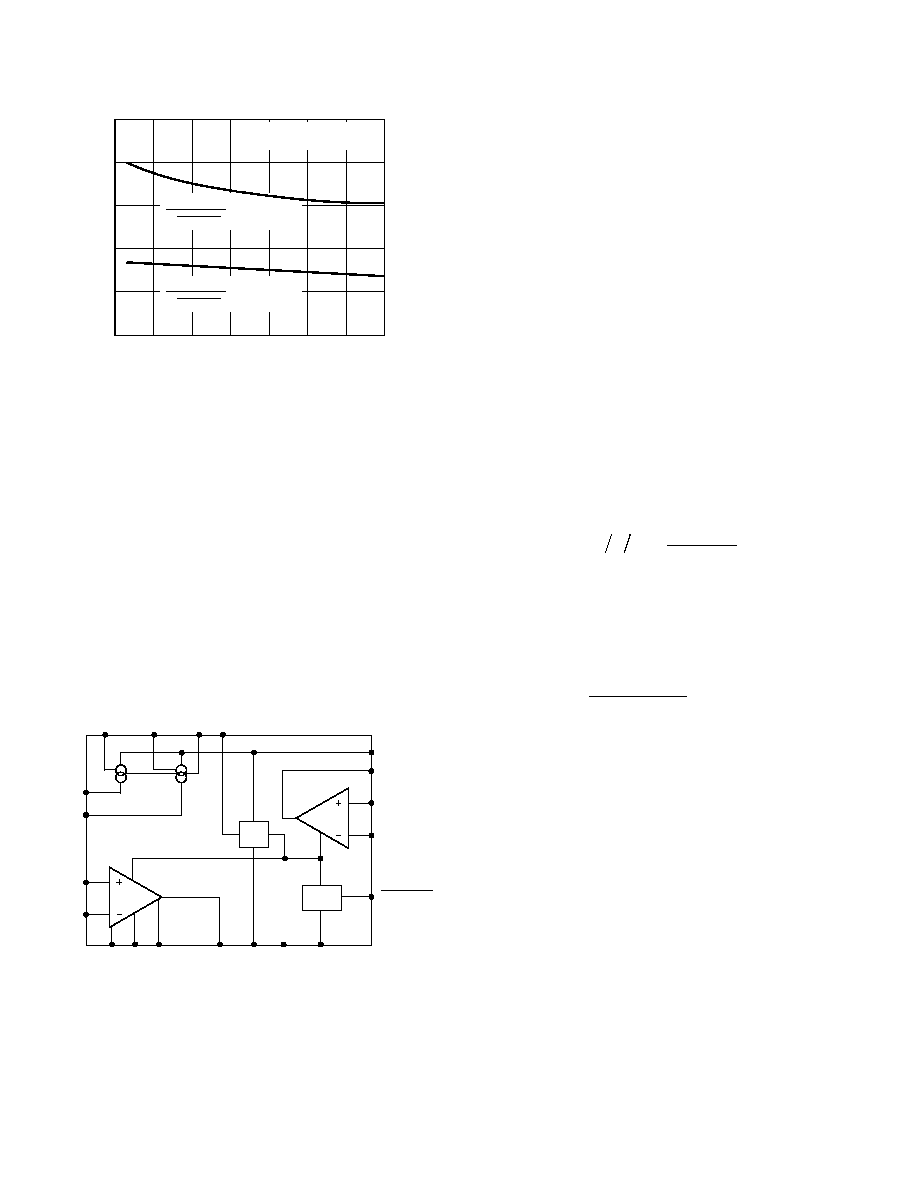

TEMPERATURE C

INSTRUMENTATION AMPLIFIER INPUT

OFFSET CURRENT pA

25

25

75

125

300

V

S

= +5V, NO LOAD

400

500

200

100

500

0

100

200

300

400

Figure 7. Instrumentation Amplifier Input Offset Current

vs. Temperature

TEMPERATURE C

INSTRUMENTATION AMPLIFIER GAIN V/V

25

25

75

125

1.45

V

S

= +5V, NO LOAD

1.4

1.5

1.55

1.6

Figure 8. Instrumentation Amplifier Gain vs. Temperature

TEMPERATURE C

OP AMP INPUT OFFSET VOLTAGE

V

25

25

75

125

60

V

S

= +5V, NO LOAD

80

100

40

20

100

0

20

40

60

80

Figure 9. Op Amp Input Offset Voltage vs. Temperature

TEMPERATURE C

OP AMP INPUT BIAS CURRENT nA

25

25

75

125

V

S

= +5V, NO LOAD

70

60

0

50

40

30

20

10

Figure 10. Op Amp Input Bias Current vs. Temperature

TEMPERATURE C

OP AMP INPUT OFFSET CURRENT pA

25

25

75

125

V

S

= +5V, NO LOAD

500

0

100

200

300

400

Figure 11. Op Amp Input Offset Current vs. Temperature

TEMPERATURE C

REFERENCE VOLTAGE V

25

25

75

125

V

S

= +5V, NO LOAD

2.49

2.495

2.5

2.505

2.51

Figure 12. Reference Voltage vs. Temperature

ADT70

REV. 0

6

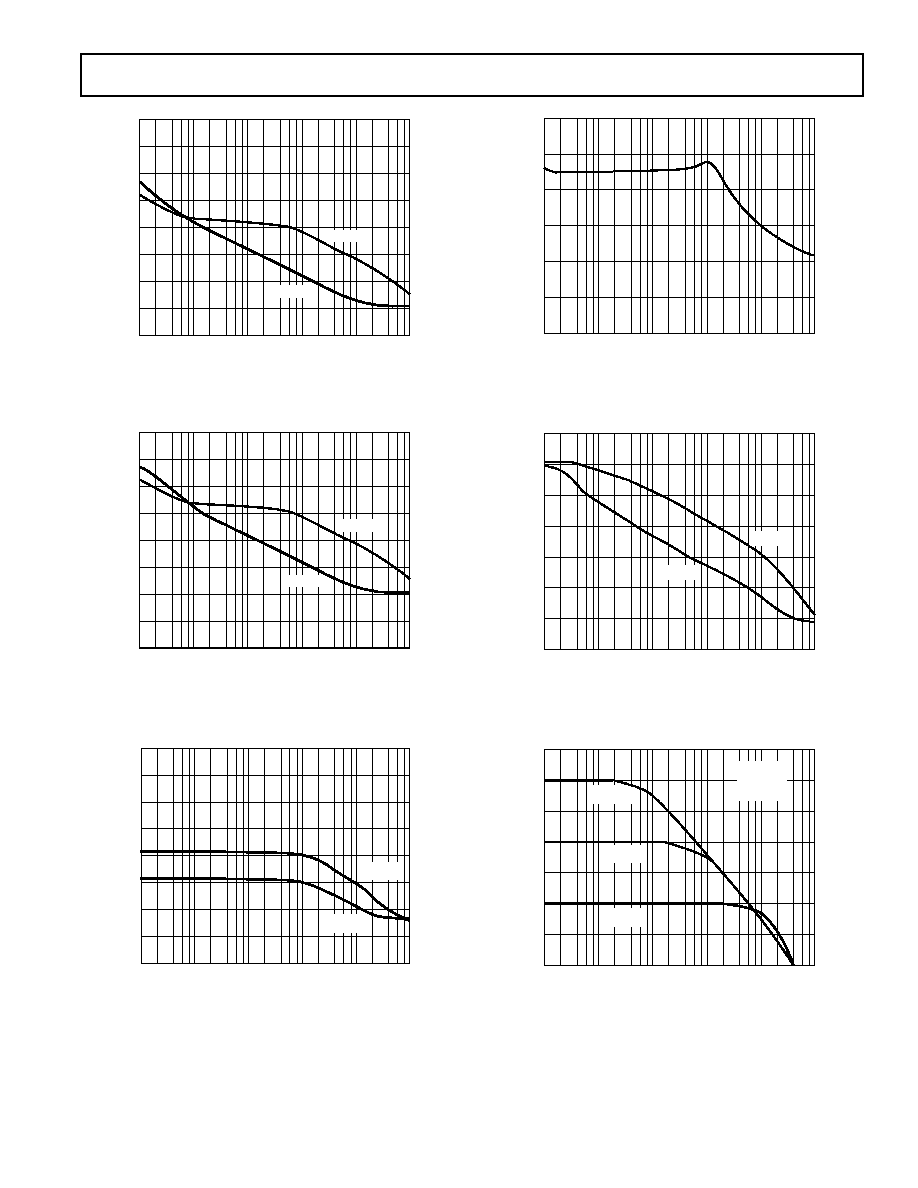

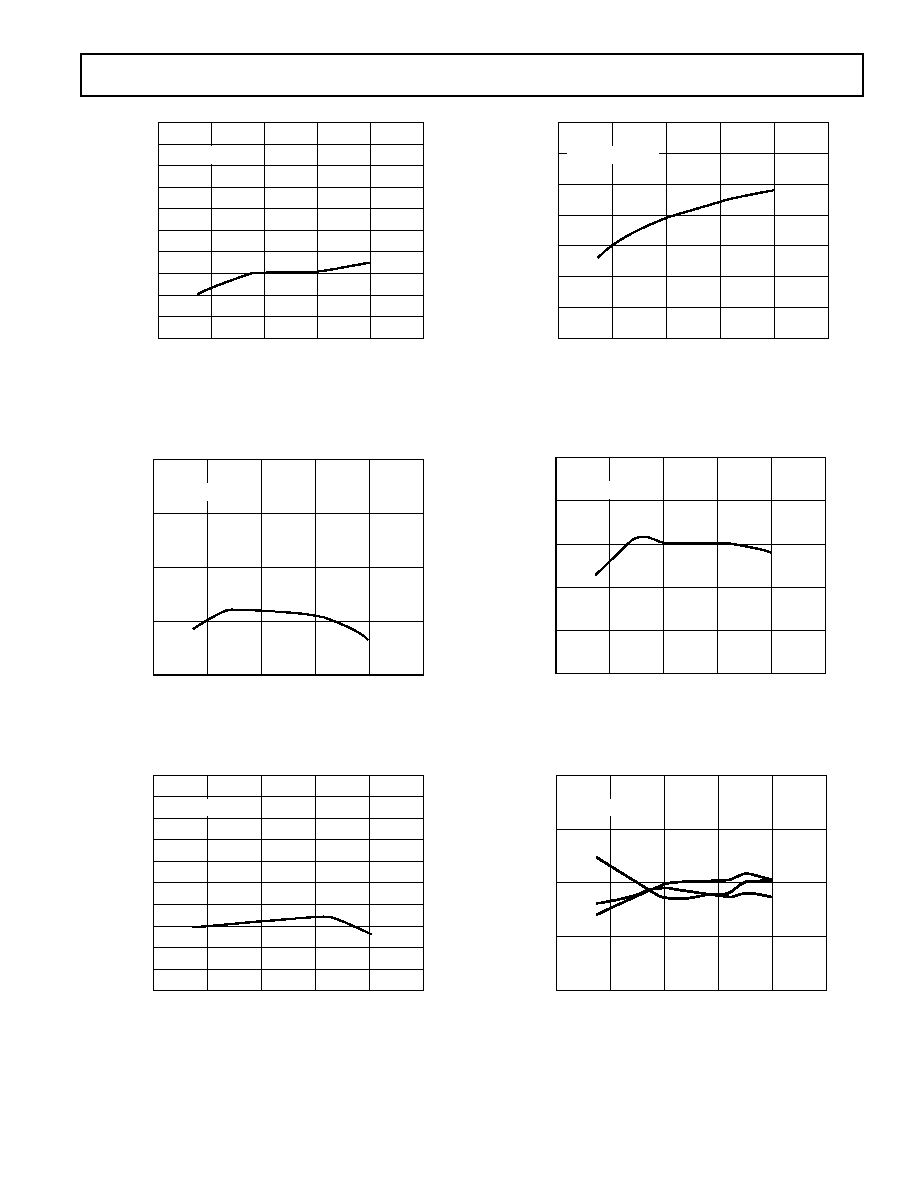

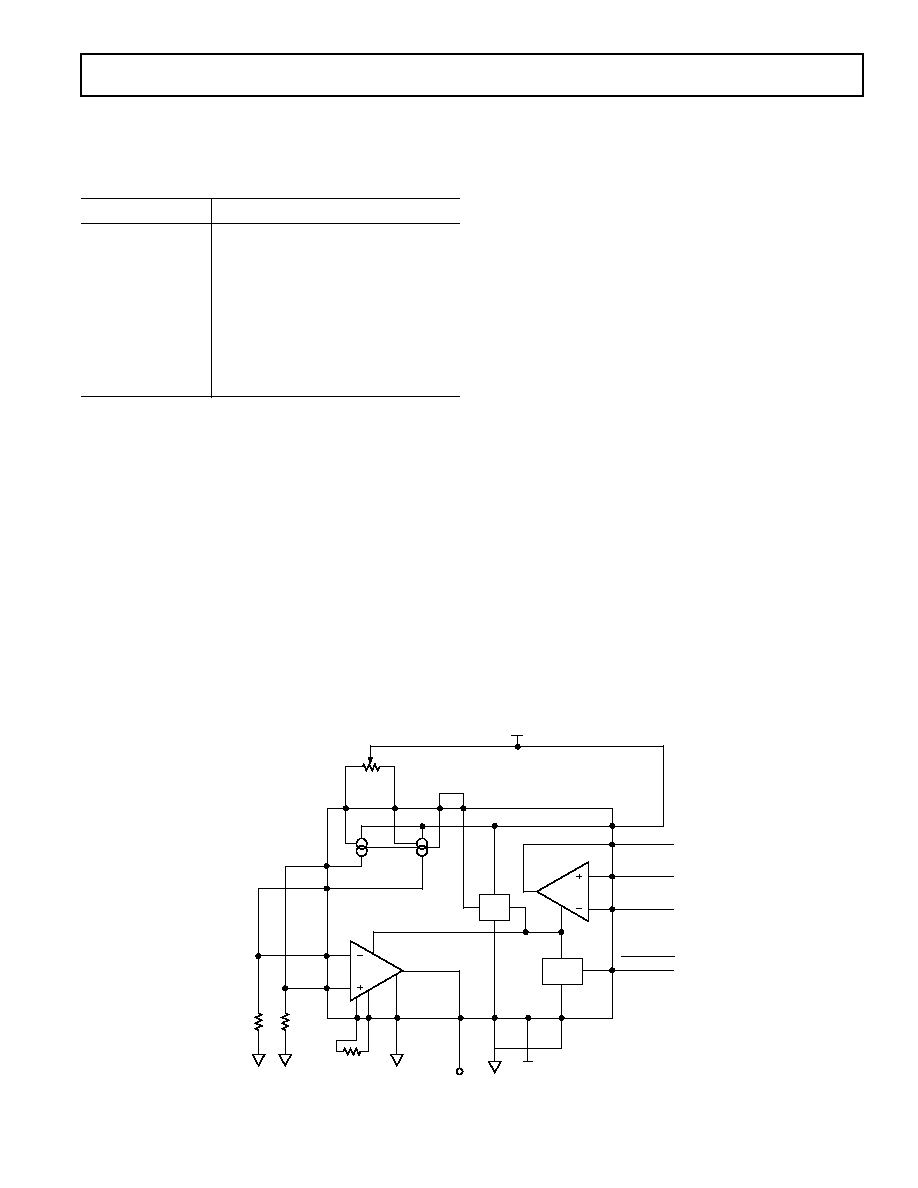

LOAD CURRENT A

1

1

10

RAIL OUTPUT VOLTAGE mV

10

100

1000

100

1k

10k

V

CC

= 5V

V

EE

= 0

T

A

= +25 C

V

CC

,

SOURCING

CURRENT

V

EE

,

SINKING

CURRENT

Figure 13. Op Amp Output Voltage from Rails vs.

Load Current

LOAD CURRENT mA

2.48

0

9

1

REFERENCE VOLTAGE V

2

3

4

5

6

7

8

2.485

2.49

2.495

2.5

2.505

2.51

2.515

2.52

V

S

= +5V, DUT SOURCING

Figure 14. Reference Voltage vs. Load Current

SUPPLY VOLTAGE Volts

4

3

4.5

I

SY

, SUPPLY CURRENT mA

3.2

4.75

5.0

5.25

5.5

T

A

= +25 C

V

CM

INAMP = 1V

V

EE

= GND

3.4

3.6

3.8

Figure 15. Supply Current vs. Supply Voltage

SUPPLY VOLTAGE Volts

910

4.75

OUTPUT OF CURRENT SOURCE

A

920

930

940

950

4.5

5.0

5.25

5.5

V

CC

= 5V

V

EE

= 0V

V

REF

= 2.5V

+125 C

+25 C

55 C

Figure 16. Output of Current Source vs. Supply Voltage

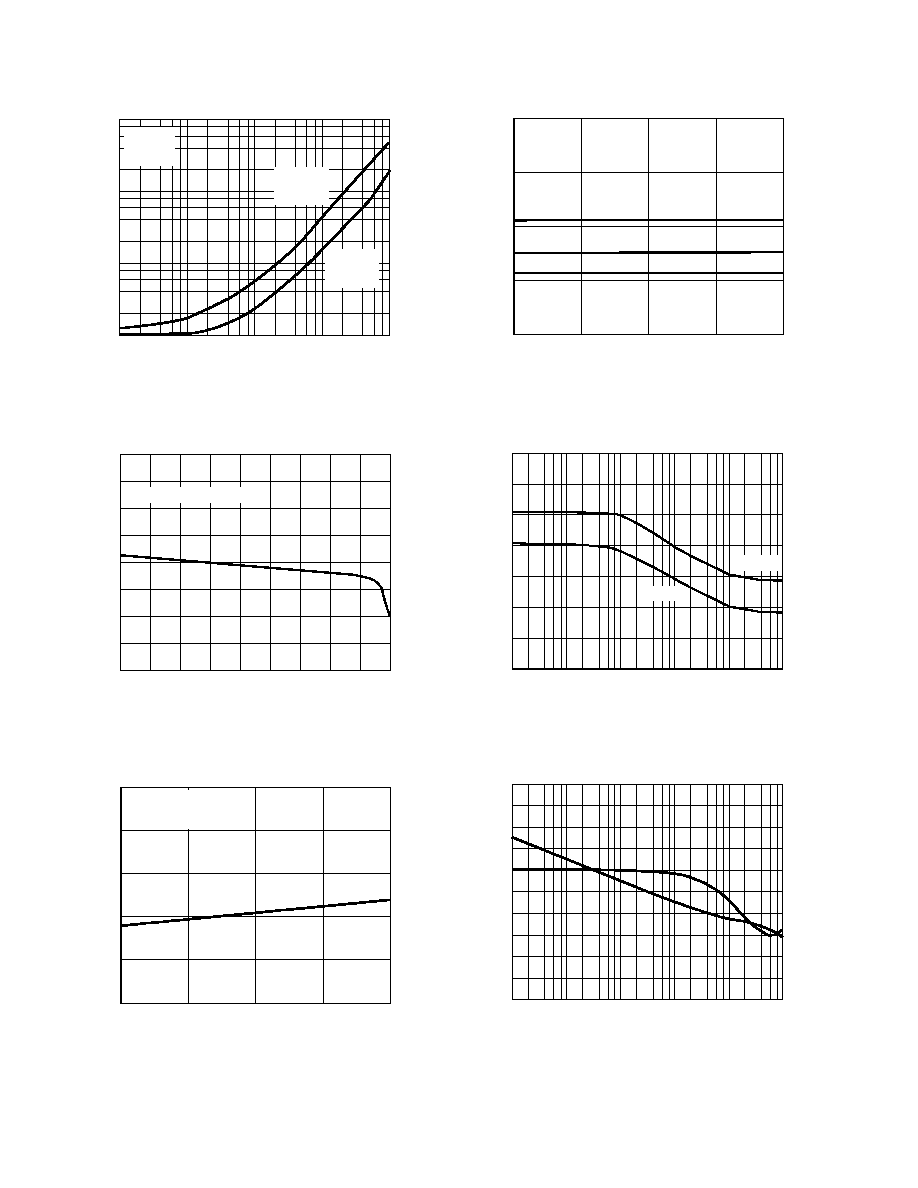

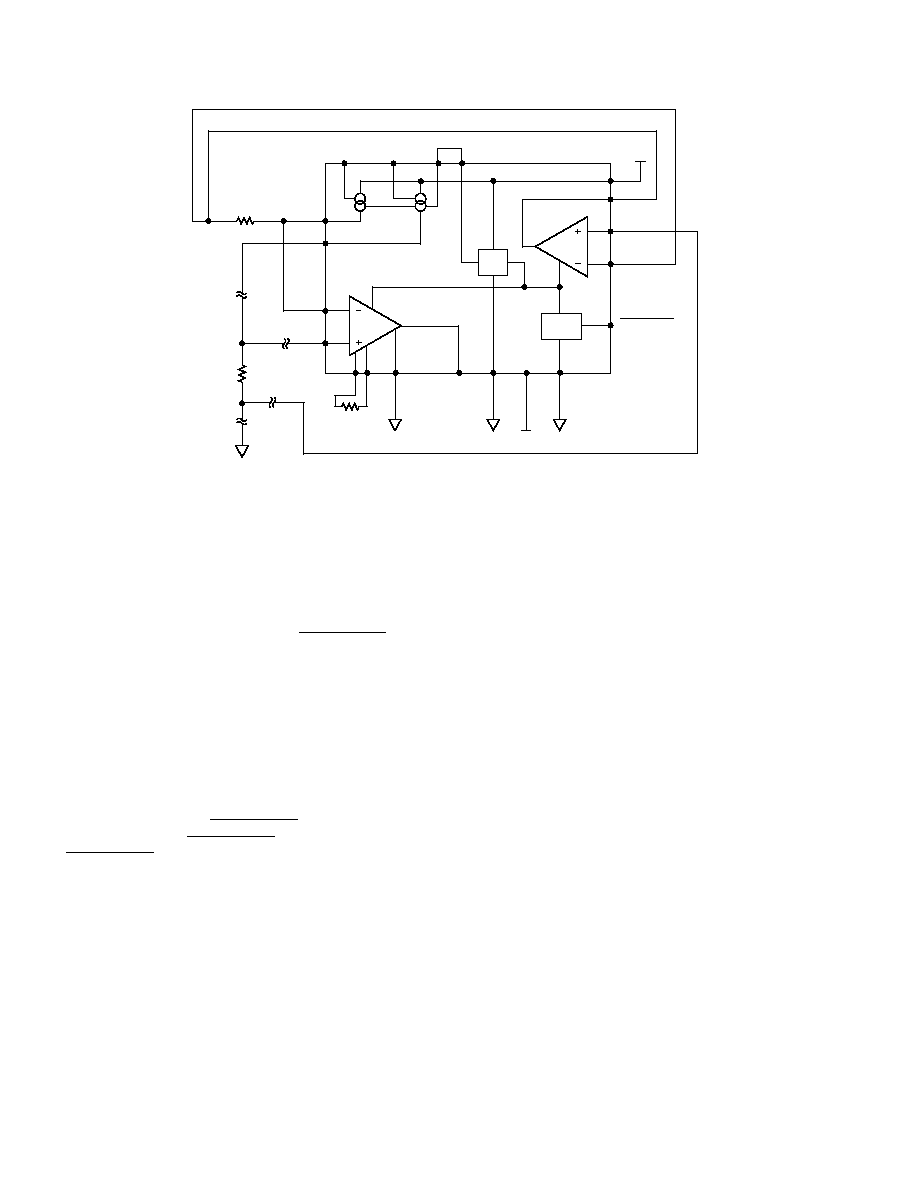

FREQUENCY Hz

0

10

CMRR dB

100

1k

10k

100k

1M

20

40

60

80

100

120

140

A

V

= 14

A

V

= 1.4

Figure 17. In Amp CMRR vs. Frequency

FREQUENCY Hz

100

GAIN dB

80

1k

10k

100k

1M

10M

60

40

20

0

20

40

60

80

100

120

135

90

45

0

45

90

135

PHASE MARGIN Degrees

180

180

225

270

Figure 18. Op Amp Open Loop Gain and Phase vs.

Frequency

ADT70

REV. 0

7

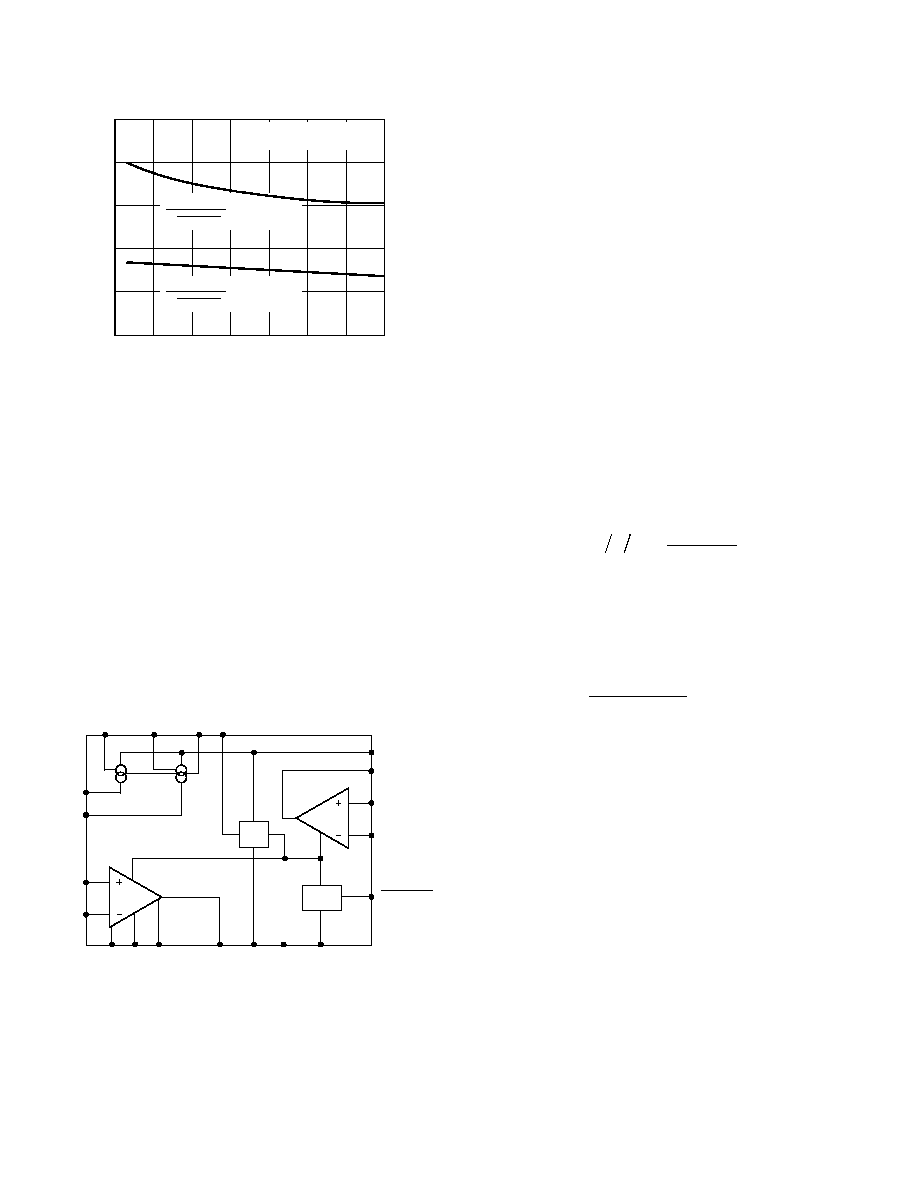

FREQUENCY Hz

10

CMRR dB

100

1k

10k

100k

1M

0

20

40

60

80

100

120

Figure 22. Op Amp CMRR vs. Frequency

FREQUENCY Hz

10

PSRR dB

100

1k

10k

100k

1M

20

20

40

60

80

100

120

0

+ PSRR

PSRR

Figure 23. Op Amp PSRR vs. Frequency

FREQUENCY Hz

100

CLOSED LOOP GAIN dB

20

1k

10k

100k

1M

10M

10

0

10

20

30

40

50

A

VCL

= 0

A

VCL

= 100

A

VCL

= 10

T

A

= +25 C

V

CC

= 4V

V

EE

= 1V

Figure 24. Op Amp Closed Loop Gain vs. Frequency

FREQUENCY Hz

10

PSRR dB

100

1k

10k

100k

1M

20

0

20

40

60

80

100

120

140

+ PSRR

PSRR

Figure 19. In Amp PSRR vs. Frequency A

V

= 1.4

FREQUENCY Hz

10

PSRR dB

100

1k

10k

100k

1M

20

0

20

40

60

80

100

120

140

+ PSRR

PSRR

Figure 20. In Amp PSRR vs. Frequency A

V

= 14

FREQUENCY Hz

100

CLOSED LOOP GAIN dB

60

1k

10k

100k

1M

10M

40

20

0

20

40

60

80

100

A

V

= 14

A

V

= 1.4

Figure 21. In Amp Closed Loop Gain vs. Frequency

ADT70

REV. 0

8

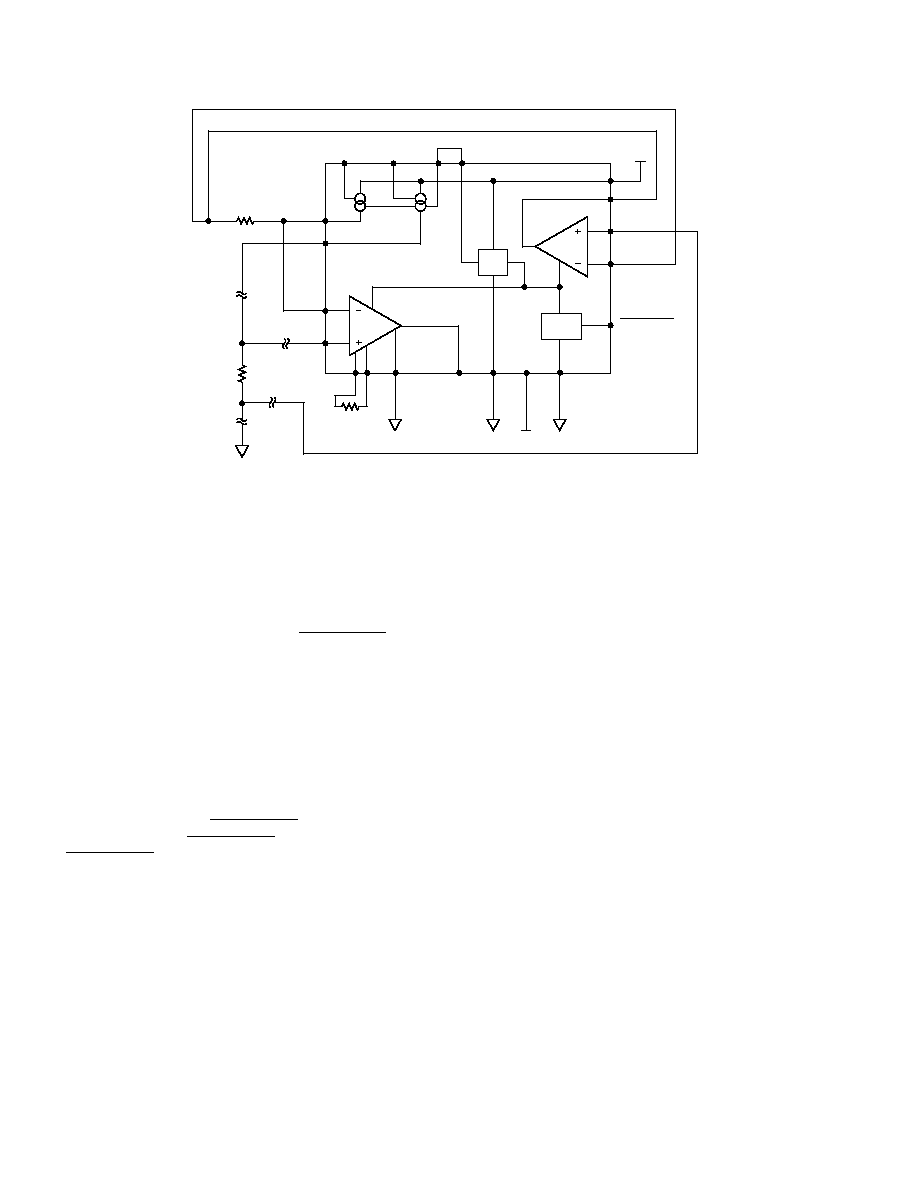

FUNCTIONAL DESCRIPTION

The ADT70 provides excitation and signal conditioning for

resistance-temperature devices (RTDs). It is ideally suited for

1 k

Platinum RTDs (PRTDs), which allow a much wider

range of temperature measurement than silicon-based sensors.

Using a low cost PRTD, the ADT70 can measure temperatures

in the range of 50

°

C to +500

°

C.

The two main components in the ADT70 are the adjustable

current sources and the instrumentation amplifier. The current

sources provide matching excitation currents to the PRTD and

to the Reference Resistor. The instrumentation amplifier com-

pares the voltage drop across both the PRTD and Reference

Resistor, and provides an amplified output signal voltage that is

proportional to temperature.

Besides the matching current sources and the instrumentation

amplifier, there is a general purpose op amp for any application

desired. The ADT70 comes with a +2.5 V reference on board.

RGA RGB

IN

IA

+IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

OUT

IA

AGND

DGND

V

S

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS 2.5V

REFOUT

ADT70

SHUTDOWN

Figure 26. Block Diagram

What is an RTD?

The measurable temperature range of the ADT70 heavily de-

pends on the characteristics of the resistance-temperature detec-

tor (RTD). Thus, it is important to choose the right RTD to

suit the actual application.

A basic physical property of any metal is that its electrical resis-

tivity changes with temperature. Some metals are known to have

a very predictable and repeatable change of resistance for a

given change in temperature. An RTD is fabricated from one of

these metals to a nominal ohmic value at a specified tempera-

ture. By measuring its resistance at some unknown temperature

and comparing this value to the resistor's nominal value, the

change in resistance is determined. Because the temperature vs.

resistance characteristics are also known, the change in tempera-

ture from the point initially specified can be calculated. This

makes the RTD a practical temperature sensor, which in its bare

form is a resistive element.

Several types of metal can be chosen for fabricating RTDs.

These include: Copper, balco (an iron-nickel alloy), nickel,

tungsten, iridium and platinum. Platinum is by far the most

popular material used, due to its nearly linear response to tem-

perature, wide temperature operating range and superior long-

term stability. The price of Platinum Resistance Temperature

Detectors (PRTDs) are becoming more competitive through the

wide use of thin-film-type resistive elements.

Temperature Coefficient of Resistance

The temperature coefficient (TC, also referred to as

) of an

RTD, describes the average resistance change per unit tempera-

ture from the ice point to the boiling point of water.

TCR

C

R

R

C

R

°

(

)

=

-

° ×

100

0

0

100

R

0

= Resistance of the sensor at 0

°

C

R

100

= Resistance of the sensor at +100

°

C

TCR = Thermal Coefficient of Resistance.

For example, a platinum thermometer measuring 100

at 0

°

C

and 138.5

at 100

°

C, has TCR 0.00385

/

/

°

C .

TCR

C

=

-

×

°

=

138 5

100

100

100

0 00385

.

.

The larger the TCR, the greater the change in resistance for a

given change in temperature. The most common use of TCR is

to distinguish between curves for platinum, which is available

with TCRs ranging from 0.00375 to 0.003927. The highest

TCR indicates the highest purity platinum and is mandated by

ITS-90 for standard platinum thermometers.

Basically, TCRs must be properly matched when replacing RTDs

or connecting them to instruments. There are no technical advan-

tages of one TCR over another in practical industrial applica-

tions. 0.00385 platinum is the most popular worldwide standard

and is available in both wire-wound and thin-film elements.

Understanding Error Source

The ADT70 uses an instrumentation amplifier that amplifies the

difference in voltage drop across the RTD and the reference resis-

tor, to output a voltage proportional to the measured temperature.

Thus, it is important to use a reference resistor that has stable resis-

tance over temperature. The accuracy of the reference resistor

should be determined by the end application.

The lead resistance of wires connecting to the RTD and the refer-

ence resistor can add inaccuracy to the ADT70. If the reference

resistor is located close to the part, while the RTD is located at a

remote location connected by wires, the lead-wires' resistance

TEMPERATURE C

0

50

SYSTEM RESPONSE TIME

s

0

10

25

25

50

75

100

125

20

30

40

50

V

OUT

OF IN AMP = 300mV

V

CC

= 5V SINGLE SUPPLY

= LOW TO HIGH

TURNING ON

V

SHUTDOWN

= HIGH TO LOW

TURNING OFF

V

SHUTDOWN

Figure 25. System Response Time from Shutdown vs.

Temperature

ADT70

REV. 0

9

would contribute to the difference in voltage drop between the

RTD and the reference resistor. Thus, an error in reading the ac-

tual temperature could occur.

Table I. Copper Wire Gauge Size to Resistance Table.

Lead-wire AWG

Ohms/foot at +25ºC

12

0.0016

14

0.0026

16

0.0041

18

0.0065

20

0.0103

22

0.0162

24

0.0257

26

0.0413

28

0.0651

30

0.1027

From Table I the amount of lead-wire resistance effect in the

circuit can be estimated. For example, connect 100 feet of

AWG 22 wire to a 100

Platinum RTD (PF element). The

lead-wire resistance will be: R = 100 ft 3 0.0162

/ft = 1.62

.

Thus the total resistance you have with the PRTD will be:

R

TOTAL

.

.

=

+

=

100

1 62

101 62

Since the 100

reference resistor is assumed to be relatively close

to the ADT70, the lead-wire resistance is negligible. This shows

1.62

of inaccuracy.

From the PRTD's data sheet, the PRTD's sensitivity rating

(

/

°

C) can be used with the lead-wire resistance to approximate

the accuracy error in temperature degree (

°

C). Following the ex-

ample above, the sensitivity of the 100

PRTD is 0.385

/

°

C

(taken from PRTD data sheet). Hence the approximate error is:

Error

C

C

=

° =

°

1 62

0 385

4 21

. / .

/

.

assuming the reference resistor is constant at 100

throughout

the temperature range.

As shown above, this is a significant inaccuracy, especially for ap-

plications where the PRTD would be hundreds of feet away from

the ADT70. To reduce lead-wire error it is recommended to use

a larger sensitivity RTD; 1 k

instead of 100

. Furthermore, in

the application circuit section, Figure 28 illustrates how to elimi-

nate such error by using the part's general purpose op amp.

Self-Heating Effect

Another contributor to measurement error is the self-heating ef-

fect on the RTD. As with any resistive element, power is dissi-

pated in an amount equal to the square of the excitation current

times the resistance of the element. The error contribution of the

heat generated by this power dissipation can easily be calculated.

For example, if the package thermal resistance is 50

°

C/W, the

RTD nominal resistance is 1 k

and the element is excited with a

1 mA current source, then the artificial increase in temperature

(

ºC) as a result of self-heating is:

° =

×

C

I R

PACKAGE

2

0

° =

( )

×

× °

C

mA

C W

1

1000

50

2

/

° =

°

C

C

0 05

.

where:

PACKAGE

= thermal resistance of package

R

0

= value of RTD resistance

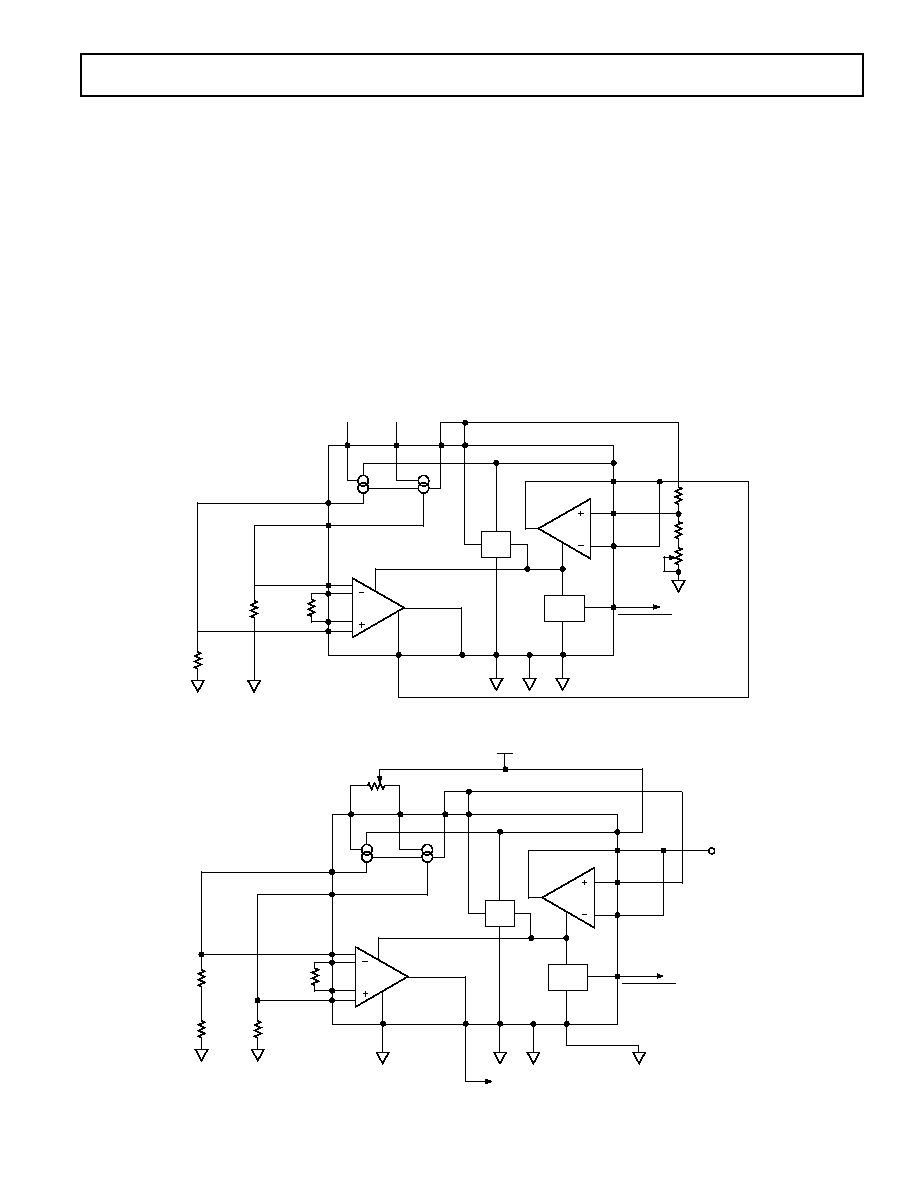

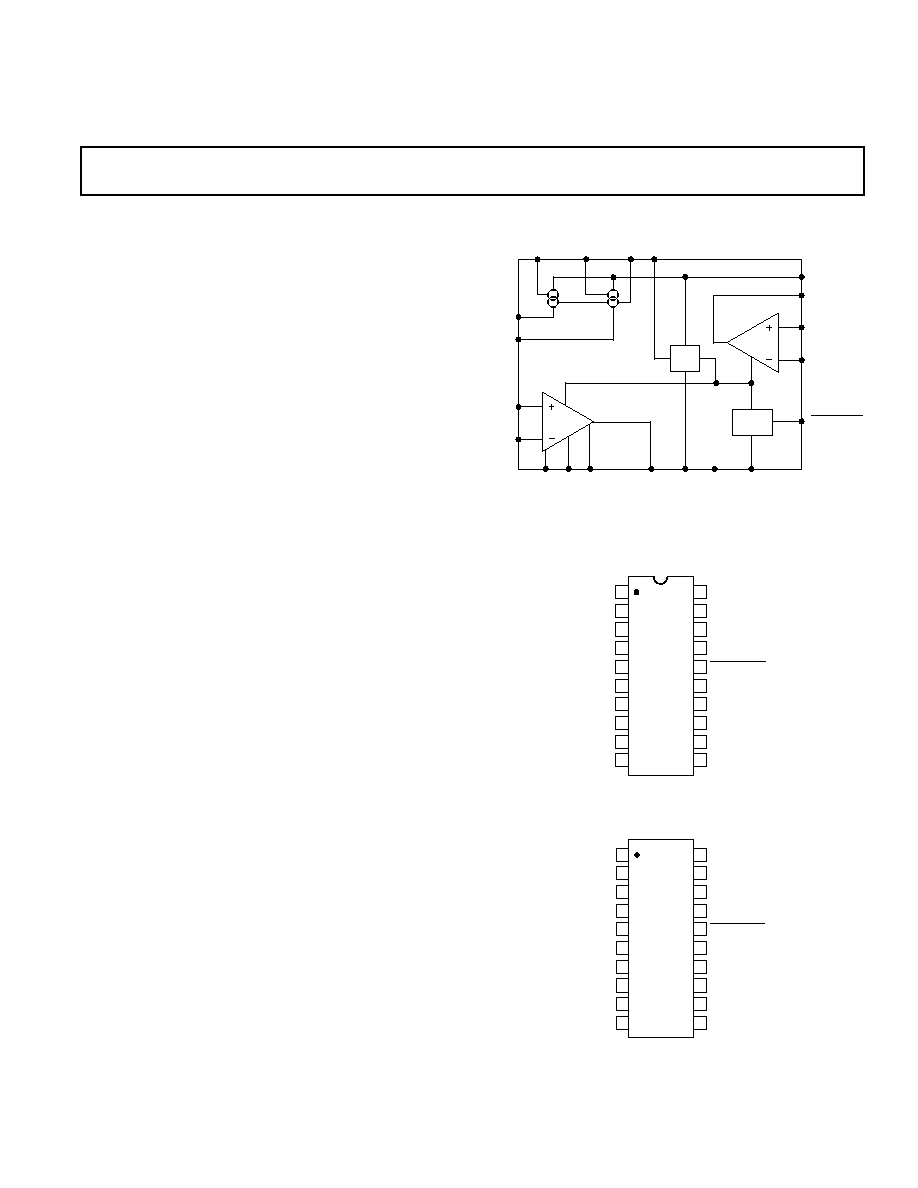

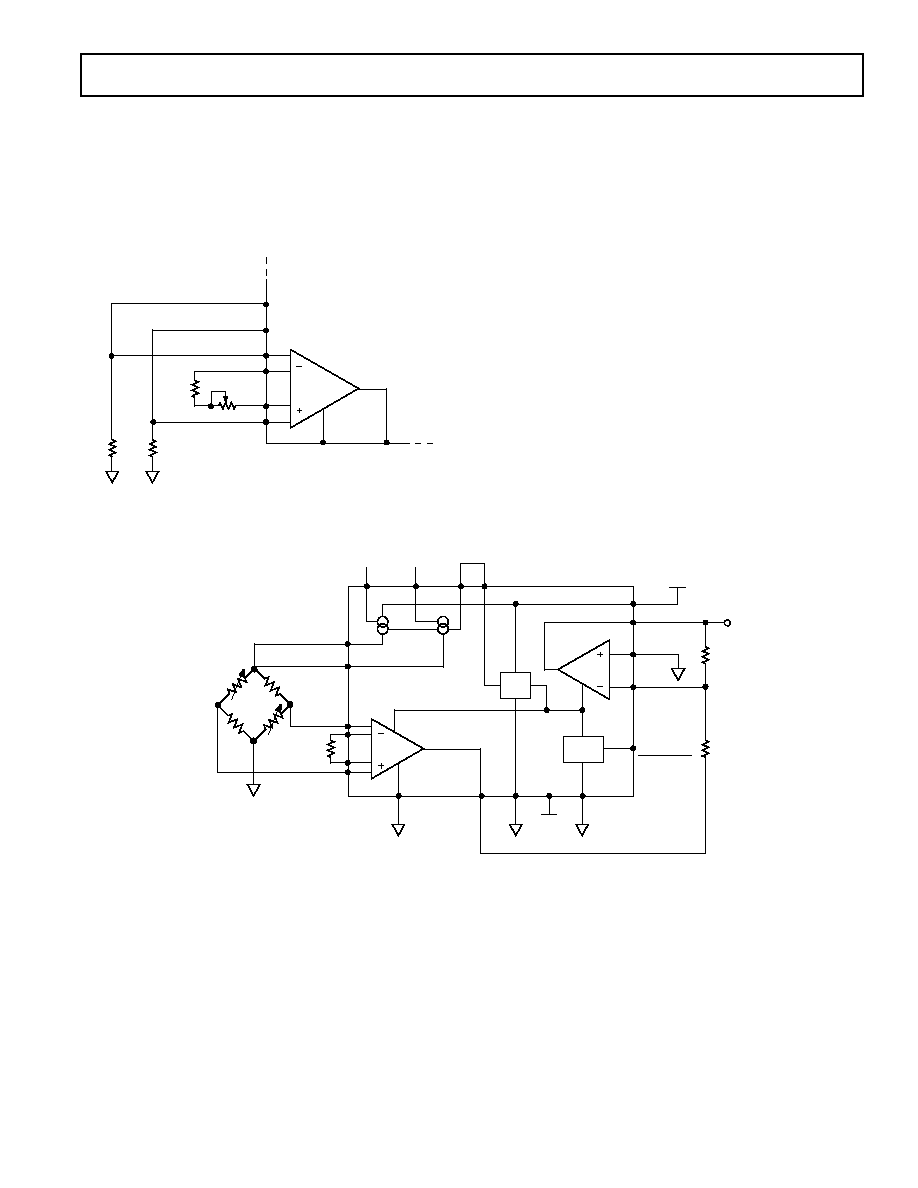

APPLICATION INFORMATION

As shown in Figure 27, using a 1 k

PRTD, 1 k

reference

resistor, 49.9 k

resistor between RG

A

(Pin 11) and RG

B

(Pin

12), and shorting BIAS (Pin 4) with V

REFOUT

(Pin 3) together,

the output of OUT

IA

(Pin 14) will have a transfer function of

V

mV

R

OUT

PRTD RESISTANCE

REFERENCE RESISTANCE

=

×

(

)

1 299

.

/

-

RGA

RGB

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

OUT

IA

AGND

DGND

V

S

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

ADT70

49.9k

V

OUT

@ 5mV/ C

INDEPENDENT

OP AMP

50k

+5V

1k

PRTD

1k

REF

RESISTOR

POTENTIOMETER

IS USED TO

ACHIEVE HIGHER

PRECISION OF

MATCHING

CURRENT.

1V <

V

S

< 5V

Figure 27. Basic Operational Diagram

ADT70

REV. 0

10

If PRTD has a tempco resistance of 0.00385

/

/

°

C or sensi-

tivity of 3.85

/

°

C, the system output voltage scaling factor will

be 5 mV/

°

C.

The gain of the instrumentation amplifier is normally at 1.30,

with a 49.9 k

gain resistor. It can be changed by changing the

gain resistor using the following equation.

Instrumentation Amp Gain

k

R

GAIN RESISTOR

.

.

=

1 30

49 9

In Figure 2 the ADT70 is powered by a dual power supply. In

order for the part to measure below 0

°

C, using a 1 k

PRTD,

V

S

has to be at least 1 V. V

S

can be grounded when the mea-

sured temperature is greater than 0

°

C using a 1 k

PRTD. GND

Sense (Pin 13), DGND (Pin 15), and AGND (Pin 2) are all con-

nected to ground. If desired, GND Sense could be connected to

whatever potential desired for an output offset of the instrumen-

tation amplifier. However, AGND and DGND must always be

connected to GND.

ADT70 will turn off if the

SHUTDOWN pin(GND) is low,

and will turn on when

SHUTDOWN pin becomes high (+V

S

).

If

SHUTDOWN is not used in the design, it should be con-

nected to +V

S

.

The undedicated op amp in the ADT70 can be used to transmit

measured signal to a remote location where noise might be intro-

duced into the signal as it travels in a noisy environment. It can

also be used as a general purpose amplifier in any application de-

sired. The op amp gain is set using standard feedback resistor

configurations.

Higher precision of matching the current sources can be

achieved by using a 50 k

potentiometer connected between

NULLA (Pin 5) and NULLB (Pin 6) with the center-tap of the

potentiometer connected to +V

S

(Pin 20). In Figure 27, the

ADT70's Bias Pin (Pin 4) is generally connected to the

V

REFOUT

(Pin 3), but it can be connected to an external voltage

reference if different output current is preferred.

Eliminating Lead-Wire Resistance by Using 4-Wire

Configuration

In applications where the lead-wire resistance can significantly

contribute error to the measured temperature, implementing a

4-wire lead-resistance canceling circuit can dramatically mini-

mize the lead-wire resistance effect.

In Figure 28, I

OUTA

and I

OUTB

provides matching excitation to

the reference resistor and the PRTD respectively. The lead-re-

sistance from the current source to the PRTD or reference resis-

tor is not of concern because the instrumentation amplifier is

measuring the difference in potential directly on the PRTD

(Node A) and reference resistor (Node C). Since there is almost

no current going from Node A and Node C into the amplifier's

input, there is no lead-wire resistance error.

A potential source of temperature measurement errors is the

possibility of voltage differences between the ground side of the

reference resistor and the PRTD. Differences in lead-wire resis-

tance from ground to these two points, coupled with the 1 mA

excitation current, will lead directly to differential voltage errors

at the input of the instrumentation amplifier of the ADT70. By

connecting the ground side of the PRTD (Node B of Figure 28)

to the noninverting input of the op amp and connecting the

ground side of the reference resistor (Node D) to both the in-

verting input and the output of the op amp, the two points can

be forced to the same potential. It is not important that this po-

tential is exactly at ground since the instrumentation amplifier

rejects common-mode signals at the input. Note that all three

connections should be made as close as possible to the body of

the reference resistor and the PRTD to minimize error.

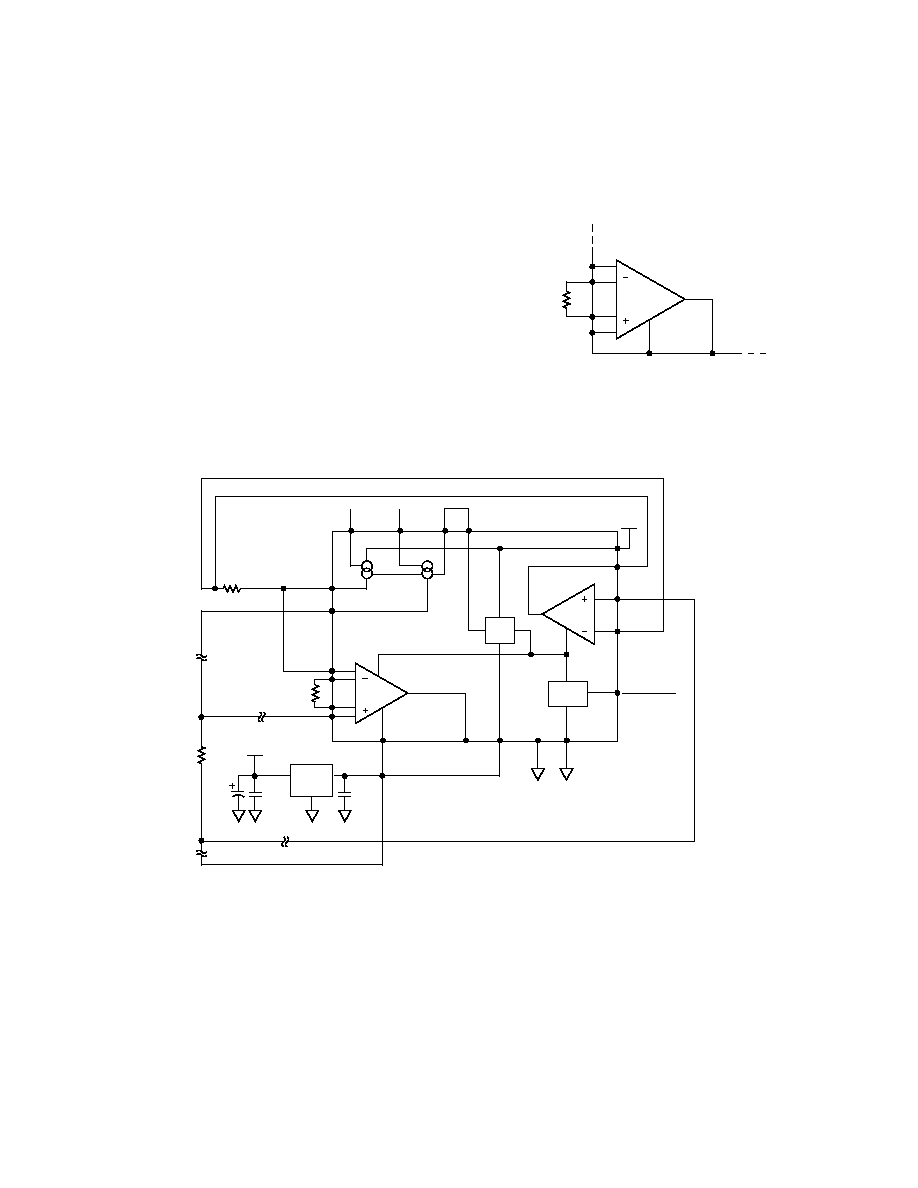

Single Supply Operation

When using the ADT70 in single supply applications a few

simple but important points need to be considered. The most

important issue is ensuring that the ADT70 is properly biased.

To bias the ADT70, first consider the 1 k

PRTD sensor. The

PRTD typically changes from 230

at 200

°

C to 4080

at

800

°

C

±

1

error. This impedance range results in an ADT70

output of 1 V to +4 V respectively, which is impossible to

RGA

RGB

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

OUT

IA

DGND

V

S

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

ADT70

50k

1k

PRTD

NODE D

1k

REF

RESISTOR

NODE C

NODE B

NODE A

5V

AGND

5V

Figure 28. 4-Wire Lead-Wire Resistance Cancellation Circuit

ADT70

REV. 0

11

achieve in a single supply application where the negative rail is

ground or 0 V. Therefore, to achieve full scale operation the

output of ADT70 should be shifted by 1 V to allow for opera-

tion in the 0 V to 5 V region.

The most straightforward method to shift the output voltage

incorporates the use of the GND SENSE as shown in Figure 29.

To shift output voltage range apply a potential equal to the neces-

sary shift on the GND SENSE pin. For example, to shift the out-

put voltage, OUT

IA

, up to 1 V to GND SENSE, apply 1 V to

GND SENSE. When applying a potential to GND SENSE, care

should be taken to ensure that the voltage source is capable of driv-

ing 2 k

and does not introduce excessive noise. Figure 29 uses the

on-board 2.5 V voltage reference for a low noise source. This refer-

ence is then divided to 1 V and buffered by the on-board op amp

to drive GND SENSE at a low impedance. A small 500

potenti-

ometer can be used to calibrate the initial offset error to zero.

However, a voltage applied to GND SENSE is not the only

method to shift the voltage range. Placing a 768

resistor in the

PRTD sensor path also shifts the output voltage by 1 V. This

second method, as shown in Figure 30, is usually not recom-

mended for the following reasons; the input voltage range of the

op amps is limited to around 1 V from the negative and positive

rails and this could cause problems at high temperature, limiting

the upper range to 600

°

C; the physical location of this resistor

(if placed at a distance from the ADT70) may have an impact

on the noise performance. The method frees up the on-board op

amp for another function and achieves the lowest impedance

ground point for GND SENSE.

This brief section on ADT70 single supply operation has focused

on simple techniques to bias the ADT70 such that all output volt-

ages are within operational range. However, these techniques may

not be useful in all single supply applications. For example, in Fig-

ure 3 the additional on-board op amp is operating at near ground

potential which will create problems in a single supply application

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

OUT

IA

DGND

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

1k

PRTD

SENSOR

RG

RG

49.9k

1k

REF

RESISTOR

TO CONTROLLER

15k

9.76k

500

POT

ADT70

Figure 29. A Single Supply Application with Shifted Ground Sense Pin

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

DGND

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

1K

PRTD

RG

RG

49.9k

768

RESISTOR

TO CONTROLLER

1K

REF

RESISTOR

V

S

TO A/D CONVERTER

V

REF

+5V

ADT70

Figure 30. A Basic Single Supply Operational Diagram with Bias Resistor in Sensor Path

ADT70

REV. 0

12

because the input voltage range of the on-board op amp only ex-

tends to about 1 V above the negative rail. If the application re-

quires the inputs of either the on-board amp or instrumentation

amplifier to operate within 1 V of ground, it will be necessary to

generate a "pseudo-ground." Figure 31 illustrates a typical

ADT70 "pseudo-ground" application. The Analog Devices'

ADR290, a 2.048 V reference, is being used to generate the

"pseudo-ground." The ADR290 was selected for the following

reasons: low noise, ability to drive the required 5 mA in this

application, good temperature stability, which is usually impor-

tant in a PRTD application. However, one undesired effect of

introducing the pseudo-ground is the loss in voltage range at

high temperature. In our example, the PRTD will only operate

from 200

°

C to +400

°

C corresponding to an input voltage

range of 1 V to 4 V.

100 PRTD Application Circuit

A 1000

PRTD sensor scales by 3.85

s/

°

C, which is exactly

ten times the scale of the 100

PRTD sensor. The ADT70

has been designed to allow for 1000

or 100

PRTD sen-

sors. Only the gain setting resistor RG needs to be altered. For

a 100

PRTD 0.00385 sensor, change RG to 4.99 k

as illus-

trated in Figure 32. In single supply application, with a 100

PRTD sensor, a "pseudo-ground" will be necessary because the

inputs of the instrumentation amplifier will be within 1 V of the

negative rail. See the section on single supply applications for

more information.

+IN

IA

IN

IA

INST

AMP

RG

RG

4.99k

GND

SENSE

OUT

Figure 32. 100

0.00385 PRTD Application Showing

New Value for RG

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

GND

SENSE

DGND

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

1k

PRTD

RG

RG

49.9k

V

S

OUT

IN

GND

ADR290

0.1 F

0.1 F

10 F

OUT

AGND

1k

REF

RESISTOR

NODE D

NODE C

+5V

+5V

ADT70

Figure 31. Single Supply Application with an ADR290 "Pseudo-Ground"

ADT70

REV. 0

13

American PRTD Application Circuit

The majority of PRTD sensors use a scale factor of 0.00385

/

/

°

C.

This type of sensor is known as the European PRTD and is the most

common PRTD sensor. However, there is also an American PRTD

sensor that uses a scale factor of 0.00392

/

/

°

C. Figure 33 illus-

trates the input section of the ADT70 configured for the Ameri-

can PRTD. The ideal value for RG is 50.98 k

when yielding a

5 mV/

°

C ADT70 output.

+IN

IA

IN

IA

INST

AMP

RG

RG

49.9k

2k

1k

REF

RESISTOR

1k

PRTD

I

OUTA

I

OUTB

NOTE: IDEAL VALUE

FOR RG

~

= 51k

GND

SENSE

OUT

Figure 33. Typical PRTD Application with American

0.003916

/

/

°

C Scale; 1 k

Scale

+IN

IA

IN

IA

INST

AMP

SHUT-

DOWN

DGND

SHUTDOWN

+IN

OA

IN

OA

OUT

OA

+V

S

2.5V

REF

I

OUTA

I

OUTB

MATCHED

CURRENT

SOURCES

NULLA

NULLB

BIAS

2.5V

REFOUT

RG

RG

+5V

R

R

R

R

COLUMBIA RESEARCH LAB

MODEL DT3617

STRAIN SENSOR

R = 1k

5V

ADT70

Figure 34. Typical Strain Sensor Application (Two Element Varying)

Strain Gauge Sensor Application Circuit

Figure 34 illustrates a typical strain gauge bridge circuit. The

versatility of the ADT70 allows the part to be used with most

bridge circuits that are within the 50 k

to 5 k

impedance

range. The sensor used in this circuit has two elements varying.

If a constant current is driven into the sensor, a linear V

OUT

is

obtained. In addition, the ADT70 will work with most bridge

circuits whether one-, two-, or all-element varying.

Securing Additional Current from the Current Sources

Some sensor applications need a higher excitation current to in-

crease sensor sensitivity. There are two methods to increase the

current from the on-board current sources of the ADT70. The

most flexible method involves changing the voltage at the BIAS

node. The equation for determining the BIAS potential vs. Out-

put current is 2.5 V for roughly 1 mA, or in other words, to

double the current output simply put 5 V into BIAS. The BIAS

node should be driven with a low-noise source, such as a refer-

ence, because output current is directly dependent on BIAS volt-

age. Directly tying BIAS to the positive supply rail may produce

too much current noise especially if the positive rail is not well

regulated. The second method involves tying the two ADT70

current outputs together which doubles the current. Of course,

this technique is most useful if, as illustrated in Figure 34, the ap-

plication requires only one current source.

ADT70

REV. 0

14

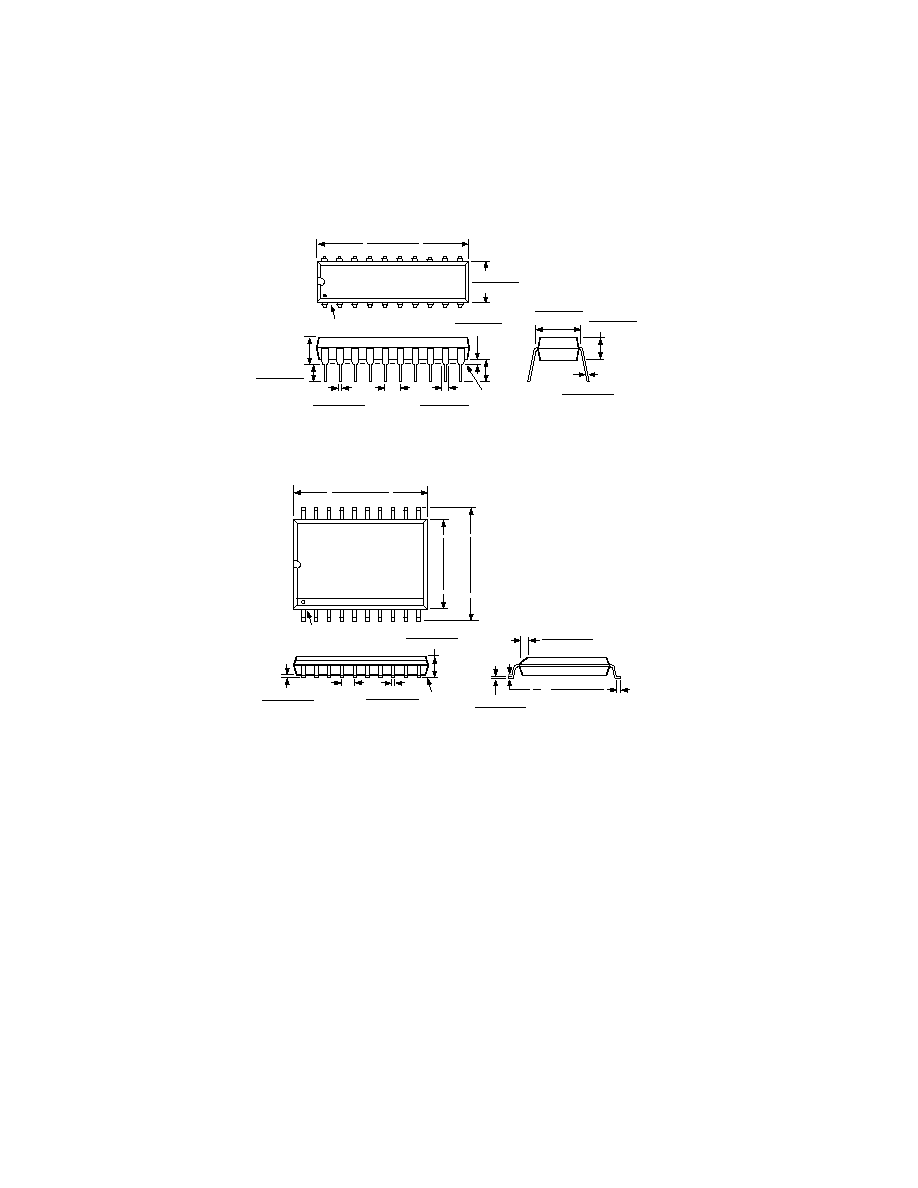

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

20-Lead Plastic DIP

(P-Suffix)

20

1

10

11

1.060 (26.90)

0.925 (23.50)

0.280 (7.11)

0.240 (6.10)

PIN 1

SEATING

PLANE

0.022 (0.558)

0.014 (0.356)

0.060 (1.52)

0.015 (0.38)

0.210 (5.33)

MAX

0.130

(3.30)

MIN

0.070 (1.77)

0.045 (1.15)

0.100

(2.54)

BSC

0.160 (4.06)

0.115 (2.93)

0.325 (8.25)

0.300 (7.62)

0.015 (0.381)

0.008 (0.204)

0.195 (4.95)

0.115 (2.93)

20-Lead SOIC

(S-Suffix)

SEATING

PLANE

0.0118 (0.30)

0.0040 (0.10)

0.0192 (0.49)

0.0138 (0.35)

0.1043 (2.65)

0.0926 (2.35)

0.0500

(1.27)

BSC

0.0125 (0.32)

0.0091 (0.23)

0.0500 (1.27)

0.0157 (0.40)

8

°

0

°

0.0291 (0.74)

0.0098 (0.25)

x 45

°

20

11

10

1

0.5118 (13.00)

0.4961 (12.60)

0.4193 (10.65)

0.3937 (10.00)

0.2992 (7.60)

0.2914 (7.40)

PIN 1

C339587/98

PRINTED IN U.S.A.